V8 Engine Maintenance: Best Practices for Durability

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Maintenance Goals

The V8 engine, a powerful and efficient internal combustion engine design, has undergone significant evolution since its inception in the early 20th century. Initially developed for high-performance automobiles, V8 engines have become a staple in various applications, from luxury vehicles to heavy-duty trucks and marine vessels. The primary goal of V8 engine maintenance has consistently been to ensure optimal performance, longevity, and reliability.

Throughout its history, V8 engine technology has seen numerous advancements aimed at improving fuel efficiency, reducing emissions, and enhancing overall durability. These developments have included the introduction of fuel injection systems, variable valve timing, and advanced materials for engine components. As environmental concerns have grown, manufacturers have focused on creating more eco-friendly V8 engines without compromising their characteristic power and performance.

The evolution of V8 engine maintenance practices has paralleled these technological advancements. Early maintenance routines primarily focused on regular oil changes and basic tune-ups. However, as engines became more complex, maintenance goals expanded to include sophisticated diagnostic procedures, preventive care, and the use of high-quality lubricants and parts designed specifically for V8 engines.

In recent years, the maintenance goals for V8 engines have shifted towards maximizing durability while minimizing environmental impact. This has led to the development of advanced maintenance techniques and the use of cutting-edge diagnostic tools. Modern V8 engine maintenance aims to extend engine life, reduce wear and tear, and maintain peak performance over extended periods.

Key maintenance goals now include optimizing combustion efficiency, reducing friction between moving parts, and preventing the buildup of harmful deposits. Additionally, there is a growing emphasis on predictive maintenance, utilizing data analytics and real-time monitoring to anticipate potential issues before they lead to significant damage or failure.

As V8 engines continue to evolve, maintenance practices are adapting to address new challenges. The integration of hybrid technologies and the potential for alternative fuels are reshaping maintenance strategies. Future maintenance goals are likely to focus on balancing traditional mechanical care with the management of advanced electronic systems and alternative power sources.

The durability of V8 engines remains a critical focus, with maintenance practices aimed at preserving engine integrity under various operating conditions. This includes addressing issues such as thermal management, oil degradation, and component fatigue. By implementing best practices in V8 engine maintenance, owners and operators can ensure their engines deliver consistent performance, improved fuel economy, and extended service life, ultimately contributing to both economic and environmental sustainability.

Throughout its history, V8 engine technology has seen numerous advancements aimed at improving fuel efficiency, reducing emissions, and enhancing overall durability. These developments have included the introduction of fuel injection systems, variable valve timing, and advanced materials for engine components. As environmental concerns have grown, manufacturers have focused on creating more eco-friendly V8 engines without compromising their characteristic power and performance.

The evolution of V8 engine maintenance practices has paralleled these technological advancements. Early maintenance routines primarily focused on regular oil changes and basic tune-ups. However, as engines became more complex, maintenance goals expanded to include sophisticated diagnostic procedures, preventive care, and the use of high-quality lubricants and parts designed specifically for V8 engines.

In recent years, the maintenance goals for V8 engines have shifted towards maximizing durability while minimizing environmental impact. This has led to the development of advanced maintenance techniques and the use of cutting-edge diagnostic tools. Modern V8 engine maintenance aims to extend engine life, reduce wear and tear, and maintain peak performance over extended periods.

Key maintenance goals now include optimizing combustion efficiency, reducing friction between moving parts, and preventing the buildup of harmful deposits. Additionally, there is a growing emphasis on predictive maintenance, utilizing data analytics and real-time monitoring to anticipate potential issues before they lead to significant damage or failure.

As V8 engines continue to evolve, maintenance practices are adapting to address new challenges. The integration of hybrid technologies and the potential for alternative fuels are reshaping maintenance strategies. Future maintenance goals are likely to focus on balancing traditional mechanical care with the management of advanced electronic systems and alternative power sources.

The durability of V8 engines remains a critical focus, with maintenance practices aimed at preserving engine integrity under various operating conditions. This includes addressing issues such as thermal management, oil degradation, and component fatigue. By implementing best practices in V8 engine maintenance, owners and operators can ensure their engines deliver consistent performance, improved fuel economy, and extended service life, ultimately contributing to both economic and environmental sustainability.

Market Demand for V8 Engine Longevity

The market demand for V8 engine longevity has been steadily increasing in recent years, driven by several key factors. Vehicle owners are increasingly seeking to maximize their investments by extending the lifespan of their engines, particularly in high-performance and luxury segments where V8 engines are prevalent. This trend is further amplified by the growing emphasis on sustainability and resource conservation, encouraging consumers to maintain and preserve their existing vehicles rather than frequently replacing them.

In the commercial sector, fleet operators and transportation companies are placing a premium on engine durability to reduce total cost of ownership and minimize downtime. The robust nature of V8 engines makes them particularly attractive for heavy-duty applications, where longevity directly translates to improved operational efficiency and profitability. As a result, there is a growing market for advanced maintenance solutions and technologies that can extend the life of V8 engines in commercial vehicles.

The automotive aftermarket has responded to this demand by developing a range of specialized products and services aimed at enhancing V8 engine durability. High-performance lubricants, advanced filtration systems, and precision-engineered replacement parts have seen increased sales, reflecting the market's willingness to invest in quality maintenance solutions. Additionally, there is a rising interest in predictive maintenance technologies and real-time monitoring systems that can help prevent engine failures and optimize maintenance schedules.

Geographically, the demand for V8 engine longevity solutions is particularly strong in regions with a high concentration of luxury and performance vehicles, such as North America, Europe, and the Middle East. In emerging markets, the focus on engine durability is driven by the need to maximize the lifespan of imported vehicles and to cope with challenging operating conditions.

The market size for V8 engine maintenance and longevity solutions is substantial, with industry analysts projecting continued growth. This expansion is supported by the increasing average age of vehicles on the road and the desire to retain high-performance characteristics over extended periods. As environmental regulations tighten and the transition to electric vehicles progresses, there is also a growing niche market for solutions that can keep existing V8 engines running efficiently and cleanly for longer periods.

In response to these market dynamics, engine manufacturers and aftermarket suppliers are investing heavily in research and development to create innovative maintenance technologies and practices. This includes the development of advanced diagnostic tools, the use of nanotechnology in lubricants, and the integration of IoT and AI for predictive maintenance. The convergence of these technologies is expected to further drive the market for V8 engine longevity solutions in the coming years.

In the commercial sector, fleet operators and transportation companies are placing a premium on engine durability to reduce total cost of ownership and minimize downtime. The robust nature of V8 engines makes them particularly attractive for heavy-duty applications, where longevity directly translates to improved operational efficiency and profitability. As a result, there is a growing market for advanced maintenance solutions and technologies that can extend the life of V8 engines in commercial vehicles.

The automotive aftermarket has responded to this demand by developing a range of specialized products and services aimed at enhancing V8 engine durability. High-performance lubricants, advanced filtration systems, and precision-engineered replacement parts have seen increased sales, reflecting the market's willingness to invest in quality maintenance solutions. Additionally, there is a rising interest in predictive maintenance technologies and real-time monitoring systems that can help prevent engine failures and optimize maintenance schedules.

Geographically, the demand for V8 engine longevity solutions is particularly strong in regions with a high concentration of luxury and performance vehicles, such as North America, Europe, and the Middle East. In emerging markets, the focus on engine durability is driven by the need to maximize the lifespan of imported vehicles and to cope with challenging operating conditions.

The market size for V8 engine maintenance and longevity solutions is substantial, with industry analysts projecting continued growth. This expansion is supported by the increasing average age of vehicles on the road and the desire to retain high-performance characteristics over extended periods. As environmental regulations tighten and the transition to electric vehicles progresses, there is also a growing niche market for solutions that can keep existing V8 engines running efficiently and cleanly for longer periods.

In response to these market dynamics, engine manufacturers and aftermarket suppliers are investing heavily in research and development to create innovative maintenance technologies and practices. This includes the development of advanced diagnostic tools, the use of nanotechnology in lubricants, and the integration of IoT and AI for predictive maintenance. The convergence of these technologies is expected to further drive the market for V8 engine longevity solutions in the coming years.

Current V8 Maintenance Challenges

V8 engine maintenance presents several challenges that require careful attention and strategic solutions. One of the primary issues is the complexity of modern V8 engines, which incorporate advanced technologies such as direct fuel injection, variable valve timing, and turbocharging. These sophisticated systems demand specialized knowledge and tools for proper maintenance, often exceeding the capabilities of traditional mechanics.

The high-performance nature of V8 engines also contributes to accelerated wear and tear on components. This is particularly evident in high-stress areas such as valve trains, piston rings, and bearings. The increased thermal and mechanical loads placed on these parts necessitate more frequent inspections and replacements, adding to the overall maintenance burden and costs.

Carbon buildup is another significant challenge, especially in direct-injection V8 engines. The absence of fuel washing over intake valves can lead to carbon deposits, potentially causing reduced performance, increased fuel consumption, and even engine misfires. Addressing this issue often requires specialized cleaning procedures or the installation of additional systems to mitigate carbon accumulation.

Oil consumption is a persistent concern in many V8 engines, particularly in high-performance or older models. Excessive oil consumption can lead to reduced engine efficiency, increased emissions, and potential engine damage if left unchecked. Identifying the root cause of oil consumption, whether it's due to worn piston rings, valve seals, or other factors, can be a complex diagnostic challenge.

The integration of electronic control systems in modern V8 engines introduces another layer of maintenance complexity. Diagnosing and resolving issues related to sensors, actuators, and control modules requires advanced diagnostic equipment and expertise in automotive electronics. This technological sophistication can make troubleshooting more time-consuming and expensive.

Cooling system maintenance is critical for V8 engines due to their higher heat generation. Ensuring proper coolant levels, addressing leaks, and maintaining optimal cooling efficiency are essential tasks that require regular attention. Failure to maintain the cooling system can lead to overheating, which can cause severe engine damage.

Fuel system maintenance presents its own set of challenges, particularly in high-performance V8 engines. Fuel injectors, high-pressure pumps, and associated components are susceptible to wear and contamination, potentially leading to reduced performance and efficiency. Regular cleaning and occasional replacement of these components are necessary to maintain optimal engine operation.

Lastly, the environmental impact of V8 engines poses a growing challenge in terms of maintenance and compliance. Stricter emissions regulations require more sophisticated emission control systems, which in turn demand more frequent maintenance and monitoring to ensure compliance and optimal performance.

The high-performance nature of V8 engines also contributes to accelerated wear and tear on components. This is particularly evident in high-stress areas such as valve trains, piston rings, and bearings. The increased thermal and mechanical loads placed on these parts necessitate more frequent inspections and replacements, adding to the overall maintenance burden and costs.

Carbon buildup is another significant challenge, especially in direct-injection V8 engines. The absence of fuel washing over intake valves can lead to carbon deposits, potentially causing reduced performance, increased fuel consumption, and even engine misfires. Addressing this issue often requires specialized cleaning procedures or the installation of additional systems to mitigate carbon accumulation.

Oil consumption is a persistent concern in many V8 engines, particularly in high-performance or older models. Excessive oil consumption can lead to reduced engine efficiency, increased emissions, and potential engine damage if left unchecked. Identifying the root cause of oil consumption, whether it's due to worn piston rings, valve seals, or other factors, can be a complex diagnostic challenge.

The integration of electronic control systems in modern V8 engines introduces another layer of maintenance complexity. Diagnosing and resolving issues related to sensors, actuators, and control modules requires advanced diagnostic equipment and expertise in automotive electronics. This technological sophistication can make troubleshooting more time-consuming and expensive.

Cooling system maintenance is critical for V8 engines due to their higher heat generation. Ensuring proper coolant levels, addressing leaks, and maintaining optimal cooling efficiency are essential tasks that require regular attention. Failure to maintain the cooling system can lead to overheating, which can cause severe engine damage.

Fuel system maintenance presents its own set of challenges, particularly in high-performance V8 engines. Fuel injectors, high-pressure pumps, and associated components are susceptible to wear and contamination, potentially leading to reduced performance and efficiency. Regular cleaning and occasional replacement of these components are necessary to maintain optimal engine operation.

Lastly, the environmental impact of V8 engines poses a growing challenge in terms of maintenance and compliance. Stricter emissions regulations require more sophisticated emission control systems, which in turn demand more frequent maintenance and monitoring to ensure compliance and optimal performance.

Existing V8 Maintenance Protocols

01 Improved cylinder block design

Enhancing the durability of V8 engines through advanced cylinder block designs. This includes optimizing the structure, material selection, and manufacturing processes to increase strength and reduce wear. Improved designs can better withstand high temperatures and pressures, extending engine life and performance.- Improved cylinder and piston design: Enhancing the durability of V8 engines through advanced cylinder and piston designs. This includes optimizing the shape, material, and coating of these components to reduce wear and increase longevity. Improved designs can help distribute forces more evenly, reduce friction, and enhance overall engine performance and lifespan.

- Advanced lubrication systems: Implementing sophisticated lubrication systems to enhance V8 engine durability. These systems ensure proper oil distribution throughout the engine, reducing friction and wear on critical components. Advanced filtration and cooling mechanisms within the lubrication system can further extend engine life by maintaining oil quality and temperature.

- Thermal management innovations: Developing innovative thermal management solutions to improve V8 engine durability. This includes advanced cooling systems, heat-resistant materials, and optimized heat dissipation designs. Effective thermal management helps prevent overheating, reduces thermal stress on engine components, and maintains optimal operating temperatures for increased longevity.

- Reinforced engine block and components: Strengthening the engine block and critical components to enhance V8 engine durability. This involves using high-strength materials, improved casting techniques, and reinforced designs for components such as crankshafts, connecting rods, and bearings. These enhancements help the engine withstand higher loads and pressures, increasing overall durability.

- Advanced electronic control systems: Implementing sophisticated electronic control systems to optimize V8 engine performance and durability. These systems monitor and adjust various engine parameters in real-time, such as fuel injection, ignition timing, and valve timing. By ensuring optimal operating conditions, these control systems can significantly extend engine life and maintain performance over time.

02 Advanced lubrication systems

Implementing sophisticated lubrication systems to reduce friction and wear in V8 engines. This involves developing more efficient oil circulation methods, using high-performance lubricants, and incorporating advanced filtration techniques. These improvements help maintain engine components and extend overall engine lifespan.Expand Specific Solutions03 Thermal management solutions

Developing effective thermal management solutions to control engine temperature and prevent overheating. This includes advanced cooling systems, heat-resistant materials, and improved heat dissipation techniques. Better thermal management contributes to increased engine durability by reducing thermal stress on components.Expand Specific Solutions04 Enhanced piston and connecting rod design

Improving the design of pistons and connecting rods to increase their durability and performance. This involves using advanced materials, optimizing geometries, and implementing new manufacturing techniques. These enhancements help withstand higher combustion pressures and reduce wear, contributing to overall engine longevity.Expand Specific Solutions05 Advanced engine control systems

Implementing sophisticated engine control systems to optimize performance and reduce stress on engine components. This includes advanced sensors, real-time monitoring, and adaptive control algorithms. These systems help maintain optimal operating conditions, prevent excessive wear, and extend engine life.Expand Specific Solutions

Key V8 Engine Manufacturers

The V8 engine maintenance market is in a mature stage, with established players and well-defined best practices. The global market size for V8 engine maintenance is substantial, driven by the widespread use of these engines in high-performance vehicles, trucks, and industrial applications. Technologically, V8 engine maintenance has evolved significantly, with companies like Toyota, Ford, and General Motors leading innovations in durability and efficiency. These industry giants, along with specialized engine manufacturers such as Cummins and Caterpillar, have developed advanced diagnostic tools and preventive maintenance techniques. The competitive landscape is characterized by a mix of OEMs and aftermarket service providers, with increasing focus on integrating digital technologies for predictive maintenance and enhanced engine longevity.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced V8 engine maintenance practices focusing on durability and longevity. Their approach includes the use of high-quality synthetic oils specifically formulated for V8 engines, which provide better protection against wear and heat degradation[1]. Toyota also implements a rigorous inspection schedule, emphasizing early detection of potential issues. They utilize advanced diagnostic tools to monitor engine performance in real-time, allowing for predictive maintenance[3]. Additionally, Toyota has introduced a thermal management system that optimizes engine temperature, reducing stress on components and extending engine life[5]. Their maintenance protocol also includes regular valve adjustments and timing chain inspections to ensure optimal performance and prevent premature wear[7].

Strengths: Comprehensive approach combining advanced materials, diagnostics, and preventive measures. Weaknesses: Potentially higher maintenance costs due to specialized procedures and materials.

Ford Global Technologies LLC

Technical Solution: Ford's V8 engine maintenance strategy focuses on durability through innovative technologies and materials. They have developed a proprietary oil formulation that enhances protection against high-temperature oxidation and viscosity breakdown, crucial for V8 engines' longevity[2]. Ford also employs advanced cylinder deactivation technology in their V8 engines, which reduces wear on inactive cylinders during light-load conditions[4]. Their maintenance protocol includes the use of high-precision electronic monitoring systems that track engine performance metrics and alert drivers to potential issues before they become critical[6]. Ford has also implemented a "smart" cooling system that precisely controls engine temperature, reducing thermal stress and extending component life[8].

Strengths: Integration of advanced technologies for proactive maintenance and wear reduction. Weaknesses: Complexity of systems may require specialized knowledge for maintenance.

Innovative V8 Durability Solutions

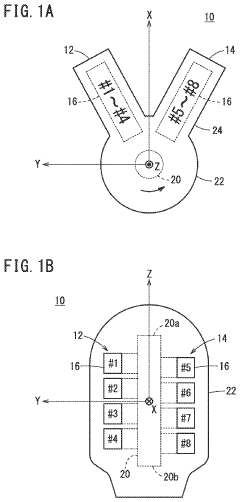

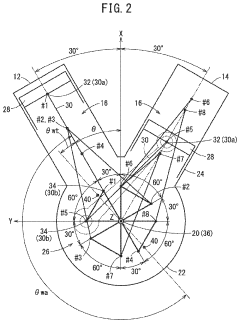

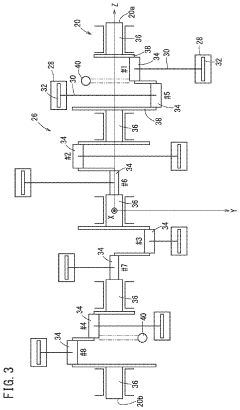

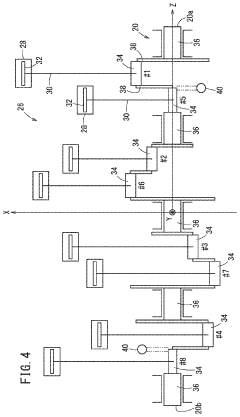

V8 engine

PatentActiveUS11821359B2

Innovation

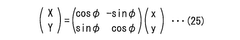

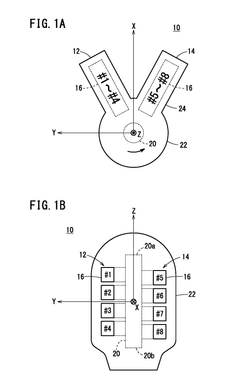

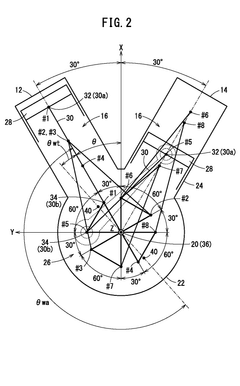

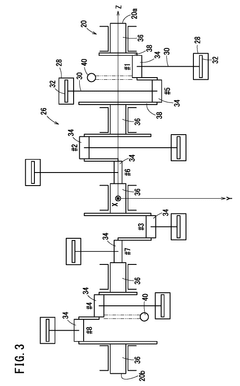

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentWO2021171405A1

Innovation

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

Environmental Impact of V8 Engines

V8 engines, known for their power and performance, have significant environmental implications that warrant careful consideration. These engines, typically found in high-performance vehicles and some heavy-duty applications, consume substantial amounts of fuel and produce considerable emissions. The environmental impact of V8 engines primarily stems from their high fuel consumption and the resulting greenhouse gas emissions, particularly carbon dioxide (CO2).

The fuel efficiency of V8 engines has improved over the years through technological advancements such as direct injection, variable valve timing, and cylinder deactivation. However, they still generally consume more fuel than smaller engines, leading to increased CO2 emissions. This contributes to global warming and climate change, which are major environmental concerns.

In addition to CO2, V8 engines also produce other pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These emissions contribute to air pollution, which can have detrimental effects on human health and ecosystems. Urban areas with high concentrations of V8-powered vehicles may experience elevated levels of smog and reduced air quality.

The manufacturing process of V8 engines also has environmental implications. The production of larger, more complex engines requires more raw materials and energy, resulting in a larger carbon footprint compared to smaller engines. Additionally, the disposal and recycling of V8 engines at the end of their lifecycle present challenges due to their size and complexity.

Regulatory pressures and environmental concerns have led to increased focus on reducing the environmental impact of V8 engines. Manufacturers are investing in technologies to improve fuel efficiency and reduce emissions, such as start-stop systems, advanced catalytic converters, and hybrid powertrains. Some are even exploring the possibility of electrifying V8 engines to create high-performance hybrid systems that offer the power of a V8 with reduced environmental impact.

Despite these efforts, the long-term sustainability of V8 engines in a world increasingly focused on reducing carbon emissions remains uncertain. As governments worldwide implement stricter emissions standards and push for the adoption of electric vehicles, the future of V8 engines may be limited to niche applications or collector vehicles. This shift could have significant implications for the automotive industry and related sectors.

In conclusion, while V8 engines continue to offer impressive performance, their environmental impact is a growing concern. Balancing the desire for high-performance vehicles with the need for environmental sustainability remains a significant challenge for the automotive industry. The future of V8 engines will likely depend on continued technological innovations to mitigate their environmental impact and adapt to a changing regulatory landscape.

The fuel efficiency of V8 engines has improved over the years through technological advancements such as direct injection, variable valve timing, and cylinder deactivation. However, they still generally consume more fuel than smaller engines, leading to increased CO2 emissions. This contributes to global warming and climate change, which are major environmental concerns.

In addition to CO2, V8 engines also produce other pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These emissions contribute to air pollution, which can have detrimental effects on human health and ecosystems. Urban areas with high concentrations of V8-powered vehicles may experience elevated levels of smog and reduced air quality.

The manufacturing process of V8 engines also has environmental implications. The production of larger, more complex engines requires more raw materials and energy, resulting in a larger carbon footprint compared to smaller engines. Additionally, the disposal and recycling of V8 engines at the end of their lifecycle present challenges due to their size and complexity.

Regulatory pressures and environmental concerns have led to increased focus on reducing the environmental impact of V8 engines. Manufacturers are investing in technologies to improve fuel efficiency and reduce emissions, such as start-stop systems, advanced catalytic converters, and hybrid powertrains. Some are even exploring the possibility of electrifying V8 engines to create high-performance hybrid systems that offer the power of a V8 with reduced environmental impact.

Despite these efforts, the long-term sustainability of V8 engines in a world increasingly focused on reducing carbon emissions remains uncertain. As governments worldwide implement stricter emissions standards and push for the adoption of electric vehicles, the future of V8 engines may be limited to niche applications or collector vehicles. This shift could have significant implications for the automotive industry and related sectors.

In conclusion, while V8 engines continue to offer impressive performance, their environmental impact is a growing concern. Balancing the desire for high-performance vehicles with the need for environmental sustainability remains a significant challenge for the automotive industry. The future of V8 engines will likely depend on continued technological innovations to mitigate their environmental impact and adapt to a changing regulatory landscape.

V8 Performance vs. Durability

The relationship between V8 engine performance and durability is a complex one, often requiring careful balancing to achieve optimal results. High-performance V8 engines are designed to deliver maximum power and torque, but this can come at the cost of reduced longevity if not properly managed.

One of the primary factors affecting this balance is the engine's compression ratio. Higher compression ratios generally lead to increased power output but also place greater stress on engine components. This increased stress can accelerate wear and potentially reduce the engine's lifespan if not adequately addressed through robust engineering and materials selection.

Another critical aspect is the engine's redline and operating temperature. Performance-oriented V8 engines often have higher redlines, allowing for greater power output at high RPMs. However, this can lead to increased heat generation and potential thermal stress on engine components. Proper cooling system design and heat management strategies are essential to maintain durability without sacrificing performance.

Fuel and air mixture also play a significant role in the performance-durability equation. Rich fuel mixtures can provide more power but may lead to increased carbon deposits and potential damage to engine components over time. Lean mixtures, while potentially more efficient, can cause higher operating temperatures and increased wear if not carefully controlled.

The choice of materials used in engine construction greatly influences both performance and durability. Lightweight materials like aluminum alloys can improve power-to-weight ratios but may be more prone to wear compared to traditional cast iron components. Advanced coatings and surface treatments can help mitigate these issues, enhancing durability without compromising performance.

Maintenance practices significantly impact the long-term durability of high-performance V8 engines. Regular oil changes with high-quality synthetic oils, proper cooling system maintenance, and adherence to manufacturer-recommended service intervals are crucial for preserving engine life while maintaining peak performance.

Ultimately, achieving the ideal balance between V8 performance and durability requires a holistic approach. This includes careful engine design, material selection, advanced manufacturing techniques, and rigorous testing programs. By addressing these factors comprehensively, it is possible to create V8 engines that deliver impressive performance while still offering the durability expected in modern automotive applications.

One of the primary factors affecting this balance is the engine's compression ratio. Higher compression ratios generally lead to increased power output but also place greater stress on engine components. This increased stress can accelerate wear and potentially reduce the engine's lifespan if not adequately addressed through robust engineering and materials selection.

Another critical aspect is the engine's redline and operating temperature. Performance-oriented V8 engines often have higher redlines, allowing for greater power output at high RPMs. However, this can lead to increased heat generation and potential thermal stress on engine components. Proper cooling system design and heat management strategies are essential to maintain durability without sacrificing performance.

Fuel and air mixture also play a significant role in the performance-durability equation. Rich fuel mixtures can provide more power but may lead to increased carbon deposits and potential damage to engine components over time. Lean mixtures, while potentially more efficient, can cause higher operating temperatures and increased wear if not carefully controlled.

The choice of materials used in engine construction greatly influences both performance and durability. Lightweight materials like aluminum alloys can improve power-to-weight ratios but may be more prone to wear compared to traditional cast iron components. Advanced coatings and surface treatments can help mitigate these issues, enhancing durability without compromising performance.

Maintenance practices significantly impact the long-term durability of high-performance V8 engines. Regular oil changes with high-quality synthetic oils, proper cooling system maintenance, and adherence to manufacturer-recommended service intervals are crucial for preserving engine life while maintaining peak performance.

Ultimately, achieving the ideal balance between V8 performance and durability requires a holistic approach. This includes careful engine design, material selection, advanced manufacturing techniques, and rigorous testing programs. By addressing these factors comprehensively, it is possible to create V8 engines that deliver impressive performance while still offering the durability expected in modern automotive applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!