How V8 Engines Shape Future Automotive Engineering?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception, shaping the landscape of automotive engineering. Initially developed in the early 20th century, V8 engines quickly gained popularity due to their compact design and impressive power output. The first mass-produced V8 engine was introduced by Cadillac in 1914, setting the stage for a revolution in automotive propulsion.

Throughout the 1920s and 1930s, V8 engines became increasingly refined, with advancements in materials and manufacturing techniques leading to improved reliability and performance. The introduction of overhead valve designs in the 1940s marked a significant milestone, allowing for higher compression ratios and increased efficiency.

The 1950s and 1960s saw a surge in V8 engine development, particularly in the United States, where the "muscle car" era drove demand for high-performance powerplants. This period witnessed the introduction of larger displacement engines, often exceeding 7 liters, and the widespread adoption of four-barrel carburetors and dual exhaust systems.

The 1970s brought new challenges for V8 engines, as stricter emissions regulations and fuel economy standards forced manufacturers to prioritize efficiency. This led to the development of electronic fuel injection systems and catalytic converters, which helped maintain performance while reducing emissions.

In the 1980s and 1990s, computer-controlled engine management systems became prevalent, allowing for more precise control over fuel delivery and ignition timing. This era also saw the introduction of variable valve timing and multi-valve cylinder heads, further enhancing efficiency and power output.

The turn of the millennium marked a new phase in V8 engine evolution, with a focus on balancing performance with environmental concerns. Direct fuel injection, cylinder deactivation, and advanced turbocharging technologies became commonplace, enabling V8 engines to deliver impressive power while meeting increasingly stringent emissions standards.

Recent years have seen a continued emphasis on efficiency and electrification. Many manufacturers have introduced hybrid V8 powertrains, combining traditional internal combustion with electric motors to boost performance and reduce fuel consumption. Additionally, advancements in materials science have led to the use of lightweight alloys and composite materials in engine construction, further improving power-to-weight ratios.

Looking ahead, the future of V8 engines in automotive engineering remains dynamic. While there is a growing shift towards electrification, V8 engines continue to evolve, with ongoing research into alternative fuels, advanced combustion techniques, and integration with hybrid and electric systems. This evolution ensures that V8 engines will continue to play a significant role in shaping the future of automotive engineering, adapting to meet the changing demands of performance, efficiency, and environmental responsibility.

Throughout the 1920s and 1930s, V8 engines became increasingly refined, with advancements in materials and manufacturing techniques leading to improved reliability and performance. The introduction of overhead valve designs in the 1940s marked a significant milestone, allowing for higher compression ratios and increased efficiency.

The 1950s and 1960s saw a surge in V8 engine development, particularly in the United States, where the "muscle car" era drove demand for high-performance powerplants. This period witnessed the introduction of larger displacement engines, often exceeding 7 liters, and the widespread adoption of four-barrel carburetors and dual exhaust systems.

The 1970s brought new challenges for V8 engines, as stricter emissions regulations and fuel economy standards forced manufacturers to prioritize efficiency. This led to the development of electronic fuel injection systems and catalytic converters, which helped maintain performance while reducing emissions.

In the 1980s and 1990s, computer-controlled engine management systems became prevalent, allowing for more precise control over fuel delivery and ignition timing. This era also saw the introduction of variable valve timing and multi-valve cylinder heads, further enhancing efficiency and power output.

The turn of the millennium marked a new phase in V8 engine evolution, with a focus on balancing performance with environmental concerns. Direct fuel injection, cylinder deactivation, and advanced turbocharging technologies became commonplace, enabling V8 engines to deliver impressive power while meeting increasingly stringent emissions standards.

Recent years have seen a continued emphasis on efficiency and electrification. Many manufacturers have introduced hybrid V8 powertrains, combining traditional internal combustion with electric motors to boost performance and reduce fuel consumption. Additionally, advancements in materials science have led to the use of lightweight alloys and composite materials in engine construction, further improving power-to-weight ratios.

Looking ahead, the future of V8 engines in automotive engineering remains dynamic. While there is a growing shift towards electrification, V8 engines continue to evolve, with ongoing research into alternative fuels, advanced combustion techniques, and integration with hybrid and electric systems. This evolution ensures that V8 engines will continue to play a significant role in shaping the future of automotive engineering, adapting to meet the changing demands of performance, efficiency, and environmental responsibility.

Market Demand Analysis

The market demand for V8 engines in automotive engineering continues to evolve, driven by a complex interplay of consumer preferences, regulatory pressures, and technological advancements. Despite the growing emphasis on fuel efficiency and environmental concerns, there remains a significant market segment that values the power, performance, and prestige associated with V8 engines.

In the luxury and high-performance vehicle sectors, V8 engines maintain a strong presence. These markets prioritize acceleration, top speed, and the distinctive sound profile that V8 engines provide. Premium automakers continue to invest in V8 technology, refining these engines to meet stricter emissions standards while preserving their desirable characteristics.

The sports car and muscle car segments also contribute substantially to the ongoing demand for V8 engines. Enthusiasts and collectors value the heritage and emotional appeal of V8-powered vehicles, creating a niche but passionate market. This demand supports the development of specialized V8 engines that balance performance with improved efficiency.

However, the broader automotive market is experiencing a shift towards downsized engines and electrification. This trend is primarily driven by tightening global emissions regulations and increasing consumer awareness of environmental issues. As a result, many manufacturers are reducing their V8 offerings in mainstream models, reserving them for flagship or performance-oriented vehicles.

The commercial vehicle sector presents another dimension of V8 engine demand. Heavy-duty trucks and large SUVs often require the torque and durability that V8 engines provide, especially for towing and hauling applications. This market segment continues to support ongoing development and refinement of V8 technology.

Geographically, the demand for V8 engines varies significantly. North America remains a stronghold, with a cultural affinity for larger engines in pickup trucks and performance cars. Europe sees declining V8 usage due to stringent emissions regulations, while emerging markets show mixed trends, with some regions embracing V8 power as a symbol of luxury and others prioritizing fuel efficiency.

Looking ahead, the market for V8 engines is expected to become more specialized. While overall volume may decrease, there will likely be continued demand in specific segments. This shift is prompting engine manufacturers to focus on developing more efficient and technologically advanced V8 engines, incorporating features such as cylinder deactivation, advanced materials, and hybrid assistance to meet future market needs and regulatory requirements.

In the luxury and high-performance vehicle sectors, V8 engines maintain a strong presence. These markets prioritize acceleration, top speed, and the distinctive sound profile that V8 engines provide. Premium automakers continue to invest in V8 technology, refining these engines to meet stricter emissions standards while preserving their desirable characteristics.

The sports car and muscle car segments also contribute substantially to the ongoing demand for V8 engines. Enthusiasts and collectors value the heritage and emotional appeal of V8-powered vehicles, creating a niche but passionate market. This demand supports the development of specialized V8 engines that balance performance with improved efficiency.

However, the broader automotive market is experiencing a shift towards downsized engines and electrification. This trend is primarily driven by tightening global emissions regulations and increasing consumer awareness of environmental issues. As a result, many manufacturers are reducing their V8 offerings in mainstream models, reserving them for flagship or performance-oriented vehicles.

The commercial vehicle sector presents another dimension of V8 engine demand. Heavy-duty trucks and large SUVs often require the torque and durability that V8 engines provide, especially for towing and hauling applications. This market segment continues to support ongoing development and refinement of V8 technology.

Geographically, the demand for V8 engines varies significantly. North America remains a stronghold, with a cultural affinity for larger engines in pickup trucks and performance cars. Europe sees declining V8 usage due to stringent emissions regulations, while emerging markets show mixed trends, with some regions embracing V8 power as a symbol of luxury and others prioritizing fuel efficiency.

Looking ahead, the market for V8 engines is expected to become more specialized. While overall volume may decrease, there will likely be continued demand in specific segments. This shift is prompting engine manufacturers to focus on developing more efficient and technologically advanced V8 engines, incorporating features such as cylinder deactivation, advanced materials, and hybrid assistance to meet future market needs and regulatory requirements.

Technical Challenges

The development of V8 engines in automotive engineering faces several significant technical challenges that shape the future of this technology. One of the primary obstacles is the ongoing pressure to improve fuel efficiency while maintaining or enhancing performance. As environmental regulations become increasingly stringent, engineers must find innovative ways to reduce fuel consumption and emissions without compromising the power output that V8 engines are known for.

Another major challenge lies in the realm of materials science. The high temperatures and pressures generated within V8 engines require materials that can withstand extreme conditions while remaining lightweight. Developing new alloys and composites that offer superior strength-to-weight ratios and heat resistance is crucial for the evolution of V8 technology.

The integration of advanced electronic control systems presents yet another hurdle. Modern V8 engines rely heavily on sophisticated engine management systems to optimize performance, fuel efficiency, and emissions. Developing and refining these systems to work seamlessly with the mechanical components of the engine requires extensive research and testing.

Weight reduction is an ongoing challenge for V8 engine designers. As automotive manufacturers strive to improve overall vehicle efficiency, reducing the mass of the engine becomes critical. This necessitates innovative design approaches and the use of lightweight materials without sacrificing durability or performance.

The push towards electrification and hybrid powertrains also poses a significant challenge for V8 engine development. Engineers must find ways to integrate electric motors and battery systems with traditional V8 engines, creating hybrid powertrains that offer the best of both worlds. This integration requires careful consideration of packaging, thermal management, and power distribution.

Noise, vibration, and harshness (NVH) control is another area of focus. While the distinctive sound of a V8 engine is often desirable, excessive noise and vibration can detract from the driving experience and vehicle comfort. Developing effective NVH solutions without compromising performance or adding significant weight is a complex engineering task.

Lastly, the challenge of scalability and manufacturing efficiency looms large. As automotive manufacturers seek to streamline production and reduce costs, developing V8 engines that can be efficiently mass-produced while maintaining high quality standards becomes increasingly important. This requires advancements in manufacturing processes, automation, and quality control systems.

Another major challenge lies in the realm of materials science. The high temperatures and pressures generated within V8 engines require materials that can withstand extreme conditions while remaining lightweight. Developing new alloys and composites that offer superior strength-to-weight ratios and heat resistance is crucial for the evolution of V8 technology.

The integration of advanced electronic control systems presents yet another hurdle. Modern V8 engines rely heavily on sophisticated engine management systems to optimize performance, fuel efficiency, and emissions. Developing and refining these systems to work seamlessly with the mechanical components of the engine requires extensive research and testing.

Weight reduction is an ongoing challenge for V8 engine designers. As automotive manufacturers strive to improve overall vehicle efficiency, reducing the mass of the engine becomes critical. This necessitates innovative design approaches and the use of lightweight materials without sacrificing durability or performance.

The push towards electrification and hybrid powertrains also poses a significant challenge for V8 engine development. Engineers must find ways to integrate electric motors and battery systems with traditional V8 engines, creating hybrid powertrains that offer the best of both worlds. This integration requires careful consideration of packaging, thermal management, and power distribution.

Noise, vibration, and harshness (NVH) control is another area of focus. While the distinctive sound of a V8 engine is often desirable, excessive noise and vibration can detract from the driving experience and vehicle comfort. Developing effective NVH solutions without compromising performance or adding significant weight is a complex engineering task.

Lastly, the challenge of scalability and manufacturing efficiency looms large. As automotive manufacturers seek to streamline production and reduce costs, developing V8 engines that can be efficiently mass-produced while maintaining high quality standards becomes increasingly important. This requires advancements in manufacturing processes, automation, and quality control systems.

Current V8 Solutions

01 V8 Engine Design and Configuration

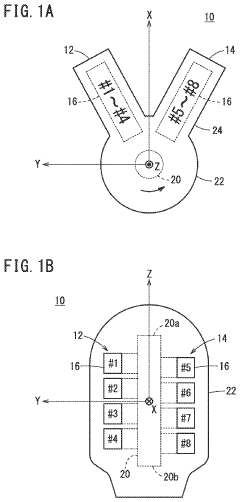

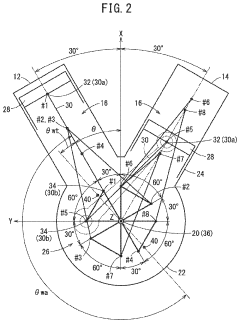

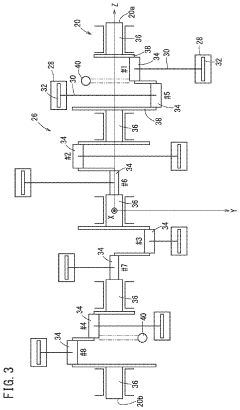

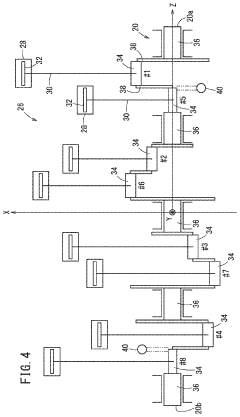

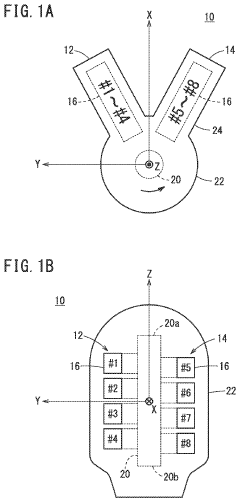

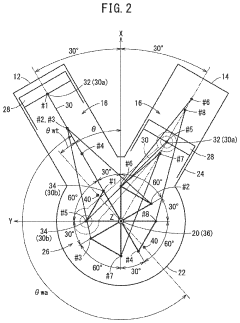

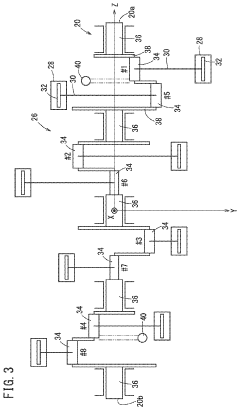

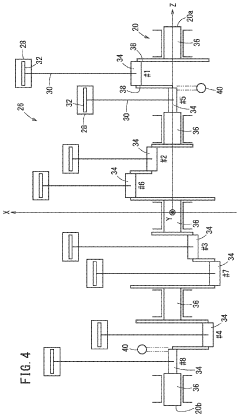

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously improved to enhance performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for compact packaging, improved balance, and higher power output compared to inline engines. Various design aspects, such as cylinder angle, firing order, and crankshaft configuration, are optimized for performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are implemented in V8 engines to enhance performance and reduce emissions. These may include direct injection, variable valve timing, and cylinder deactivation technologies. Optimized fuel delivery and combustion processes contribute to improved power output, fuel efficiency, and environmental compliance.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to increase power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and resulting in higher power density. Various configurations and control strategies are used to optimize boost pressure and minimize turbo lag.

- Engine Block and Component Materials: Advanced materials and manufacturing techniques are used in V8 engine construction to reduce weight, improve durability, and enhance thermal management. This may include the use of aluminum alloys, composite materials, and specialized coatings for engine blocks, cylinder heads, and internal components. Material selection and design contribute to overall engine performance and longevity.

- Cooling and Lubrication Systems: Efficient cooling and lubrication systems are crucial for V8 engine performance and reliability. Advanced cooling strategies, such as precision cooling and variable flow systems, help maintain optimal operating temperatures. Improved oil circulation and filtration techniques ensure proper lubrication of critical components, reducing wear and extending engine life.

02 Fuel Efficiency and Emissions Control in V8 Engines

Innovations in V8 engine technology focus on improving fuel efficiency and reducing emissions. This includes the development of advanced fuel injection systems, variable valve timing, cylinder deactivation, and exhaust gas recirculation. These technologies aim to optimize combustion, reduce fuel consumption, and meet increasingly stringent environmental regulations.Expand Specific Solutions03 Performance Enhancement of V8 Engines

Techniques to enhance V8 engine performance include turbocharging, supercharging, and the use of advanced materials for engine components. These improvements aim to increase power output, torque, and overall engine efficiency. Additionally, electronic engine management systems are developed to optimize performance across various operating conditions.Expand Specific Solutions04 Cooling and Lubrication Systems for V8 Engines

Effective cooling and lubrication are crucial for V8 engine performance and longevity. Innovations in this area include advanced coolant formulations, improved oil circulation systems, and optimized cooling channel designs. These developments aim to maintain optimal operating temperatures and reduce friction, thereby enhancing engine efficiency and durability.Expand Specific Solutions05 Integration of V8 Engines with Hybrid and Electric Systems

As automotive technology evolves, there is a growing trend to integrate V8 engines with hybrid and electric systems. This integration aims to combine the power and performance of V8 engines with the efficiency and environmental benefits of electric propulsion. Such hybrid V8 systems can offer improved fuel economy and reduced emissions while maintaining high performance capabilities.Expand Specific Solutions

Key Industry Players

The V8 engine market is in a mature stage, with established players like GM, BMW, Honda, and Toyota dominating the landscape. However, the industry is experiencing a shift towards more efficient and environmentally friendly technologies. The global V8 engine market size is estimated to be in the billions, driven by demand in high-performance vehicles and luxury segments. Technologically, companies are focusing on improving fuel efficiency and reducing emissions while maintaining power output. Key players like Ford, Nissan, and Hyundai are investing in advanced V8 technologies, including hybrid and electric adaptations, to meet evolving regulatory standards and consumer preferences for performance and sustainability.

GM Global Technology Operations LLC

Technical Solution: GM's approach to V8 engine development focuses on advanced combustion technologies and electrification integration. They have introduced Dynamic Fuel Management (DFM) in their V8 engines, which can deactivate up to seven cylinders for improved fuel efficiency[1]. GM is also exploring hybrid V8 systems, combining traditional V8 power with electric motors for enhanced performance and reduced emissions. Their latest V8 engines feature direct injection, variable valve timing, and advanced materials for weight reduction, achieving a balance between power and efficiency[2]. GM is investing in cylinder deactivation technology, allowing their V8 engines to operate as four-cylinder engines under light loads, significantly improving fuel economy[3].

Strengths: Innovative cylinder deactivation technology, hybrid integration potential, and balanced performance-efficiency approach. Weaknesses: Continued reliance on fossil fuels, potential complexity in hybrid systems.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to V8 engine technology emphasizes high performance and gradual electrification. Their latest N63 4.4-liter twin-turbo V8 engine features advanced technologies such as direct injection, variable valve timing, and a hot-vee turbocharger layout for improved responsiveness and efficiency[13]. BMW is also exploring mild-hybrid systems for their V8 engines, incorporating 48V electrical systems to enhance performance and reduce fuel consumption. In terms of future automotive engineering, BMW is developing a new generation of V8 engines that will comply with Euro 7 emissions standards, potentially incorporating more advanced electrification technologies[14]. The company is also investing in modular engine designs that allow for flexible production and easier integration of hybrid technologies across their engine lineup, including V8s[15].

Strengths: Advanced turbocharging technology, focus on high-performance applications, and gradual integration of electrification. Weaknesses: Potential challenges in meeting future emissions regulations while maintaining performance characteristics.

Core V8 Innovations

V8 engine

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Emissions Regulations

Emissions regulations have become a critical factor in shaping the future of automotive engineering, particularly in the context of V8 engines. These powerful and iconic powerplants have long been associated with high performance and luxury vehicles, but their future is increasingly challenged by stringent environmental standards.

The global push for reduced carbon emissions has led to the implementation of increasingly strict regulations across major automotive markets. In the European Union, the Euro 6d standard has set ambitious targets for reducing nitrogen oxides (NOx) and particulate matter emissions. Similarly, the United States Environmental Protection Agency (EPA) has established rigorous Corporate Average Fuel Economy (CAFE) standards, which aim to improve fuel efficiency and reduce greenhouse gas emissions.

These regulations have forced automakers to innovate and adapt their V8 engine designs. One key approach has been the integration of advanced fuel injection systems, such as direct injection and dual injection technologies. These systems optimize fuel delivery, resulting in more efficient combustion and reduced emissions. Additionally, variable valve timing and lift systems have been widely adopted to enhance engine efficiency across different operating conditions.

Turbocharging and supercharging technologies have also played a crucial role in meeting emissions standards while maintaining performance. By downsizing engine displacement and utilizing forced induction, manufacturers can achieve higher power outputs with reduced fuel consumption and emissions. This trend has led to the development of smaller, more efficient V8 engines that still deliver the performance characteristics expected from this engine configuration.

Another significant development in V8 engine technology is the implementation of cylinder deactivation systems. These systems allow the engine to operate on fewer cylinders during low-load conditions, substantially improving fuel efficiency and reducing emissions during everyday driving scenarios. Advanced engine management systems and sophisticated software algorithms enable seamless transitions between full and partial cylinder operation.

The integration of hybrid technologies with V8 engines has emerged as a promising solution to meet emissions regulations. Mild hybrid systems, which incorporate small electric motors and battery packs, provide additional power assistance and enable features like start-stop technology and regenerative braking. More advanced hybrid powertrains, combining V8 engines with larger electric motors and batteries, offer significant improvements in fuel efficiency and emissions reduction while preserving the characteristic performance of V8 engines.

As emissions regulations continue to evolve, the future of V8 engines in automotive engineering remains uncertain. While technological advancements have allowed these engines to meet current standards, the long-term viability of V8 powerplants in mass-market vehicles may be challenged by the shift towards electrification and zero-emission vehicles. However, the ongoing development of synthetic fuels and hydrogen combustion technologies may provide new avenues for V8 engines to comply with future emissions regulations, particularly in niche markets and high-performance applications.

The global push for reduced carbon emissions has led to the implementation of increasingly strict regulations across major automotive markets. In the European Union, the Euro 6d standard has set ambitious targets for reducing nitrogen oxides (NOx) and particulate matter emissions. Similarly, the United States Environmental Protection Agency (EPA) has established rigorous Corporate Average Fuel Economy (CAFE) standards, which aim to improve fuel efficiency and reduce greenhouse gas emissions.

These regulations have forced automakers to innovate and adapt their V8 engine designs. One key approach has been the integration of advanced fuel injection systems, such as direct injection and dual injection technologies. These systems optimize fuel delivery, resulting in more efficient combustion and reduced emissions. Additionally, variable valve timing and lift systems have been widely adopted to enhance engine efficiency across different operating conditions.

Turbocharging and supercharging technologies have also played a crucial role in meeting emissions standards while maintaining performance. By downsizing engine displacement and utilizing forced induction, manufacturers can achieve higher power outputs with reduced fuel consumption and emissions. This trend has led to the development of smaller, more efficient V8 engines that still deliver the performance characteristics expected from this engine configuration.

Another significant development in V8 engine technology is the implementation of cylinder deactivation systems. These systems allow the engine to operate on fewer cylinders during low-load conditions, substantially improving fuel efficiency and reducing emissions during everyday driving scenarios. Advanced engine management systems and sophisticated software algorithms enable seamless transitions between full and partial cylinder operation.

The integration of hybrid technologies with V8 engines has emerged as a promising solution to meet emissions regulations. Mild hybrid systems, which incorporate small electric motors and battery packs, provide additional power assistance and enable features like start-stop technology and regenerative braking. More advanced hybrid powertrains, combining V8 engines with larger electric motors and batteries, offer significant improvements in fuel efficiency and emissions reduction while preserving the characteristic performance of V8 engines.

As emissions regulations continue to evolve, the future of V8 engines in automotive engineering remains uncertain. While technological advancements have allowed these engines to meet current standards, the long-term viability of V8 powerplants in mass-market vehicles may be challenged by the shift towards electrification and zero-emission vehicles. However, the ongoing development of synthetic fuels and hydrogen combustion technologies may provide new avenues for V8 engines to comply with future emissions regulations, particularly in niche markets and high-performance applications.

Hybrid V8 Systems

Hybrid V8 systems represent a significant evolution in automotive engineering, combining the power and performance of traditional V8 engines with the efficiency and environmental benefits of electric propulsion. These systems typically integrate an electric motor with a conventional V8 engine, creating a powertrain that can seamlessly switch between or combine both power sources.

The development of hybrid V8 systems has been driven by the need to meet increasingly stringent emissions regulations while maintaining the performance characteristics that V8 engines are known for. Manufacturers have employed various strategies to achieve this balance, including parallel hybrid systems, where the electric motor and V8 engine can operate independently or in tandem, and series hybrid systems, where the V8 engine primarily serves as a generator for the electric drivetrain.

One of the key advantages of hybrid V8 systems is their ability to provide instant torque from the electric motor, complementing the high-end power of the V8 engine. This combination results in improved acceleration and overall performance, particularly at lower speeds where traditional V8 engines may be less efficient. Additionally, the electric component allows for regenerative braking, capturing energy typically lost during deceleration and converting it into electricity to recharge the battery.

Manufacturers have also focused on optimizing the integration of these systems to minimize weight and space requirements. Advanced control systems and power electronics play a crucial role in managing the interplay between the V8 engine and electric motor, ensuring smooth transitions and optimal efficiency across various driving conditions.

The implementation of hybrid V8 systems has extended beyond high-performance sports cars to luxury sedans and SUVs, offering a compelling blend of power and efficiency. This technology has allowed manufacturers to maintain the prestige and emotional appeal associated with V8 engines while addressing environmental concerns and fuel economy requirements.

Looking ahead, the future of hybrid V8 systems may involve further electrification, potentially leading to plug-in hybrid variants that offer extended electric-only driving ranges. Additionally, advancements in battery technology and power electronics are likely to enhance the overall efficiency and performance of these systems, potentially extending their viability in an increasingly electrified automotive landscape.

The development of hybrid V8 systems has been driven by the need to meet increasingly stringent emissions regulations while maintaining the performance characteristics that V8 engines are known for. Manufacturers have employed various strategies to achieve this balance, including parallel hybrid systems, where the electric motor and V8 engine can operate independently or in tandem, and series hybrid systems, where the V8 engine primarily serves as a generator for the electric drivetrain.

One of the key advantages of hybrid V8 systems is their ability to provide instant torque from the electric motor, complementing the high-end power of the V8 engine. This combination results in improved acceleration and overall performance, particularly at lower speeds where traditional V8 engines may be less efficient. Additionally, the electric component allows for regenerative braking, capturing energy typically lost during deceleration and converting it into electricity to recharge the battery.

Manufacturers have also focused on optimizing the integration of these systems to minimize weight and space requirements. Advanced control systems and power electronics play a crucial role in managing the interplay between the V8 engine and electric motor, ensuring smooth transitions and optimal efficiency across various driving conditions.

The implementation of hybrid V8 systems has extended beyond high-performance sports cars to luxury sedans and SUVs, offering a compelling blend of power and efficiency. This technology has allowed manufacturers to maintain the prestige and emotional appeal associated with V8 engines while addressing environmental concerns and fuel economy requirements.

Looking ahead, the future of hybrid V8 systems may involve further electrification, potentially leading to plug-in hybrid variants that offer extended electric-only driving ranges. Additionally, advancements in battery technology and power electronics are likely to enhance the overall efficiency and performance of these systems, potentially extending their viability in an increasingly electrified automotive landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!