How V8 Engines Enhance Vehicle Acceleration?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The evolution of V8 engines has been a remarkable journey in automotive engineering, significantly impacting vehicle acceleration and performance. This powerful engine configuration has undergone numerous refinements and innovations since its inception in the early 20th century.

Initially developed for aircraft applications, V8 engines found their way into automobiles in the 1910s. The first mass-produced V8 engine was introduced by Cadillac in 1914, marking the beginning of a new era in automotive power. These early V8s were relatively simple in design, with flathead valve arrangements and modest power outputs.

The 1930s and 1940s saw significant advancements in V8 technology. The introduction of overhead valve (OHV) designs greatly improved engine efficiency and power output. This period also witnessed the birth of the iconic Ford flathead V8, which became a favorite among hot rodders and set the stage for future performance engines.

The 1950s and 1960s are often referred to as the golden age of V8 engines. During this time, manufacturers like Chevrolet, Ford, and Chrysler engaged in fierce competition, constantly pushing the boundaries of V8 performance. The introduction of high-compression ratios, larger displacements, and multiple carburetors led to unprecedented power outputs, fueling the muscle car era.

The 1970s brought new challenges with stricter emission regulations and fuel economy concerns. This led to a temporary decline in V8 performance as manufacturers struggled to meet new standards while maintaining power. However, this period also spurred innovation, leading to the development of electronic fuel injection systems and more efficient engine designs.

The 1980s and 1990s saw a resurgence in V8 performance, thanks to advancements in computer-controlled engine management systems. These technologies allowed for precise control over fuel delivery and ignition timing, resulting in improved power, efficiency, and emissions compliance. This era also saw the introduction of overhead cam V8 designs, further enhancing performance potential.

In the 21st century, V8 engines have continued to evolve, incorporating cutting-edge technologies to meet increasingly stringent emissions standards while delivering exceptional performance. Modern V8s often feature direct fuel injection, variable valve timing, cylinder deactivation, and forced induction systems such as turbocharging and supercharging. These innovations have allowed V8 engines to achieve remarkable power outputs while maintaining fuel efficiency and meeting environmental regulations.

The latest developments in V8 technology include the integration of hybrid systems, further improving fuel economy and performance. Additionally, advancements in materials science have led to the use of lightweight alloys and composite materials, reducing engine weight and improving power-to-weight ratios.

Initially developed for aircraft applications, V8 engines found their way into automobiles in the 1910s. The first mass-produced V8 engine was introduced by Cadillac in 1914, marking the beginning of a new era in automotive power. These early V8s were relatively simple in design, with flathead valve arrangements and modest power outputs.

The 1930s and 1940s saw significant advancements in V8 technology. The introduction of overhead valve (OHV) designs greatly improved engine efficiency and power output. This period also witnessed the birth of the iconic Ford flathead V8, which became a favorite among hot rodders and set the stage for future performance engines.

The 1950s and 1960s are often referred to as the golden age of V8 engines. During this time, manufacturers like Chevrolet, Ford, and Chrysler engaged in fierce competition, constantly pushing the boundaries of V8 performance. The introduction of high-compression ratios, larger displacements, and multiple carburetors led to unprecedented power outputs, fueling the muscle car era.

The 1970s brought new challenges with stricter emission regulations and fuel economy concerns. This led to a temporary decline in V8 performance as manufacturers struggled to meet new standards while maintaining power. However, this period also spurred innovation, leading to the development of electronic fuel injection systems and more efficient engine designs.

The 1980s and 1990s saw a resurgence in V8 performance, thanks to advancements in computer-controlled engine management systems. These technologies allowed for precise control over fuel delivery and ignition timing, resulting in improved power, efficiency, and emissions compliance. This era also saw the introduction of overhead cam V8 designs, further enhancing performance potential.

In the 21st century, V8 engines have continued to evolve, incorporating cutting-edge technologies to meet increasingly stringent emissions standards while delivering exceptional performance. Modern V8s often feature direct fuel injection, variable valve timing, cylinder deactivation, and forced induction systems such as turbocharging and supercharging. These innovations have allowed V8 engines to achieve remarkable power outputs while maintaining fuel efficiency and meeting environmental regulations.

The latest developments in V8 technology include the integration of hybrid systems, further improving fuel economy and performance. Additionally, advancements in materials science have led to the use of lightweight alloys and composite materials, reducing engine weight and improving power-to-weight ratios.

Market Demand Analysis

The market demand for V8 engines in vehicles continues to evolve, driven by a complex interplay of consumer preferences, regulatory pressures, and technological advancements. Despite the growing emphasis on fuel efficiency and environmental concerns, there remains a significant segment of consumers who prioritize performance and acceleration in their vehicle choices.

In the luxury and sports car segments, V8 engines maintain a strong presence due to their ability to deliver superior acceleration and power. High-end manufacturers like Ferrari, Lamborghini, and Aston Martin continue to feature V8 engines in their flagship models, catering to enthusiasts who value the distinctive sound and performance characteristics of these powerplants.

The muscle car market, particularly in North America, shows sustained demand for V8-powered vehicles. Models like the Ford Mustang GT, Chevrolet Camaro SS, and Dodge Challenger R/T continue to attract buyers seeking the quintessential American performance car experience. This segment has shown resilience, with manufacturers investing in modernizing V8 engines to meet emissions standards while maintaining their performance appeal.

In the truck and SUV market, V8 engines remain popular for their towing capacity and overall performance. Large SUVs and full-size pickup trucks often offer V8 options to meet the needs of consumers requiring substantial power for hauling and off-road capabilities. This demand is particularly strong in regions where these vehicle types are prevalent, such as North America and the Middle East.

However, the market for V8 engines faces challenges from increasingly stringent emissions regulations and a global shift towards electrification. Many automakers are investing heavily in electric and hybrid technologies, which could potentially impact the long-term demand for V8 engines. Some manufacturers are responding by developing hybrid V8 powertrains, aiming to combine the performance characteristics of V8 engines with improved fuel efficiency and reduced emissions.

The racing and motorsport industry continues to be a significant driver of V8 engine development and demand. Formula 1's use of V8 engines in the past and their continued presence in other racing series maintain interest and technological advancement in this engine configuration. This racing heritage often translates to consumer demand for high-performance road cars featuring V8 engines.

Market analysis indicates that while the overall automotive industry is trending towards smaller, more efficient engines and electrification, there remains a niche but passionate market for V8-powered vehicles. This demand is likely to persist in specific segments, particularly in performance-oriented and luxury vehicles, as well as in certain utility applications.

In the luxury and sports car segments, V8 engines maintain a strong presence due to their ability to deliver superior acceleration and power. High-end manufacturers like Ferrari, Lamborghini, and Aston Martin continue to feature V8 engines in their flagship models, catering to enthusiasts who value the distinctive sound and performance characteristics of these powerplants.

The muscle car market, particularly in North America, shows sustained demand for V8-powered vehicles. Models like the Ford Mustang GT, Chevrolet Camaro SS, and Dodge Challenger R/T continue to attract buyers seeking the quintessential American performance car experience. This segment has shown resilience, with manufacturers investing in modernizing V8 engines to meet emissions standards while maintaining their performance appeal.

In the truck and SUV market, V8 engines remain popular for their towing capacity and overall performance. Large SUVs and full-size pickup trucks often offer V8 options to meet the needs of consumers requiring substantial power for hauling and off-road capabilities. This demand is particularly strong in regions where these vehicle types are prevalent, such as North America and the Middle East.

However, the market for V8 engines faces challenges from increasingly stringent emissions regulations and a global shift towards electrification. Many automakers are investing heavily in electric and hybrid technologies, which could potentially impact the long-term demand for V8 engines. Some manufacturers are responding by developing hybrid V8 powertrains, aiming to combine the performance characteristics of V8 engines with improved fuel efficiency and reduced emissions.

The racing and motorsport industry continues to be a significant driver of V8 engine development and demand. Formula 1's use of V8 engines in the past and their continued presence in other racing series maintain interest and technological advancement in this engine configuration. This racing heritage often translates to consumer demand for high-performance road cars featuring V8 engines.

Market analysis indicates that while the overall automotive industry is trending towards smaller, more efficient engines and electrification, there remains a niche but passionate market for V8-powered vehicles. This demand is likely to persist in specific segments, particularly in performance-oriented and luxury vehicles, as well as in certain utility applications.

Technical Challenges

V8 engines face several technical challenges in enhancing vehicle acceleration. One of the primary issues is the balance between power output and fuel efficiency. As V8 engines are designed to produce high levels of power, they often consume more fuel compared to smaller engines. This trade-off becomes particularly significant in an era where environmental concerns and fuel economy regulations are increasingly stringent.

Another challenge lies in managing the heat generated by V8 engines during high-performance operations. The increased power output results in higher temperatures, which can lead to thermal stress on engine components and potential performance degradation. Engineers must develop advanced cooling systems and materials to mitigate these thermal issues without compromising the engine's power delivery.

Weight distribution presents a further challenge for V8-powered vehicles. The larger size and weight of V8 engines can affect the vehicle's overall balance and handling characteristics, particularly in sports cars and performance vehicles where agility is crucial. Designers must carefully consider engine placement and chassis design to optimize weight distribution and maintain desirable driving dynamics.

The complexity of V8 engines also poses challenges in terms of manufacturing and maintenance. With more moving parts and intricate systems compared to smaller engines, V8s require precise engineering and assembly processes. This complexity can lead to higher production costs and potentially increased maintenance requirements for vehicle owners.

Emissions control is another significant hurdle for V8 engines. Meeting increasingly strict emissions standards while maintaining high performance is a constant challenge for engineers. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation are being employed to address these concerns, but implementing these solutions without compromising the V8's characteristic power and sound is a delicate balancing act.

Vibration and noise management present additional technical challenges. V8 engines, due to their configuration and power output, can produce significant vibrations and noise levels. Engineers must develop sophisticated engine mounts, sound insulation, and exhaust systems to ensure a refined driving experience without diminishing the engine's performance or its iconic sound.

Lastly, the integration of modern technologies such as hybrid systems and advanced driver assistance features with V8 engines presents new challenges. Adapting these powerful engines to work seamlessly with electric motors and complex electronic systems requires innovative engineering solutions to maintain performance while embracing future automotive trends.

Another challenge lies in managing the heat generated by V8 engines during high-performance operations. The increased power output results in higher temperatures, which can lead to thermal stress on engine components and potential performance degradation. Engineers must develop advanced cooling systems and materials to mitigate these thermal issues without compromising the engine's power delivery.

Weight distribution presents a further challenge for V8-powered vehicles. The larger size and weight of V8 engines can affect the vehicle's overall balance and handling characteristics, particularly in sports cars and performance vehicles where agility is crucial. Designers must carefully consider engine placement and chassis design to optimize weight distribution and maintain desirable driving dynamics.

The complexity of V8 engines also poses challenges in terms of manufacturing and maintenance. With more moving parts and intricate systems compared to smaller engines, V8s require precise engineering and assembly processes. This complexity can lead to higher production costs and potentially increased maintenance requirements for vehicle owners.

Emissions control is another significant hurdle for V8 engines. Meeting increasingly strict emissions standards while maintaining high performance is a constant challenge for engineers. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation are being employed to address these concerns, but implementing these solutions without compromising the V8's characteristic power and sound is a delicate balancing act.

Vibration and noise management present additional technical challenges. V8 engines, due to their configuration and power output, can produce significant vibrations and noise levels. Engineers must develop sophisticated engine mounts, sound insulation, and exhaust systems to ensure a refined driving experience without diminishing the engine's performance or its iconic sound.

Lastly, the integration of modern technologies such as hybrid systems and advanced driver assistance features with V8 engines presents new challenges. Adapting these powerful engines to work seamlessly with electric motors and complex electronic systems requires innovative engineering solutions to maintain performance while embracing future automotive trends.

Current V8 Solutions

01 Engine design optimization for improved acceleration

V8 engines can be optimized for better acceleration through various design improvements. These may include enhancing the combustion process, optimizing valve timing, and improving the intake and exhaust systems. Such modifications can lead to increased power output and faster response times, resulting in improved acceleration performance.- Engine design optimization for improved acceleration: V8 engines can be optimized for better acceleration through various design improvements. These may include enhancing the combustion process, optimizing valve timing, and improving the intake and exhaust systems. Such modifications can lead to increased power output and faster response times, resulting in improved acceleration performance.

- Electronic control systems for acceleration enhancement: Advanced electronic control systems can be implemented in V8 engines to enhance acceleration. These systems may include sophisticated engine management units, variable valve timing controllers, and adaptive fuel injection systems. By precisely controlling various engine parameters, these electronic systems can optimize power delivery and improve acceleration across different driving conditions.

- Turbocharging and supercharging for increased power: Implementing forced induction systems such as turbochargers or superchargers can significantly boost the power output of V8 engines. These systems increase the amount of air and fuel mixture entering the combustion chambers, resulting in higher power output and improved acceleration, especially at lower RPMs.

- Lightweight materials and components for better power-to-weight ratio: Utilizing lightweight materials and components in V8 engine construction can improve the power-to-weight ratio, leading to enhanced acceleration. This may include the use of aluminum alloys, carbon fiber, or other advanced materials for engine blocks, pistons, and other components, reducing overall weight while maintaining structural integrity.

- Fuel injection and combustion optimization: Advancements in fuel injection technology and combustion optimization can lead to improved acceleration in V8 engines. This may involve the use of direct injection systems, multiple injectors per cylinder, or advanced fuel atomization techniques. Optimizing the combustion process can result in more efficient power generation and faster engine response.

02 Electronic control systems for V8 engine acceleration

Advanced electronic control systems play a crucial role in optimizing V8 engine acceleration. These systems can manage fuel injection, ignition timing, and throttle response to maximize power output and improve acceleration. They may also incorporate adaptive learning algorithms to fine-tune engine performance based on driving conditions and driver behavior.Expand Specific Solutions03 Turbocharging and supercharging for enhanced acceleration

Forced induction systems such as turbochargers and superchargers can significantly boost the acceleration capabilities of V8 engines. These systems increase the amount of air and fuel entering the combustion chamber, resulting in higher power output and improved acceleration across a wide range of engine speeds.Expand Specific Solutions04 Lightweight materials and components for improved power-to-weight ratio

Utilizing lightweight materials and components in V8 engine construction can enhance acceleration performance. This approach reduces overall engine weight while maintaining or improving power output, resulting in a better power-to-weight ratio and faster acceleration. Materials such as aluminum alloys and carbon fiber composites may be used for various engine components.Expand Specific Solutions05 Variable valve timing and lift systems for optimized acceleration

Implementing variable valve timing and lift systems in V8 engines can significantly improve acceleration performance. These systems allow for dynamic adjustment of valve operation based on engine speed and load, optimizing air intake and exhaust flow across different operating conditions. This results in improved power delivery and faster acceleration response.Expand Specific Solutions

Key Manufacturers

The V8 engine technology market is in a mature stage, with established players dominating the landscape. The global market size for V8 engines is substantial, driven by demand in high-performance vehicles and luxury segments. Technologically, V8 engines are well-developed, with companies like Toyota, GM, Ford, and Honda leading innovation. These firms, along with BMW and Nissan, continually refine V8 technology to enhance acceleration while improving fuel efficiency. Emerging players like Hyundai and Chinese manufacturers are also making strides in V8 development, intensifying competition. The focus is shifting towards integrating V8 engines with hybrid systems and improving power-to-weight ratios to meet evolving performance and environmental standards.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced V8 engines with Direct Injection 4-Stroke Gasoline Engine Superior Version (D-4S) technology. This system combines direct and port fuel injection for optimal fuel efficiency and power output. Toyota's V8 engines feature Dual VVT-i (Variable Valve Timing-intelligent) system, which adjusts both intake and exhaust valve timing for improved performance across all RPM ranges[1]. The company has also implemented a high compression ratio of 11.8:1 in some V8 models, enhancing thermal efficiency and power output[2]. Additionally, Toyota has integrated advanced electronic control units (ECUs) that optimize fuel injection timing and ignition spark for maximum acceleration and responsiveness[3].

Strengths: High thermal efficiency, excellent balance of power and fuel economy, smooth power delivery. Weaknesses: Complexity of the D-4S system may lead to higher maintenance costs, relatively high fuel consumption compared to smaller engines.

GM Global Technology Operations LLC

Technical Solution: GM's V8 engine technology focuses on Dynamic Fuel Management (DFM) system, which can deactivate cylinders in 17 different patterns to optimize power delivery and fuel efficiency[4]. Their latest V8 engines feature direct injection, variable valve timing, and Active Fuel Management, allowing for seamless transitions between 8 and 4-cylinder operation. GM has also developed a new electrical architecture that supports faster processing speeds, enabling quicker throttle response and more precise fuel management[5]. The company's V8 engines often incorporate lightweight materials such as aluminum for the block and heads, reducing overall vehicle weight and improving acceleration[6].

Strengths: Advanced cylinder deactivation technology, improved fuel efficiency without sacrificing power, quick throttle response. Weaknesses: Complexity of DFM system may increase production costs, potential reliability concerns with frequent cylinder activation/deactivation.

Core V8 Technologies

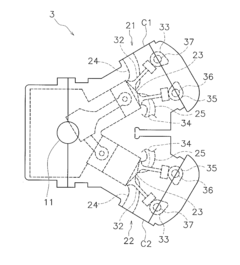

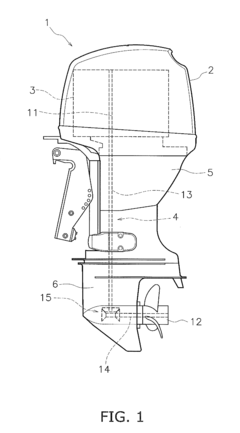

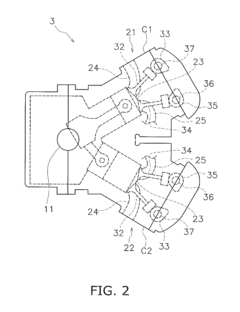

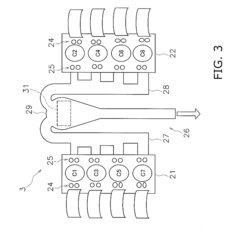

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

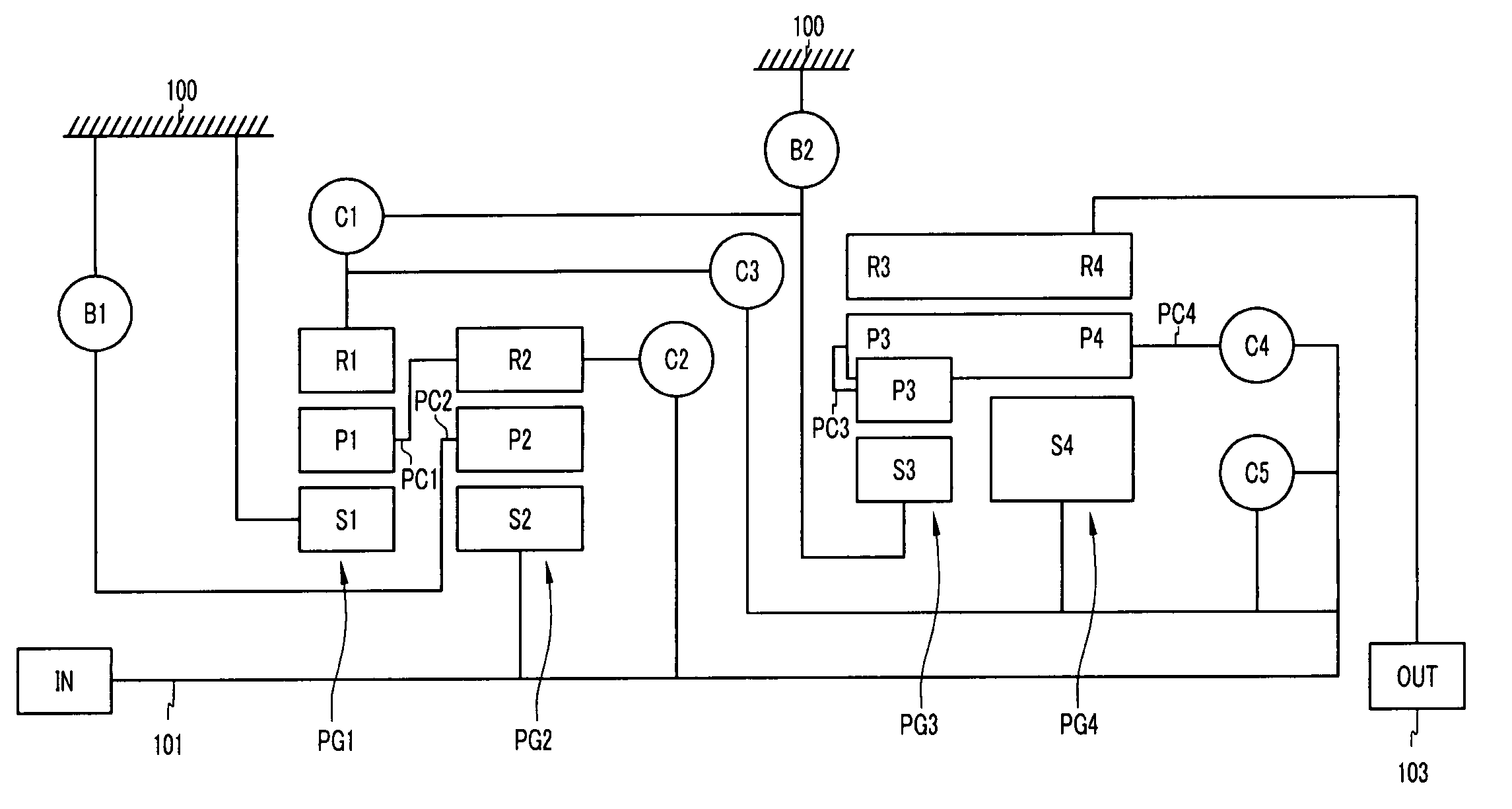

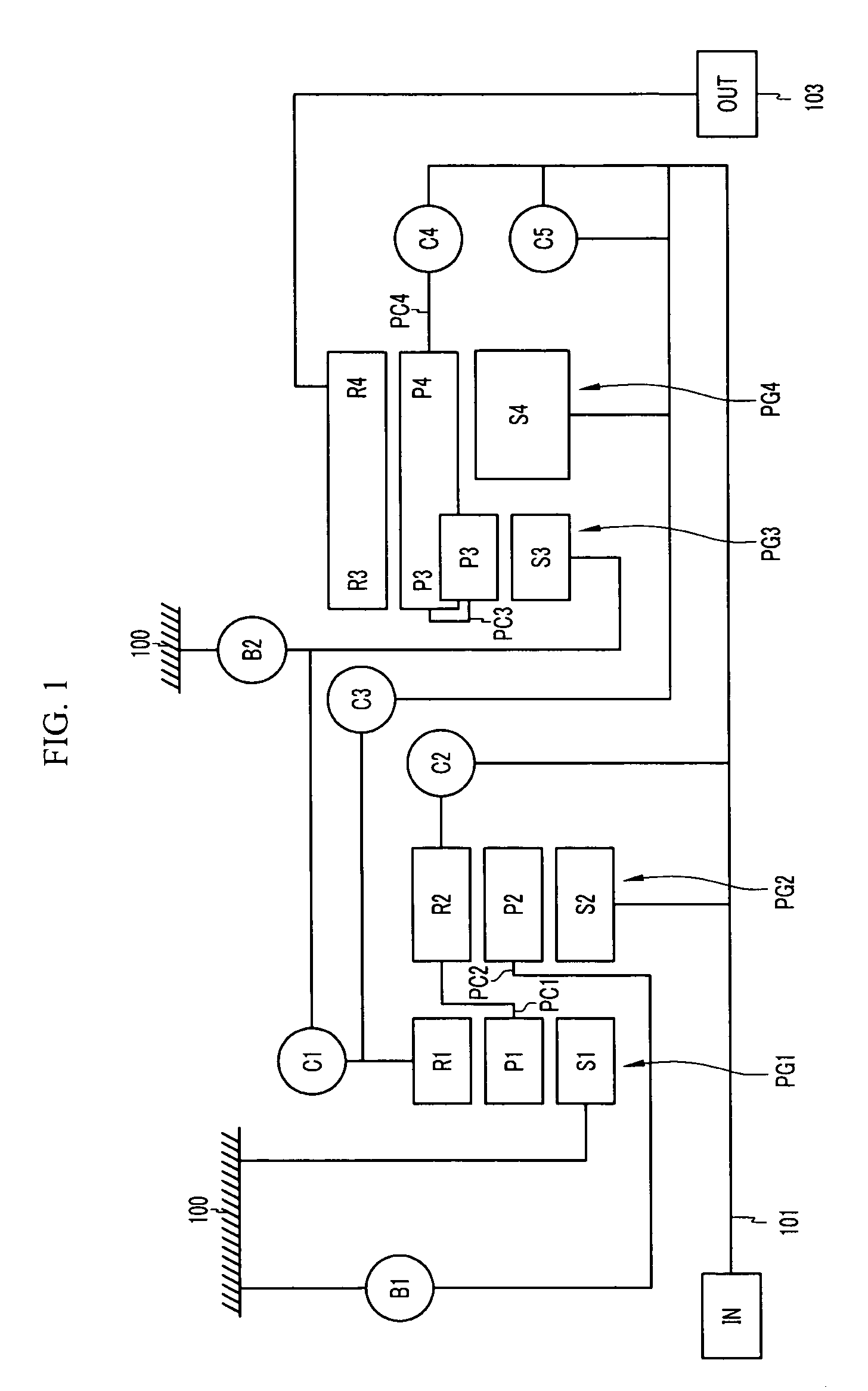

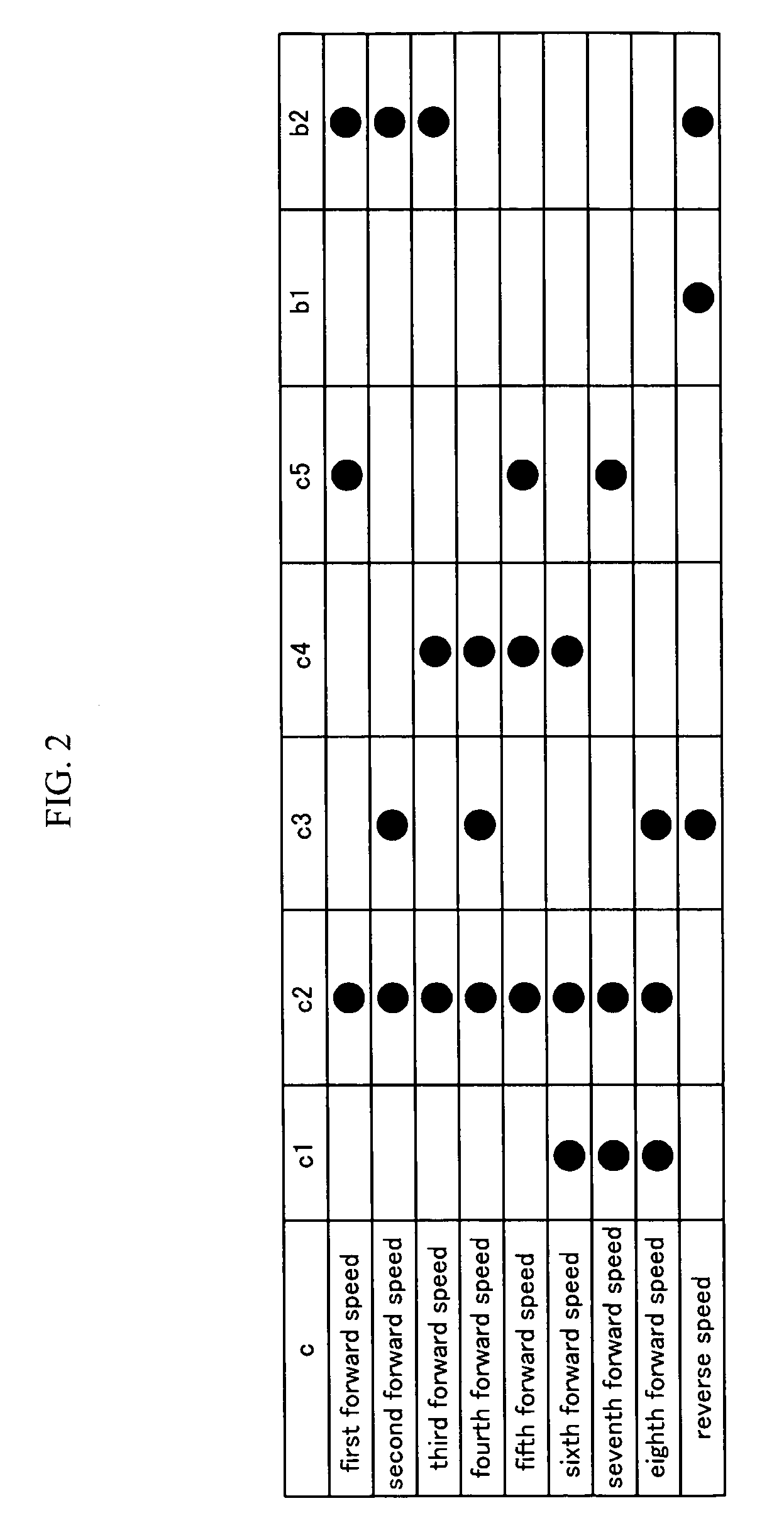

Eight speed powertrain of automatic transmission for vehicle

PatentInactiveUS7452303B2

Innovation

- An eight-speed powertrain is developed using four planetary gear sets and a combination of clutches and brakes, specifically arranging the first, second, third, and fourth planetary gear sets with fixed and variably connected elements to achieve eight forward speeds and one reverse speed, utilizing a double pinion planetary gear set and Ravingneaux type configuration.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development and performance of V8 engines. These regulations aim to reduce harmful emissions and improve fuel efficiency, posing challenges for manufacturers seeking to enhance vehicle acceleration while complying with environmental standards.

The introduction of stricter emission standards, such as Euro 6 in Europe and Tier 3 in the United States, has led to the implementation of advanced technologies in V8 engines. These include direct fuel injection, variable valve timing, and cylinder deactivation systems, which help optimize fuel consumption and reduce emissions without compromising acceleration performance.

To meet these regulations, V8 engine manufacturers have invested heavily in exhaust gas aftertreatment systems. Catalytic converters, particulate filters, and selective catalytic reduction (SCR) technologies have been integrated into V8-powered vehicles to minimize harmful emissions. These systems effectively reduce nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter, ensuring compliance with stringent emission standards.

The push for lower CO2 emissions has also led to the development of more efficient V8 engines. Manufacturers have focused on reducing engine weight, improving thermal efficiency, and implementing start-stop systems to minimize fuel consumption during idle periods. These advancements contribute to better acceleration while maintaining compliance with emissions regulations.

Turbocharging and supercharging technologies have gained prominence in V8 engines as a means to enhance acceleration while meeting emission standards. These forced induction systems allow for smaller displacement engines that produce comparable power to larger naturally aspirated V8s, resulting in improved fuel efficiency and reduced emissions without sacrificing performance.

The integration of hybrid powertrains with V8 engines has emerged as a solution to balance performance and emissions compliance. By combining electric motors with V8 engines, manufacturers can achieve rapid acceleration while significantly reducing overall emissions. This approach allows for electric-only operation in urban environments, further contributing to emission reduction efforts.

As emissions regulations continue to evolve, V8 engine manufacturers are exploring alternative fuels and advanced combustion technologies. Research into synthetic fuels, hydrogen combustion, and low-temperature combustion processes aims to further reduce emissions while maintaining the high-performance characteristics associated with V8 engines.

The introduction of stricter emission standards, such as Euro 6 in Europe and Tier 3 in the United States, has led to the implementation of advanced technologies in V8 engines. These include direct fuel injection, variable valve timing, and cylinder deactivation systems, which help optimize fuel consumption and reduce emissions without compromising acceleration performance.

To meet these regulations, V8 engine manufacturers have invested heavily in exhaust gas aftertreatment systems. Catalytic converters, particulate filters, and selective catalytic reduction (SCR) technologies have been integrated into V8-powered vehicles to minimize harmful emissions. These systems effectively reduce nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter, ensuring compliance with stringent emission standards.

The push for lower CO2 emissions has also led to the development of more efficient V8 engines. Manufacturers have focused on reducing engine weight, improving thermal efficiency, and implementing start-stop systems to minimize fuel consumption during idle periods. These advancements contribute to better acceleration while maintaining compliance with emissions regulations.

Turbocharging and supercharging technologies have gained prominence in V8 engines as a means to enhance acceleration while meeting emission standards. These forced induction systems allow for smaller displacement engines that produce comparable power to larger naturally aspirated V8s, resulting in improved fuel efficiency and reduced emissions without sacrificing performance.

The integration of hybrid powertrains with V8 engines has emerged as a solution to balance performance and emissions compliance. By combining electric motors with V8 engines, manufacturers can achieve rapid acceleration while significantly reducing overall emissions. This approach allows for electric-only operation in urban environments, further contributing to emission reduction efforts.

As emissions regulations continue to evolve, V8 engine manufacturers are exploring alternative fuels and advanced combustion technologies. Research into synthetic fuels, hydrogen combustion, and low-temperature combustion processes aims to further reduce emissions while maintaining the high-performance characteristics associated with V8 engines.

Performance Testing

Performance testing is a critical aspect of evaluating how V8 engines enhance vehicle acceleration. This process involves a series of rigorous tests designed to measure and quantify the acceleration capabilities of vehicles equipped with V8 engines. These tests are conducted under controlled conditions to ensure consistency and reliability of results.

One of the primary methods used in performance testing is the 0-60 mph acceleration test. This test measures the time it takes for a vehicle to accelerate from a standstill to 60 miles per hour. V8-powered vehicles typically excel in this test due to their high power output and torque characteristics. Advanced timing equipment and GPS-based systems are employed to accurately measure these acceleration times, often down to the hundredth of a second.

Quarter-mile testing is another crucial performance metric. This test measures both the time and speed at which a vehicle covers a quarter-mile distance from a standing start. V8 engines, with their robust power delivery, often demonstrate impressive quarter-mile times and trap speeds, showcasing their ability to maintain strong acceleration even at higher speeds.

To further assess the acceleration capabilities of V8 engines, rolling start tests are conducted. These tests evaluate how quickly a vehicle can accelerate from a set speed, typically 50 mph or 70 mph, to a higher speed. This assessment is particularly relevant for real-world driving scenarios and highway passing maneuvers.

Dynamometer testing plays a vital role in quantifying the power output of V8 engines. These tests measure horsepower and torque across the engine's RPM range, providing detailed insights into the engine's performance characteristics. The results often reveal the V8's ability to produce substantial power throughout a wide RPM band, contributing to its strong acceleration properties.

In-gear acceleration tests are also performed to evaluate the engine's responsiveness and power delivery in different gears. These tests typically involve measuring the time taken to accelerate from one speed to another while remaining in a specific gear. V8 engines often demonstrate impressive in-gear acceleration due to their high torque output.

To ensure comprehensive evaluation, performance testing also includes various environmental conditions. Tests are conducted at different ambient temperatures, altitudes, and humidity levels to assess how these factors affect the V8 engine's acceleration performance. This data is crucial for understanding the engine's real-world capabilities across diverse driving conditions.

Advanced data acquisition systems are employed throughout these tests to collect and analyze a wide range of parameters. These include not only speed and acceleration data but also engine RPM, throttle position, boost pressure (in turbocharged V8s), and various temperatures. This comprehensive data collection allows for in-depth analysis of the V8 engine's performance characteristics and how they contribute to enhanced vehicle acceleration.

One of the primary methods used in performance testing is the 0-60 mph acceleration test. This test measures the time it takes for a vehicle to accelerate from a standstill to 60 miles per hour. V8-powered vehicles typically excel in this test due to their high power output and torque characteristics. Advanced timing equipment and GPS-based systems are employed to accurately measure these acceleration times, often down to the hundredth of a second.

Quarter-mile testing is another crucial performance metric. This test measures both the time and speed at which a vehicle covers a quarter-mile distance from a standing start. V8 engines, with their robust power delivery, often demonstrate impressive quarter-mile times and trap speeds, showcasing their ability to maintain strong acceleration even at higher speeds.

To further assess the acceleration capabilities of V8 engines, rolling start tests are conducted. These tests evaluate how quickly a vehicle can accelerate from a set speed, typically 50 mph or 70 mph, to a higher speed. This assessment is particularly relevant for real-world driving scenarios and highway passing maneuvers.

Dynamometer testing plays a vital role in quantifying the power output of V8 engines. These tests measure horsepower and torque across the engine's RPM range, providing detailed insights into the engine's performance characteristics. The results often reveal the V8's ability to produce substantial power throughout a wide RPM band, contributing to its strong acceleration properties.

In-gear acceleration tests are also performed to evaluate the engine's responsiveness and power delivery in different gears. These tests typically involve measuring the time taken to accelerate from one speed to another while remaining in a specific gear. V8 engines often demonstrate impressive in-gear acceleration due to their high torque output.

To ensure comprehensive evaluation, performance testing also includes various environmental conditions. Tests are conducted at different ambient temperatures, altitudes, and humidity levels to assess how these factors affect the V8 engine's acceleration performance. This data is crucial for understanding the engine's real-world capabilities across diverse driving conditions.

Advanced data acquisition systems are employed throughout these tests to collect and analyze a wide range of parameters. These include not only speed and acceleration data but also engine RPM, throttle position, boost pressure (in turbocharged V8s), and various temperatures. This comprehensive data collection allows for in-depth analysis of the V8 engine's performance characteristics and how they contribute to enhanced vehicle acceleration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!