V8 Engine Advancements: A Technical Foresight Analysis

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine, a marvel of automotive engineering, has undergone significant evolution since its inception in the early 20th century. Initially developed to provide more power and smoother operation compared to inline engines, the V8 has become synonymous with performance and luxury in the automotive world. Its journey from a niche powerplant to a mainstream engine configuration has been marked by continuous technological advancements and refinements.

The primary objective of V8 engine development has been to strike a balance between power output, fuel efficiency, and environmental sustainability. Over the decades, engineers have focused on improving combustion efficiency, reducing friction losses, and optimizing the engine's overall design to meet these goals. The advent of computer-aided design and simulation tools has greatly accelerated this process, allowing for more precise engineering and faster iteration cycles.

In recent years, the automotive industry has faced increasing pressure to reduce emissions and improve fuel economy. This has led to a new era of V8 engine development, with a focus on technologies such as direct fuel injection, variable valve timing, cylinder deactivation, and turbocharging. These advancements have allowed V8 engines to maintain their performance characteristics while significantly reducing fuel consumption and emissions.

The integration of hybrid and electric technologies has opened up new avenues for V8 engine evolution. Mild hybrid systems and plug-in hybrid powertrains incorporating V8 engines have emerged as a way to combine the traditional appeal of V8 power with improved efficiency and reduced environmental impact. This trend is likely to continue as automakers strive to meet increasingly stringent emissions regulations while still catering to consumers who desire high-performance vehicles.

Looking ahead, the objectives for V8 engine development are multifaceted. Engineers are exploring advanced materials and manufacturing techniques to reduce engine weight and improve thermal efficiency. There is also a growing focus on alternative fuels, with research into hydrogen-powered V8 engines and synthetic fuels that could potentially extend the lifespan of internal combustion engines in an increasingly electrified automotive landscape.

The future of V8 engines will likely involve a convergence of traditional mechanical engineering with cutting-edge digital technologies. The integration of artificial intelligence and machine learning in engine management systems promises to further optimize performance and efficiency. Additionally, the development of smart materials that can adapt to different operating conditions could revolutionize engine design and functionality.

As we look towards the horizon of automotive technology, the V8 engine stands at a crossroads. While facing challenges from alternative powertrains, it continues to evolve, adapting to new requirements and technologies. The ongoing objective is to preserve the V8's iconic status while pushing the boundaries of what is possible in terms of performance, efficiency, and environmental responsibility.

The primary objective of V8 engine development has been to strike a balance between power output, fuel efficiency, and environmental sustainability. Over the decades, engineers have focused on improving combustion efficiency, reducing friction losses, and optimizing the engine's overall design to meet these goals. The advent of computer-aided design and simulation tools has greatly accelerated this process, allowing for more precise engineering and faster iteration cycles.

In recent years, the automotive industry has faced increasing pressure to reduce emissions and improve fuel economy. This has led to a new era of V8 engine development, with a focus on technologies such as direct fuel injection, variable valve timing, cylinder deactivation, and turbocharging. These advancements have allowed V8 engines to maintain their performance characteristics while significantly reducing fuel consumption and emissions.

The integration of hybrid and electric technologies has opened up new avenues for V8 engine evolution. Mild hybrid systems and plug-in hybrid powertrains incorporating V8 engines have emerged as a way to combine the traditional appeal of V8 power with improved efficiency and reduced environmental impact. This trend is likely to continue as automakers strive to meet increasingly stringent emissions regulations while still catering to consumers who desire high-performance vehicles.

Looking ahead, the objectives for V8 engine development are multifaceted. Engineers are exploring advanced materials and manufacturing techniques to reduce engine weight and improve thermal efficiency. There is also a growing focus on alternative fuels, with research into hydrogen-powered V8 engines and synthetic fuels that could potentially extend the lifespan of internal combustion engines in an increasingly electrified automotive landscape.

The future of V8 engines will likely involve a convergence of traditional mechanical engineering with cutting-edge digital technologies. The integration of artificial intelligence and machine learning in engine management systems promises to further optimize performance and efficiency. Additionally, the development of smart materials that can adapt to different operating conditions could revolutionize engine design and functionality.

As we look towards the horizon of automotive technology, the V8 engine stands at a crossroads. While facing challenges from alternative powertrains, it continues to evolve, adapting to new requirements and technologies. The ongoing objective is to preserve the V8's iconic status while pushing the boundaries of what is possible in terms of performance, efficiency, and environmental responsibility.

Market Demand Analysis for V8 Engines

The market demand for V8 engines has undergone significant shifts in recent years, driven by evolving consumer preferences, regulatory pressures, and technological advancements. Despite the global push towards electrification and downsizing, V8 engines continue to maintain a strong presence in specific market segments, particularly in high-performance vehicles, luxury cars, and certain truck applications.

In the performance car segment, V8 engines remain highly sought after for their distinctive sound, power delivery, and emotional appeal. Sports car manufacturers and premium brands continue to offer V8 options to cater to enthusiasts who value the traditional characteristics of these powerplants. This demand is particularly strong in markets such as North America and the Middle East, where fuel costs are relatively lower and performance-oriented driving cultures persist.

The luxury car market also sustains a notable demand for V8 engines, especially in flagship models where smoothness, refinement, and effortless power are key selling points. While there is a trend towards smaller, turbocharged engines in this segment, many consumers still associate V8 power with prestige and superior driving experience, maintaining a steady market for these engines.

In the truck and SUV market, V8 engines continue to play a crucial role, particularly in full-size pickup trucks and large SUVs. These vehicles often require high towing capacities and payload capabilities, which V8 engines are well-suited to provide. The North American market, in particular, shows strong demand for V8-powered trucks, with manufacturers continually improving these engines to meet both performance expectations and increasingly stringent fuel efficiency standards.

However, the overall market trend indicates a gradual decline in V8 engine demand across most vehicle segments. This shift is primarily driven by stricter emissions regulations, increasing fuel costs, and growing environmental consciousness among consumers. Many automakers are responding by developing advanced turbocharged six-cylinder engines or hybrid powertrains that aim to deliver V8-like performance with improved efficiency.

The future market demand for V8 engines is likely to become more niche-oriented, focusing on specialized applications where their unique characteristics are most valued. This includes high-end sports cars, luxury vehicles, and heavy-duty trucks. To remain relevant, V8 engine technology must continue to evolve, incorporating advanced materials, improved thermal management, and potentially hybridization to meet future emissions and efficiency requirements while maintaining the performance characteristics that define the V8 experience.

In the performance car segment, V8 engines remain highly sought after for their distinctive sound, power delivery, and emotional appeal. Sports car manufacturers and premium brands continue to offer V8 options to cater to enthusiasts who value the traditional characteristics of these powerplants. This demand is particularly strong in markets such as North America and the Middle East, where fuel costs are relatively lower and performance-oriented driving cultures persist.

The luxury car market also sustains a notable demand for V8 engines, especially in flagship models where smoothness, refinement, and effortless power are key selling points. While there is a trend towards smaller, turbocharged engines in this segment, many consumers still associate V8 power with prestige and superior driving experience, maintaining a steady market for these engines.

In the truck and SUV market, V8 engines continue to play a crucial role, particularly in full-size pickup trucks and large SUVs. These vehicles often require high towing capacities and payload capabilities, which V8 engines are well-suited to provide. The North American market, in particular, shows strong demand for V8-powered trucks, with manufacturers continually improving these engines to meet both performance expectations and increasingly stringent fuel efficiency standards.

However, the overall market trend indicates a gradual decline in V8 engine demand across most vehicle segments. This shift is primarily driven by stricter emissions regulations, increasing fuel costs, and growing environmental consciousness among consumers. Many automakers are responding by developing advanced turbocharged six-cylinder engines or hybrid powertrains that aim to deliver V8-like performance with improved efficiency.

The future market demand for V8 engines is likely to become more niche-oriented, focusing on specialized applications where their unique characteristics are most valued. This includes high-end sports cars, luxury vehicles, and heavy-duty trucks. To remain relevant, V8 engine technology must continue to evolve, incorporating advanced materials, improved thermal management, and potentially hybridization to meet future emissions and efficiency requirements while maintaining the performance characteristics that define the V8 experience.

Current V8 Technology Challenges

The V8 engine, developed by Google, has been a cornerstone of JavaScript performance for over a decade. However, as web applications become increasingly complex and demanding, V8 faces several significant challenges in maintaining its edge and meeting the evolving needs of developers and users alike.

One of the primary challenges for V8 is optimizing performance for modern JavaScript paradigms. As developers embrace newer language features and coding patterns, such as async/await, generators, and modules, V8 must continually adapt its optimization strategies. The engine's just-in-time (JIT) compiler needs to efficiently handle these constructs while minimizing overhead and maximizing execution speed.

Memory management remains a critical concern for V8. With web applications growing in size and complexity, efficient garbage collection becomes paramount. V8 must balance the need for rapid memory reclamation with minimizing application pauses, particularly in scenarios involving large object graphs or long-running processes. This challenge is further compounded by the increasing use of WebAssembly, which introduces new memory management considerations.

Another significant hurdle for V8 is improving startup performance. As web applications become more sophisticated, the time required for initial parsing and compilation of JavaScript code can lead to noticeable delays in application load times. V8 must find ways to reduce this startup overhead without compromising on runtime performance, potentially through more aggressive caching strategies or improved ahead-of-time compilation techniques.

The rise of serverless computing and edge computing presents new challenges for V8. These environments often require rapid startup times and efficient resource utilization, pushing V8 to optimize for scenarios where JavaScript execution may be more ephemeral and resource-constrained than in traditional browser contexts.

Security remains an ongoing concern for V8. As a critical component of web browsers and Node.js, V8 is a prime target for attackers. The engine must continually evolve its security measures to protect against potential vulnerabilities, such as those arising from just-in-time compilation or speculative execution, while maintaining performance.

Cross-platform consistency is another challenge facing V8. With JavaScript running on an ever-widening array of devices and architectures, from low-power IoT devices to high-performance servers, V8 must strive to deliver consistent behavior and performance across diverse hardware environments. This includes optimizing for ARM-based systems and emerging architectures.

Lastly, V8 faces the challenge of balancing innovation with backwards compatibility. As the engine introduces new optimizations and features, it must ensure that existing code continues to run correctly, maintaining the stability that developers and businesses rely on while pushing the boundaries of JavaScript performance.

One of the primary challenges for V8 is optimizing performance for modern JavaScript paradigms. As developers embrace newer language features and coding patterns, such as async/await, generators, and modules, V8 must continually adapt its optimization strategies. The engine's just-in-time (JIT) compiler needs to efficiently handle these constructs while minimizing overhead and maximizing execution speed.

Memory management remains a critical concern for V8. With web applications growing in size and complexity, efficient garbage collection becomes paramount. V8 must balance the need for rapid memory reclamation with minimizing application pauses, particularly in scenarios involving large object graphs or long-running processes. This challenge is further compounded by the increasing use of WebAssembly, which introduces new memory management considerations.

Another significant hurdle for V8 is improving startup performance. As web applications become more sophisticated, the time required for initial parsing and compilation of JavaScript code can lead to noticeable delays in application load times. V8 must find ways to reduce this startup overhead without compromising on runtime performance, potentially through more aggressive caching strategies or improved ahead-of-time compilation techniques.

The rise of serverless computing and edge computing presents new challenges for V8. These environments often require rapid startup times and efficient resource utilization, pushing V8 to optimize for scenarios where JavaScript execution may be more ephemeral and resource-constrained than in traditional browser contexts.

Security remains an ongoing concern for V8. As a critical component of web browsers and Node.js, V8 is a prime target for attackers. The engine must continually evolve its security measures to protect against potential vulnerabilities, such as those arising from just-in-time compilation or speculative execution, while maintaining performance.

Cross-platform consistency is another challenge facing V8. With JavaScript running on an ever-widening array of devices and architectures, from low-power IoT devices to high-performance servers, V8 must strive to deliver consistent behavior and performance across diverse hardware environments. This includes optimizing for ARM-based systems and emerging architectures.

Lastly, V8 faces the challenge of balancing innovation with backwards compatibility. As the engine introduces new optimizations and features, it must ensure that existing code continues to run correctly, maintaining the stability that developers and businesses rely on while pushing the boundaries of JavaScript performance.

Current V8 Engine Solutions

01 Improved Cylinder Design

Advancements in V8 engine cylinder design focus on optimizing combustion efficiency and reducing friction. This includes innovations in cylinder head geometry, piston design, and valve arrangements to enhance power output and fuel economy while minimizing emissions.- Improved Cylinder Design: Advancements in V8 engine cylinder design focus on enhancing combustion efficiency and reducing friction. This includes optimized cylinder shapes, improved cooling systems, and innovative materials to withstand higher temperatures and pressures. These improvements contribute to increased power output and better fuel economy.

- Advanced Fuel Injection Systems: Modern V8 engines incorporate sophisticated fuel injection systems for precise fuel delivery. These systems utilize high-pressure direct injection, multiple injectors per cylinder, and advanced electronic control units to optimize fuel atomization and combustion timing. The result is improved performance, reduced emissions, and better fuel efficiency.

- Variable Valve Timing and Lift: V8 engine advancements include variable valve timing and lift mechanisms. These systems allow for dynamic adjustment of valve operation based on engine speed and load, optimizing performance across a wide range of operating conditions. This technology enhances power output, improves fuel economy, and reduces emissions.

- Turbocharging and Supercharging: Forced induction technologies, such as turbocharging and supercharging, have been integrated into V8 engines to boost power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and generating increased power from a smaller displacement engine. Advanced designs include twin-turbo setups and electric superchargers for improved responsiveness.

- Engine Management and Control Systems: Modern V8 engines utilize sophisticated engine management and control systems. These include advanced sensors, real-time monitoring, and adaptive algorithms to optimize engine performance, fuel efficiency, and emissions control. Integration with vehicle systems allows for features like cylinder deactivation and start-stop technology, further improving overall efficiency.

02 Advanced Fuel Injection Systems

Modern V8 engines incorporate sophisticated fuel injection technologies, such as direct injection and variable fuel pressure systems. These advancements improve fuel atomization, combustion efficiency, and overall engine performance across various operating conditions.Expand Specific Solutions03 Variable Valve Timing and Lift

Implementing variable valve timing and lift mechanisms in V8 engines allows for optimized air intake and exhaust flow across different engine speeds. This technology enhances power output, fuel efficiency, and reduces emissions by adjusting valve operation based on engine load and RPM.Expand Specific Solutions04 Turbocharging and Supercharging

Forced induction systems, including turbochargers and superchargers, are increasingly used in V8 engines to boost power output and efficiency. These systems compress incoming air, allowing for increased fuel combustion and improved performance without significantly increasing engine size.Expand Specific Solutions05 Engine Management and Control Systems

Advanced electronic control units (ECUs) and sensors are employed in modern V8 engines to optimize performance, fuel efficiency, and emissions. These systems continuously monitor and adjust engine parameters in real-time, ensuring optimal operation across various driving conditions.Expand Specific Solutions

Key V8 Engine Manufacturers

The V8 engine advancements market is in a mature stage, with established players like Toyota, BMW, and Honda leading innovation. The global market size for V8 engines is estimated to be over $30 billion, driven by demand in high-performance vehicles and luxury segments. Technologically, V8 engines are highly developed, with companies focusing on improving efficiency, reducing emissions, and integrating hybrid technologies. Toyota, BMW, and Honda are at the forefront, investing heavily in R&D to enhance V8 performance while meeting stricter environmental regulations. Emerging players like Guangxi Yuchai Machinery are also making strides, particularly in developing markets, indicating a competitive and evolving landscape in V8 engine technology.

Toyota Motor Corp.

Technical Solution: Toyota has made significant advancements in V8 engine technology, focusing on improving efficiency and performance. Their latest V8 engines incorporate direct injection, variable valve timing, and cylinder deactivation technologies. Toyota's Dynamic Force V8 engine achieves a thermal efficiency of up to 41%, which is among the highest in the industry for gasoline engines[1]. The company has also developed a new electrically controlled variable displacement oil pump that reduces parasitic losses and improves fuel economy[2]. Additionally, Toyota has implemented advanced combustion techniques, such as high-speed combustion and high tumble port designs, to enhance fuel efficiency and reduce emissions while maintaining power output[3].

Strengths: High thermal efficiency, advanced fuel-saving technologies, and robust performance. Weaknesses: Relatively high production costs and complexity in manufacturing compared to smaller engines.

GM Global Technology Operations LLC

Technical Solution: GM has developed a cutting-edge V8 engine platform called the Small Block V8, which incorporates advanced technologies for improved performance and efficiency. The latest generation features Dynamic Fuel Management, allowing the engine to operate on anywhere from two to eight cylinders depending on demand[4]. GM's V8 engines also utilize direct injection, variable valve timing, and Active Fuel Management for enhanced fuel economy. The company has implemented a patented tri-power valvetrain design that enables cylinder deactivation across a wide range of engine speeds and loads[5]. Furthermore, GM has developed an innovative oil control system that reduces friction and improves durability in their V8 engines[6].

Strengths: Versatile cylinder deactivation technology, advanced valvetrain design, and improved oil management. Weaknesses: Complexity of systems may lead to higher maintenance costs over time.

Core V8 Engine Innovations

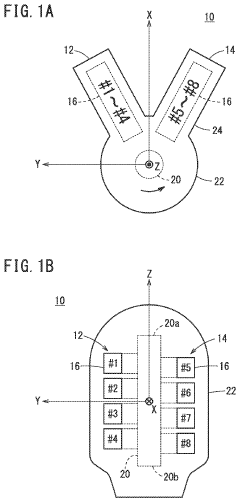

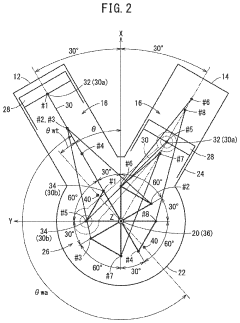

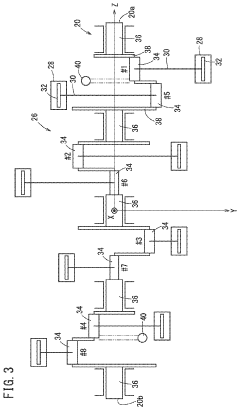

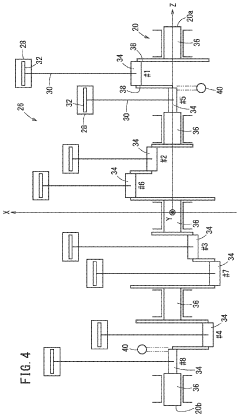

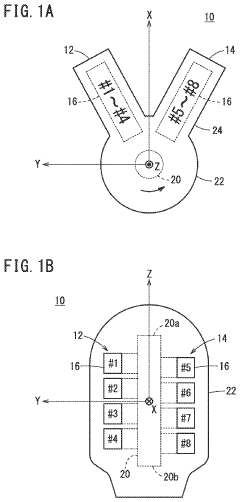

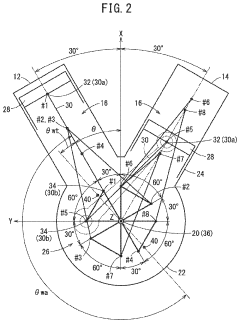

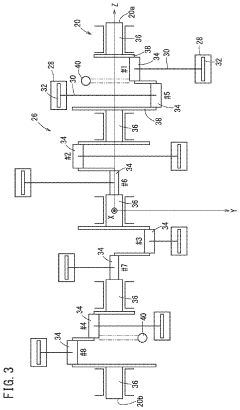

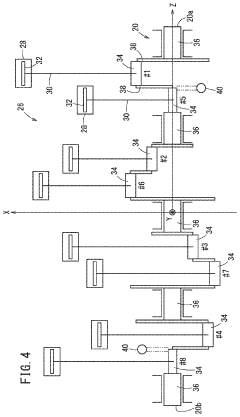

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

Environmental Impact of V8 Engines

The environmental impact of V8 engines has been a subject of increasing concern in recent years, as the automotive industry grapples with the challenge of balancing performance with sustainability. V8 engines, known for their power and distinctive sound, have long been associated with high-performance vehicles and luxury cars. However, their environmental footprint has come under scrutiny due to their typically higher fuel consumption and emissions compared to smaller engine configurations.

One of the primary environmental concerns associated with V8 engines is their carbon dioxide (CO2) emissions. These engines generally consume more fuel per mile driven, resulting in higher CO2 output. This contributes significantly to greenhouse gas emissions and, consequently, to global climate change. The automotive industry has been working to address this issue through various technological advancements, including improved fuel injection systems, variable valve timing, and cylinder deactivation technologies.

Another environmental impact of V8 engines is their contribution to air pollution. These engines typically produce higher levels of nitrogen oxides (NOx) and particulate matter, which can have detrimental effects on air quality and human health, particularly in urban areas. Stringent emissions regulations, such as Euro 6 in Europe and Tier 3 in the United States, have forced manufacturers to implement advanced exhaust after-treatment systems to mitigate these pollutants.

The production and disposal of V8 engines also have environmental implications. These larger engines require more raw materials and energy to manufacture, increasing their overall environmental footprint. Additionally, the complexity of V8 engines can make them more challenging to recycle at the end of their life cycle, potentially leading to increased waste.

Despite these challenges, recent advancements in V8 engine technology have aimed to improve their environmental performance. Manufacturers have been implementing technologies such as start-stop systems, which reduce idling time and fuel consumption in urban driving conditions. Additionally, the integration of hybrid systems with V8 engines has shown promise in reducing overall emissions while maintaining performance characteristics.

The shift towards electrification in the automotive industry is also influencing the future of V8 engines. As electric vehicles gain market share, the role of V8 engines may evolve, potentially becoming more specialized for high-performance applications or niche markets. This transition could lead to a reduction in the overall environmental impact of V8 engines as their production and use become more limited.

In conclusion, while V8 engines have historically had a significant environmental impact, ongoing technological advancements and regulatory pressures are driving improvements in their efficiency and emissions. The future of V8 engines will likely involve a delicate balance between preserving their performance characteristics and meeting increasingly stringent environmental standards.

One of the primary environmental concerns associated with V8 engines is their carbon dioxide (CO2) emissions. These engines generally consume more fuel per mile driven, resulting in higher CO2 output. This contributes significantly to greenhouse gas emissions and, consequently, to global climate change. The automotive industry has been working to address this issue through various technological advancements, including improved fuel injection systems, variable valve timing, and cylinder deactivation technologies.

Another environmental impact of V8 engines is their contribution to air pollution. These engines typically produce higher levels of nitrogen oxides (NOx) and particulate matter, which can have detrimental effects on air quality and human health, particularly in urban areas. Stringent emissions regulations, such as Euro 6 in Europe and Tier 3 in the United States, have forced manufacturers to implement advanced exhaust after-treatment systems to mitigate these pollutants.

The production and disposal of V8 engines also have environmental implications. These larger engines require more raw materials and energy to manufacture, increasing their overall environmental footprint. Additionally, the complexity of V8 engines can make them more challenging to recycle at the end of their life cycle, potentially leading to increased waste.

Despite these challenges, recent advancements in V8 engine technology have aimed to improve their environmental performance. Manufacturers have been implementing technologies such as start-stop systems, which reduce idling time and fuel consumption in urban driving conditions. Additionally, the integration of hybrid systems with V8 engines has shown promise in reducing overall emissions while maintaining performance characteristics.

The shift towards electrification in the automotive industry is also influencing the future of V8 engines. As electric vehicles gain market share, the role of V8 engines may evolve, potentially becoming more specialized for high-performance applications or niche markets. This transition could lead to a reduction in the overall environmental impact of V8 engines as their production and use become more limited.

In conclusion, while V8 engines have historically had a significant environmental impact, ongoing technological advancements and regulatory pressures are driving improvements in their efficiency and emissions. The future of V8 engines will likely involve a delicate balance between preserving their performance characteristics and meeting increasingly stringent environmental standards.

V8 Engine Performance Metrics

V8 engine performance metrics serve as crucial indicators for evaluating the advancements and capabilities of these powerplants. These metrics encompass a wide range of parameters that collectively define the engine's efficiency, power output, and overall performance characteristics.

One of the primary performance metrics for V8 engines is horsepower, which measures the engine's ability to perform work over time. Modern V8 engines have seen significant improvements in this area, with some high-performance variants producing over 700 horsepower. Closely related to horsepower is torque, which quantifies the rotational force generated by the engine. V8 engines are renowned for their high torque output, particularly at lower RPMs, contributing to their robust acceleration and towing capabilities.

Fuel efficiency has become an increasingly important metric in recent years, driven by environmental concerns and regulatory pressures. V8 engines have made substantial progress in this area through technologies such as direct injection, variable valve timing, and cylinder deactivation. These advancements have allowed V8 engines to achieve fuel economy figures that were once thought impossible for such large displacement powerplants.

Emissions performance is another critical metric, closely tied to fuel efficiency. Modern V8 engines employ sophisticated exhaust after-treatment systems, including catalytic converters and particulate filters, to meet stringent emissions standards. The ability to balance high performance with low emissions has become a key differentiator in V8 engine development.

Reliability and durability metrics are essential for assessing the long-term performance of V8 engines. These include factors such as mean time between failures (MTBF), component wear rates, and overall engine lifespan. Advancements in materials science and manufacturing processes have contributed to significant improvements in these areas, with many modern V8 engines capable of running for hundreds of thousands of miles with proper maintenance.

Power-to-weight ratio is a metric that highlights the efficiency of V8 engines in terms of power output relative to their mass. This is particularly important in performance and racing applications, where minimizing weight while maximizing power is crucial. Recent advancements in lightweight materials and compact design have allowed V8 engines to achieve impressive power-to-weight ratios.

Thermal efficiency, which measures the engine's ability to convert fuel energy into mechanical work, has seen steady improvements in V8 engines. Technologies such as higher compression ratios, improved combustion chamber designs, and advanced cooling systems have contributed to these gains. Some modern V8 engines now approach thermal efficiencies of 40%, a significant improvement over earlier generations.

One of the primary performance metrics for V8 engines is horsepower, which measures the engine's ability to perform work over time. Modern V8 engines have seen significant improvements in this area, with some high-performance variants producing over 700 horsepower. Closely related to horsepower is torque, which quantifies the rotational force generated by the engine. V8 engines are renowned for their high torque output, particularly at lower RPMs, contributing to their robust acceleration and towing capabilities.

Fuel efficiency has become an increasingly important metric in recent years, driven by environmental concerns and regulatory pressures. V8 engines have made substantial progress in this area through technologies such as direct injection, variable valve timing, and cylinder deactivation. These advancements have allowed V8 engines to achieve fuel economy figures that were once thought impossible for such large displacement powerplants.

Emissions performance is another critical metric, closely tied to fuel efficiency. Modern V8 engines employ sophisticated exhaust after-treatment systems, including catalytic converters and particulate filters, to meet stringent emissions standards. The ability to balance high performance with low emissions has become a key differentiator in V8 engine development.

Reliability and durability metrics are essential for assessing the long-term performance of V8 engines. These include factors such as mean time between failures (MTBF), component wear rates, and overall engine lifespan. Advancements in materials science and manufacturing processes have contributed to significant improvements in these areas, with many modern V8 engines capable of running for hundreds of thousands of miles with proper maintenance.

Power-to-weight ratio is a metric that highlights the efficiency of V8 engines in terms of power output relative to their mass. This is particularly important in performance and racing applications, where minimizing weight while maximizing power is crucial. Recent advancements in lightweight materials and compact design have allowed V8 engines to achieve impressive power-to-weight ratios.

Thermal efficiency, which measures the engine's ability to convert fuel energy into mechanical work, has seen steady improvements in V8 engines. Technologies such as higher compression ratios, improved combustion chamber designs, and advanced cooling systems have contributed to these gains. Some modern V8 engines now approach thermal efficiencies of 40%, a significant improvement over earlier generations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!