V8 Engine Modifications: Popular Enhancements Explained

JUL 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception in the early 20th century. Initially designed for high-performance applications, the V8 configuration has become a staple in automotive engineering, known for its compact design and impressive power output. The evolution of V8 engines can be traced through several key phases, each marked by technological advancements and changing market demands.

In the early days, V8 engines were primarily used in luxury and performance vehicles. The 1930s and 1940s saw the introduction of more efficient designs, including the flathead V8 popularized by Ford. This era laid the groundwork for future developments in V8 technology, focusing on increasing power output and reliability.

The 1950s and 1960s marked the golden age of V8 engines, particularly in American muscle cars. During this period, manufacturers pushed the boundaries of displacement and horsepower, resulting in iconic engines such as the Chevrolet Small-Block V8. These engines set new standards for performance and became the foundation for many future modifications.

The 1970s brought significant challenges to V8 development with the oil crisis and stricter emissions regulations. This led to a shift in focus towards fuel efficiency and cleaner combustion. Manufacturers began implementing technologies like electronic fuel injection and catalytic converters to meet new environmental standards while maintaining performance.

The 1980s and 1990s saw a resurgence in V8 technology, with advancements in materials science and computer-aided design. This period introduced more sophisticated engine management systems, variable valve timing, and multi-valve designs, allowing for improved efficiency without sacrificing power.

In the 21st century, V8 engines have continued to evolve, incorporating cutting-edge technologies to meet increasingly stringent emissions standards and performance expectations. Modern V8s often feature direct injection, turbocharging, and cylinder deactivation, allowing for remarkable power outputs while achieving better fuel economy than their predecessors.

The most recent developments in V8 technology have focused on hybridization and electrification. Many manufacturers are now combining V8 engines with electric motors to create high-performance hybrid powertrains, offering the best of both worlds in terms of power and efficiency.

Throughout its evolution, the V8 engine has remained a popular platform for modifications and enhancements. From simple bolt-on upgrades to complete engine rebuilds, enthusiasts and engineers continue to push the boundaries of V8 performance, adapting this iconic engine configuration to meet the changing demands of the automotive landscape.

In the early days, V8 engines were primarily used in luxury and performance vehicles. The 1930s and 1940s saw the introduction of more efficient designs, including the flathead V8 popularized by Ford. This era laid the groundwork for future developments in V8 technology, focusing on increasing power output and reliability.

The 1950s and 1960s marked the golden age of V8 engines, particularly in American muscle cars. During this period, manufacturers pushed the boundaries of displacement and horsepower, resulting in iconic engines such as the Chevrolet Small-Block V8. These engines set new standards for performance and became the foundation for many future modifications.

The 1970s brought significant challenges to V8 development with the oil crisis and stricter emissions regulations. This led to a shift in focus towards fuel efficiency and cleaner combustion. Manufacturers began implementing technologies like electronic fuel injection and catalytic converters to meet new environmental standards while maintaining performance.

The 1980s and 1990s saw a resurgence in V8 technology, with advancements in materials science and computer-aided design. This period introduced more sophisticated engine management systems, variable valve timing, and multi-valve designs, allowing for improved efficiency without sacrificing power.

In the 21st century, V8 engines have continued to evolve, incorporating cutting-edge technologies to meet increasingly stringent emissions standards and performance expectations. Modern V8s often feature direct injection, turbocharging, and cylinder deactivation, allowing for remarkable power outputs while achieving better fuel economy than their predecessors.

The most recent developments in V8 technology have focused on hybridization and electrification. Many manufacturers are now combining V8 engines with electric motors to create high-performance hybrid powertrains, offering the best of both worlds in terms of power and efficiency.

Throughout its evolution, the V8 engine has remained a popular platform for modifications and enhancements. From simple bolt-on upgrades to complete engine rebuilds, enthusiasts and engineers continue to push the boundaries of V8 performance, adapting this iconic engine configuration to meet the changing demands of the automotive landscape.

Market Demand Analysis

The market demand for V8 engine modifications has been steadily growing, driven by enthusiasts seeking enhanced performance and power from their vehicles. This trend is particularly prominent in the automotive aftermarket sector, where consumers are increasingly looking to customize and upgrade their vehicles beyond factory specifications.

The V8 engine, known for its power and distinctive sound, has long been a favorite among car enthusiasts. As environmental regulations tighten and manufacturers shift towards smaller, more efficient engines, the demand for V8 engine modifications has paradoxically increased. This surge is partly due to enthusiasts wanting to preserve and enhance the performance characteristics of V8-powered vehicles.

Popular V8 engine modifications cater to various market segments. The muscle car and classic car restoration markets show significant demand for period-correct performance upgrades and modernization of older V8 engines. In the high-performance and racing sectors, there's a constant push for more power, better throttle response, and improved reliability.

The truck and SUV market also contributes substantially to the demand for V8 engine modifications. Owners of these vehicles often seek increased towing capacity and overall performance, driving the need for aftermarket solutions. This segment has seen growth in recent years as larger vehicles maintain popularity among consumers.

Geographically, North America remains the largest market for V8 engine modifications, given the historical popularity of V8-powered vehicles in this region. However, growing interest in American muscle cars and performance vehicles in Europe, the Middle East, and Australia has expanded the global market for these modifications.

The aftermarket industry has responded to this demand with a wide range of products. These include performance camshafts, high-flow intake systems, exhaust upgrades, and engine management systems. There's also a growing market for complete crate engines and turnkey solutions, catering to consumers looking for significant power increases without extensive custom work.

Environmental concerns and regulations have influenced the market, leading to increased demand for modifications that improve fuel efficiency alongside performance. This has spurred innovation in areas such as direct injection upgrades, variable valve timing modifications, and cylinder deactivation systems for V8 engines.

The rise of electric vehicles and stricter emissions standards pose challenges to the V8 modification market. However, this has also created opportunities for companies developing hybrid technologies and efficient forced induction systems for V8 engines, aiming to balance performance with environmental considerations.

The V8 engine, known for its power and distinctive sound, has long been a favorite among car enthusiasts. As environmental regulations tighten and manufacturers shift towards smaller, more efficient engines, the demand for V8 engine modifications has paradoxically increased. This surge is partly due to enthusiasts wanting to preserve and enhance the performance characteristics of V8-powered vehicles.

Popular V8 engine modifications cater to various market segments. The muscle car and classic car restoration markets show significant demand for period-correct performance upgrades and modernization of older V8 engines. In the high-performance and racing sectors, there's a constant push for more power, better throttle response, and improved reliability.

The truck and SUV market also contributes substantially to the demand for V8 engine modifications. Owners of these vehicles often seek increased towing capacity and overall performance, driving the need for aftermarket solutions. This segment has seen growth in recent years as larger vehicles maintain popularity among consumers.

Geographically, North America remains the largest market for V8 engine modifications, given the historical popularity of V8-powered vehicles in this region. However, growing interest in American muscle cars and performance vehicles in Europe, the Middle East, and Australia has expanded the global market for these modifications.

The aftermarket industry has responded to this demand with a wide range of products. These include performance camshafts, high-flow intake systems, exhaust upgrades, and engine management systems. There's also a growing market for complete crate engines and turnkey solutions, catering to consumers looking for significant power increases without extensive custom work.

Environmental concerns and regulations have influenced the market, leading to increased demand for modifications that improve fuel efficiency alongside performance. This has spurred innovation in areas such as direct injection upgrades, variable valve timing modifications, and cylinder deactivation systems for V8 engines.

The rise of electric vehicles and stricter emissions standards pose challenges to the V8 modification market. However, this has also created opportunities for companies developing hybrid technologies and efficient forced induction systems for V8 engines, aiming to balance performance with environmental considerations.

Current Challenges

Despite the popularity and widespread adoption of V8 engine modifications, several significant challenges persist in this field. One of the primary obstacles is the delicate balance between performance enhancement and engine reliability. As enthusiasts push for more power, the risk of compromising engine longevity increases. This challenge is particularly evident in high-performance applications where the engine components are subjected to extreme stress and temperatures.

Another major hurdle is the complexity of modern engine management systems. As V8 engines become more sophisticated, with advanced electronic controls and emissions systems, modifying them without triggering fault codes or compromising their efficiency becomes increasingly difficult. This complexity often requires specialized knowledge and tools, making it challenging for amateur enthusiasts to perform modifications without professional assistance.

Emissions regulations pose a significant challenge to V8 engine modifications. Stricter environmental standards in many countries limit the extent of modifications that can be legally performed while maintaining compliance. This regulatory landscape forces enthusiasts and manufacturers to develop innovative solutions that enhance performance without violating emissions laws, a task that often involves substantial research and development costs.

The rising cost of performance parts and specialized labor presents another obstacle. High-quality components necessary for significant power gains can be prohibitively expensive for many enthusiasts. Additionally, the specialized skills required for advanced modifications drive up labor costs, making comprehensive engine upgrades a significant financial investment.

Thermal management remains a critical challenge in V8 engine modifications. As power output increases, so does heat generation. Efficiently dissipating this additional heat without compromising engine performance or reliability requires careful engineering and often necessitates upgrades to cooling systems, adding further complexity and cost to modification projects.

Lastly, the integration of aftermarket modifications with factory systems presents ongoing challenges. Ensuring that modified components work seamlessly with original equipment manufacturer (OEM) parts and control systems often requires extensive testing and calibration. This integration challenge is particularly pronounced in modern V8 engines with advanced driver assistance systems and integrated powertrain management.

Another major hurdle is the complexity of modern engine management systems. As V8 engines become more sophisticated, with advanced electronic controls and emissions systems, modifying them without triggering fault codes or compromising their efficiency becomes increasingly difficult. This complexity often requires specialized knowledge and tools, making it challenging for amateur enthusiasts to perform modifications without professional assistance.

Emissions regulations pose a significant challenge to V8 engine modifications. Stricter environmental standards in many countries limit the extent of modifications that can be legally performed while maintaining compliance. This regulatory landscape forces enthusiasts and manufacturers to develop innovative solutions that enhance performance without violating emissions laws, a task that often involves substantial research and development costs.

The rising cost of performance parts and specialized labor presents another obstacle. High-quality components necessary for significant power gains can be prohibitively expensive for many enthusiasts. Additionally, the specialized skills required for advanced modifications drive up labor costs, making comprehensive engine upgrades a significant financial investment.

Thermal management remains a critical challenge in V8 engine modifications. As power output increases, so does heat generation. Efficiently dissipating this additional heat without compromising engine performance or reliability requires careful engineering and often necessitates upgrades to cooling systems, adding further complexity and cost to modification projects.

Lastly, the integration of aftermarket modifications with factory systems presents ongoing challenges. Ensuring that modified components work seamlessly with original equipment manufacturer (OEM) parts and control systems often requires extensive testing and calibration. This integration challenge is particularly pronounced in modern V8 engines with advanced driver assistance systems and integrated powertrain management.

Popular V8 Mods

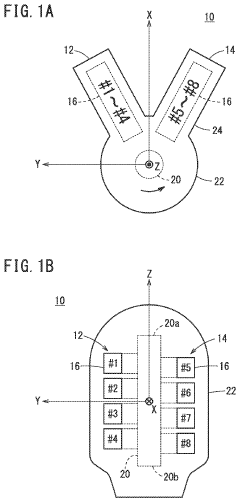

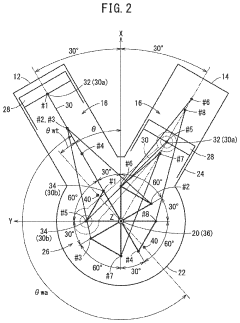

01 Cylinder configuration optimization

Optimizing the cylinder configuration in V8 engines can significantly improve performance. This includes adjusting the angle between cylinder banks, optimizing cylinder firing order, and implementing variable cylinder management systems. These modifications can enhance power output, fuel efficiency, and overall engine balance.- Cylinder head design optimization: Improving the design of cylinder heads in V8 engines can significantly enhance performance. This includes optimizing the intake and exhaust ports, valve arrangement, and combustion chamber shape to improve airflow and fuel mixture, resulting in better combustion efficiency and increased power output.

- Advanced fuel injection systems: Implementing advanced fuel injection systems in V8 engines can lead to improved performance. These systems offer precise control over fuel delivery, optimizing the air-fuel mixture for different operating conditions. This results in better fuel efficiency, increased power, and reduced emissions.

- Variable valve timing and lift: Incorporating variable valve timing and lift mechanisms in V8 engines can enhance performance across a wide range of engine speeds. These systems allow for optimal valve operation at different RPMs, improving both low-end torque and high-end power while also increasing fuel efficiency.

- Turbocharging and supercharging: Implementing forced induction systems such as turbochargers or superchargers can significantly boost V8 engine performance. These systems increase the amount of air entering the combustion chamber, allowing for more fuel to be burned and resulting in higher power output without necessarily increasing engine displacement.

- Engine management system optimization: Enhancing the engine management system of V8 engines can lead to improved performance. This includes optimizing the engine control unit (ECU) programming, implementing advanced sensors for real-time monitoring, and utilizing adaptive learning algorithms to fine-tune engine parameters for optimal performance under various conditions.

02 Intake and exhaust system improvements

Enhancing the intake and exhaust systems of V8 engines can boost performance. This involves designing more efficient air intake manifolds, implementing variable valve timing, and optimizing exhaust flow. These improvements can increase horsepower, torque, and engine responsiveness across different RPM ranges.Expand Specific Solutions03 Fuel injection and combustion optimization

Improving fuel injection systems and combustion processes can enhance V8 engine performance. This includes implementing direct injection technology, optimizing fuel spray patterns, and fine-tuning combustion chamber design. These advancements can lead to better fuel atomization, more complete combustion, and increased power output.Expand Specific Solutions04 Turbocharging and supercharging solutions

Implementing forced induction systems such as turbochargers or superchargers can significantly boost V8 engine performance. These systems increase the amount of air and fuel entering the combustion chambers, resulting in higher power output and improved torque characteristics across a wider RPM range.Expand Specific Solutions05 Engine management and control systems

Advanced engine management and control systems play a crucial role in optimizing V8 engine performance. This includes implementing sophisticated ECU programming, adaptive fuel management, and real-time performance monitoring. These systems can fine-tune engine parameters on-the-fly, ensuring optimal performance under various operating conditions.Expand Specific Solutions

Key Industry Players

The V8 engine modification market is in a mature stage, with a well-established ecosystem of manufacturers and aftermarket suppliers. The global market size for performance engine parts is estimated to be in the billions of dollars, driven by enthusiasts and racing applications. Technologically, V8 modifications range from simple bolt-on upgrades to complex forced induction systems. Key players like K&N Engineering and BorgWarner offer advanced solutions, while major automakers such as Toyota, GM, Ford, and Honda continue to innovate in factory V8 designs. The aftermarket is highly competitive, with companies constantly developing new products to enhance power, efficiency, and reliability of V8 engines.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced V8 engine modifications, focusing on their Small Block V8 architecture. They have implemented Active Fuel Management (AFM) technology, which deactivates four cylinders during light load conditions, improving fuel efficiency by up to 12% [1]. GM has also introduced Dynamic Fuel Management (DFM), an advanced cylinder deactivation system that can operate on as few as one cylinder, offering 17 different firing patterns for optimal efficiency and performance [2]. Additionally, GM has incorporated direct fuel injection and variable valve timing to enhance power output and reduce emissions [3].

Strengths: Improved fuel efficiency, reduced emissions, and enhanced performance. Weaknesses: Increased complexity and potential reliability concerns with advanced systems.

Bayerische Motoren Werke AG

Technical Solution: BMW has focused on enhancing their V8 engines through various modifications. They have implemented a hot-vee turbocharger layout, placing the turbochargers between the cylinder banks for improved throttle response and reduced turbo lag [7]. BMW has also developed a cross-bank exhaust manifold, which optimizes exhaust gas flow and enhances turbocharger efficiency [8]. The company has incorporated high-precision direct fuel injection and VALVETRONIC variable valve lift technology to improve fuel economy and reduce emissions while maintaining performance [9].

Strengths: Improved throttle response, enhanced turbocharger efficiency, and better overall performance. Weaknesses: Increased heat management challenges and potential reliability issues with complex systems.

Innovative Techniques

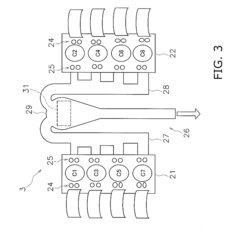

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

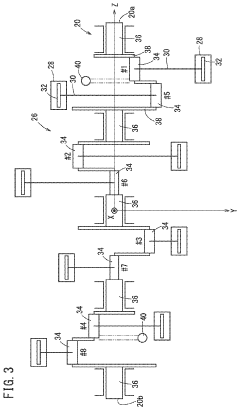

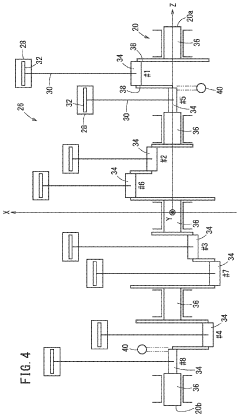

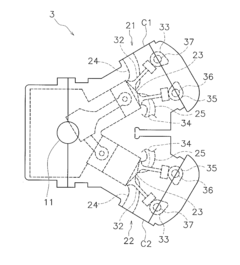

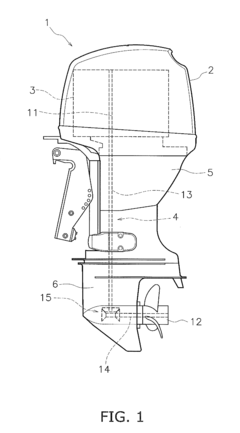

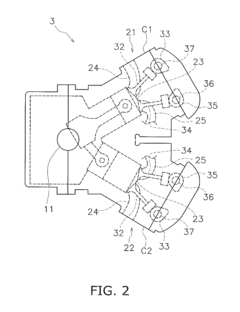

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

Environmental Impact

The environmental impact of V8 engine modifications is a critical consideration in today's automotive landscape. While performance enhancements are often the primary focus, the ecological consequences of these modifications cannot be overlooked. V8 engines, known for their power and distinctive sound, are already significant contributors to carbon emissions in their stock form. Modifications typically exacerbate this issue, leading to increased fuel consumption and higher emissions of greenhouse gases and pollutants.

Popular V8 engine enhancements, such as increased displacement, higher compression ratios, and forced induction systems, often result in greater fuel consumption. This directly translates to higher carbon dioxide emissions, contributing to global warming and climate change. Additionally, modifications that alter the air-fuel mixture or bypass emission control systems can lead to increased emissions of nitrogen oxides, carbon monoxide, and unburned hydrocarbons, all of which have detrimental effects on air quality and human health.

However, not all V8 engine modifications necessarily have negative environmental impacts. Some enhancements, particularly those focused on improving engine efficiency, can potentially reduce fuel consumption and emissions. For instance, advanced fuel injection systems, improved engine management software, and lightweight components can optimize combustion and reduce overall engine load, leading to better fuel economy and lower emissions in certain driving conditions.

The automotive aftermarket industry has also begun to address environmental concerns by developing eco-friendly performance parts. These include high-flow catalytic converters that maintain emissions compliance while allowing for increased power, and advanced air intake systems that improve engine breathing without compromising filtration efficiency. Some enthusiasts are even exploring the integration of hybrid technologies with V8 engines, aiming to balance performance with reduced environmental impact.

Regulatory bodies worldwide are increasingly scrutinizing vehicle modifications, including those for V8 engines, to ensure compliance with emissions standards. This has led to a growing emphasis on "green performance" within the automotive community, encouraging innovation in sustainable modification techniques. As environmental awareness continues to grow, the future of V8 engine modifications may lie in finding a balance between performance enhancement and ecological responsibility, potentially leading to new technologies that satisfy both performance enthusiasts and environmental advocates.

Popular V8 engine enhancements, such as increased displacement, higher compression ratios, and forced induction systems, often result in greater fuel consumption. This directly translates to higher carbon dioxide emissions, contributing to global warming and climate change. Additionally, modifications that alter the air-fuel mixture or bypass emission control systems can lead to increased emissions of nitrogen oxides, carbon monoxide, and unburned hydrocarbons, all of which have detrimental effects on air quality and human health.

However, not all V8 engine modifications necessarily have negative environmental impacts. Some enhancements, particularly those focused on improving engine efficiency, can potentially reduce fuel consumption and emissions. For instance, advanced fuel injection systems, improved engine management software, and lightweight components can optimize combustion and reduce overall engine load, leading to better fuel economy and lower emissions in certain driving conditions.

The automotive aftermarket industry has also begun to address environmental concerns by developing eco-friendly performance parts. These include high-flow catalytic converters that maintain emissions compliance while allowing for increased power, and advanced air intake systems that improve engine breathing without compromising filtration efficiency. Some enthusiasts are even exploring the integration of hybrid technologies with V8 engines, aiming to balance performance with reduced environmental impact.

Regulatory bodies worldwide are increasingly scrutinizing vehicle modifications, including those for V8 engines, to ensure compliance with emissions standards. This has led to a growing emphasis on "green performance" within the automotive community, encouraging innovation in sustainable modification techniques. As environmental awareness continues to grow, the future of V8 engine modifications may lie in finding a balance between performance enhancement and ecological responsibility, potentially leading to new technologies that satisfy both performance enthusiasts and environmental advocates.

Performance Testing

Performance testing is a critical aspect of V8 engine modifications, providing quantifiable data on the effectiveness of various enhancements. This process involves rigorous evaluation of key performance metrics before and after modifications to assess their impact accurately. Common parameters measured include horsepower, torque, acceleration, fuel efficiency, and overall engine responsiveness.

Dynamometer testing stands as the gold standard for evaluating engine performance. This method allows for precise measurement of power output across different RPM ranges, enabling engineers to identify specific areas of improvement or potential issues. Chassis dynamometers are particularly useful for testing complete vehicle systems, while engine dynamometers provide more isolated data on the engine itself.

In-field testing complements dynamometer results by assessing real-world performance. This includes acceleration tests, such as 0-60 mph and quarter-mile times, which offer practical insights into the engine's capabilities. Top speed runs and lap times on race tracks can also provide valuable data, especially for high-performance applications.

Fuel efficiency testing is another crucial component, particularly given the increasing emphasis on environmental concerns. This involves standardized driving cycles to measure fuel consumption under various conditions, ensuring that performance gains do not come at the expense of excessive fuel use.

Advanced data logging systems play a vital role in modern performance testing. These systems capture a wide array of engine parameters in real-time, including air/fuel ratios, boost pressure, exhaust gas temperatures, and ignition timing. This wealth of data allows for fine-tuning of engine management systems and helps identify potential reliability issues.

Thermal imaging and temperature monitoring are essential for evaluating the effectiveness of cooling system modifications and identifying potential hot spots in the engine. This is particularly important for high-output engines that generate significant heat.

Emissions testing is becoming increasingly important, even for modified engines. This ensures that performance enhancements comply with local regulations and environmental standards. Modern emissions testing equipment can provide detailed analysis of exhaust gases, helping engineers balance performance gains with emissions control.

Longevity and durability testing, while time-consuming, are crucial for assessing the long-term impact of modifications. This may involve extended running periods, simulated harsh conditions, and accelerated wear testing to ensure that performance gains are sustainable over the engine's lifespan.

Dynamometer testing stands as the gold standard for evaluating engine performance. This method allows for precise measurement of power output across different RPM ranges, enabling engineers to identify specific areas of improvement or potential issues. Chassis dynamometers are particularly useful for testing complete vehicle systems, while engine dynamometers provide more isolated data on the engine itself.

In-field testing complements dynamometer results by assessing real-world performance. This includes acceleration tests, such as 0-60 mph and quarter-mile times, which offer practical insights into the engine's capabilities. Top speed runs and lap times on race tracks can also provide valuable data, especially for high-performance applications.

Fuel efficiency testing is another crucial component, particularly given the increasing emphasis on environmental concerns. This involves standardized driving cycles to measure fuel consumption under various conditions, ensuring that performance gains do not come at the expense of excessive fuel use.

Advanced data logging systems play a vital role in modern performance testing. These systems capture a wide array of engine parameters in real-time, including air/fuel ratios, boost pressure, exhaust gas temperatures, and ignition timing. This wealth of data allows for fine-tuning of engine management systems and helps identify potential reliability issues.

Thermal imaging and temperature monitoring are essential for evaluating the effectiveness of cooling system modifications and identifying potential hot spots in the engine. This is particularly important for high-output engines that generate significant heat.

Emissions testing is becoming increasingly important, even for modified engines. This ensures that performance enhancements comply with local regulations and environmental standards. Modern emissions testing equipment can provide detailed analysis of exhaust gases, helping engineers balance performance gains with emissions control.

Longevity and durability testing, while time-consuming, are crucial for assessing the long-term impact of modifications. This may involve extended running periods, simulated harsh conditions, and accelerated wear testing to ensure that performance gains are sustainable over the engine's lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!