Latest Developments in V8 Engine Technologies

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine, a marvel of automotive engineering, has undergone significant evolution since its inception. Originally developed in the early 20th century, this engine configuration has become synonymous with power, performance, and prestige in the automotive world. The V8's journey from its early days to the present has been marked by continuous improvements in efficiency, power output, and environmental compatibility.

In recent years, the focus of V8 engine development has shifted dramatically. While traditionally prized for their raw power and distinctive sound, modern V8 engines are now being engineered with a keen eye on fuel efficiency and emissions reduction. This shift is largely driven by increasingly stringent environmental regulations and a growing global emphasis on sustainable transportation solutions.

One of the key objectives in contemporary V8 engine development is the integration of advanced technologies to enhance performance while reducing fuel consumption. This includes the implementation of direct fuel injection systems, variable valve timing, and cylinder deactivation technologies. These innovations allow V8 engines to deliver impressive power when needed, while operating more efficiently under light load conditions.

Another significant trend in V8 engine evolution is the move towards downsizing. Manufacturers are developing smaller displacement V8 engines that utilize turbocharging or supercharging to maintain or even exceed the power output of their larger predecessors. This approach not only improves fuel efficiency but also helps in meeting stricter emissions standards without sacrificing the performance characteristics that V8 enthusiasts crave.

The integration of hybrid and electric technologies into V8 powertrains represents another frontier in their evolution. Some manufacturers are exploring mild hybrid systems that can provide additional power and improve efficiency, while others are developing plug-in hybrid V8 systems that can operate in fully electric mode for short distances.

Looking ahead, the objectives for V8 engine development are multifaceted. Engineers are striving to further reduce emissions and fuel consumption while maintaining the power and character that define the V8 experience. This includes exploring alternative fuels, such as hydrogen, and developing more advanced materials to reduce weight and improve thermal efficiency.

The ultimate goal is to ensure that the V8 engine remains relevant in an increasingly eco-conscious automotive landscape. By embracing cutting-edge technologies and innovative design approaches, developers aim to create V8 engines that can meet future emissions regulations while still delivering the performance and driving experience that has made them legendary in the automotive world.

In recent years, the focus of V8 engine development has shifted dramatically. While traditionally prized for their raw power and distinctive sound, modern V8 engines are now being engineered with a keen eye on fuel efficiency and emissions reduction. This shift is largely driven by increasingly stringent environmental regulations and a growing global emphasis on sustainable transportation solutions.

One of the key objectives in contemporary V8 engine development is the integration of advanced technologies to enhance performance while reducing fuel consumption. This includes the implementation of direct fuel injection systems, variable valve timing, and cylinder deactivation technologies. These innovations allow V8 engines to deliver impressive power when needed, while operating more efficiently under light load conditions.

Another significant trend in V8 engine evolution is the move towards downsizing. Manufacturers are developing smaller displacement V8 engines that utilize turbocharging or supercharging to maintain or even exceed the power output of their larger predecessors. This approach not only improves fuel efficiency but also helps in meeting stricter emissions standards without sacrificing the performance characteristics that V8 enthusiasts crave.

The integration of hybrid and electric technologies into V8 powertrains represents another frontier in their evolution. Some manufacturers are exploring mild hybrid systems that can provide additional power and improve efficiency, while others are developing plug-in hybrid V8 systems that can operate in fully electric mode for short distances.

Looking ahead, the objectives for V8 engine development are multifaceted. Engineers are striving to further reduce emissions and fuel consumption while maintaining the power and character that define the V8 experience. This includes exploring alternative fuels, such as hydrogen, and developing more advanced materials to reduce weight and improve thermal efficiency.

The ultimate goal is to ensure that the V8 engine remains relevant in an increasingly eco-conscious automotive landscape. By embracing cutting-edge technologies and innovative design approaches, developers aim to create V8 engines that can meet future emissions regulations while still delivering the performance and driving experience that has made them legendary in the automotive world.

Market Demand Analysis for V8 Engines

The market demand for V8 engines has been evolving rapidly in recent years, driven by a combination of technological advancements, changing consumer preferences, and regulatory pressures. In the automotive sector, V8 engines have traditionally been associated with high-performance vehicles, luxury cars, and large SUVs. However, the market landscape is shifting due to several factors.

One significant trend is the increasing focus on fuel efficiency and environmental concerns. This has led to a decline in demand for V8 engines in mainstream passenger vehicles, as automakers prioritize smaller, more fuel-efficient powertrains. Despite this overall trend, there remains a niche market for V8 engines in premium and performance vehicles, where power and prestige are still highly valued.

The sports car and high-performance vehicle segment continues to show strong demand for V8 engines. Manufacturers like Ferrari, Lamborghini, and Aston Martin still rely heavily on V8 powerplants for their flagship models. In this sector, the latest V8 engine technologies focus on improving power output while meeting stringent emissions regulations.

In the luxury SUV market, V8 engines maintain their appeal, particularly in regions where fuel costs are less of a concern. Models from brands like Range Rover, Mercedes-Benz, and BMW continue to offer V8 options to cater to customers seeking both performance and prestige.

The commercial vehicle sector, particularly in heavy-duty trucks and specialized industrial applications, represents another significant market for V8 engines. Here, the demand is driven by the need for high torque and durability in challenging operating conditions.

Emerging markets, especially in regions with less stringent emissions regulations, show potential growth for V8 engines. Countries with developing economies and a rising affluent class often see increased demand for luxury and high-performance vehicles, many of which are equipped with V8 engines.

The racing and motorsport industry continues to be a key driver of innovation in V8 engine technology. Advancements in this sector often trickle down to consumer vehicles, maintaining interest and demand in V8 powerplants.

Looking at market size, while the overall share of V8 engines in the global automotive market has decreased, they still represent a significant segment in terms of value. The premium nature of V8-equipped vehicles means they command higher prices and profit margins, making them an attractive proposition for manufacturers despite lower volume sales.

In conclusion, while the mass-market demand for V8 engines is declining due to environmental concerns and shifting consumer preferences, there remains a robust niche market in high-performance, luxury, and specialized vehicle segments. The future of V8 engines will likely involve continued technological advancements to improve efficiency and meet emissions standards while maintaining the power and prestige associated with these powerplants.

One significant trend is the increasing focus on fuel efficiency and environmental concerns. This has led to a decline in demand for V8 engines in mainstream passenger vehicles, as automakers prioritize smaller, more fuel-efficient powertrains. Despite this overall trend, there remains a niche market for V8 engines in premium and performance vehicles, where power and prestige are still highly valued.

The sports car and high-performance vehicle segment continues to show strong demand for V8 engines. Manufacturers like Ferrari, Lamborghini, and Aston Martin still rely heavily on V8 powerplants for their flagship models. In this sector, the latest V8 engine technologies focus on improving power output while meeting stringent emissions regulations.

In the luxury SUV market, V8 engines maintain their appeal, particularly in regions where fuel costs are less of a concern. Models from brands like Range Rover, Mercedes-Benz, and BMW continue to offer V8 options to cater to customers seeking both performance and prestige.

The commercial vehicle sector, particularly in heavy-duty trucks and specialized industrial applications, represents another significant market for V8 engines. Here, the demand is driven by the need for high torque and durability in challenging operating conditions.

Emerging markets, especially in regions with less stringent emissions regulations, show potential growth for V8 engines. Countries with developing economies and a rising affluent class often see increased demand for luxury and high-performance vehicles, many of which are equipped with V8 engines.

The racing and motorsport industry continues to be a key driver of innovation in V8 engine technology. Advancements in this sector often trickle down to consumer vehicles, maintaining interest and demand in V8 powerplants.

Looking at market size, while the overall share of V8 engines in the global automotive market has decreased, they still represent a significant segment in terms of value. The premium nature of V8-equipped vehicles means they command higher prices and profit margins, making them an attractive proposition for manufacturers despite lower volume sales.

In conclusion, while the mass-market demand for V8 engines is declining due to environmental concerns and shifting consumer preferences, there remains a robust niche market in high-performance, luxury, and specialized vehicle segments. The future of V8 engines will likely involve continued technological advancements to improve efficiency and meet emissions standards while maintaining the power and prestige associated with these powerplants.

Current V8 Technology Landscape

The V8 engine technology landscape has undergone significant advancements in recent years, driven by the automotive industry's push for improved performance, fuel efficiency, and emissions reduction. Current V8 engines employ a range of cutting-edge technologies to meet these demands while maintaining the power and character that enthusiasts expect from this iconic configuration.

One of the most prominent trends in modern V8 engines is the widespread adoption of direct fuel injection systems. This technology allows for precise control over fuel delivery, resulting in improved combustion efficiency and reduced emissions. Many manufacturers have paired direct injection with turbocharging or supercharging to achieve higher power outputs from smaller displacement engines, a concept known as downsizing.

Variable valve timing and lift systems have become standard features in contemporary V8 engines. These systems optimize engine breathing across the entire RPM range, enhancing both low-end torque and high-end power. Advanced implementations, such as BMW's Valvetronic and Audi's Valvelift, can even eliminate the need for a traditional throttle body, further improving efficiency.

Cylinder deactivation technology has gained traction as a means to improve fuel economy in V8 engines. This system allows the engine to operate on fewer cylinders under light load conditions, effectively turning a V8 into a V4 when full power is not required. General Motors' Dynamic Fuel Management and Chrysler's Multi-Displacement System are examples of this technology in action.

Materials science has played a crucial role in advancing V8 engine technology. Lightweight alloys, such as aluminum and even magnesium, are now commonly used for engine blocks and cylinder heads, reducing overall engine weight and improving vehicle dynamics. Some high-performance V8 engines also utilize exotic materials like titanium for connecting rods and valves to reduce reciprocating mass and increase rev limits.

Thermal management has become a key focus area, with advanced cooling systems and integrated exhaust manifolds helping to optimize engine temperatures for improved efficiency and longevity. Additionally, start-stop systems and mild hybrid technologies are being integrated into V8 powertrains to further reduce fuel consumption and emissions during urban driving.

The current V8 technology landscape also sees increased use of advanced engine management systems and sensors. These sophisticated electronic controls allow for real-time adjustments to engine parameters, ensuring optimal performance and efficiency across all operating conditions. Some systems even incorporate predictive algorithms and connectivity features to anticipate driving conditions and adjust engine behavior accordingly.

One of the most prominent trends in modern V8 engines is the widespread adoption of direct fuel injection systems. This technology allows for precise control over fuel delivery, resulting in improved combustion efficiency and reduced emissions. Many manufacturers have paired direct injection with turbocharging or supercharging to achieve higher power outputs from smaller displacement engines, a concept known as downsizing.

Variable valve timing and lift systems have become standard features in contemporary V8 engines. These systems optimize engine breathing across the entire RPM range, enhancing both low-end torque and high-end power. Advanced implementations, such as BMW's Valvetronic and Audi's Valvelift, can even eliminate the need for a traditional throttle body, further improving efficiency.

Cylinder deactivation technology has gained traction as a means to improve fuel economy in V8 engines. This system allows the engine to operate on fewer cylinders under light load conditions, effectively turning a V8 into a V4 when full power is not required. General Motors' Dynamic Fuel Management and Chrysler's Multi-Displacement System are examples of this technology in action.

Materials science has played a crucial role in advancing V8 engine technology. Lightweight alloys, such as aluminum and even magnesium, are now commonly used for engine blocks and cylinder heads, reducing overall engine weight and improving vehicle dynamics. Some high-performance V8 engines also utilize exotic materials like titanium for connecting rods and valves to reduce reciprocating mass and increase rev limits.

Thermal management has become a key focus area, with advanced cooling systems and integrated exhaust manifolds helping to optimize engine temperatures for improved efficiency and longevity. Additionally, start-stop systems and mild hybrid technologies are being integrated into V8 powertrains to further reduce fuel consumption and emissions during urban driving.

The current V8 technology landscape also sees increased use of advanced engine management systems and sensors. These sophisticated electronic controls allow for real-time adjustments to engine parameters, ensuring optimal performance and efficiency across all operating conditions. Some systems even incorporate predictive algorithms and connectivity features to anticipate driving conditions and adjust engine behavior accordingly.

Current V8 Engine Solutions

01 V8 Engine Design and Configuration

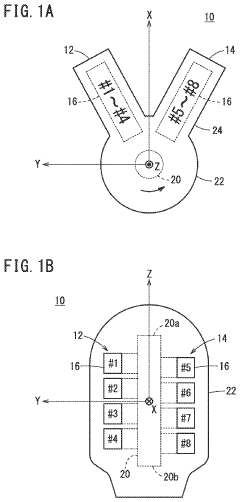

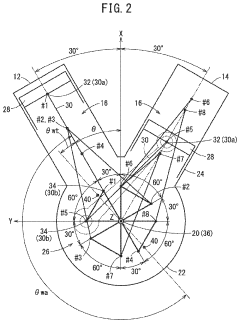

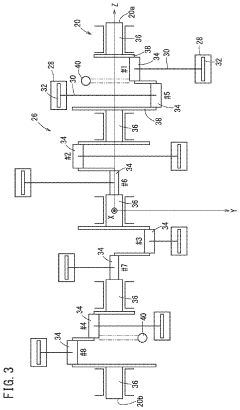

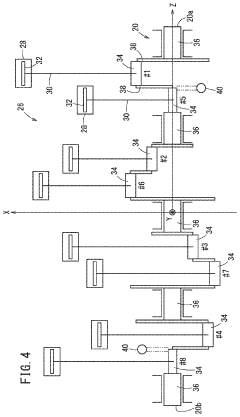

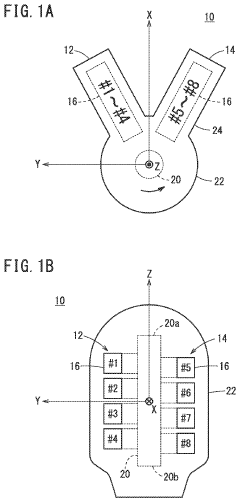

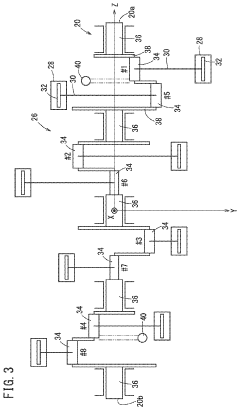

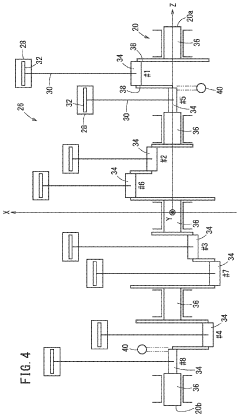

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are continuously optimized to enhance performance and efficiency.

- Fuel Efficiency and Emissions Control: Modern V8 engines incorporate advanced technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Innovations in engine management systems and combustion chamber design also contribute to better fuel economy and lower emissions while maintaining high performance.

- Performance Enhancement and Tuning: Various methods and components are developed to enhance V8 engine performance. These include turbocharging, supercharging, intercooling, and high-flow intake and exhaust systems. Advanced engine tuning techniques, such as remapping engine control units and optimizing air-fuel ratios, are employed to maximize power output and torque across different RPM ranges.

- Cooling and Lubrication Systems: Efficient cooling and lubrication are crucial for V8 engine reliability and longevity. Innovations in coolant flow design, oil pump efficiency, and thermal management systems help maintain optimal operating temperatures and reduce friction. Advanced materials and coatings are also used to improve heat dissipation and reduce wear on engine components.

- Manufacturing and Assembly Techniques: Advancements in manufacturing processes and assembly techniques for V8 engines focus on improving precision, reducing weight, and enhancing durability. These may include the use of lightweight materials, advanced casting methods, and automated assembly processes. Innovations in quality control and testing procedures ensure consistent performance and reliability across production runs.

02 Fuel Efficiency and Emissions Reduction

Modern V8 engines incorporate technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced engine management systems. Innovations in combustion chamber design and fuel delivery systems contribute to optimized fuel consumption and lower environmental impact.Expand Specific Solutions03 Performance Enhancement and Tuning

Various methods and components are developed to enhance V8 engine performance. These include turbocharging, supercharging, intercooling, and exhaust system optimization. Advanced materials and manufacturing techniques are employed to reduce weight, increase strength, and improve thermal efficiency. Engine tuning software and hardware modifications allow for customized performance characteristics.Expand Specific Solutions04 Cooling and Lubrication Systems

Effective cooling and lubrication are crucial for V8 engine reliability and longevity. Innovations in coolant circulation, oil pump designs, and thermal management systems help maintain optimal operating temperatures and reduce friction. Advanced cooling strategies may include precision coolant control and integrated thermal management for improved efficiency.Expand Specific Solutions05 Integration with Hybrid and Electric Systems

As automotive technology evolves, V8 engines are being integrated with hybrid and electric systems to meet stricter emissions standards while maintaining high performance. This includes the development of mild hybrid systems, regenerative braking, and start-stop technology specifically tailored for V8 engines. These integrations aim to combine the power of V8 engines with improved fuel economy and reduced environmental impact.Expand Specific Solutions

Key V8 Engine Manufacturers

The V8 engine technology market is in a mature stage, with ongoing innovations driven by established automotive manufacturers and research institutions. The global market size for V8 engines is substantial, though exact figures are not provided. Major players like Toyota, Honda, BMW, and Ford are at the forefront of V8 engine development, leveraging their extensive R&D capabilities. Universities such as Tsinghua and Chongqing are also contributing to advancements. The technology's maturity is evident in the diverse applications across passenger vehicles, trucks, and high-performance cars. However, with the automotive industry's shift towards electrification, V8 engine technology faces challenges in maintaining relevance and meeting stricter emissions standards.

Toyota Motor Corp.

Technical Solution: Toyota has been developing its V8 engine technology with a focus on reliability and efficiency. Their latest advancements include the implementation of D-4S direct and port fuel injection systems in their UR-family V8 engines, which optimizes fuel delivery for improved combustion efficiency and reduced emissions[9]. Toyota has also incorporated VVT-iE (Variable Valve Timing - intelligent by Electric motor) on the intake camshafts, allowing for more precise valve timing control and better engine performance across a wider range of operating conditions[10]. In addition, Toyota has developed an advanced thermal management system that includes a variable-flow oil pump and an electric water pump to reduce parasitic losses and improve overall engine efficiency. The company has also focused on weight reduction through the use of aluminum alloys for engine blocks and heads.

Strengths: Proven reliability, advanced fuel injection technology, and sophisticated valve timing control. Weaknesses: Conservative approach to innovation may result in less cutting-edge performance compared to some competitors, and some models may have lower power output relative to displacement.

Honda Motor Co., Ltd.

Technical Solution: Honda has made significant progress in V8 engine technology, particularly in their racing division. While Honda does not currently offer V8 engines in their consumer vehicles, their experience in Formula 1 and IndyCar racing has led to advanced V8 designs. Honda's racing V8 engines feature pneumatic valve springs, which allow for higher engine speeds and improved valve control[11]. They have also implemented advanced combustion chamber designs and port geometries to optimize airflow and fuel mixture. Honda's V8 engines benefit from sophisticated engine management systems that precisely control fuel injection, ignition timing, and valve timing to maximize performance and efficiency. Additionally, Honda has explored the use of exotic materials and coatings to reduce friction and improve heat management in high-stress racing environments[12].

Strengths: High-revving capability, advanced valve control technology, and sophisticated engine management systems. Weaknesses: Limited application to consumer vehicles, and the high-performance focus may result in designs that are less suitable for everyday driving conditions.

Core V8 Engine Innovations

V8 engine

PatentActiveUS11821359B2

Innovation

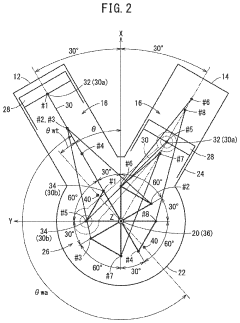

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Environmental Regulations Impact

Environmental regulations have significantly impacted the development of V8 engine technologies in recent years. Stringent emission standards, particularly in Europe and North America, have forced manufacturers to innovate and adapt their V8 engines to meet these requirements while maintaining performance.

One of the primary focuses has been on reducing carbon dioxide (CO2) emissions. This has led to the widespread adoption of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation in V8 engines. Direct fuel injection allows for more precise control over fuel delivery, improving combustion efficiency and reducing emissions. Variable valve timing optimizes engine performance across different operating conditions, further enhancing fuel economy and reducing emissions.

Cylinder deactivation, also known as variable displacement, has become increasingly common in V8 engines. This technology allows the engine to shut down a portion of its cylinders during light load conditions, effectively operating as a smaller, more fuel-efficient engine. When more power is needed, all cylinders are reactivated seamlessly.

Turbocharging and supercharging have also gained prominence in V8 engine design as a response to environmental regulations. These forced induction technologies allow manufacturers to downsize engines while maintaining or even increasing power output. Smaller displacement V8 engines with turbochargers or superchargers can deliver comparable performance to larger naturally aspirated engines while consuming less fuel and producing fewer emissions.

The push for cleaner engines has also led to advancements in exhaust after-treatment systems. Modern V8 engines are equipped with sophisticated catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems to further reduce harmful emissions. These technologies work in tandem to minimize the release of nitrogen oxides (NOx), particulate matter, and other pollutants.

Hybrid and mild-hybrid systems have been integrated into V8 powertrains to meet increasingly strict fuel economy and emission standards. These systems typically incorporate an electric motor and battery pack to assist the V8 engine, allowing for improved efficiency and reduced emissions, particularly in urban driving conditions.

Looking ahead, the impact of environmental regulations on V8 engine technologies is expected to intensify. Manufacturers are exploring more advanced combustion strategies, such as homogeneous charge compression ignition (HCCI), to further improve efficiency and reduce emissions. Additionally, the development of synthetic fuels and hydrogen combustion technologies may provide new avenues for V8 engines to comply with future environmental regulations while preserving their distinctive character and performance attributes.

One of the primary focuses has been on reducing carbon dioxide (CO2) emissions. This has led to the widespread adoption of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation in V8 engines. Direct fuel injection allows for more precise control over fuel delivery, improving combustion efficiency and reducing emissions. Variable valve timing optimizes engine performance across different operating conditions, further enhancing fuel economy and reducing emissions.

Cylinder deactivation, also known as variable displacement, has become increasingly common in V8 engines. This technology allows the engine to shut down a portion of its cylinders during light load conditions, effectively operating as a smaller, more fuel-efficient engine. When more power is needed, all cylinders are reactivated seamlessly.

Turbocharging and supercharging have also gained prominence in V8 engine design as a response to environmental regulations. These forced induction technologies allow manufacturers to downsize engines while maintaining or even increasing power output. Smaller displacement V8 engines with turbochargers or superchargers can deliver comparable performance to larger naturally aspirated engines while consuming less fuel and producing fewer emissions.

The push for cleaner engines has also led to advancements in exhaust after-treatment systems. Modern V8 engines are equipped with sophisticated catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems to further reduce harmful emissions. These technologies work in tandem to minimize the release of nitrogen oxides (NOx), particulate matter, and other pollutants.

Hybrid and mild-hybrid systems have been integrated into V8 powertrains to meet increasingly strict fuel economy and emission standards. These systems typically incorporate an electric motor and battery pack to assist the V8 engine, allowing for improved efficiency and reduced emissions, particularly in urban driving conditions.

Looking ahead, the impact of environmental regulations on V8 engine technologies is expected to intensify. Manufacturers are exploring more advanced combustion strategies, such as homogeneous charge compression ignition (HCCI), to further improve efficiency and reduce emissions. Additionally, the development of synthetic fuels and hydrogen combustion technologies may provide new avenues for V8 engines to comply with future environmental regulations while preserving their distinctive character and performance attributes.

V8 Engine Performance Metrics

V8 engine performance metrics have evolved significantly in recent years, reflecting the industry's focus on efficiency, power output, and environmental sustainability. Key performance indicators now encompass a broader range of factors, including specific power output, fuel efficiency, emissions levels, and thermal efficiency.

One of the most critical metrics is specific power output, typically measured in horsepower per liter (hp/L) or kilowatts per liter (kW/L). Modern V8 engines have seen substantial improvements in this area, with some high-performance variants achieving over 100 hp/L. This increase is largely attributed to advancements in turbocharging, direct fuel injection, and variable valve timing technologies.

Fuel efficiency remains a paramount concern, especially given stringent global emissions regulations. The latest V8 engines employ various strategies to optimize fuel consumption, including cylinder deactivation, start-stop systems, and advanced engine management systems. These technologies have enabled some V8 engines to achieve fuel economy figures previously associated with smaller displacement engines.

Emissions performance has become increasingly important, with manufacturers striving to meet ever-tightening standards. Modern V8 engines utilize sophisticated aftertreatment systems, including three-way catalytic converters, particulate filters, and selective catalytic reduction (SCR) technology. The effectiveness of these systems is measured through various emissions tests, with particular focus on CO2, NOx, and particulate matter levels.

Thermal efficiency, which measures how effectively an engine converts fuel energy into mechanical work, has also seen significant improvements. Some of the latest V8 engines boast thermal efficiencies approaching 40%, a marked increase from earlier generations. This improvement is achieved through optimized combustion processes, reduced friction losses, and advanced thermal management systems.

Durability and reliability metrics continue to be crucial, with manufacturers conducting extensive testing to ensure longevity. Mean time between failures (MTBF) and overall engine lifespan have both increased, thanks to improved materials, more precise manufacturing techniques, and advanced lubrication systems.

Performance under varying conditions is another key metric, with modern V8 engines designed to maintain optimal performance across a wide range of temperatures, altitudes, and load conditions. This adaptability is achieved through sophisticated engine control units (ECUs) and variable geometry turbochargers.

In conclusion, the performance metrics for V8 engines have become increasingly comprehensive and sophisticated, reflecting the complex balance between power, efficiency, and environmental responsibility that defines modern engine design.

One of the most critical metrics is specific power output, typically measured in horsepower per liter (hp/L) or kilowatts per liter (kW/L). Modern V8 engines have seen substantial improvements in this area, with some high-performance variants achieving over 100 hp/L. This increase is largely attributed to advancements in turbocharging, direct fuel injection, and variable valve timing technologies.

Fuel efficiency remains a paramount concern, especially given stringent global emissions regulations. The latest V8 engines employ various strategies to optimize fuel consumption, including cylinder deactivation, start-stop systems, and advanced engine management systems. These technologies have enabled some V8 engines to achieve fuel economy figures previously associated with smaller displacement engines.

Emissions performance has become increasingly important, with manufacturers striving to meet ever-tightening standards. Modern V8 engines utilize sophisticated aftertreatment systems, including three-way catalytic converters, particulate filters, and selective catalytic reduction (SCR) technology. The effectiveness of these systems is measured through various emissions tests, with particular focus on CO2, NOx, and particulate matter levels.

Thermal efficiency, which measures how effectively an engine converts fuel energy into mechanical work, has also seen significant improvements. Some of the latest V8 engines boast thermal efficiencies approaching 40%, a marked increase from earlier generations. This improvement is achieved through optimized combustion processes, reduced friction losses, and advanced thermal management systems.

Durability and reliability metrics continue to be crucial, with manufacturers conducting extensive testing to ensure longevity. Mean time between failures (MTBF) and overall engine lifespan have both increased, thanks to improved materials, more precise manufacturing techniques, and advanced lubrication systems.

Performance under varying conditions is another key metric, with modern V8 engines designed to maintain optimal performance across a wide range of temperatures, altitudes, and load conditions. This adaptability is achieved through sophisticated engine control units (ECUs) and variable geometry turbochargers.

In conclusion, the performance metrics for V8 engines have become increasingly comprehensive and sophisticated, reflecting the complex balance between power, efficiency, and environmental responsibility that defines modern engine design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!