Future Trends in V8 Engine Design for Automobiles

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine has been a cornerstone of automotive engineering since its inception in the early 20th century. Initially developed to provide high power output in a compact package, V8 engines have evolved significantly over the decades, adapting to changing market demands, environmental regulations, and technological advancements.

In the early stages, V8 engines were primarily focused on raw power and performance. The 1950s and 1960s saw the golden age of American muscle cars, where large displacement V8 engines dominated the market. However, the oil crisis of the 1970s forced a shift towards more fuel-efficient designs, leading to the development of smaller, more economical V8 engines.

The 1980s and 1990s brought about significant technological advancements, including electronic fuel injection, variable valve timing, and improved engine management systems. These innovations allowed V8 engines to maintain their performance characteristics while meeting increasingly stringent emissions standards.

In recent years, the focus has shifted towards sustainability and efficiency without compromising performance. This has led to the development of technologies such as cylinder deactivation, direct fuel injection, and turbocharging. These advancements have allowed V8 engines to remain relevant in an era of increasing environmental consciousness.

Looking towards the future, the objectives for V8 engine design are multifaceted. One primary goal is to further improve fuel efficiency and reduce emissions. This involves exploring advanced materials for weight reduction, implementing more sophisticated engine management systems, and integrating hybrid technologies.

Another key objective is to enhance performance while maintaining reliability. This includes developing more efficient combustion processes, optimizing thermal management, and exploring new valve control technologies. Additionally, there is a growing focus on noise, vibration, and harshness (NVH) reduction to improve overall driving experience.

Electrification is also playing a significant role in shaping the future of V8 engines. Many manufacturers are exploring hybrid V8 powertrains, combining traditional internal combustion with electric motors to boost performance and efficiency. This trend is likely to continue, with the possibility of fully electric V8 configurations being developed to maintain the characteristic sound and feel of V8 engines in an electric future.

As we move forward, the evolution of V8 engines will likely be driven by a balance between performance, efficiency, and environmental responsibility. The challenge lies in preserving the unique characteristics that have made V8 engines iconic while adapting to the changing landscape of automotive technology and global regulations.

In the early stages, V8 engines were primarily focused on raw power and performance. The 1950s and 1960s saw the golden age of American muscle cars, where large displacement V8 engines dominated the market. However, the oil crisis of the 1970s forced a shift towards more fuel-efficient designs, leading to the development of smaller, more economical V8 engines.

The 1980s and 1990s brought about significant technological advancements, including electronic fuel injection, variable valve timing, and improved engine management systems. These innovations allowed V8 engines to maintain their performance characteristics while meeting increasingly stringent emissions standards.

In recent years, the focus has shifted towards sustainability and efficiency without compromising performance. This has led to the development of technologies such as cylinder deactivation, direct fuel injection, and turbocharging. These advancements have allowed V8 engines to remain relevant in an era of increasing environmental consciousness.

Looking towards the future, the objectives for V8 engine design are multifaceted. One primary goal is to further improve fuel efficiency and reduce emissions. This involves exploring advanced materials for weight reduction, implementing more sophisticated engine management systems, and integrating hybrid technologies.

Another key objective is to enhance performance while maintaining reliability. This includes developing more efficient combustion processes, optimizing thermal management, and exploring new valve control technologies. Additionally, there is a growing focus on noise, vibration, and harshness (NVH) reduction to improve overall driving experience.

Electrification is also playing a significant role in shaping the future of V8 engines. Many manufacturers are exploring hybrid V8 powertrains, combining traditional internal combustion with electric motors to boost performance and efficiency. This trend is likely to continue, with the possibility of fully electric V8 configurations being developed to maintain the characteristic sound and feel of V8 engines in an electric future.

As we move forward, the evolution of V8 engines will likely be driven by a balance between performance, efficiency, and environmental responsibility. The challenge lies in preserving the unique characteristics that have made V8 engines iconic while adapting to the changing landscape of automotive technology and global regulations.

Market Demand Analysis for V8 Engines

The market demand for V8 engines in automobiles has been undergoing significant shifts in recent years, driven by various factors including environmental regulations, consumer preferences, and technological advancements. Despite the growing trend towards electrification and downsizing in the automotive industry, V8 engines continue to maintain a niche but passionate market segment.

In the luxury and high-performance vehicle sectors, V8 engines remain highly sought after for their distinctive power delivery, sound characteristics, and emotional appeal. Premium automakers such as Mercedes-Benz, BMW, and Audi continue to offer V8 options in their flagship models, catering to customers who prioritize performance and prestige. The sports car and muscle car segments also contribute significantly to V8 engine demand, with manufacturers like Ford, Chevrolet, and Dodge incorporating advanced V8 designs in their performance-oriented vehicles.

However, the overall market for V8 engines has been contracting due to stringent emissions regulations and the push for improved fuel efficiency. This has led to a decline in V8 offerings in mid-range vehicles and SUVs, where they were once more common. Many automakers are now focusing on turbocharged V6 or even four-cylinder engines as alternatives, capable of delivering comparable power with better fuel economy.

The commercial vehicle sector, particularly in heavy-duty trucks and specialized industrial applications, continues to show steady demand for V8 engines. These engines are valued for their durability, torque output, and ability to handle heavy loads, making them essential in certain commercial and industrial contexts.

Looking ahead, the market for V8 engines is expected to become increasingly specialized. Manufacturers are likely to focus on developing more efficient and environmentally friendly V8 designs to meet future emissions standards while maintaining performance characteristics. This may include the integration of hybrid technologies, advanced materials for weight reduction, and innovative combustion strategies.

The collector and enthusiast market also plays a role in sustaining demand for V8 engines. Limited edition models and high-end performance vehicles featuring V8 powerplants continue to command premium prices and generate significant interest among automotive enthusiasts.

In conclusion, while the overall market share of V8 engines is declining, there remains a dedicated demand in specific segments. The future of V8 engines will likely involve a balance between meeting regulatory requirements and satisfying the desires of performance-oriented consumers, potentially leading to more advanced and specialized V8 designs in the coming years.

In the luxury and high-performance vehicle sectors, V8 engines remain highly sought after for their distinctive power delivery, sound characteristics, and emotional appeal. Premium automakers such as Mercedes-Benz, BMW, and Audi continue to offer V8 options in their flagship models, catering to customers who prioritize performance and prestige. The sports car and muscle car segments also contribute significantly to V8 engine demand, with manufacturers like Ford, Chevrolet, and Dodge incorporating advanced V8 designs in their performance-oriented vehicles.

However, the overall market for V8 engines has been contracting due to stringent emissions regulations and the push for improved fuel efficiency. This has led to a decline in V8 offerings in mid-range vehicles and SUVs, where they were once more common. Many automakers are now focusing on turbocharged V6 or even four-cylinder engines as alternatives, capable of delivering comparable power with better fuel economy.

The commercial vehicle sector, particularly in heavy-duty trucks and specialized industrial applications, continues to show steady demand for V8 engines. These engines are valued for their durability, torque output, and ability to handle heavy loads, making them essential in certain commercial and industrial contexts.

Looking ahead, the market for V8 engines is expected to become increasingly specialized. Manufacturers are likely to focus on developing more efficient and environmentally friendly V8 designs to meet future emissions standards while maintaining performance characteristics. This may include the integration of hybrid technologies, advanced materials for weight reduction, and innovative combustion strategies.

The collector and enthusiast market also plays a role in sustaining demand for V8 engines. Limited edition models and high-end performance vehicles featuring V8 powerplants continue to command premium prices and generate significant interest among automotive enthusiasts.

In conclusion, while the overall market share of V8 engines is declining, there remains a dedicated demand in specific segments. The future of V8 engines will likely involve a balance between meeting regulatory requirements and satisfying the desires of performance-oriented consumers, potentially leading to more advanced and specialized V8 designs in the coming years.

Current V8 Technology and Challenges

V8 engines have long been a staple in high-performance automobiles, known for their power and distinctive sound. However, the current landscape of V8 technology faces significant challenges in the face of evolving environmental regulations and shifting consumer preferences.

Modern V8 engines employ advanced technologies to enhance efficiency and performance. Direct fuel injection, variable valve timing, and cylinder deactivation are now commonplace features. These innovations have allowed V8 engines to maintain their power output while improving fuel economy and reducing emissions. Turbocharging and supercharging have also become increasingly prevalent, enabling smaller displacement V8s to produce power comparable to larger naturally aspirated engines.

Despite these advancements, V8 engines still struggle with fuel efficiency compared to smaller, more compact engine configurations. The inherent design of eight cylinders results in greater friction and pumping losses, which contribute to higher fuel consumption. This inefficiency poses a significant challenge in meeting increasingly stringent emissions standards worldwide.

Another major hurdle for V8 engines is their carbon footprint. As governments worldwide implement stricter CO2 emission regulations, automakers are under pressure to reduce the environmental impact of their vehicles. This has led to a trend of downsizing and electrification, which threatens the traditional V8's place in the automotive market.

The weight of V8 engines presents an additional challenge. Their size and complexity often result in a heavier powertrain, which can negatively impact vehicle dynamics and overall efficiency. This is particularly problematic in an era where lightweight construction is prioritized for improved performance and fuel economy.

Noise regulations also pose a challenge for V8 engines. While the distinctive sound of a V8 is often celebrated by enthusiasts, it can be problematic in meeting noise pollution standards, especially in urban environments. Engineers must find ways to maintain the engine's character while adhering to these regulations.

Lastly, the complexity of V8 engines presents challenges in terms of manufacturing costs and maintenance. With more components than smaller engines, V8s are typically more expensive to produce and maintain, which can impact their viability in mass-market vehicles.

As the automotive industry shifts towards electrification, the future of V8 engines hangs in the balance. Manufacturers must innovate to address these challenges if the V8 is to remain relevant in the evolving automotive landscape. This may involve integrating hybrid technologies, developing more advanced materials, or reimagining the V8 concept entirely to meet future performance and efficiency demands.

Modern V8 engines employ advanced technologies to enhance efficiency and performance. Direct fuel injection, variable valve timing, and cylinder deactivation are now commonplace features. These innovations have allowed V8 engines to maintain their power output while improving fuel economy and reducing emissions. Turbocharging and supercharging have also become increasingly prevalent, enabling smaller displacement V8s to produce power comparable to larger naturally aspirated engines.

Despite these advancements, V8 engines still struggle with fuel efficiency compared to smaller, more compact engine configurations. The inherent design of eight cylinders results in greater friction and pumping losses, which contribute to higher fuel consumption. This inefficiency poses a significant challenge in meeting increasingly stringent emissions standards worldwide.

Another major hurdle for V8 engines is their carbon footprint. As governments worldwide implement stricter CO2 emission regulations, automakers are under pressure to reduce the environmental impact of their vehicles. This has led to a trend of downsizing and electrification, which threatens the traditional V8's place in the automotive market.

The weight of V8 engines presents an additional challenge. Their size and complexity often result in a heavier powertrain, which can negatively impact vehicle dynamics and overall efficiency. This is particularly problematic in an era where lightweight construction is prioritized for improved performance and fuel economy.

Noise regulations also pose a challenge for V8 engines. While the distinctive sound of a V8 is often celebrated by enthusiasts, it can be problematic in meeting noise pollution standards, especially in urban environments. Engineers must find ways to maintain the engine's character while adhering to these regulations.

Lastly, the complexity of V8 engines presents challenges in terms of manufacturing costs and maintenance. With more components than smaller engines, V8s are typically more expensive to produce and maintain, which can impact their viability in mass-market vehicles.

As the automotive industry shifts towards electrification, the future of V8 engines hangs in the balance. Manufacturers must innovate to address these challenges if the V8 is to remain relevant in the evolving automotive landscape. This may involve integrating hybrid technologies, developing more advanced materials, or reimagining the V8 concept entirely to meet future performance and efficiency demands.

Current V8 Engine Design Solutions

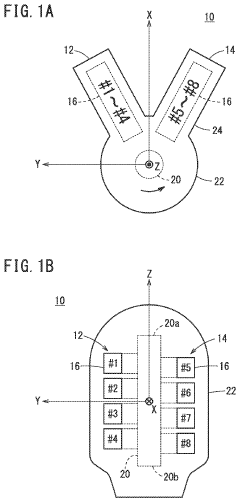

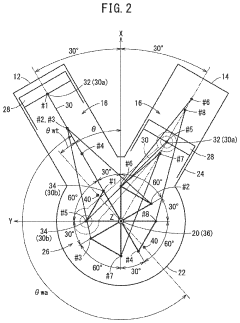

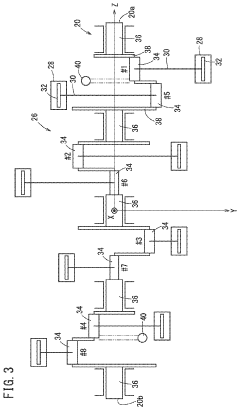

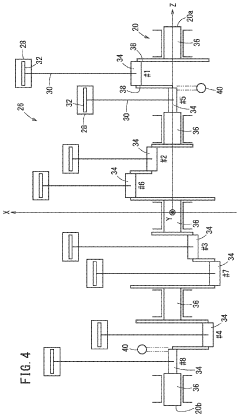

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are characterized by their V-shaped configuration of eight cylinders. This design allows for a compact engine layout while providing high power output. Various improvements in V8 engine design focus on optimizing cylinder arrangement, crankshaft design, and overall engine geometry to enhance performance and efficiency.

- Fuel Efficiency and Emissions Control: Modern V8 engines incorporate technologies to improve fuel efficiency and reduce emissions. These may include advanced fuel injection systems, variable valve timing, cylinder deactivation, and exhaust gas recirculation. Such innovations help V8 engines meet stringent environmental regulations while maintaining high performance.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often used in V8 engines to increase power output and efficiency. These systems compress the intake air, allowing more fuel to be burned and generating more power from the same engine displacement.

- Cooling and Lubrication Systems: Effective cooling and lubrication are crucial for V8 engine performance and longevity. Innovations in these areas include advanced coolant circulation systems, oil cooling techniques, and improved lubricant formulations to manage the high heat and stress generated by V8 engines.

- Materials and Manufacturing Techniques: Advancements in materials science and manufacturing processes contribute to V8 engine improvements. This includes the use of lightweight alloys, composite materials, and precision manufacturing techniques to reduce engine weight, improve durability, and enhance overall performance.

02 Fuel Efficiency and Emissions Control

Modern V8 engines incorporate technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Such innovations help V8 engines meet stringent environmental regulations while maintaining high performance.Expand Specific Solutions03 Performance Enhancement and Tuning

Various methods and components are used to enhance V8 engine performance. These may include turbocharging, supercharging, high-flow intake and exhaust systems, and engine management system tuning. Performance enhancements aim to increase horsepower, torque, and overall engine responsiveness.Expand Specific Solutions04 Cooling and Lubrication Systems

Effective cooling and lubrication are crucial for V8 engine reliability and longevity. Advanced cooling systems may incorporate precision-controlled electric water pumps, while lubrication systems often feature high-capacity oil pumps and sophisticated oil filtration. These systems help maintain optimal operating temperatures and reduce wear on engine components.Expand Specific Solutions05 Manufacturing and Assembly Techniques

Innovative manufacturing and assembly techniques are employed in V8 engine production to improve quality, reduce weight, and enhance durability. These may include the use of advanced materials like aluminum alloys, precision machining processes, and automated assembly systems. Such techniques contribute to the overall performance and reliability of V8 engines.Expand Specific Solutions

Major V8 Engine Manufacturers

The future trends in V8 engine design for automobiles are characterized by a competitive landscape in a mature industry. Major players like GM, Ford, Toyota, and BMW are investing in advanced technologies to improve efficiency and performance. The market size remains significant, but growth is slowing due to the shift towards electrification. Technological maturity is high, with companies like Honda and Volkswagen focusing on incremental improvements in areas such as fuel efficiency, emissions reduction, and power output. Emerging players like Chery and Leapmotor are also entering the space, particularly in developing markets, adding to the competitive dynamics of this evolving sector.

GM Global Technology Operations LLC

Technical Solution: GM is focusing on the evolution of V8 engines with a dual approach: enhancing traditional designs and exploring hybrid integration. Their latest V8 engines feature dynamic fuel management, which can deactivate cylinders in 17 different patterns to optimize efficiency[9]. GM is also developing advanced combustion systems, including high compression ratios and lean-burn technologies, to improve fuel economy and reduce emissions[10]. The company is investing in smart materials and coatings to reduce friction and improve thermal management in V8 engines[11]. Additionally, GM is exploring the integration of electric superchargers and e-turbo systems with V8 engines to enhance performance while reducing fuel consumption[12].

Strengths: Extensive experience in V8 production, strong market presence in segments valuing V8 engines, and advanced manufacturing capabilities. Weaknesses: Balancing V8 development with increasing focus on electric vehicles, potential challenges in meeting future emissions standards.

Toyota Motor Corp.

Technical Solution: Toyota is pioneering the development of high-efficiency V8 engines with advanced technologies. Their latest V8 design incorporates direct injection, variable valve timing, and cylinder deactivation to improve fuel economy and reduce emissions[1]. Toyota is also exploring the integration of hybrid technology with V8 engines, as seen in their i-FORCE MAX powertrain[2]. This system combines a twin-turbo V8 with an electric motor, providing enhanced power and efficiency. Additionally, Toyota is investing in materials research, utilizing lightweight alloys and composite materials to reduce engine weight while maintaining durability[3]. The company is also focusing on advanced combustion techniques, such as homogeneous charge compression ignition (HCCI), to further improve efficiency and reduce emissions in future V8 designs[4].

Strengths: Strong reputation for reliability, extensive R&D capabilities, and a balanced approach to performance and efficiency. Weaknesses: Relatively conservative approach to radical design changes, potential challenges in meeting stringent future emissions regulations with V8 engines.

Key V8 Engine Innovations

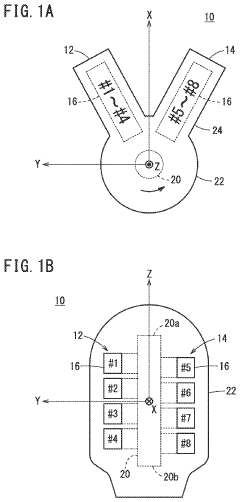

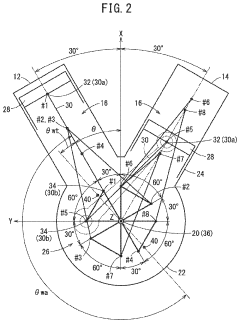

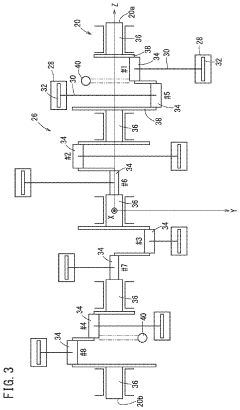

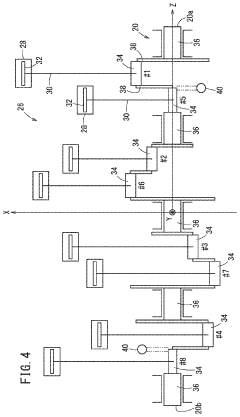

V8 engine

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Environmental Regulations Impact

Environmental regulations are playing an increasingly significant role in shaping the future of V8 engine design for automobiles. As governments worldwide implement stricter emissions standards and fuel efficiency requirements, manufacturers are compelled to adapt their V8 engines to meet these new challenges.

One of the primary impacts of environmental regulations is the push towards improved fuel efficiency. V8 engines, traditionally known for their power but not their fuel economy, are now being redesigned to consume less fuel while maintaining performance. This has led to the development of technologies such as cylinder deactivation, where half of the cylinders can be shut off during low-load conditions, effectively turning the V8 into a more efficient four-cylinder engine when full power is not required.

Another significant trend driven by environmental regulations is the integration of hybrid technology into V8 engines. By combining electric motors with traditional V8 powertrains, manufacturers can achieve substantial reductions in emissions and fuel consumption. This hybrid approach allows for the retention of V8 power when needed, while providing more environmentally friendly operation during city driving or at lower speeds.

Emissions control systems are also becoming more advanced in response to tightening regulations. Modern V8 engines are incorporating sophisticated catalytic converters, particulate filters, and exhaust gas recirculation systems to minimize harmful emissions. These technologies are continually evolving to meet ever-stricter standards, particularly in regions like Europe and California.

The impact of environmental regulations extends to the materials used in V8 engine construction. Lightweight materials such as aluminum and carbon fiber are being increasingly utilized to reduce overall vehicle weight, thereby improving fuel efficiency and reducing emissions. This shift in materials science is driving innovation in engine design and manufacturing processes.

Furthermore, environmental concerns are pushing manufacturers to explore alternative fuels for V8 engines. Biofuels, synthetic fuels, and even hydrogen are being considered as potential replacements for traditional gasoline, requiring adaptations in engine design to accommodate these new fuel sources.

The regulatory landscape is also accelerating research into advanced combustion technologies. High-efficiency combustion processes, such as homogeneous charge compression ignition (HCCI), are being explored to maximize fuel efficiency and minimize emissions in V8 engines. These technologies aim to combine the best attributes of gasoline and diesel engines, potentially revolutionizing V8 performance and environmental impact.

As environmental regulations continue to evolve, the future of V8 engine design will likely see a convergence of multiple technologies. This may include combinations of electrification, alternative fuels, advanced materials, and innovative combustion processes, all working together to create V8 engines that can meet stringent environmental standards while still delivering the power and performance that enthusiasts crave.

One of the primary impacts of environmental regulations is the push towards improved fuel efficiency. V8 engines, traditionally known for their power but not their fuel economy, are now being redesigned to consume less fuel while maintaining performance. This has led to the development of technologies such as cylinder deactivation, where half of the cylinders can be shut off during low-load conditions, effectively turning the V8 into a more efficient four-cylinder engine when full power is not required.

Another significant trend driven by environmental regulations is the integration of hybrid technology into V8 engines. By combining electric motors with traditional V8 powertrains, manufacturers can achieve substantial reductions in emissions and fuel consumption. This hybrid approach allows for the retention of V8 power when needed, while providing more environmentally friendly operation during city driving or at lower speeds.

Emissions control systems are also becoming more advanced in response to tightening regulations. Modern V8 engines are incorporating sophisticated catalytic converters, particulate filters, and exhaust gas recirculation systems to minimize harmful emissions. These technologies are continually evolving to meet ever-stricter standards, particularly in regions like Europe and California.

The impact of environmental regulations extends to the materials used in V8 engine construction. Lightweight materials such as aluminum and carbon fiber are being increasingly utilized to reduce overall vehicle weight, thereby improving fuel efficiency and reducing emissions. This shift in materials science is driving innovation in engine design and manufacturing processes.

Furthermore, environmental concerns are pushing manufacturers to explore alternative fuels for V8 engines. Biofuels, synthetic fuels, and even hydrogen are being considered as potential replacements for traditional gasoline, requiring adaptations in engine design to accommodate these new fuel sources.

The regulatory landscape is also accelerating research into advanced combustion technologies. High-efficiency combustion processes, such as homogeneous charge compression ignition (HCCI), are being explored to maximize fuel efficiency and minimize emissions in V8 engines. These technologies aim to combine the best attributes of gasoline and diesel engines, potentially revolutionizing V8 performance and environmental impact.

As environmental regulations continue to evolve, the future of V8 engine design will likely see a convergence of multiple technologies. This may include combinations of electrification, alternative fuels, advanced materials, and innovative combustion processes, all working together to create V8 engines that can meet stringent environmental standards while still delivering the power and performance that enthusiasts crave.

V8 Engine Performance Metrics

V8 engine performance metrics have evolved significantly over the years, reflecting advancements in technology and changing priorities in the automotive industry. These metrics serve as crucial indicators of an engine's capabilities and efficiency, guiding both manufacturers and consumers in their decision-making processes.

One of the primary performance metrics for V8 engines is horsepower, which measures the engine's overall power output. Modern V8 engines have seen substantial improvements in this area, with some high-performance models producing over 700 horsepower. This increase in power has been achieved through various technological advancements, including improved fuel injection systems, turbocharging, and advanced materials that allow for higher compression ratios.

Torque, another critical metric, represents the rotational force produced by the engine. V8 engines are renowned for their high torque output, which contributes to their strong acceleration and towing capabilities. Recent trends show a focus on increasing low-end torque for better everyday drivability and improved fuel efficiency.

Fuel efficiency has become an increasingly important metric in V8 engine design. Despite their reputation for high fuel consumption, modern V8 engines have made significant strides in this area. Technologies such as cylinder deactivation, direct fuel injection, and variable valve timing have contributed to improved fuel economy without sacrificing performance.

Emissions performance is another crucial metric, especially given stringent environmental regulations. V8 engine designers have implemented various technologies to reduce emissions, including advanced catalytic converters, exhaust gas recirculation systems, and particulate filters. The challenge lies in balancing emissions reduction with performance and fuel efficiency.

Reliability and durability metrics have also gained prominence. Manufacturers are focusing on extending engine life and reducing maintenance requirements through improved materials, better lubrication systems, and more robust designs. This includes metrics such as mean time between failures (MTBF) and overall engine lifespan.

Power-to-weight ratio is a metric that has seen increased attention, particularly in performance and sports car applications. By using lightweight materials and optimizing engine design, manufacturers have been able to improve this ratio, resulting in better acceleration and handling characteristics.

Noise, vibration, and harshness (NVH) metrics have become more sophisticated, with a focus on enhancing the driving experience. Modern V8 engines are designed to provide a balance between the characteristic V8 sound and comfortable, refined operation.

As the automotive industry moves towards electrification, new hybrid-specific metrics are emerging for V8 engines. These include metrics related to electric assist performance, regenerative braking efficiency, and overall system integration.

One of the primary performance metrics for V8 engines is horsepower, which measures the engine's overall power output. Modern V8 engines have seen substantial improvements in this area, with some high-performance models producing over 700 horsepower. This increase in power has been achieved through various technological advancements, including improved fuel injection systems, turbocharging, and advanced materials that allow for higher compression ratios.

Torque, another critical metric, represents the rotational force produced by the engine. V8 engines are renowned for their high torque output, which contributes to their strong acceleration and towing capabilities. Recent trends show a focus on increasing low-end torque for better everyday drivability and improved fuel efficiency.

Fuel efficiency has become an increasingly important metric in V8 engine design. Despite their reputation for high fuel consumption, modern V8 engines have made significant strides in this area. Technologies such as cylinder deactivation, direct fuel injection, and variable valve timing have contributed to improved fuel economy without sacrificing performance.

Emissions performance is another crucial metric, especially given stringent environmental regulations. V8 engine designers have implemented various technologies to reduce emissions, including advanced catalytic converters, exhaust gas recirculation systems, and particulate filters. The challenge lies in balancing emissions reduction with performance and fuel efficiency.

Reliability and durability metrics have also gained prominence. Manufacturers are focusing on extending engine life and reducing maintenance requirements through improved materials, better lubrication systems, and more robust designs. This includes metrics such as mean time between failures (MTBF) and overall engine lifespan.

Power-to-weight ratio is a metric that has seen increased attention, particularly in performance and sports car applications. By using lightweight materials and optimizing engine design, manufacturers have been able to improve this ratio, resulting in better acceleration and handling characteristics.

Noise, vibration, and harshness (NVH) metrics have become more sophisticated, with a focus on enhancing the driving experience. Modern V8 engines are designed to provide a balance between the characteristic V8 sound and comfortable, refined operation.

As the automotive industry moves towards electrification, new hybrid-specific metrics are emerging for V8 engines. These include metrics related to electric assist performance, regenerative braking efficiency, and overall system integration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!