The Role of V8 Engines in Energy Efficient Vehicles

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception in the early 20th century. Initially designed for high-performance applications, V8 engines have gradually adapted to meet the growing demands for energy efficiency in modern vehicles. This evolution can be traced through several key stages, each marked by technological advancements and shifting market priorities.

In the early days, V8 engines were primarily focused on power output, with little regard for fuel efficiency. The 1950s and 1960s saw the golden age of American muscle cars, where large-displacement V8 engines dominated the market. However, the oil crisis of the 1970s sparked a paradigm shift, forcing manufacturers to reconsider their approach to engine design.

The 1980s and 1990s witnessed the introduction of electronic fuel injection and computer-controlled engine management systems. These technologies allowed for more precise control over fuel delivery and ignition timing, resulting in improved efficiency without sacrificing performance. Concurrently, materials science advancements led to the development of lighter engine components, further enhancing overall vehicle efficiency.

The turn of the millennium brought about a renewed focus on environmental concerns and stricter emissions regulations. This prompted engine designers to explore innovative solutions such as variable valve timing, cylinder deactivation, and direct fuel injection. These technologies enabled V8 engines to operate more efficiently under varying load conditions, effectively bridging the gap between performance and economy.

In recent years, the push for energy efficiency has intensified, leading to the integration of hybrid and mild-hybrid systems with V8 engines. These setups utilize electric motors to supplement the internal combustion engine, allowing for improved fuel economy in urban driving scenarios while maintaining the characteristic power of a V8 for high-performance applications.

The latest developments in V8 engine technology include advanced turbocharging systems, which allow for engine downsizing without compromising power output. Additionally, the implementation of start-stop technology and regenerative braking systems has further enhanced the energy efficiency of vehicles equipped with V8 engines.

Looking ahead, the evolution of V8 engines is likely to continue along the path of increased electrification and integration with alternative fuel technologies. While the traditional V8 configuration may see reduced prevalence in mainstream vehicles, its legacy of power and performance ensures its continued relevance in specialized applications and high-end vehicles, albeit in increasingly efficient forms.

In the early days, V8 engines were primarily focused on power output, with little regard for fuel efficiency. The 1950s and 1960s saw the golden age of American muscle cars, where large-displacement V8 engines dominated the market. However, the oil crisis of the 1970s sparked a paradigm shift, forcing manufacturers to reconsider their approach to engine design.

The 1980s and 1990s witnessed the introduction of electronic fuel injection and computer-controlled engine management systems. These technologies allowed for more precise control over fuel delivery and ignition timing, resulting in improved efficiency without sacrificing performance. Concurrently, materials science advancements led to the development of lighter engine components, further enhancing overall vehicle efficiency.

The turn of the millennium brought about a renewed focus on environmental concerns and stricter emissions regulations. This prompted engine designers to explore innovative solutions such as variable valve timing, cylinder deactivation, and direct fuel injection. These technologies enabled V8 engines to operate more efficiently under varying load conditions, effectively bridging the gap between performance and economy.

In recent years, the push for energy efficiency has intensified, leading to the integration of hybrid and mild-hybrid systems with V8 engines. These setups utilize electric motors to supplement the internal combustion engine, allowing for improved fuel economy in urban driving scenarios while maintaining the characteristic power of a V8 for high-performance applications.

The latest developments in V8 engine technology include advanced turbocharging systems, which allow for engine downsizing without compromising power output. Additionally, the implementation of start-stop technology and regenerative braking systems has further enhanced the energy efficiency of vehicles equipped with V8 engines.

Looking ahead, the evolution of V8 engines is likely to continue along the path of increased electrification and integration with alternative fuel technologies. While the traditional V8 configuration may see reduced prevalence in mainstream vehicles, its legacy of power and performance ensures its continued relevance in specialized applications and high-end vehicles, albeit in increasingly efficient forms.

Market Demand Analysis

The market demand for V8 engines in energy-efficient vehicles has undergone significant shifts in recent years. Traditionally, V8 engines were synonymous with high-performance vehicles, prized for their power and acceleration capabilities. However, the automotive industry's focus on fuel efficiency and environmental sustainability has led to a reevaluation of the V8's role in modern vehicles.

Despite the overall trend towards downsizing and electrification, there remains a niche market for V8-powered vehicles that combine performance with improved fuel economy. This demand is primarily driven by enthusiasts and luxury vehicle buyers who seek the distinctive sound and power delivery of a V8 engine, but also desire better fuel efficiency.

The market for V8 engines in energy-efficient vehicles is largely concentrated in the premium and sports car segments. Manufacturers have responded by developing advanced V8 engines that incorporate technologies such as cylinder deactivation, direct injection, and variable valve timing to improve fuel economy without sacrificing performance.

In the United States, which has historically been a strong market for V8-powered vehicles, there has been a gradual decline in V8 engine sales. However, this decline has been partially offset by increased demand in emerging markets, particularly in the Middle East and China, where luxury vehicles with powerful engines are still highly sought after.

The truck and SUV market continues to be a significant driver for V8 engine demand. Many consumers in this segment prioritize towing capacity and acceleration, areas where V8 engines excel. As a result, manufacturers have focused on developing more efficient V8 engines specifically for these vehicle types.

Looking at future trends, the market for V8 engines in energy-efficient vehicles is expected to face increasing pressure from stricter emissions regulations and the rise of electric vehicles. However, there is potential for growth in hybrid powertrains that combine V8 engines with electric motors, offering a compromise between performance and efficiency.

The aftermarket sector also plays a role in sustaining demand for V8 engines. Performance enthusiasts continue to seek out V8 engines for modifications and custom builds, driving a secondary market for these powerplants.

In conclusion, while the overall automotive market is shifting towards smaller, more efficient engines and electrification, there remains a dedicated segment of consumers who value the unique characteristics of V8 engines. The challenge for manufacturers is to continue innovating and improving the efficiency of V8 engines to meet both consumer demands and regulatory requirements in the evolving landscape of energy-efficient vehicles.

Despite the overall trend towards downsizing and electrification, there remains a niche market for V8-powered vehicles that combine performance with improved fuel economy. This demand is primarily driven by enthusiasts and luxury vehicle buyers who seek the distinctive sound and power delivery of a V8 engine, but also desire better fuel efficiency.

The market for V8 engines in energy-efficient vehicles is largely concentrated in the premium and sports car segments. Manufacturers have responded by developing advanced V8 engines that incorporate technologies such as cylinder deactivation, direct injection, and variable valve timing to improve fuel economy without sacrificing performance.

In the United States, which has historically been a strong market for V8-powered vehicles, there has been a gradual decline in V8 engine sales. However, this decline has been partially offset by increased demand in emerging markets, particularly in the Middle East and China, where luxury vehicles with powerful engines are still highly sought after.

The truck and SUV market continues to be a significant driver for V8 engine demand. Many consumers in this segment prioritize towing capacity and acceleration, areas where V8 engines excel. As a result, manufacturers have focused on developing more efficient V8 engines specifically for these vehicle types.

Looking at future trends, the market for V8 engines in energy-efficient vehicles is expected to face increasing pressure from stricter emissions regulations and the rise of electric vehicles. However, there is potential for growth in hybrid powertrains that combine V8 engines with electric motors, offering a compromise between performance and efficiency.

The aftermarket sector also plays a role in sustaining demand for V8 engines. Performance enthusiasts continue to seek out V8 engines for modifications and custom builds, driving a secondary market for these powerplants.

In conclusion, while the overall automotive market is shifting towards smaller, more efficient engines and electrification, there remains a dedicated segment of consumers who value the unique characteristics of V8 engines. The challenge for manufacturers is to continue innovating and improving the efficiency of V8 engines to meet both consumer demands and regulatory requirements in the evolving landscape of energy-efficient vehicles.

Technical Challenges

The integration of V8 engines in energy-efficient vehicles presents several significant technical challenges. One of the primary obstacles is balancing power output with fuel efficiency. V8 engines are traditionally known for their high performance and power, but this often comes at the cost of increased fuel consumption. Engineers must develop innovative solutions to optimize combustion processes and reduce energy losses while maintaining the characteristic power and torque of V8 engines.

Another major challenge lies in weight reduction. V8 engines are typically heavier than smaller engine configurations, which can negatively impact overall vehicle efficiency. Manufacturers are exploring advanced materials and design techniques to minimize engine weight without compromising structural integrity or performance. This includes the use of lightweight alloys, composite materials, and optimized component designs.

Emissions control poses a substantial technical hurdle for V8 engines in energy-efficient vehicles. Stricter environmental regulations require significant reductions in greenhouse gas emissions and pollutants. Engineers must develop advanced exhaust aftertreatment systems, improve catalytic converter efficiency, and implement sophisticated engine management systems to meet these stringent requirements while preserving the V8's performance characteristics.

Thermal management is another critical challenge. V8 engines generate considerable heat, which can affect overall efficiency and component longevity. Developing effective cooling systems that can dissipate heat quickly and efficiently, without adding excessive weight or complexity to the vehicle, is crucial. This may involve advanced coolant formulations, innovative radiator designs, and intelligent thermal management strategies.

The integration of hybrid and electric technologies with V8 engines presents both opportunities and challenges. While hybridization can potentially offset some of the efficiency drawbacks of V8 engines, it introduces complexity in terms of system integration, power management, and packaging. Engineers must develop sophisticated control algorithms to seamlessly blend electric and combustion power sources, optimize energy recovery systems, and manage the additional weight of batteries and electric motors.

Noise, vibration, and harshness (NVH) control is another area of focus. V8 engines are known for their distinctive sound, which is often desirable in performance vehicles. However, in the context of energy-efficient vehicles, excessive noise and vibration can be perceived negatively and may increase energy consumption. Developing solutions that maintain the V8's characteristic sound while minimizing unwanted NVH effects requires advanced acoustic engineering and vibration damping technologies.

Lastly, the challenge of cost-effectiveness cannot be overlooked. Implementing advanced technologies to make V8 engines more energy-efficient often comes with increased production costs. Balancing these costs with market demands and regulatory requirements while maintaining profitability is a significant challenge for manufacturers. This necessitates innovative manufacturing processes, supply chain optimization, and strategic product positioning to justify the inclusion of V8 engines in energy-efficient vehicle lineups.

Another major challenge lies in weight reduction. V8 engines are typically heavier than smaller engine configurations, which can negatively impact overall vehicle efficiency. Manufacturers are exploring advanced materials and design techniques to minimize engine weight without compromising structural integrity or performance. This includes the use of lightweight alloys, composite materials, and optimized component designs.

Emissions control poses a substantial technical hurdle for V8 engines in energy-efficient vehicles. Stricter environmental regulations require significant reductions in greenhouse gas emissions and pollutants. Engineers must develop advanced exhaust aftertreatment systems, improve catalytic converter efficiency, and implement sophisticated engine management systems to meet these stringent requirements while preserving the V8's performance characteristics.

Thermal management is another critical challenge. V8 engines generate considerable heat, which can affect overall efficiency and component longevity. Developing effective cooling systems that can dissipate heat quickly and efficiently, without adding excessive weight or complexity to the vehicle, is crucial. This may involve advanced coolant formulations, innovative radiator designs, and intelligent thermal management strategies.

The integration of hybrid and electric technologies with V8 engines presents both opportunities and challenges. While hybridization can potentially offset some of the efficiency drawbacks of V8 engines, it introduces complexity in terms of system integration, power management, and packaging. Engineers must develop sophisticated control algorithms to seamlessly blend electric and combustion power sources, optimize energy recovery systems, and manage the additional weight of batteries and electric motors.

Noise, vibration, and harshness (NVH) control is another area of focus. V8 engines are known for their distinctive sound, which is often desirable in performance vehicles. However, in the context of energy-efficient vehicles, excessive noise and vibration can be perceived negatively and may increase energy consumption. Developing solutions that maintain the V8's characteristic sound while minimizing unwanted NVH effects requires advanced acoustic engineering and vibration damping technologies.

Lastly, the challenge of cost-effectiveness cannot be overlooked. Implementing advanced technologies to make V8 engines more energy-efficient often comes with increased production costs. Balancing these costs with market demands and regulatory requirements while maintaining profitability is a significant challenge for manufacturers. This necessitates innovative manufacturing processes, supply chain optimization, and strategic product positioning to justify the inclusion of V8 engines in energy-efficient vehicle lineups.

Current V8 Solutions

01 Improved combustion efficiency

V8 engines can achieve better energy efficiency through optimized combustion processes. This includes advanced fuel injection systems, improved air-fuel mixture control, and enhanced combustion chamber designs. These improvements lead to more complete fuel burning, reduced emissions, and increased overall engine performance.- Improved fuel efficiency in V8 engines: Various technologies are employed to enhance the fuel efficiency of V8 engines. These include advanced fuel injection systems, variable valve timing, and cylinder deactivation. Such improvements allow V8 engines to maintain their power output while reducing fuel consumption, making them more environmentally friendly and cost-effective.

- Engine management systems for V8 optimization: Sophisticated engine management systems are developed to optimize V8 engine performance and efficiency. These systems use sensors and advanced algorithms to control various engine parameters in real-time, such as fuel injection timing, ignition timing, and air-fuel ratio. This results in improved energy efficiency across different operating conditions.

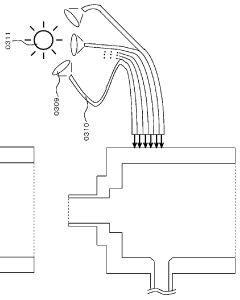

- Hybrid and electric technologies integration with V8 engines: Integration of hybrid and electric technologies with V8 engines is explored to boost overall energy efficiency. This includes the development of hybrid powertrains that combine V8 engines with electric motors, as well as start-stop systems that shut off the engine during idle periods. These innovations significantly reduce fuel consumption in urban driving conditions.

- Aerodynamic improvements for vehicles with V8 engines: Aerodynamic enhancements are implemented in vehicles equipped with V8 engines to reduce drag and improve overall energy efficiency. This includes redesigning vehicle bodies, adding aerodynamic features, and optimizing underbody airflow. These improvements help to decrease the power required to overcome air resistance, thereby increasing fuel efficiency.

- Weight reduction strategies for V8-powered vehicles: Various weight reduction strategies are employed in vehicles with V8 engines to improve energy efficiency. This includes the use of lightweight materials such as aluminum and carbon fiber in engine components and vehicle structures. Reducing the overall weight of the vehicle decreases the power required for acceleration and maintaining speed, leading to improved fuel economy.

02 Variable displacement technology

Implementing variable displacement technology in V8 engines allows for selective deactivation of cylinders during low-load conditions. This reduces fuel consumption and improves energy efficiency by operating the engine with fewer active cylinders when full power is not required, while maintaining the ability to utilize all eight cylinders when needed.Expand Specific Solutions03 Advanced engine management systems

Sophisticated engine management systems utilize sensors and computer controls to optimize V8 engine performance and efficiency. These systems can adjust various parameters such as ignition timing, fuel injection, and valve timing in real-time, based on driving conditions and engine load, to maximize energy efficiency and reduce fuel consumption.Expand Specific Solutions04 Lightweight materials and design

Incorporating lightweight materials and innovative design techniques in V8 engine construction can significantly improve energy efficiency. The use of materials such as aluminum alloys and composite materials reduces overall engine weight, leading to improved power-to-weight ratios and reduced fuel consumption.Expand Specific Solutions05 Hybrid and electrification integration

Integrating hybrid and electrification technologies with V8 engines can substantially enhance energy efficiency. This approach combines the power of a V8 engine with electric motors and battery systems, allowing for regenerative braking, electric-only operation at low speeds, and improved overall fuel economy without sacrificing performance.Expand Specific Solutions

Key Industry Players

The competitive landscape for V8 engines in energy-efficient vehicles is evolving as the industry transitions towards more sustainable solutions. The market is in a mature phase, with established players like Toyota, Ford, GM, and BMW leading innovation. However, the market size for V8 engines in this segment is likely shrinking due to increasing focus on electrification and downsizing. Technologically, companies are exploring ways to improve V8 efficiency through advanced materials, cylinder deactivation, and hybridization. Emerging players like Turntide Technologies are also disrupting the space with novel electric motor technologies, challenging traditional V8 manufacturers to adapt or risk obsolescence in the energy-efficient vehicle market.

Toyota Motor Corp.

Technical Solution: Toyota has developed a high-efficiency V8 engine for their luxury vehicles, focusing on both performance and fuel economy. Their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology combines direct and port fuel injection, optimizing fuel delivery based on driving conditions[1]. The engine features variable valve timing with intelligence (VVT-i) on both intake and exhaust camshafts, allowing for precise control over valve timing to improve efficiency across a wide range of engine speeds[2]. Additionally, Toyota has implemented cylinder deactivation technology, which can shut down four cylinders during light load conditions, significantly reducing fuel consumption[3].

Strengths: Advanced fuel injection system, variable valve timing, and cylinder deactivation technology improve fuel efficiency. Weaknesses: V8 engines are inherently less fuel-efficient than smaller engines, limiting their role in highly energy-efficient vehicles.

Ford Global Technologies LLC

Technical Solution: Ford has developed the 5.0L Coyote V8 engine with advanced technologies to improve energy efficiency. The engine features dual overhead camshafts (DOHC) with variable camshaft timing (VCT) for both intake and exhaust valves, allowing for optimized engine breathing and reduced pumping losses[4]. Ford has also implemented direct fuel injection, which improves fuel atomization and allows for higher compression ratios, enhancing both power output and fuel efficiency[5]. The company's plasma transferred wire arc (PTWA) cylinder coating technology reduces friction and improves heat transfer, further contributing to efficiency gains[6]. Additionally, Ford has explored cylinder deactivation and start-stop technology for their V8 engines to reduce fuel consumption during light load and idle conditions.

Strengths: Advanced valve control, direct injection, and friction-reducing technologies improve efficiency. Weaknesses: The large displacement still results in higher fuel consumption compared to smaller engines, limiting its use in ultra-efficient vehicles.

Core V8 Innovations

Engine

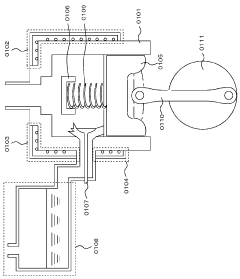

PatentWO2009144827A1

Innovation

- An engine design that uses external heat to induce a vapor explosion in a cylinder, utilizing the explosion pressure as a driving force, with features like a conical or dome-shaped cylinder and piston head, vapor film management, and a simpler exhaust valve mechanism to minimize fuel consumption and emissions.

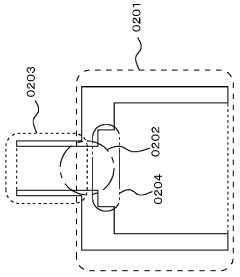

Drive train arrangement for a vehicle

PatentInactiveEP2276657A1

Innovation

- A drivetrain arrangement featuring an internal combustion engine coupled to an automatic transmission with a direct gear ratio and an additional power source, such as an electric machine, to provide a power reserve and optimize fuel efficiency by maintaining or improving driving comfort and reducing shifting needs.

Emissions Regulations

Emissions regulations have played a crucial role in shaping the automotive industry, particularly in the context of V8 engines and energy-efficient vehicles. These regulations, implemented by governments worldwide, aim to reduce harmful emissions and improve air quality. The impact on V8 engines has been significant, as these powerful but traditionally fuel-intensive powerplants have faced increasing scrutiny.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind emissions reduction efforts. These standards set specific fuel efficiency targets for automakers' vehicle fleets, indirectly influencing the viability of V8 engines in mainstream vehicles. Similarly, the European Union has implemented stringent CO2 emissions targets, pushing manufacturers to adopt more efficient technologies or face substantial fines.

The evolution of emissions regulations has led to a technological arms race among automakers. V8 engine manufacturers have been compelled to innovate, developing advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies to improve efficiency while maintaining performance. These advancements have allowed V8 engines to remain relevant in certain market segments, particularly in luxury vehicles and high-performance sports cars.

However, the regulatory landscape continues to tighten. Many countries have announced plans to phase out internal combustion engines entirely in favor of electric vehicles. This shift poses a significant challenge for V8 engines, as their inherent design makes it difficult to meet increasingly strict emissions standards without substantial modifications or hybridization.

The impact of emissions regulations on V8 engines in energy-efficient vehicles has been multifaceted. While some manufacturers have chosen to downsize their engines or switch to smaller turbocharged options, others have invested heavily in electrification. This has led to the development of hybrid V8 powertrains, which combine the traditional appeal of a V8 engine with electric motors to boost efficiency and reduce emissions.

Looking ahead, the future of V8 engines in the context of emissions regulations remains uncertain. As governments worldwide push for greater reductions in greenhouse gas emissions, the pressure on high-displacement engines will only increase. Manufacturers will need to continue innovating to ensure V8 engines can meet these stringent requirements while still delivering the performance and character that enthusiasts demand.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind emissions reduction efforts. These standards set specific fuel efficiency targets for automakers' vehicle fleets, indirectly influencing the viability of V8 engines in mainstream vehicles. Similarly, the European Union has implemented stringent CO2 emissions targets, pushing manufacturers to adopt more efficient technologies or face substantial fines.

The evolution of emissions regulations has led to a technological arms race among automakers. V8 engine manufacturers have been compelled to innovate, developing advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies to improve efficiency while maintaining performance. These advancements have allowed V8 engines to remain relevant in certain market segments, particularly in luxury vehicles and high-performance sports cars.

However, the regulatory landscape continues to tighten. Many countries have announced plans to phase out internal combustion engines entirely in favor of electric vehicles. This shift poses a significant challenge for V8 engines, as their inherent design makes it difficult to meet increasingly strict emissions standards without substantial modifications or hybridization.

The impact of emissions regulations on V8 engines in energy-efficient vehicles has been multifaceted. While some manufacturers have chosen to downsize their engines or switch to smaller turbocharged options, others have invested heavily in electrification. This has led to the development of hybrid V8 powertrains, which combine the traditional appeal of a V8 engine with electric motors to boost efficiency and reduce emissions.

Looking ahead, the future of V8 engines in the context of emissions regulations remains uncertain. As governments worldwide push for greater reductions in greenhouse gas emissions, the pressure on high-displacement engines will only increase. Manufacturers will need to continue innovating to ensure V8 engines can meet these stringent requirements while still delivering the performance and character that enthusiasts demand.

Hybrid V8 Systems

Hybrid V8 systems represent a significant advancement in the pursuit of energy-efficient vehicles, combining the power and performance of traditional V8 engines with the fuel economy benefits of hybrid technology. These systems typically integrate an electric motor and battery pack with a V8 internal combustion engine, allowing for improved fuel efficiency and reduced emissions without sacrificing the characteristic power and sound that V8 enthusiasts appreciate.

The core principle behind hybrid V8 systems is the ability to utilize electric power for low-speed driving and assist the combustion engine during acceleration, effectively reducing fuel consumption in urban environments and during stop-and-go traffic. During highway cruising, the V8 engine takes over, providing the necessary power for sustained high-speed travel. This dual-mode operation allows for a balance between performance and efficiency that was previously difficult to achieve with conventional V8 engines alone.

One of the key components in hybrid V8 systems is the power-split device, which allows for seamless transitions between electric and combustion power sources. This device, often a planetary gear set, enables the engine and electric motor to work together in various combinations, optimizing power delivery and efficiency based on driving conditions. Additionally, regenerative braking systems are employed to capture and store energy that would otherwise be lost during deceleration, further improving overall efficiency.

Advanced engine management systems play a crucial role in hybrid V8 setups, continuously adjusting the power distribution between the electric motor and combustion engine to maximize efficiency. These systems often incorporate predictive algorithms that analyze driving patterns, road conditions, and even GPS data to optimize power usage and battery management.

The integration of hybrid technology with V8 engines has led to innovative designs in thermal management. Cooling systems must be carefully engineered to handle both the high heat output of the V8 engine and the specific cooling requirements of the electric components. This often results in dual cooling circuits and advanced heat exchanger designs to ensure optimal operating temperatures for all system components.

While hybrid V8 systems offer significant improvements in fuel efficiency, they also present challenges in terms of weight management and packaging. The addition of electric motors, batteries, and associated control systems can add considerable mass to a vehicle, potentially offsetting some of the efficiency gains. As a result, manufacturers are increasingly focusing on lightweight materials and compact designs to mitigate these effects and maintain the performance characteristics expected from V8-powered vehicles.

The core principle behind hybrid V8 systems is the ability to utilize electric power for low-speed driving and assist the combustion engine during acceleration, effectively reducing fuel consumption in urban environments and during stop-and-go traffic. During highway cruising, the V8 engine takes over, providing the necessary power for sustained high-speed travel. This dual-mode operation allows for a balance between performance and efficiency that was previously difficult to achieve with conventional V8 engines alone.

One of the key components in hybrid V8 systems is the power-split device, which allows for seamless transitions between electric and combustion power sources. This device, often a planetary gear set, enables the engine and electric motor to work together in various combinations, optimizing power delivery and efficiency based on driving conditions. Additionally, regenerative braking systems are employed to capture and store energy that would otherwise be lost during deceleration, further improving overall efficiency.

Advanced engine management systems play a crucial role in hybrid V8 setups, continuously adjusting the power distribution between the electric motor and combustion engine to maximize efficiency. These systems often incorporate predictive algorithms that analyze driving patterns, road conditions, and even GPS data to optimize power usage and battery management.

The integration of hybrid technology with V8 engines has led to innovative designs in thermal management. Cooling systems must be carefully engineered to handle both the high heat output of the V8 engine and the specific cooling requirements of the electric components. This often results in dual cooling circuits and advanced heat exchanger designs to ensure optimal operating temperatures for all system components.

While hybrid V8 systems offer significant improvements in fuel efficiency, they also present challenges in terms of weight management and packaging. The addition of electric motors, batteries, and associated control systems can add considerable mass to a vehicle, potentially offsetting some of the efficiency gains. As a result, manufacturers are increasingly focusing on lightweight materials and compact designs to mitigate these effects and maintain the performance characteristics expected from V8-powered vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!