V8 Engine Repair: Expert Methods and Procedures

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Repair Objectives

The V8 engine, a marvel of automotive engineering, has undergone significant evolution since its inception in the early 20th century. This powerful and efficient engine design has become a staple in high-performance vehicles, trucks, and even some aircraft. The primary objective of V8 engine repair is to maintain and restore these complex powerplants to their optimal performance levels while ensuring longevity and reliability.

Throughout its history, the V8 engine has seen numerous advancements in materials, design, and technology. From early cast iron blocks to modern aluminum constructions, the pursuit of lighter, more durable engines has been a constant driving force. Fuel injection systems have replaced carburetors, improving efficiency and power output. Variable valve timing and cylinder deactivation technologies have further enhanced performance and fuel economy.

The evolution of V8 engines has also been influenced by environmental concerns and regulatory pressures. This has led to the development of more fuel-efficient designs, improved emissions control systems, and the integration of hybrid technologies in some V8 applications. As a result, modern V8 engines often combine high performance with relatively good fuel economy and reduced emissions.

In the context of repair objectives, the primary goals are to diagnose issues accurately, restore performance, and extend the engine's lifespan. This involves a comprehensive understanding of the engine's mechanical, electrical, and electronic systems. Repair procedures must address wear and tear on components such as pistons, valves, and bearings, as well as the intricate fuel and ignition systems.

Advanced diagnostic tools and techniques have become essential in V8 engine repair. Computer-aided diagnostics, real-time data analysis, and precision measurement tools allow technicians to identify problems with greater accuracy and efficiency. This technological integration has transformed the repair process, enabling more precise and effective interventions.

The repair objectives also extend to improving engine performance and efficiency where possible. This may involve upgrading components, fine-tuning engine management systems, or implementing aftermarket solutions that enhance power output or fuel economy. However, these modifications must be balanced against reliability and compliance with environmental regulations.

As V8 engines continue to evolve, repair objectives are expanding to include the integration of new technologies. This includes working with hybrid systems, adapting to new fuel types, and understanding the complexities of advanced engine management computers. The goal is not just to fix what's broken, but to ensure that V8 engines remain viable and competitive in an increasingly technology-driven automotive landscape.

Throughout its history, the V8 engine has seen numerous advancements in materials, design, and technology. From early cast iron blocks to modern aluminum constructions, the pursuit of lighter, more durable engines has been a constant driving force. Fuel injection systems have replaced carburetors, improving efficiency and power output. Variable valve timing and cylinder deactivation technologies have further enhanced performance and fuel economy.

The evolution of V8 engines has also been influenced by environmental concerns and regulatory pressures. This has led to the development of more fuel-efficient designs, improved emissions control systems, and the integration of hybrid technologies in some V8 applications. As a result, modern V8 engines often combine high performance with relatively good fuel economy and reduced emissions.

In the context of repair objectives, the primary goals are to diagnose issues accurately, restore performance, and extend the engine's lifespan. This involves a comprehensive understanding of the engine's mechanical, electrical, and electronic systems. Repair procedures must address wear and tear on components such as pistons, valves, and bearings, as well as the intricate fuel and ignition systems.

Advanced diagnostic tools and techniques have become essential in V8 engine repair. Computer-aided diagnostics, real-time data analysis, and precision measurement tools allow technicians to identify problems with greater accuracy and efficiency. This technological integration has transformed the repair process, enabling more precise and effective interventions.

The repair objectives also extend to improving engine performance and efficiency where possible. This may involve upgrading components, fine-tuning engine management systems, or implementing aftermarket solutions that enhance power output or fuel economy. However, these modifications must be balanced against reliability and compliance with environmental regulations.

As V8 engines continue to evolve, repair objectives are expanding to include the integration of new technologies. This includes working with hybrid systems, adapting to new fuel types, and understanding the complexities of advanced engine management computers. The goal is not just to fix what's broken, but to ensure that V8 engines remain viable and competitive in an increasingly technology-driven automotive landscape.

Market Analysis for V8 Engine Repair Services

The V8 engine repair market has experienced significant growth in recent years, driven by the increasing number of vehicles equipped with V8 engines and the rising demand for high-performance automobiles. This market segment primarily caters to luxury cars, sports cars, and certain trucks, which often feature V8 engines for their power and performance characteristics.

Market research indicates that the global V8 engine repair services market is expected to grow steadily over the next five years. This growth is attributed to several factors, including the aging fleet of V8-equipped vehicles, the complexity of modern V8 engines requiring specialized repair services, and the ongoing popularity of V8-powered vehicles in certain regions and market segments.

The market for V8 engine repair services is geographically diverse, with strong demand in North America, Europe, and parts of Asia. North America, particularly the United States, remains a key market due to the historical popularity of V8 engines in muscle cars, trucks, and luxury vehicles. Europe sees significant demand in countries with a strong automotive industry and a preference for high-performance vehicles, such as Germany and the United Kingdom.

Consumer trends show an increasing willingness to invest in professional V8 engine repair services rather than opting for DIY solutions. This shift is driven by the growing complexity of modern V8 engines, which often incorporate advanced technologies like direct injection, variable valve timing, and cylinder deactivation. These technologies require specialized diagnostic equipment and expertise, making professional repair services more appealing to vehicle owners.

The market is characterized by a mix of service providers, including authorized dealerships, independent repair shops, and specialized performance tuning centers. Authorized dealerships often have an advantage in terms of access to proprietary diagnostic tools and manufacturer-specific training. However, independent repair shops and specialized centers are gaining market share by offering competitive pricing and expertise in performance modifications.

A notable trend in the V8 engine repair market is the growing demand for preventive maintenance services. As vehicle owners become more aware of the benefits of regular maintenance in extending engine life and maintaining performance, there is an increased focus on scheduled services and proactive repairs. This trend is particularly pronounced in the luxury and high-performance vehicle segments, where owners are more likely to invest in preserving their vehicles' value and performance.

Market research indicates that the global V8 engine repair services market is expected to grow steadily over the next five years. This growth is attributed to several factors, including the aging fleet of V8-equipped vehicles, the complexity of modern V8 engines requiring specialized repair services, and the ongoing popularity of V8-powered vehicles in certain regions and market segments.

The market for V8 engine repair services is geographically diverse, with strong demand in North America, Europe, and parts of Asia. North America, particularly the United States, remains a key market due to the historical popularity of V8 engines in muscle cars, trucks, and luxury vehicles. Europe sees significant demand in countries with a strong automotive industry and a preference for high-performance vehicles, such as Germany and the United Kingdom.

Consumer trends show an increasing willingness to invest in professional V8 engine repair services rather than opting for DIY solutions. This shift is driven by the growing complexity of modern V8 engines, which often incorporate advanced technologies like direct injection, variable valve timing, and cylinder deactivation. These technologies require specialized diagnostic equipment and expertise, making professional repair services more appealing to vehicle owners.

The market is characterized by a mix of service providers, including authorized dealerships, independent repair shops, and specialized performance tuning centers. Authorized dealerships often have an advantage in terms of access to proprietary diagnostic tools and manufacturer-specific training. However, independent repair shops and specialized centers are gaining market share by offering competitive pricing and expertise in performance modifications.

A notable trend in the V8 engine repair market is the growing demand for preventive maintenance services. As vehicle owners become more aware of the benefits of regular maintenance in extending engine life and maintaining performance, there is an increased focus on scheduled services and proactive repairs. This trend is particularly pronounced in the luxury and high-performance vehicle segments, where owners are more likely to invest in preserving their vehicles' value and performance.

Current V8 Engine Repair Challenges

V8 engine repair faces several significant challenges in the current automotive landscape. One of the primary issues is the increasing complexity of modern V8 engines, which incorporate advanced technologies such as direct injection, variable valve timing, and turbocharging. These sophisticated systems require specialized diagnostic tools and expertise to accurately identify and resolve problems, making repairs more time-consuming and costly.

The integration of electronic components and control modules in V8 engines presents another hurdle. Technicians must possess a deep understanding of both mechanical and electrical systems to effectively diagnose and repair issues. This dual expertise is not always readily available, leading to potential misdiagnoses or incomplete repairs.

Environmental regulations have also impacted V8 engine repair procedures. Stricter emissions standards necessitate more frequent maintenance and repairs to ensure compliance. This includes addressing issues related to exhaust gas recirculation systems, catalytic converters, and oxygen sensors, which can be complex and labor-intensive to repair or replace.

The availability of genuine parts for older V8 engines poses a challenge, particularly for classic or vintage vehicles. As manufacturers phase out production of certain components, technicians may struggle to source appropriate replacements, sometimes resorting to aftermarket parts that may not meet original equipment specifications.

Heat management is another critical concern in V8 engine repair. The high-performance nature of these engines often leads to increased thermal stress on components, resulting in premature wear or failure. Addressing heat-related issues requires careful consideration of cooling system design and the use of high-quality materials in repairs.

The trend towards lightweight materials in engine construction, such as aluminum alloys, introduces new repair challenges. These materials require specific handling and repair techniques to prevent damage during service, and technicians must be trained in these specialized procedures to ensure the integrity of the engine.

Lastly, the increasing prevalence of hybrid and electric vehicles has led to a shift in focus within the automotive industry. This trend has resulted in reduced investment and training opportunities for traditional V8 engine repair, potentially leading to a shortage of skilled technicians in the future. As a result, maintaining a high level of expertise in V8 engine repair may become more challenging as the automotive landscape continues to evolve.

The integration of electronic components and control modules in V8 engines presents another hurdle. Technicians must possess a deep understanding of both mechanical and electrical systems to effectively diagnose and repair issues. This dual expertise is not always readily available, leading to potential misdiagnoses or incomplete repairs.

Environmental regulations have also impacted V8 engine repair procedures. Stricter emissions standards necessitate more frequent maintenance and repairs to ensure compliance. This includes addressing issues related to exhaust gas recirculation systems, catalytic converters, and oxygen sensors, which can be complex and labor-intensive to repair or replace.

The availability of genuine parts for older V8 engines poses a challenge, particularly for classic or vintage vehicles. As manufacturers phase out production of certain components, technicians may struggle to source appropriate replacements, sometimes resorting to aftermarket parts that may not meet original equipment specifications.

Heat management is another critical concern in V8 engine repair. The high-performance nature of these engines often leads to increased thermal stress on components, resulting in premature wear or failure. Addressing heat-related issues requires careful consideration of cooling system design and the use of high-quality materials in repairs.

The trend towards lightweight materials in engine construction, such as aluminum alloys, introduces new repair challenges. These materials require specific handling and repair techniques to prevent damage during service, and technicians must be trained in these specialized procedures to ensure the integrity of the engine.

Lastly, the increasing prevalence of hybrid and electric vehicles has led to a shift in focus within the automotive industry. This trend has resulted in reduced investment and training opportunities for traditional V8 engine repair, potentially leading to a shortage of skilled technicians in the future. As a result, maintaining a high level of expertise in V8 engine repair may become more challenging as the automotive landscape continues to evolve.

Standard V8 Engine Repair Procedures

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously improved to enhance performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously improved to enhance performance and efficiency.

- Fuel Efficiency and Emissions Reduction: Modern V8 engines incorporate technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced engine management systems. Innovations in combustion chamber design and fuel delivery systems contribute to optimizing the air-fuel mixture and combustion process, resulting in improved performance and reduced environmental impact.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to increase power output and efficiency. These systems compress the intake air, allowing more fuel to be burned and generating more power from a smaller displacement engine. Advanced designs integrate intercoolers and variable geometry turbochargers to optimize performance across different operating conditions.

- Materials and Manufacturing Techniques: Advancements in materials science and manufacturing techniques have led to improvements in V8 engine construction. Lightweight alloys, composite materials, and advanced coatings are used to reduce engine weight, improve heat dissipation, and enhance durability. Precision manufacturing methods, such as 3D printing and advanced machining techniques, enable the production of complex engine components with tighter tolerances.

- Cooling and Lubrication Systems: Efficient cooling and lubrication systems are crucial for V8 engine performance and longevity. Innovations in these areas include advanced coolant formulations, precision oil delivery systems, and integrated thermal management solutions. Some designs incorporate oil jet cooling for pistons, variable displacement oil pumps, and sophisticated electronic control systems to optimize engine temperature and lubrication under various operating conditions.

02 Fuel Efficiency and Emissions Control

Modern V8 engines incorporate advanced technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Innovations in engine management systems and combustion processes aim to optimize performance while meeting stringent environmental regulations.Expand Specific Solutions03 Performance Enhancement and Tuning

Various methods and components are developed to enhance V8 engine performance. These include turbocharging, supercharging, intercooling, and high-flow intake and exhaust systems. Advanced materials and manufacturing techniques are employed to reduce weight, increase strength, and improve thermal efficiency of engine components.Expand Specific Solutions04 Cooling and Lubrication Systems

Effective cooling and lubrication are crucial for V8 engine performance and longevity. Innovations in coolant flow design, oil circulation systems, and heat management techniques are implemented to maintain optimal operating temperatures and reduce wear on engine components. Advanced materials and coatings are used to improve heat dissipation and reduce friction.Expand Specific Solutions05 Integration with Vehicle Systems

V8 engines are integrated with various vehicle systems to optimize overall performance and drivability. This includes advanced transmission systems, electronic stability control, traction control, and adaptive suspension systems. Innovations focus on improving the interaction between the engine and other vehicle components to enhance driving dynamics and efficiency.Expand Specific Solutions

Major V8 Engine Manufacturers and Repair Specialists

The V8 engine repair market is in a mature stage, characterized by established players and well-defined repair procedures. The global automotive repair and maintenance services market, which includes V8 engine repair, is projected to reach $810 billion by 2026. Technologically, V8 engine repair methods are well-developed, with companies like General Motors, BMW, and Honda leading in expertise. However, emerging trends in electric vehicles and hybrid powertrains are influencing the future of V8 engine maintenance. Companies such as Bosch and Siemens are investing in advanced diagnostic tools and repair techniques to keep pace with evolving engine technologies.

General Electric Company

Technical Solution: GE's V8 engine repair technology focuses on advanced diagnostics and predictive maintenance. They utilize IoT sensors and data analytics to monitor engine performance in real-time, allowing for early detection of potential issues[1]. Their repair procedures incorporate additive manufacturing for rapid production of replacement parts, reducing downtime[2]. GE also employs AI-driven repair planning systems that optimize the repair process based on historical data and current engine conditions[3]. Their methods include advanced non-destructive testing techniques such as computed tomography and ultrasonic imaging for precise fault detection[4].

Strengths: Cutting-edge diagnostics, predictive maintenance, and AI-driven repair planning. Weaknesses: High initial investment costs and potential over-reliance on technology.

Robert Bosch GmbH

Technical Solution: Bosch's V8 engine repair technology emphasizes precision and efficiency. They have developed a suite of advanced diagnostic tools that can quickly identify issues within the engine's complex systems[5]. Their repair procedures utilize robotics and automation for tasks such as disassembly and reassembly, ensuring consistency and reducing human error[6]. Bosch also employs advanced materials science in their repair solutions, including nano-coatings for improved wear resistance and thermal management[7]. Their methods incorporate augmented reality (AR) systems to guide technicians through complex repair procedures, enhancing accuracy and reducing repair times[8].

Strengths: High precision diagnostics, automated repair processes, and innovative materials. Weaknesses: Potential high costs for smaller repair shops to adopt the technology.

Innovative V8 Engine Repair Techniques

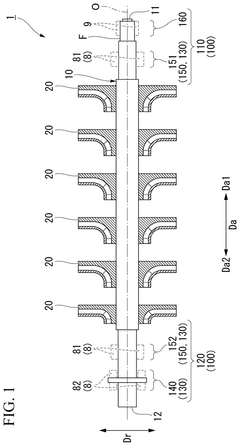

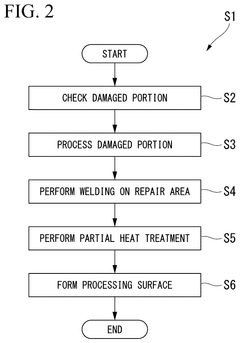

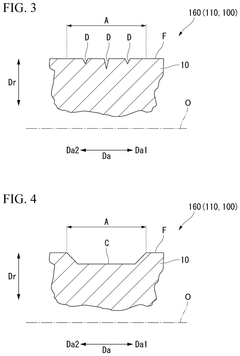

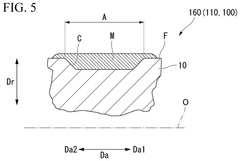

Repair method of rotor

PatentActiveUS20250033150A1

Innovation

- A repair method involving welding to fill damaged areas, followed by partial heat treatment only on the repair area, and finally scraping part of the welded portion to form a smooth processing surface connected to the outer surface.

Methods of repairing engine components

PatentActiveEP2082826A3

Innovation

- A method involving the application of a first braze alloy mixture with specific compositions, followed by a second braze alloy mixture, and subsequent heat treatment to melt and flow the alloys into structural features, restoring geometry and dimension, using a stepped heat cycle to ensure metallurgical binding and improved strength.

Environmental Impact of V8 Engine Repair

The environmental impact of V8 engine repair is a critical consideration in today's automotive industry. As vehicles with V8 engines continue to operate on roads worldwide, their maintenance and repair processes significantly contribute to environmental concerns. The repair of V8 engines involves various activities that can have both direct and indirect effects on the environment.

One of the primary environmental issues associated with V8 engine repair is the generation of hazardous waste. During the repair process, technicians often deal with used motor oil, coolants, and other fluids that contain harmful chemicals. Improper disposal of these substances can lead to soil and water contamination, posing risks to ecosystems and human health.

Air pollution is another significant concern in V8 engine repair. The process often involves the use of cleaning solvents and degreasers that release volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to smog formation and can have adverse effects on air quality, particularly in urban areas where repair shops are concentrated.

Energy consumption during V8 engine repair also has environmental implications. The use of power tools, diagnostic equipment, and facility lighting all contribute to increased electricity demand. This energy consumption indirectly leads to greenhouse gas emissions, especially in regions where electricity is primarily generated from fossil fuels.

The repair process may also involve the replacement of parts, which raises questions about resource consumption and waste management. Manufacturing new components requires raw materials and energy, while discarded parts contribute to the growing problem of electronic and mechanical waste. Proper recycling and disposal of these materials are essential to mitigate their environmental impact.

However, it's important to note that V8 engine repair can also have positive environmental effects. By extending the lifespan of existing vehicles, repair services reduce the demand for new vehicle production, which is a resource-intensive process. Additionally, well-maintained engines operate more efficiently, potentially reducing fuel consumption and emissions during vehicle operation.

Advancements in repair techniques and technologies are helping to address some of these environmental concerns. The development of eco-friendly cleaning solutions, more efficient diagnostic tools, and improved waste management practices in repair facilities are all contributing to reducing the environmental footprint of V8 engine repair.

In conclusion, while V8 engine repair presents several environmental challenges, ongoing efforts in the industry are aimed at minimizing these impacts. As environmental regulations become more stringent and public awareness grows, the automotive repair sector continues to evolve, seeking more sustainable practices in V8 engine maintenance and repair.

One of the primary environmental issues associated with V8 engine repair is the generation of hazardous waste. During the repair process, technicians often deal with used motor oil, coolants, and other fluids that contain harmful chemicals. Improper disposal of these substances can lead to soil and water contamination, posing risks to ecosystems and human health.

Air pollution is another significant concern in V8 engine repair. The process often involves the use of cleaning solvents and degreasers that release volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to smog formation and can have adverse effects on air quality, particularly in urban areas where repair shops are concentrated.

Energy consumption during V8 engine repair also has environmental implications. The use of power tools, diagnostic equipment, and facility lighting all contribute to increased electricity demand. This energy consumption indirectly leads to greenhouse gas emissions, especially in regions where electricity is primarily generated from fossil fuels.

The repair process may also involve the replacement of parts, which raises questions about resource consumption and waste management. Manufacturing new components requires raw materials and energy, while discarded parts contribute to the growing problem of electronic and mechanical waste. Proper recycling and disposal of these materials are essential to mitigate their environmental impact.

However, it's important to note that V8 engine repair can also have positive environmental effects. By extending the lifespan of existing vehicles, repair services reduce the demand for new vehicle production, which is a resource-intensive process. Additionally, well-maintained engines operate more efficiently, potentially reducing fuel consumption and emissions during vehicle operation.

Advancements in repair techniques and technologies are helping to address some of these environmental concerns. The development of eco-friendly cleaning solutions, more efficient diagnostic tools, and improved waste management practices in repair facilities are all contributing to reducing the environmental footprint of V8 engine repair.

In conclusion, while V8 engine repair presents several environmental challenges, ongoing efforts in the industry are aimed at minimizing these impacts. As environmental regulations become more stringent and public awareness grows, the automotive repair sector continues to evolve, seeking more sustainable practices in V8 engine maintenance and repair.

V8 Engine Diagnostics and Troubleshooting

V8 engine diagnostics and troubleshooting are critical aspects of engine repair and maintenance. These processes involve systematic approaches to identify and resolve issues affecting V8 engine performance, efficiency, and longevity. The first step in diagnostics is typically a thorough visual inspection, checking for obvious signs of wear, damage, or leaks. This is followed by the use of advanced diagnostic tools, such as OBD-II scanners, to read engine codes and gather real-time data on various engine parameters.

One of the primary diagnostic methods involves analyzing engine performance data. This includes monitoring fuel trim levels, oxygen sensor readings, and mass airflow sensor outputs. Abnormalities in these readings can indicate issues with fuel delivery, air intake, or exhaust systems. Compression testing is another crucial diagnostic procedure, helping to assess the condition of engine cylinders, pistons, and valves. Low compression in one or more cylinders often points to internal engine damage or wear.

Vacuum testing is also a valuable diagnostic tool for V8 engines. By measuring engine vacuum at idle and under various operating conditions, technicians can identify issues related to valve timing, piston ring sealing, and overall engine efficiency. Additionally, cylinder balance tests, which involve disabling individual cylinders and observing the effect on engine performance, can help isolate problems to specific cylinders or components.

For more complex issues, advanced techniques such as cylinder leakage testing and borescope inspections may be employed. These methods allow for a more detailed examination of internal engine components without the need for complete disassembly. Electrical system diagnostics are equally important, involving the testing of the battery, alternator, and starter, as well as examining the ignition system components like spark plugs, coils, and wires.

Troubleshooting often follows a logical progression based on the symptoms observed and the data collected during diagnostics. Common V8 engine issues include misfires, rough idling, loss of power, and excessive oil consumption. Each of these symptoms can have multiple potential causes, requiring a systematic approach to isolate and address the root problem. For instance, a misfire could be caused by a faulty spark plug, a clogged fuel injector, or a more serious internal engine issue.

In conclusion, effective V8 engine diagnostics and troubleshooting require a combination of technical knowledge, experience, and the proper use of diagnostic tools. By following a structured approach and utilizing both traditional and advanced diagnostic techniques, technicians can accurately identify and resolve a wide range of V8 engine issues, ensuring optimal performance and longevity of these powerful engines.

One of the primary diagnostic methods involves analyzing engine performance data. This includes monitoring fuel trim levels, oxygen sensor readings, and mass airflow sensor outputs. Abnormalities in these readings can indicate issues with fuel delivery, air intake, or exhaust systems. Compression testing is another crucial diagnostic procedure, helping to assess the condition of engine cylinders, pistons, and valves. Low compression in one or more cylinders often points to internal engine damage or wear.

Vacuum testing is also a valuable diagnostic tool for V8 engines. By measuring engine vacuum at idle and under various operating conditions, technicians can identify issues related to valve timing, piston ring sealing, and overall engine efficiency. Additionally, cylinder balance tests, which involve disabling individual cylinders and observing the effect on engine performance, can help isolate problems to specific cylinders or components.

For more complex issues, advanced techniques such as cylinder leakage testing and borescope inspections may be employed. These methods allow for a more detailed examination of internal engine components without the need for complete disassembly. Electrical system diagnostics are equally important, involving the testing of the battery, alternator, and starter, as well as examining the ignition system components like spark plugs, coils, and wires.

Troubleshooting often follows a logical progression based on the symptoms observed and the data collected during diagnostics. Common V8 engine issues include misfires, rough idling, loss of power, and excessive oil consumption. Each of these symptoms can have multiple potential causes, requiring a systematic approach to isolate and address the root problem. For instance, a misfire could be caused by a faulty spark plug, a clogged fuel injector, or a more serious internal engine issue.

In conclusion, effective V8 engine diagnostics and troubleshooting require a combination of technical knowledge, experience, and the proper use of diagnostic tools. By following a structured approach and utilizing both traditional and advanced diagnostic techniques, technicians can accurately identify and resolve a wide range of V8 engine issues, ensuring optimal performance and longevity of these powerful engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!