How V8 Engines Facilitate New Business Models in R&D?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The evolution of V8 engines has been a remarkable journey in automotive engineering, significantly impacting research and development (R&D) practices and business models. This evolution can be traced through several key phases, each marked by technological advancements and shifting market demands.

In the early stages, V8 engines were primarily focused on raw power and performance. The 1950s and 1960s saw the rise of muscle cars, where V8 engines became synonymous with high-performance vehicles. This era drove R&D efforts towards maximizing horsepower and torque, often at the expense of fuel efficiency and emissions control.

The 1970s brought a paradigm shift with the oil crisis and increasing environmental concerns. This period marked a critical turning point in V8 engine development, pushing manufacturers to explore ways to maintain performance while improving fuel economy. This challenge led to innovations in engine management systems, fuel injection technologies, and the introduction of computer-controlled engine operations.

The 1980s and 1990s witnessed the integration of electronic fuel injection systems and more sophisticated engine control units (ECUs). These advancements allowed for more precise control over fuel delivery and ignition timing, resulting in improved efficiency and reduced emissions. This phase also saw the introduction of variable valve timing and multi-valve cylinder heads, further enhancing engine performance and efficiency.

The turn of the millennium brought about a new era of V8 engine development, characterized by the pursuit of sustainable performance. Manufacturers began exploring hybrid technologies, combining V8 engines with electric motors to create high-performance vehicles with improved fuel economy. This trend has continued into the present day, with the development of plug-in hybrid systems and the integration of V8 engines into more diverse vehicle types, including SUVs and luxury sedans.

Recent years have seen a focus on downsizing and turbocharging V8 engines. This approach aims to maintain or even increase power output while reducing engine displacement and improving fuel efficiency. Advanced materials and manufacturing techniques have also played a crucial role in this evolution, allowing for lighter, more compact V8 engines that can meet stringent emissions regulations without sacrificing performance.

The evolution of V8 engines has not only driven technological advancements but has also facilitated new business models in R&D. It has encouraged collaborations between automotive manufacturers and technology companies, leading to the development of innovative powertrain solutions. This evolution has also spurred investment in specialized R&D facilities and testing equipment, creating new opportunities for engineering firms and technology providers.

In the early stages, V8 engines were primarily focused on raw power and performance. The 1950s and 1960s saw the rise of muscle cars, where V8 engines became synonymous with high-performance vehicles. This era drove R&D efforts towards maximizing horsepower and torque, often at the expense of fuel efficiency and emissions control.

The 1970s brought a paradigm shift with the oil crisis and increasing environmental concerns. This period marked a critical turning point in V8 engine development, pushing manufacturers to explore ways to maintain performance while improving fuel economy. This challenge led to innovations in engine management systems, fuel injection technologies, and the introduction of computer-controlled engine operations.

The 1980s and 1990s witnessed the integration of electronic fuel injection systems and more sophisticated engine control units (ECUs). These advancements allowed for more precise control over fuel delivery and ignition timing, resulting in improved efficiency and reduced emissions. This phase also saw the introduction of variable valve timing and multi-valve cylinder heads, further enhancing engine performance and efficiency.

The turn of the millennium brought about a new era of V8 engine development, characterized by the pursuit of sustainable performance. Manufacturers began exploring hybrid technologies, combining V8 engines with electric motors to create high-performance vehicles with improved fuel economy. This trend has continued into the present day, with the development of plug-in hybrid systems and the integration of V8 engines into more diverse vehicle types, including SUVs and luxury sedans.

Recent years have seen a focus on downsizing and turbocharging V8 engines. This approach aims to maintain or even increase power output while reducing engine displacement and improving fuel efficiency. Advanced materials and manufacturing techniques have also played a crucial role in this evolution, allowing for lighter, more compact V8 engines that can meet stringent emissions regulations without sacrificing performance.

The evolution of V8 engines has not only driven technological advancements but has also facilitated new business models in R&D. It has encouraged collaborations between automotive manufacturers and technology companies, leading to the development of innovative powertrain solutions. This evolution has also spurred investment in specialized R&D facilities and testing equipment, creating new opportunities for engineering firms and technology providers.

Market Demand Analysis

The market demand for V8 engines in research and development (R&D) has been evolving rapidly, driven by the need for more efficient and powerful engines in various industries. V8 engines, known for their high performance and reliability, have traditionally been associated with automotive applications. However, their potential in facilitating new business models in R&D extends far beyond the automotive sector.

In the automotive industry, there is a growing demand for V8 engines in high-performance vehicles and luxury cars. Despite the trend towards electrification, many consumers still prefer the distinctive sound and power delivery of V8 engines. This has led to increased R&D efforts to develop more fuel-efficient and environmentally friendly V8 engines, creating new business opportunities for engine manufacturers and automotive companies.

The aerospace industry has also shown significant interest in V8 engine technology for small aircraft and unmanned aerial vehicles (UAVs). The compact size and high power-to-weight ratio of V8 engines make them attractive for these applications. This has opened up new avenues for R&D collaborations between automotive engine manufacturers and aerospace companies, fostering innovation and cross-industry partnerships.

In the marine sector, there is a rising demand for V8 engines in high-performance boats and yachts. The durability and power output of V8 engines make them ideal for marine applications, leading to increased R&D investments in adapting automotive V8 technology for marine use. This has created new business opportunities for engine manufacturers to diversify their product offerings and enter new markets.

The industrial sector has also recognized the potential of V8 engines in power generation and heavy machinery. The reliability and power density of V8 engines make them suitable for use in generators, construction equipment, and agricultural machinery. This has led to increased R&D efforts to adapt V8 engines for these applications, creating new business models for engine manufacturers and industrial equipment producers.

The growing focus on sustainability and environmental regulations has driven demand for research into alternative fuels and hybrid technologies for V8 engines. This has created new business opportunities for companies specializing in fuel technology, emissions control, and powertrain electrification. The development of bio-fuel compatible V8 engines and hybrid V8 powertrains has opened up new markets and research collaborations.

As a result of these market demands, there has been a surge in R&D investments related to V8 engine technology. This has led to the emergence of new business models, including joint ventures between automotive and non-automotive companies, licensing agreements for V8 engine technology, and the establishment of specialized R&D centers focused on V8 engine innovation. These new business models are reshaping the landscape of engine development and creating opportunities for companies to leverage their expertise across multiple industries.

In the automotive industry, there is a growing demand for V8 engines in high-performance vehicles and luxury cars. Despite the trend towards electrification, many consumers still prefer the distinctive sound and power delivery of V8 engines. This has led to increased R&D efforts to develop more fuel-efficient and environmentally friendly V8 engines, creating new business opportunities for engine manufacturers and automotive companies.

The aerospace industry has also shown significant interest in V8 engine technology for small aircraft and unmanned aerial vehicles (UAVs). The compact size and high power-to-weight ratio of V8 engines make them attractive for these applications. This has opened up new avenues for R&D collaborations between automotive engine manufacturers and aerospace companies, fostering innovation and cross-industry partnerships.

In the marine sector, there is a rising demand for V8 engines in high-performance boats and yachts. The durability and power output of V8 engines make them ideal for marine applications, leading to increased R&D investments in adapting automotive V8 technology for marine use. This has created new business opportunities for engine manufacturers to diversify their product offerings and enter new markets.

The industrial sector has also recognized the potential of V8 engines in power generation and heavy machinery. The reliability and power density of V8 engines make them suitable for use in generators, construction equipment, and agricultural machinery. This has led to increased R&D efforts to adapt V8 engines for these applications, creating new business models for engine manufacturers and industrial equipment producers.

The growing focus on sustainability and environmental regulations has driven demand for research into alternative fuels and hybrid technologies for V8 engines. This has created new business opportunities for companies specializing in fuel technology, emissions control, and powertrain electrification. The development of bio-fuel compatible V8 engines and hybrid V8 powertrains has opened up new markets and research collaborations.

As a result of these market demands, there has been a surge in R&D investments related to V8 engine technology. This has led to the emergence of new business models, including joint ventures between automotive and non-automotive companies, licensing agreements for V8 engine technology, and the establishment of specialized R&D centers focused on V8 engine innovation. These new business models are reshaping the landscape of engine development and creating opportunities for companies to leverage their expertise across multiple industries.

V8 Technical Challenges

V8 engines, while renowned for their power and performance in automotive applications, face significant technical challenges when adapted for research and development purposes. One of the primary hurdles is the complexity of integrating V8 engines into diverse R&D environments, which often require specialized modifications and instrumentation. This integration process demands extensive engineering expertise to ensure accurate data collection and analysis without compromising the engine's core functionality.

Another critical challenge lies in the optimization of fuel efficiency and emissions control. As environmental regulations become increasingly stringent, R&D teams must develop innovative solutions to reduce the carbon footprint of V8 engines while maintaining their characteristic power output. This necessitates advanced research into alternative fuels, combustion processes, and exhaust aftertreatment systems, all of which present their own set of technical difficulties.

The thermal management of V8 engines in R&D settings poses yet another significant challenge. The high heat output of these engines requires sophisticated cooling systems and heat dissipation strategies, particularly when subjected to prolonged testing periods or extreme operating conditions. Researchers must develop novel approaches to manage thermal loads effectively, ensuring consistent performance and preventing premature component failure during extensive experimentation.

Durability and reliability testing of V8 engines in R&D contexts also presents unique challenges. The engines must undergo rigorous stress testing to simulate long-term use and extreme conditions, which can be both time-consuming and resource-intensive. Developing accelerated testing methodologies that accurately predict long-term performance while reducing development cycles is a constant area of focus for R&D teams.

Furthermore, the adaptation of V8 engines for emerging technologies, such as hybrid and electric powertrains, introduces a new set of technical hurdles. Integrating electric motors, battery systems, and advanced control algorithms with traditional V8 architecture requires innovative engineering solutions and extensive testing to ensure seamless operation and optimal performance across various driving modes.

Lastly, the challenge of data acquisition and analysis in V8 engine R&D cannot be overstated. The sheer volume of data generated during testing, coupled with the need for real-time processing and interpretation, demands sophisticated data management systems and analytics tools. Developing robust data infrastructures that can handle the complexity and scale of V8 engine testing while providing actionable insights remains a significant technical challenge for research teams.

Another critical challenge lies in the optimization of fuel efficiency and emissions control. As environmental regulations become increasingly stringent, R&D teams must develop innovative solutions to reduce the carbon footprint of V8 engines while maintaining their characteristic power output. This necessitates advanced research into alternative fuels, combustion processes, and exhaust aftertreatment systems, all of which present their own set of technical difficulties.

The thermal management of V8 engines in R&D settings poses yet another significant challenge. The high heat output of these engines requires sophisticated cooling systems and heat dissipation strategies, particularly when subjected to prolonged testing periods or extreme operating conditions. Researchers must develop novel approaches to manage thermal loads effectively, ensuring consistent performance and preventing premature component failure during extensive experimentation.

Durability and reliability testing of V8 engines in R&D contexts also presents unique challenges. The engines must undergo rigorous stress testing to simulate long-term use and extreme conditions, which can be both time-consuming and resource-intensive. Developing accelerated testing methodologies that accurately predict long-term performance while reducing development cycles is a constant area of focus for R&D teams.

Furthermore, the adaptation of V8 engines for emerging technologies, such as hybrid and electric powertrains, introduces a new set of technical hurdles. Integrating electric motors, battery systems, and advanced control algorithms with traditional V8 architecture requires innovative engineering solutions and extensive testing to ensure seamless operation and optimal performance across various driving modes.

Lastly, the challenge of data acquisition and analysis in V8 engine R&D cannot be overstated. The sheer volume of data generated during testing, coupled with the need for real-time processing and interpretation, demands sophisticated data management systems and analytics tools. Developing robust data infrastructures that can handle the complexity and scale of V8 engine testing while providing actionable insights remains a significant technical challenge for research teams.

Current V8 Solutions

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design while providing high power output. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and balanced operation. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized to enhance performance and efficiency.

- Fuel Injection Systems for V8 Engines: Advanced fuel injection systems are developed for V8 engines to improve fuel efficiency and power output. These systems may include direct injection, multi-point injection, or a combination of both. Innovations in fuel injector design, fuel pressure regulation, and electronic control units contribute to optimized fuel delivery and combustion in V8 engines.

- V8 Engine Cooling and Lubrication: Efficient cooling and lubrication systems are crucial for V8 engine performance and longevity. Innovations in coolant circulation, oil pump design, and heat exchanger technology help maintain optimal operating temperatures and reduce friction in high-performance V8 engines. Advanced materials and coatings may also be used to enhance thermal management and reduce wear.

- V8 Engine Performance Enhancement: Various technologies are employed to enhance V8 engine performance, including turbocharging, supercharging, and variable valve timing. These innovations aim to increase power output, improve torque characteristics, and optimize fuel efficiency across a wide range of operating conditions. Advanced engine management systems and electronic controls play a crucial role in maximizing V8 engine performance.

- Emissions Control in V8 Engines: To meet increasingly stringent emissions regulations, V8 engines incorporate advanced emissions control technologies. These may include exhaust gas recirculation (EGR) systems, catalytic converters, particulate filters, and advanced engine control strategies. Innovations in combustion chamber design and fuel management also contribute to reducing harmful emissions while maintaining performance.

02 Fuel Injection Systems for V8 Engines

Advanced fuel injection systems are developed for V8 engines to improve fuel efficiency and performance. These systems may include direct injection, multi-point injection, or a combination of both. Innovations in fuel injector design and control strategies help optimize fuel delivery and combustion processes in V8 engines.Expand Specific Solutions03 V8 Engine Performance Enhancement

Various technologies and methods are employed to enhance the performance of V8 engines. These may include turbocharging, supercharging, variable valve timing, and advanced engine management systems. Such enhancements aim to increase power output, improve fuel efficiency, and reduce emissions while maintaining the characteristic V8 sound and feel.Expand Specific Solutions04 V8 Engine Cooling and Lubrication Systems

Efficient cooling and lubrication systems are crucial for V8 engine performance and longevity. Innovations in these areas include advanced coolant circulation designs, oil cooling techniques, and improved lubricant formulations. These systems help manage the high heat output of V8 engines and ensure proper lubrication of critical components.Expand Specific Solutions05 V8 Engine Emissions Control

To meet increasingly stringent emissions regulations, V8 engines incorporate various emissions control technologies. These may include advanced catalytic converters, exhaust gas recirculation systems, and particulate filters. Innovations in engine design and combustion processes also contribute to reducing harmful emissions while maintaining performance.Expand Specific Solutions

Key V8 Industry Players

The V8 engine technology market is in a mature stage, with established players dominating the landscape. The global market size for V8 engines is substantial, driven by demand in high-performance vehicles and luxury segments. Technologically, V8 engines have reached a high level of sophistication, with companies like Honda, BMW, Toyota, and Ford leading innovation. These firms are focusing on improving efficiency, reducing emissions, and integrating hybrid technologies to meet evolving regulatory standards and consumer preferences. The competitive landscape is characterized by intense rivalry among major automotive manufacturers, with a growing emphasis on R&D to develop more sustainable and powerful V8 engine variants.

Honda Motor Co., Ltd.

Technical Solution: Honda has utilized V8 engine technology to drive new business models in R&D, although their focus on V8 engines has been limited compared to some competitors. The company developed a 3.5L V8 engine for their Acura brand, used in the Acura RL and MDX models. This engine featured Variable Cylinder Management (VCM) technology, allowing it to operate on three, four, or all six cylinders depending on driving conditions[11]. Honda's R&D efforts in V8 technology have primarily focused on racing applications, particularly in Formula One, where they developed high-performance V8 engines before the sport transitioned to V6 turbos[12]. The company has applied lessons learned from V8 development to their smaller engine designs, incorporating technologies such as VTEC (Variable Valve Timing and Lift Electronic Control) across their engine lineup[13].

Strengths: Racing heritage, efficient engine technologies, application of V8 learnings to smaller engines. Weaknesses: Limited consumer V8 offerings, focus shifted towards smaller engines and electrification.

Toyota Motor Corp.

Technical Solution: Toyota has leveraged V8 engine technology to foster new business models in R&D through their UR engine family. The company's 5.7L 3UR-FE V8 engine, used in vehicles like the Tundra and Land Cruiser, incorporates Dual VVT-i (Variable Valve Timing with intelligence) and an Acoustic Control Induction System (ACIS) for improved performance and efficiency[8]. Toyota's R&D efforts have also focused on integrating V8 engines with hybrid technology, as seen in the Lexus LS 500h, which combines a V6 engine with electric motors but applies lessons learned from V8 development[9]. The company has invested in advanced materials and manufacturing techniques for V8 engines, including the use of aluminum alloys and precision machining processes to reduce weight and improve thermal efficiency[10].

Strengths: Integration of advanced technologies, hybrid system expertise, focus on efficiency. Weaknesses: Limited V8 offerings compared to some competitors, potential shift towards smaller engines and electrification.

V8 Core Innovations

Code generation method, device, electronic device and computer storage medium

PatentActiveCN111857678B

Innovation

- By obtaining the intermediate code to be language converted, detect and mark the call points of safe point calls and exception handling, and generate the marked intermediate code for subsequent adaptive processing, improving the compatibility of the target code with the V8 engine.

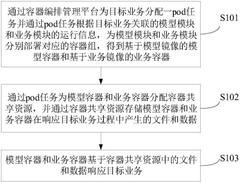

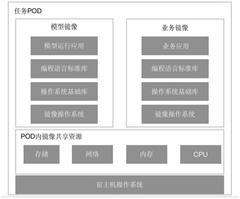

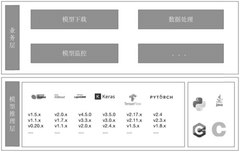

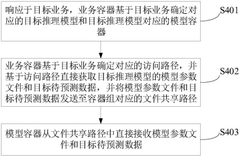

Model deployment method and device, electronic equipment and storage medium

PatentPendingCN119806809A

Innovation

- Through the sidecar model of the container orchestration management platform k8s, container groups are deployed for the model module and business module respectively, model containers and business containers are obtained, and container shared resources are allocated, so that the model container and business container respond to target services based on files and data in the shared resources.

V8 Business Models

The V8 engine, renowned for its power and efficiency, has become a catalyst for innovative business models in research and development (R&D) within the automotive industry. These new models leverage the unique characteristics of V8 engines to create value and drive technological advancements.

One prominent business model centers around performance customization. Companies specializing in aftermarket modifications for V8 engines have emerged, offering tailored solutions to enhance power output, fuel efficiency, and overall performance. This model capitalizes on the enthusiast market, providing a range of products from simple bolt-on upgrades to complete engine rebuilds.

Another innovative approach involves the development of hybrid V8 systems. R&D teams are exploring ways to combine the traditional V8 engine with electric motors, creating high-performance hybrid powertrains. This model addresses the growing demand for environmentally friendly vehicles without sacrificing the power and prestige associated with V8 engines.

The concept of engine leasing has also gained traction, particularly in motorsports. Instead of selling engines outright, some manufacturers offer leasing programs for their high-performance V8 engines. This model provides racing teams with access to cutting-edge technology while allowing manufacturers to maintain control over their intellectual property and gather valuable performance data.

In the realm of industrial applications, V8 engines are finding new uses beyond automotive. R&D efforts are focused on adapting these powerful engines for use in generators, marine propulsion systems, and even specialized agricultural equipment. This diversification model opens up new markets and revenue streams for engine manufacturers.

The rise of digital twin technology has spawned another innovative business model. Companies are creating virtual replicas of V8 engines, allowing for extensive simulation and testing without the need for physical prototypes. This approach significantly reduces development costs and time-to-market for new engine designs.

Lastly, the circular economy model is gaining prominence in V8 engine R&D. Manufacturers are exploring ways to design engines with improved recyclability and remanufacturing potential. This model not only addresses environmental concerns but also creates new business opportunities in the aftermarket and recycling sectors.

These emerging business models demonstrate how V8 engines continue to drive innovation and create value in the R&D landscape, adapting to changing market demands and technological advancements.

One prominent business model centers around performance customization. Companies specializing in aftermarket modifications for V8 engines have emerged, offering tailored solutions to enhance power output, fuel efficiency, and overall performance. This model capitalizes on the enthusiast market, providing a range of products from simple bolt-on upgrades to complete engine rebuilds.

Another innovative approach involves the development of hybrid V8 systems. R&D teams are exploring ways to combine the traditional V8 engine with electric motors, creating high-performance hybrid powertrains. This model addresses the growing demand for environmentally friendly vehicles without sacrificing the power and prestige associated with V8 engines.

The concept of engine leasing has also gained traction, particularly in motorsports. Instead of selling engines outright, some manufacturers offer leasing programs for their high-performance V8 engines. This model provides racing teams with access to cutting-edge technology while allowing manufacturers to maintain control over their intellectual property and gather valuable performance data.

In the realm of industrial applications, V8 engines are finding new uses beyond automotive. R&D efforts are focused on adapting these powerful engines for use in generators, marine propulsion systems, and even specialized agricultural equipment. This diversification model opens up new markets and revenue streams for engine manufacturers.

The rise of digital twin technology has spawned another innovative business model. Companies are creating virtual replicas of V8 engines, allowing for extensive simulation and testing without the need for physical prototypes. This approach significantly reduces development costs and time-to-market for new engine designs.

Lastly, the circular economy model is gaining prominence in V8 engine R&D. Manufacturers are exploring ways to design engines with improved recyclability and remanufacturing potential. This model not only addresses environmental concerns but also creates new business opportunities in the aftermarket and recycling sectors.

These emerging business models demonstrate how V8 engines continue to drive innovation and create value in the R&D landscape, adapting to changing market demands and technological advancements.

V8 R&D Strategies

V8 engines have become a catalyst for innovative research and development strategies in the automotive industry, driving new business models and technological advancements. These powerful engines, known for their high performance and efficiency, have opened up opportunities for companies to explore novel approaches to product development and market positioning.

One key aspect of V8 R&D strategies is the focus on performance optimization. Engineers are constantly pushing the boundaries of what these engines can achieve, exploring ways to increase horsepower and torque while maintaining or improving fuel efficiency. This pursuit of excellence has led to the development of advanced materials, precision manufacturing techniques, and cutting-edge engine management systems.

Sustainability has also become a central theme in V8 R&D strategies. With increasing environmental concerns, companies are investing heavily in technologies that can reduce emissions and improve fuel economy without compromising the power and performance that V8 engines are known for. This has resulted in the integration of hybrid systems, advanced fuel injection technologies, and innovative combustion processes.

The development of V8 engines has also spurred collaboration between automotive manufacturers and technology companies. These partnerships have led to the creation of smart engine systems that can adapt to driving conditions, optimize performance in real-time, and provide valuable data for further improvements. This convergence of automotive and digital technologies has opened up new revenue streams and business models centered around data analytics and predictive maintenance.

Furthermore, V8 R&D strategies have expanded beyond traditional automotive applications. The high-performance characteristics of these engines have found applications in marine propulsion, aviation, and even specialized industrial equipment. This diversification has allowed companies to tap into new markets and create unique value propositions.

The pursuit of V8 engine excellence has also driven advancements in manufacturing processes. Companies are investing in advanced robotics, 3D printing technologies, and AI-driven quality control systems to produce these complex engines with unprecedented precision and efficiency. These manufacturing innovations have broader implications, often trickling down to other areas of production and fostering overall industrial advancement.

Lastly, V8 R&D strategies have become a platform for talent development and knowledge transfer within organizations. The complex nature of these engines requires a multidisciplinary approach, bringing together experts in materials science, thermodynamics, fluid dynamics, and electronics. This collaborative environment fosters innovation and helps companies build a robust knowledge base that can be applied to other areas of product development.

One key aspect of V8 R&D strategies is the focus on performance optimization. Engineers are constantly pushing the boundaries of what these engines can achieve, exploring ways to increase horsepower and torque while maintaining or improving fuel efficiency. This pursuit of excellence has led to the development of advanced materials, precision manufacturing techniques, and cutting-edge engine management systems.

Sustainability has also become a central theme in V8 R&D strategies. With increasing environmental concerns, companies are investing heavily in technologies that can reduce emissions and improve fuel economy without compromising the power and performance that V8 engines are known for. This has resulted in the integration of hybrid systems, advanced fuel injection technologies, and innovative combustion processes.

The development of V8 engines has also spurred collaboration between automotive manufacturers and technology companies. These partnerships have led to the creation of smart engine systems that can adapt to driving conditions, optimize performance in real-time, and provide valuable data for further improvements. This convergence of automotive and digital technologies has opened up new revenue streams and business models centered around data analytics and predictive maintenance.

Furthermore, V8 R&D strategies have expanded beyond traditional automotive applications. The high-performance characteristics of these engines have found applications in marine propulsion, aviation, and even specialized industrial equipment. This diversification has allowed companies to tap into new markets and create unique value propositions.

The pursuit of V8 engine excellence has also driven advancements in manufacturing processes. Companies are investing in advanced robotics, 3D printing technologies, and AI-driven quality control systems to produce these complex engines with unprecedented precision and efficiency. These manufacturing innovations have broader implications, often trickling down to other areas of production and fostering overall industrial advancement.

Lastly, V8 R&D strategies have become a platform for talent development and knowledge transfer within organizations. The complex nature of these engines requires a multidisciplinary approach, bringing together experts in materials science, thermodynamics, fluid dynamics, and electronics. This collaborative environment fosters innovation and helps companies build a robust knowledge base that can be applied to other areas of product development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!