How V8 Engines are Revolutionizing Off-Road Vehicles?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception, revolutionizing the off-road vehicle industry. Initially developed for high-performance automobiles, V8 engines have found their way into rugged terrain vehicles, offering unparalleled power and torque.

The journey of V8 engines in off-road vehicles began in the mid-20th century when manufacturers recognized the need for more robust powertrains in challenging environments. Early adaptations focused on increasing durability and reliability to withstand harsh conditions. Engineers reinforced engine components, improved cooling systems, and enhanced lubrication to ensure optimal performance in extreme temperatures and dusty terrains.

As technology advanced, V8 engines for off-road use saw substantial improvements in fuel efficiency and emissions control. The introduction of electronic fuel injection systems and variable valve timing allowed for better fuel management and reduced environmental impact without compromising power output. This evolution addressed growing concerns about fuel consumption and environmental regulations while maintaining the V8's signature performance characteristics.

The integration of advanced materials played a crucial role in the V8's off-road evolution. Lightweight alloys and composite materials reduced engine weight, improving overall vehicle dynamics and fuel efficiency. These innovations allowed manufacturers to create more powerful engines without significantly increasing vehicle mass, a critical factor in off-road performance.

Another significant milestone was the development of adaptive engine management systems. These sophisticated electronic controls allowed V8 engines to adjust their performance characteristics based on terrain and driving conditions. Features like variable displacement, which deactivates cylinders during low-load situations, further enhanced fuel efficiency without sacrificing the power available when needed.

The latest generation of V8 engines for off-road vehicles has seen the integration of forced induction technologies. Turbocharging and supercharging have dramatically increased power output and torque, especially at lower RPMs, which is crucial for off-road driving. These advancements have enabled smaller displacement V8 engines to deliver performance comparable to larger naturally aspirated units, offering a better balance of power and efficiency.

Recent developments have also focused on improving the V8's compatibility with alternative fuels and hybrid systems. Flex-fuel capabilities and the integration of electric motors have expanded the versatility of V8-powered off-road vehicles, addressing both environmental concerns and the demand for increased performance. This evolution demonstrates the V8's adaptability and continued relevance in the face of changing automotive trends and regulations.

The journey of V8 engines in off-road vehicles began in the mid-20th century when manufacturers recognized the need for more robust powertrains in challenging environments. Early adaptations focused on increasing durability and reliability to withstand harsh conditions. Engineers reinforced engine components, improved cooling systems, and enhanced lubrication to ensure optimal performance in extreme temperatures and dusty terrains.

As technology advanced, V8 engines for off-road use saw substantial improvements in fuel efficiency and emissions control. The introduction of electronic fuel injection systems and variable valve timing allowed for better fuel management and reduced environmental impact without compromising power output. This evolution addressed growing concerns about fuel consumption and environmental regulations while maintaining the V8's signature performance characteristics.

The integration of advanced materials played a crucial role in the V8's off-road evolution. Lightweight alloys and composite materials reduced engine weight, improving overall vehicle dynamics and fuel efficiency. These innovations allowed manufacturers to create more powerful engines without significantly increasing vehicle mass, a critical factor in off-road performance.

Another significant milestone was the development of adaptive engine management systems. These sophisticated electronic controls allowed V8 engines to adjust their performance characteristics based on terrain and driving conditions. Features like variable displacement, which deactivates cylinders during low-load situations, further enhanced fuel efficiency without sacrificing the power available when needed.

The latest generation of V8 engines for off-road vehicles has seen the integration of forced induction technologies. Turbocharging and supercharging have dramatically increased power output and torque, especially at lower RPMs, which is crucial for off-road driving. These advancements have enabled smaller displacement V8 engines to deliver performance comparable to larger naturally aspirated units, offering a better balance of power and efficiency.

Recent developments have also focused on improving the V8's compatibility with alternative fuels and hybrid systems. Flex-fuel capabilities and the integration of electric motors have expanded the versatility of V8-powered off-road vehicles, addressing both environmental concerns and the demand for increased performance. This evolution demonstrates the V8's adaptability and continued relevance in the face of changing automotive trends and regulations.

Off-Road Market Trends

The off-road vehicle market has been experiencing significant growth and transformation in recent years, driven by increasing consumer interest in outdoor recreation and adventure activities. This trend has been further accelerated by the COVID-19 pandemic, which has led to a surge in demand for outdoor leisure pursuits and vehicles that can facilitate these experiences.

Market data indicates that the global off-road vehicle market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including rising disposable incomes, expanding urbanization, and a growing enthusiasm for outdoor sports and activities.

One of the most notable trends in the off-road market is the increasing demand for high-performance vehicles, particularly those equipped with powerful engines such as V8s. Consumers are seeking vehicles that can deliver exceptional performance in challenging terrains while also providing comfort and luxury features. This shift has led to a blurring of lines between traditional off-road vehicles and high-end SUVs, creating a new category of premium off-road vehicles.

Another significant trend is the growing focus on environmental sustainability. While V8 engines are known for their power, there is an increasing push for more fuel-efficient and environmentally friendly options. This has led to the development of advanced V8 engines with improved fuel economy and reduced emissions, as well as the introduction of hybrid and electric powertrains in the off-road segment.

The market is also witnessing a rise in customization and aftermarket modifications. Off-road enthusiasts are increasingly looking to personalize their vehicles with upgrades to enhance performance, aesthetics, and functionality. This trend has created a thriving aftermarket industry for off-road vehicle parts and accessories, particularly for V8-powered vehicles.

Geographically, North America continues to dominate the off-road vehicle market, with the United States being the largest consumer. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth, driven by increasing urbanization and rising disposable incomes in these regions.

The competitive landscape of the off-road vehicle market is evolving, with traditional manufacturers facing competition from new entrants, particularly in the high-performance and luxury segments. This has led to increased innovation and the introduction of new technologies, especially in V8 engine development and integration.

Market data indicates that the global off-road vehicle market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including rising disposable incomes, expanding urbanization, and a growing enthusiasm for outdoor sports and activities.

One of the most notable trends in the off-road market is the increasing demand for high-performance vehicles, particularly those equipped with powerful engines such as V8s. Consumers are seeking vehicles that can deliver exceptional performance in challenging terrains while also providing comfort and luxury features. This shift has led to a blurring of lines between traditional off-road vehicles and high-end SUVs, creating a new category of premium off-road vehicles.

Another significant trend is the growing focus on environmental sustainability. While V8 engines are known for their power, there is an increasing push for more fuel-efficient and environmentally friendly options. This has led to the development of advanced V8 engines with improved fuel economy and reduced emissions, as well as the introduction of hybrid and electric powertrains in the off-road segment.

The market is also witnessing a rise in customization and aftermarket modifications. Off-road enthusiasts are increasingly looking to personalize their vehicles with upgrades to enhance performance, aesthetics, and functionality. This trend has created a thriving aftermarket industry for off-road vehicle parts and accessories, particularly for V8-powered vehicles.

Geographically, North America continues to dominate the off-road vehicle market, with the United States being the largest consumer. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth, driven by increasing urbanization and rising disposable incomes in these regions.

The competitive landscape of the off-road vehicle market is evolving, with traditional manufacturers facing competition from new entrants, particularly in the high-performance and luxury segments. This has led to increased innovation and the introduction of new technologies, especially in V8 engine development and integration.

V8 Tech Challenges

The integration of V8 engines into off-road vehicles presents several significant technical challenges that manufacturers and engineers must overcome. One of the primary hurdles is the adaptation of these powerful engines to the unique demands of off-road environments. V8 engines, traditionally designed for high-performance road vehicles, require substantial modifications to withstand the harsh conditions encountered in off-road settings.

Heat management poses a critical challenge in off-road V8 applications. The intense power output of these engines, combined with the slower speeds and challenging terrain typical of off-road driving, can lead to overheating issues. Engineers must develop advanced cooling systems capable of maintaining optimal engine temperatures under extreme conditions, often with limited airflow.

Weight distribution is another key concern when incorporating V8 engines into off-road vehicles. The substantial mass of these powerplants can negatively impact vehicle balance and handling, particularly in rough terrain. Designers must carefully consider engine placement and chassis design to ensure proper weight distribution and maintain the vehicle's center of gravity at an appropriate level for off-road performance.

Fuel efficiency remains a significant challenge for V8-powered off-road vehicles. The high fuel consumption characteristic of V8 engines is exacerbated by the demanding nature of off-road driving. Engineers are tasked with developing innovative fuel management systems and exploring alternative fuels to improve efficiency without compromising power output.

Durability and reliability are paramount in off-road applications, presenting another set of challenges for V8 integration. Components must be reinforced to withstand the constant vibration, impacts, and stress associated with off-road use. This includes strengthening engine mounts, developing more robust lubrication systems, and enhancing filtration to protect against dust and debris ingestion.

Emissions control presents a growing challenge as environmental regulations become increasingly stringent. Engineers must develop advanced exhaust systems and catalytic converters capable of reducing emissions while maintaining performance in off-road conditions. This often requires innovative solutions to deal with the unique operating conditions encountered in off-road use.

Noise reduction is another area of concern, particularly as V8 engines are known for their distinctive, powerful sound. While this may be desirable in some contexts, excessive noise can be problematic in certain off-road environments. Developing effective sound dampening solutions without compromising engine performance or adding significant weight is a complex engineering task.

Heat management poses a critical challenge in off-road V8 applications. The intense power output of these engines, combined with the slower speeds and challenging terrain typical of off-road driving, can lead to overheating issues. Engineers must develop advanced cooling systems capable of maintaining optimal engine temperatures under extreme conditions, often with limited airflow.

Weight distribution is another key concern when incorporating V8 engines into off-road vehicles. The substantial mass of these powerplants can negatively impact vehicle balance and handling, particularly in rough terrain. Designers must carefully consider engine placement and chassis design to ensure proper weight distribution and maintain the vehicle's center of gravity at an appropriate level for off-road performance.

Fuel efficiency remains a significant challenge for V8-powered off-road vehicles. The high fuel consumption characteristic of V8 engines is exacerbated by the demanding nature of off-road driving. Engineers are tasked with developing innovative fuel management systems and exploring alternative fuels to improve efficiency without compromising power output.

Durability and reliability are paramount in off-road applications, presenting another set of challenges for V8 integration. Components must be reinforced to withstand the constant vibration, impacts, and stress associated with off-road use. This includes strengthening engine mounts, developing more robust lubrication systems, and enhancing filtration to protect against dust and debris ingestion.

Emissions control presents a growing challenge as environmental regulations become increasingly stringent. Engineers must develop advanced exhaust systems and catalytic converters capable of reducing emissions while maintaining performance in off-road conditions. This often requires innovative solutions to deal with the unique operating conditions encountered in off-road use.

Noise reduction is another area of concern, particularly as V8 engines are known for their distinctive, powerful sound. While this may be desirable in some contexts, excessive noise can be problematic in certain off-road environments. Developing effective sound dampening solutions without compromising engine performance or adding significant weight is a complex engineering task.

Current V8 Solutions

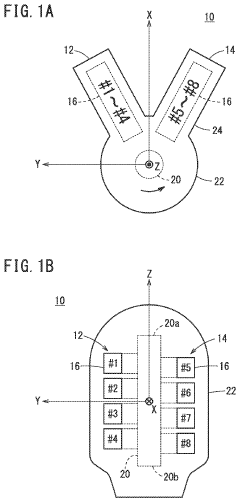

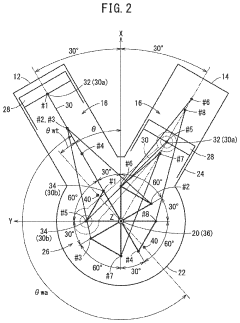

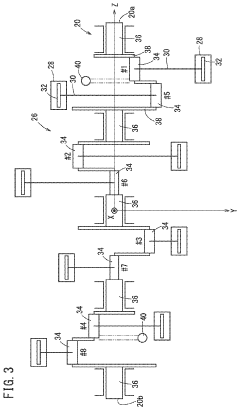

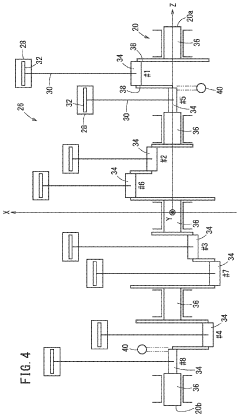

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for compact packaging, improved balance, and higher power output compared to inline engines. Various design aspects, such as cylinder angle, firing order, and crankshaft configuration, are optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design while providing high power output. The design often includes features for improved performance, fuel efficiency, and reduced emissions.

- Fuel Injection Systems for V8 Engines: Advanced fuel injection systems are developed for V8 engines to optimize fuel delivery and combustion. These systems may include direct injection, multi-port injection, or a combination of both, aimed at improving engine efficiency and power output while reducing fuel consumption.

- Valve Train and Camshaft Innovations: Innovations in valve train and camshaft designs for V8 engines focus on improving engine breathing, reducing friction, and enhancing overall performance. This may include variable valve timing, lift systems, and advanced materials for camshaft construction.

- Turbocharging and Supercharging V8 Engines: Forced induction systems, such as turbochargers and superchargers, are applied to V8 engines to increase power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and resulting in higher engine performance.

- Cooling and Lubrication Systems for V8 Engines: Specialized cooling and lubrication systems are developed for V8 engines to manage heat and reduce friction. These systems may include advanced coolant circulation methods, oil cooling techniques, and high-performance lubricants to ensure optimal engine operation and longevity.

02 Fuel Injection Systems for V8 Engines

Advanced fuel injection systems are developed for V8 engines to improve fuel efficiency and performance. These systems may include direct injection, multi-port injection, or a combination of both. Precise fuel delivery and atomization contribute to better combustion, reduced emissions, and increased power output.Expand Specific Solutions03 Valve Train and Camshaft Innovations

Innovations in valve train components and camshaft designs enhance V8 engine performance. Variable valve timing, lift control systems, and advanced camshaft profiles optimize airflow and combustion efficiency across different engine speeds and loads. These technologies contribute to improved power delivery, fuel economy, and emissions control.Expand Specific Solutions04 Turbocharging and Supercharging V8 Engines

Forced induction systems, such as turbochargers and superchargers, are applied to V8 engines to increase power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and resulting in higher power density. Advanced control strategies and integration with other engine systems optimize performance across various operating conditions.Expand Specific Solutions05 Cooling and Lubrication Systems for V8 Engines

Specialized cooling and lubrication systems are developed for V8 engines to manage heat and reduce friction. Advanced coolant flow designs, oil circulation methods, and thermal management strategies ensure optimal engine performance and longevity. These systems may include features such as variable-flow oil pumps, targeted piston cooling, and integrated heat exchangers.Expand Specific Solutions

Key V8 Manufacturers

The V8 engine revolution in off-road vehicles is shaping a competitive landscape characterized by rapid technological advancements and market expansion. The industry is in a growth phase, with increasing demand for high-performance off-road vehicles driving market size expansion. Technological maturity varies among key players, with companies like Yamaha Motor Co., Ltd., Honda Motor Co., Ltd., and Caterpillar, Inc. leading in innovation. These firms, along with emerging players such as Great Wall Motor Co., Ltd. and BYD Co., Ltd., are investing heavily in V8 engine development for off-road applications. The market is seeing a blend of established automotive giants and specialized off-road vehicle manufacturers competing to deliver superior power, efficiency, and durability in V8-equipped off-road vehicles.

Honda Motor Co., Ltd.

Technical Solution: While Honda is not traditionally associated with V8 engines in off-road vehicles, the company has made significant advancements in engine technology that could potentially be applied to V8 configurations for off-road use. Honda's Earth Dreams Technology initiative focuses on improving engine efficiency and performance across various engine types. The company has developed advanced variable cylinder management systems and direct injection technologies that could be adapted to V8 engines for off-road applications[7]. Honda's expertise in lightweight engine design and advanced materials could contribute to creating more efficient and powerful V8 engines for future off-road vehicles.

Strengths: Strong reputation for engine reliability and efficiency, advanced research and development capabilities in engine technology. Weaknesses: Limited experience with V8 engines in production vehicles, and current focus on smaller displacement engines and electrification.

Caterpillar, Inc.

Technical Solution: Caterpillar has been at the forefront of revolutionizing off-road vehicles with V8 engines. Their advanced V8 diesel engines, such as the C13B, deliver exceptional power and torque for heavy-duty off-road applications. These engines feature advanced fuel injection systems and turbocharging technology, resulting in improved fuel efficiency and reduced emissions[1]. Caterpillar's V8 engines also incorporate sophisticated electronic control modules that optimize performance across various terrains and operating conditions. The company has invested heavily in developing engine technologies that meet stringent emissions standards while maintaining the robustness required for off-road use[2].

Strengths: Unparalleled durability and reliability in harsh environments, extensive global service network, and proven track record in off-road applications. Weaknesses: Higher initial cost compared to some competitors, and potential complexity in maintenance for some advanced features.

V8 Off-Road Patents

V8 engine

PatentActiveUS20230109196A1

Innovation

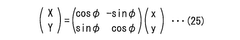

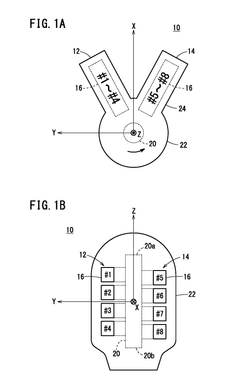

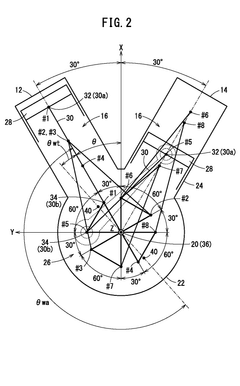

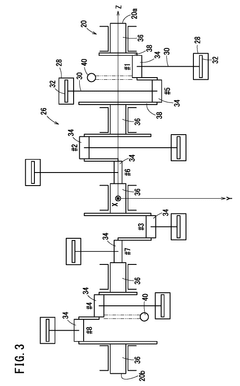

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentWO2021171405A1

Innovation

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

Emissions Regulations

The integration of V8 engines into off-road vehicles has brought significant advancements in performance and capability. However, these powerful engines also face increasing scrutiny due to stringent emissions regulations worldwide. As governments and environmental agencies push for cleaner transportation, off-road vehicle manufacturers must adapt their V8 engines to meet these evolving standards.

In recent years, many countries have implemented stricter emissions regulations for off-road vehicles, including those equipped with V8 engines. These regulations typically focus on reducing greenhouse gas emissions, particulate matter, and nitrogen oxides. The United States Environmental Protection Agency (EPA) and the European Union's Euro emissions standards are at the forefront of these regulatory efforts, setting increasingly stringent limits on pollutants emitted by off-road vehicles.

To comply with these regulations, manufacturers have been forced to innovate and implement new technologies in their V8 engines. One common approach is the use of advanced exhaust after-treatment systems, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF). These systems help reduce harmful emissions by treating exhaust gases before they are released into the atmosphere.

Another strategy employed by manufacturers is the development of more efficient fuel injection systems and combustion processes. Direct injection technology, for example, allows for more precise control over fuel delivery, resulting in improved fuel efficiency and reduced emissions. Additionally, variable valve timing and lift systems help optimize engine performance across different operating conditions, further enhancing efficiency and reducing emissions.

Some manufacturers have also turned to hybrid powertrains, combining V8 engines with electric motors to improve fuel economy and reduce emissions. This approach allows off-road vehicles to maintain their high-performance capabilities while meeting stricter regulatory requirements. Furthermore, start-stop technology, which automatically shuts off the engine when the vehicle is stationary, has been implemented in some V8-powered off-road vehicles to reduce unnecessary idling and emissions.

Despite these advancements, meeting future emissions regulations remains a significant challenge for V8 engines in off-road vehicles. As standards continue to tighten, manufacturers may need to explore more radical solutions, such as downsizing engines or transitioning to alternative fuel sources like hydrogen or fully electric powertrains. The balance between maintaining the power and performance that V8 engines are known for and meeting increasingly stringent emissions regulations will likely drive further innovation in the off-road vehicle industry.

In recent years, many countries have implemented stricter emissions regulations for off-road vehicles, including those equipped with V8 engines. These regulations typically focus on reducing greenhouse gas emissions, particulate matter, and nitrogen oxides. The United States Environmental Protection Agency (EPA) and the European Union's Euro emissions standards are at the forefront of these regulatory efforts, setting increasingly stringent limits on pollutants emitted by off-road vehicles.

To comply with these regulations, manufacturers have been forced to innovate and implement new technologies in their V8 engines. One common approach is the use of advanced exhaust after-treatment systems, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF). These systems help reduce harmful emissions by treating exhaust gases before they are released into the atmosphere.

Another strategy employed by manufacturers is the development of more efficient fuel injection systems and combustion processes. Direct injection technology, for example, allows for more precise control over fuel delivery, resulting in improved fuel efficiency and reduced emissions. Additionally, variable valve timing and lift systems help optimize engine performance across different operating conditions, further enhancing efficiency and reducing emissions.

Some manufacturers have also turned to hybrid powertrains, combining V8 engines with electric motors to improve fuel economy and reduce emissions. This approach allows off-road vehicles to maintain their high-performance capabilities while meeting stricter regulatory requirements. Furthermore, start-stop technology, which automatically shuts off the engine when the vehicle is stationary, has been implemented in some V8-powered off-road vehicles to reduce unnecessary idling and emissions.

Despite these advancements, meeting future emissions regulations remains a significant challenge for V8 engines in off-road vehicles. As standards continue to tighten, manufacturers may need to explore more radical solutions, such as downsizing engines or transitioning to alternative fuel sources like hydrogen or fully electric powertrains. The balance between maintaining the power and performance that V8 engines are known for and meeting increasingly stringent emissions regulations will likely drive further innovation in the off-road vehicle industry.

Fuel Efficiency Adv.

The integration of V8 engines in off-road vehicles has led to significant advancements in fuel efficiency, challenging the traditional notion that powerful engines are inherently fuel-hungry. Modern V8 engines designed for off-road applications have undergone extensive engineering improvements to optimize fuel consumption without compromising performance.

One of the key factors contributing to enhanced fuel efficiency is the implementation of advanced fuel injection systems. Direct fuel injection technology, coupled with precise electronic control units, allows for more accurate fuel metering and improved combustion efficiency. This results in a more complete burn of the fuel-air mixture, reducing waste and improving overall fuel economy.

Variable valve timing (VVT) and cylinder deactivation systems have also played crucial roles in boosting fuel efficiency. VVT allows the engine to adjust valve timing based on driving conditions, optimizing performance and fuel consumption across a wide range of operating scenarios. Cylinder deactivation, on the other hand, enables the engine to shut down a portion of its cylinders during low-load conditions, effectively reducing fuel consumption without sacrificing the ability to deliver full power when needed.

Lightweight materials and advanced manufacturing techniques have contributed to reducing the overall weight of V8 engines, further enhancing fuel efficiency. The use of aluminum alloys, composite materials, and innovative design approaches has resulted in engines that are lighter yet maintain their structural integrity and performance capabilities.

Turbocharging and supercharging technologies have been refined to work in harmony with V8 engines, allowing for downsizing without compromising power output. These forced induction systems enable smaller displacement V8 engines to produce power comparable to larger naturally aspirated engines while consuming less fuel under normal driving conditions.

The integration of start-stop technology in V8-powered off-road vehicles has also contributed to improved fuel efficiency, particularly in urban environments or during frequent stops in challenging terrain. This system automatically shuts off the engine when the vehicle is stationary and restarts it when the driver is ready to move, reducing unnecessary fuel consumption during idle periods.

Advanced thermal management systems have been developed to optimize engine operating temperatures, reducing friction and improving overall efficiency. These systems include variable-speed water pumps, active grille shutters, and intelligent cooling strategies that work together to maintain ideal operating conditions while minimizing parasitic losses.

In conclusion, the fuel efficiency advancements in V8 engines for off-road vehicles demonstrate a significant leap forward in engineering and design. These improvements have successfully addressed the historical fuel consumption concerns associated with powerful engines, making V8-powered off-road vehicles more economical and environmentally friendly without sacrificing the performance and capability that enthusiasts demand.

One of the key factors contributing to enhanced fuel efficiency is the implementation of advanced fuel injection systems. Direct fuel injection technology, coupled with precise electronic control units, allows for more accurate fuel metering and improved combustion efficiency. This results in a more complete burn of the fuel-air mixture, reducing waste and improving overall fuel economy.

Variable valve timing (VVT) and cylinder deactivation systems have also played crucial roles in boosting fuel efficiency. VVT allows the engine to adjust valve timing based on driving conditions, optimizing performance and fuel consumption across a wide range of operating scenarios. Cylinder deactivation, on the other hand, enables the engine to shut down a portion of its cylinders during low-load conditions, effectively reducing fuel consumption without sacrificing the ability to deliver full power when needed.

Lightweight materials and advanced manufacturing techniques have contributed to reducing the overall weight of V8 engines, further enhancing fuel efficiency. The use of aluminum alloys, composite materials, and innovative design approaches has resulted in engines that are lighter yet maintain their structural integrity and performance capabilities.

Turbocharging and supercharging technologies have been refined to work in harmony with V8 engines, allowing for downsizing without compromising power output. These forced induction systems enable smaller displacement V8 engines to produce power comparable to larger naturally aspirated engines while consuming less fuel under normal driving conditions.

The integration of start-stop technology in V8-powered off-road vehicles has also contributed to improved fuel efficiency, particularly in urban environments or during frequent stops in challenging terrain. This system automatically shuts off the engine when the vehicle is stationary and restarts it when the driver is ready to move, reducing unnecessary fuel consumption during idle periods.

Advanced thermal management systems have been developed to optimize engine operating temperatures, reducing friction and improving overall efficiency. These systems include variable-speed water pumps, active grille shutters, and intelligent cooling strategies that work together to maintain ideal operating conditions while minimizing parasitic losses.

In conclusion, the fuel efficiency advancements in V8 engines for off-road vehicles demonstrate a significant leap forward in engineering and design. These improvements have successfully addressed the historical fuel consumption concerns associated with powerful engines, making V8-powered off-road vehicles more economical and environmentally friendly without sacrificing the performance and capability that enthusiasts demand.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!