How V8 Engines Optimize Performance for Towing?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Towing Evolution

The evolution of V8 engines for towing performance has been a journey of continuous innovation and refinement. In the early days of automotive engineering, V8 engines were primarily designed for power and speed, with towing capabilities being a secondary consideration. However, as consumer demands shifted and the popularity of trucks and SUVs grew, manufacturers began to focus on optimizing V8 engines specifically for towing applications.

The 1960s and 1970s saw the introduction of high-displacement V8 engines, which provided the raw power needed for towing but often at the expense of fuel efficiency. These engines typically ranged from 5.0 to 7.5 liters in displacement and relied on carburetors for fuel delivery. While effective for towing, they were not optimized for the specific demands of hauling heavy loads.

The 1980s marked a significant turning point in V8 engine development for towing. With the introduction of electronic fuel injection systems, engineers gained greater control over fuel delivery and combustion timing. This allowed for more precise tuning of engines to meet the unique demands of towing, such as maintaining consistent power output under varying load conditions.

The 1990s and early 2000s saw further advancements in V8 engine technology for towing applications. Variable valve timing systems were introduced, allowing engines to optimize performance across a wider range of operating conditions. Additionally, improvements in materials science led to the development of lighter, stronger engine components, enabling higher compression ratios and increased durability.

In recent years, the focus has shifted towards achieving a balance between power and efficiency. Modern V8 engines designed for towing now incorporate technologies such as direct fuel injection, turbocharging, and cylinder deactivation. These innovations allow engines to deliver substantial towing capacity while also improving fuel economy during normal driving conditions.

The latest generation of V8 engines optimized for towing also features advanced electronic control systems. These systems continuously monitor engine performance, load conditions, and environmental factors to adjust engine parameters in real-time. This level of adaptive control ensures optimal performance and efficiency across a wide range of towing scenarios.

Looking ahead, the evolution of V8 engines for towing is likely to continue with a focus on further improving efficiency and reducing emissions. Technologies such as mild hybrid systems and advanced thermal management are being explored to enhance towing capabilities while meeting increasingly stringent environmental regulations.

The 1960s and 1970s saw the introduction of high-displacement V8 engines, which provided the raw power needed for towing but often at the expense of fuel efficiency. These engines typically ranged from 5.0 to 7.5 liters in displacement and relied on carburetors for fuel delivery. While effective for towing, they were not optimized for the specific demands of hauling heavy loads.

The 1980s marked a significant turning point in V8 engine development for towing. With the introduction of electronic fuel injection systems, engineers gained greater control over fuel delivery and combustion timing. This allowed for more precise tuning of engines to meet the unique demands of towing, such as maintaining consistent power output under varying load conditions.

The 1990s and early 2000s saw further advancements in V8 engine technology for towing applications. Variable valve timing systems were introduced, allowing engines to optimize performance across a wider range of operating conditions. Additionally, improvements in materials science led to the development of lighter, stronger engine components, enabling higher compression ratios and increased durability.

In recent years, the focus has shifted towards achieving a balance between power and efficiency. Modern V8 engines designed for towing now incorporate technologies such as direct fuel injection, turbocharging, and cylinder deactivation. These innovations allow engines to deliver substantial towing capacity while also improving fuel economy during normal driving conditions.

The latest generation of V8 engines optimized for towing also features advanced electronic control systems. These systems continuously monitor engine performance, load conditions, and environmental factors to adjust engine parameters in real-time. This level of adaptive control ensures optimal performance and efficiency across a wide range of towing scenarios.

Looking ahead, the evolution of V8 engines for towing is likely to continue with a focus on further improving efficiency and reducing emissions. Technologies such as mild hybrid systems and advanced thermal management are being explored to enhance towing capabilities while meeting increasingly stringent environmental regulations.

Towing Market Analysis

The towing market has experienced significant growth in recent years, driven by increasing demand for recreational vehicles, boats, and trailers. This trend is particularly evident in North America, where outdoor activities and road trips have gained popularity. The global towing vehicle market was valued at $26.5 billion in 2020 and is projected to reach $38.2 billion by 2027, growing at a CAGR of 5.3% during the forecast period.

The market for towing vehicles is segmented based on vehicle type, including passenger cars, light commercial vehicles, and heavy commercial vehicles. Among these, light commercial vehicles, particularly pickup trucks, dominate the market due to their versatility and towing capabilities. The increasing adoption of SUVs and crossovers with towing capabilities has also contributed to market growth.

In terms of regional analysis, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, has a strong towing culture, with millions of households owning recreational vehicles and boats. This has led to a high demand for vehicles with robust towing capabilities, especially those equipped with V8 engines.

The towing market is also influenced by technological advancements in vehicle design and engine performance. Manufacturers are focusing on developing more fuel-efficient engines that can deliver high towing capacities without compromising on performance. This has led to innovations in V8 engine technology, including direct injection, variable valve timing, and cylinder deactivation systems.

Consumer preferences are shifting towards vehicles that offer both power and efficiency. This trend has prompted automakers to invest in research and development to optimize V8 engines for towing applications. The market has seen an increase in the number of vehicles offering advanced towing features, such as integrated trailer brake controllers, towing-specific drive modes, and advanced stability control systems.

Environmental regulations and fuel efficiency standards have also impacted the towing market. Manufacturers are under pressure to reduce emissions and improve fuel economy while maintaining towing capabilities. This has led to the development of more efficient V8 engines and the exploration of alternative powertrain options, such as hybrid and electric systems, for towing applications.

The competitive landscape of the towing market is characterized by the presence of major automotive manufacturers, including Ford, General Motors, Stellantis (formerly FCA), Toyota, and others. These companies are continuously innovating to improve their towing offerings and gain a competitive edge in the market.

The market for towing vehicles is segmented based on vehicle type, including passenger cars, light commercial vehicles, and heavy commercial vehicles. Among these, light commercial vehicles, particularly pickup trucks, dominate the market due to their versatility and towing capabilities. The increasing adoption of SUVs and crossovers with towing capabilities has also contributed to market growth.

In terms of regional analysis, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, has a strong towing culture, with millions of households owning recreational vehicles and boats. This has led to a high demand for vehicles with robust towing capabilities, especially those equipped with V8 engines.

The towing market is also influenced by technological advancements in vehicle design and engine performance. Manufacturers are focusing on developing more fuel-efficient engines that can deliver high towing capacities without compromising on performance. This has led to innovations in V8 engine technology, including direct injection, variable valve timing, and cylinder deactivation systems.

Consumer preferences are shifting towards vehicles that offer both power and efficiency. This trend has prompted automakers to invest in research and development to optimize V8 engines for towing applications. The market has seen an increase in the number of vehicles offering advanced towing features, such as integrated trailer brake controllers, towing-specific drive modes, and advanced stability control systems.

Environmental regulations and fuel efficiency standards have also impacted the towing market. Manufacturers are under pressure to reduce emissions and improve fuel economy while maintaining towing capabilities. This has led to the development of more efficient V8 engines and the exploration of alternative powertrain options, such as hybrid and electric systems, for towing applications.

The competitive landscape of the towing market is characterized by the presence of major automotive manufacturers, including Ford, General Motors, Stellantis (formerly FCA), Toyota, and others. These companies are continuously innovating to improve their towing offerings and gain a competitive edge in the market.

V8 Towing Challenges

V8 engines face several significant challenges when optimizing performance for towing applications. One of the primary issues is managing heat generation and dissipation. During towing operations, the engine works harder and produces more heat, which can lead to increased wear and potential damage if not properly addressed. This necessitates robust cooling systems and heat management strategies to maintain optimal operating temperatures under heavy loads.

Another challenge is maintaining fuel efficiency while delivering the power required for towing. V8 engines typically consume more fuel than smaller engines, and this consumption increases further when towing. Balancing power output with fuel economy becomes crucial, especially for long-distance towing scenarios where fuel costs can significantly impact overall operating expenses.

Torque delivery is a critical factor in towing performance. V8 engines need to provide substantial low-end torque to overcome the inertia of a heavy load and maintain speed on inclines. However, achieving this while also offering smooth power delivery across a wide RPM range presents a significant engineering challenge. Engineers must optimize camshaft profiles, valve timing, and fuel injection systems to ensure adequate torque is available when needed without compromising overall engine performance.

Durability and reliability are paramount concerns for V8 engines used in towing applications. The increased stress on engine components during towing operations can lead to accelerated wear and potential failures if not properly addressed. This requires the use of high-strength materials, improved lubrication systems, and robust design principles to ensure the engine can withstand prolonged periods of high-load operation.

Emissions control presents another significant challenge for V8 engines in towing applications. Stricter environmental regulations require engines to meet increasingly stringent emissions standards, even under heavy load conditions. This necessitates advanced exhaust after-treatment systems and precise engine management to reduce pollutants without compromising towing performance.

Lastly, the weight of V8 engines themselves can be a challenge in vehicle design for towing applications. While their power output is beneficial for towing, the added weight of a V8 engine can impact the vehicle's overall payload capacity and handling characteristics. Engineers must balance the benefits of V8 power with the need for efficient vehicle design and weight distribution to optimize overall towing performance.

Another challenge is maintaining fuel efficiency while delivering the power required for towing. V8 engines typically consume more fuel than smaller engines, and this consumption increases further when towing. Balancing power output with fuel economy becomes crucial, especially for long-distance towing scenarios where fuel costs can significantly impact overall operating expenses.

Torque delivery is a critical factor in towing performance. V8 engines need to provide substantial low-end torque to overcome the inertia of a heavy load and maintain speed on inclines. However, achieving this while also offering smooth power delivery across a wide RPM range presents a significant engineering challenge. Engineers must optimize camshaft profiles, valve timing, and fuel injection systems to ensure adequate torque is available when needed without compromising overall engine performance.

Durability and reliability are paramount concerns for V8 engines used in towing applications. The increased stress on engine components during towing operations can lead to accelerated wear and potential failures if not properly addressed. This requires the use of high-strength materials, improved lubrication systems, and robust design principles to ensure the engine can withstand prolonged periods of high-load operation.

Emissions control presents another significant challenge for V8 engines in towing applications. Stricter environmental regulations require engines to meet increasingly stringent emissions standards, even under heavy load conditions. This necessitates advanced exhaust after-treatment systems and precise engine management to reduce pollutants without compromising towing performance.

Lastly, the weight of V8 engines themselves can be a challenge in vehicle design for towing applications. While their power output is beneficial for towing, the added weight of a V8 engine can impact the vehicle's overall payload capacity and handling characteristics. Engineers must balance the benefits of V8 power with the need for efficient vehicle design and weight distribution to optimize overall towing performance.

Current V8 Towing Solutions

01 Cylinder configuration and design

V8 engine performance can be enhanced through optimized cylinder configuration and design. This includes improvements in cylinder head geometry, valve arrangement, and combustion chamber design to increase efficiency and power output. Advanced manufacturing techniques and materials may be used to reduce weight and improve heat dissipation.- Cylinder configuration and design: V8 engine performance can be enhanced through optimized cylinder configuration and design. This includes improvements in cylinder head geometry, valve arrangement, and combustion chamber design to increase efficiency and power output. Advanced manufacturing techniques and materials may be used to reduce weight and improve thermal management.

- Fuel injection and ignition systems: Performance improvements in V8 engines can be achieved through advanced fuel injection and ignition systems. This may involve direct injection technology, variable fuel injection timing, and precision ignition control. These systems can optimize fuel-air mixture and combustion timing, leading to increased power output and improved fuel efficiency.

- Turbocharging and supercharging: Forced induction systems such as turbochargers and superchargers can significantly boost V8 engine performance. These systems increase the amount of air entering the combustion chamber, allowing for more fuel to be burned and resulting in higher power output. Advanced designs may include variable geometry turbochargers or electric superchargers for improved response and efficiency.

- Variable valve timing and lift: Implementing variable valve timing and lift mechanisms in V8 engines can optimize performance across different operating conditions. These systems allow for dynamic adjustment of valve opening duration and lift height, improving both low-end torque and high-end power. Advanced camshaft designs and electronic control systems may be used to achieve precise valve actuation.

- Engine management and control systems: Sophisticated engine management and control systems play a crucial role in maximizing V8 engine performance. These systems integrate various sensors and actuators to optimize engine parameters in real-time. Advanced algorithms and machine learning techniques may be employed to continuously adapt engine operation for optimal performance, fuel efficiency, and emissions control.

02 Fuel injection and ignition systems

Performance improvements in V8 engines can be achieved through advanced fuel injection and ignition systems. This may involve direct injection technology, variable fuel injection timing, and precision ignition control. These systems can optimize fuel-air mixture and combustion timing for increased power and efficiency.Expand Specific Solutions03 Turbocharging and supercharging

Forced induction systems such as turbochargers and superchargers can significantly boost V8 engine performance. These systems increase air intake, allowing for more fuel to be burned and resulting in higher power output. Advanced designs may include variable geometry turbochargers or electric superchargers for improved response and efficiency.Expand Specific Solutions04 Variable valve timing and lift

Implementing variable valve timing and lift mechanisms can enhance V8 engine performance across a wide range of operating conditions. These systems allow for optimized air intake and exhaust flow, improving both low-end torque and high-end power. Advanced camshaft designs and electronic control systems may be used to achieve precise valve actuation.Expand Specific Solutions05 Engine management and control systems

Sophisticated engine management and control systems play a crucial role in maximizing V8 engine performance. These systems may include advanced sensors, real-time monitoring, and adaptive algorithms to optimize various engine parameters. Features such as cylinder deactivation, adaptive cooling, and performance modes can be implemented to balance power, efficiency, and emissions.Expand Specific Solutions

V8 Towing Industry Leaders

The competition landscape for V8 engine performance optimization in towing applications is characterized by a mature market with established players and ongoing technological advancements. Major automotive manufacturers like Ford, GM, Toyota, and Volkswagen are at the forefront, leveraging their extensive R&D capabilities and market presence. The market size is substantial, driven by the demand for high-performance towing vehicles in commercial and recreational sectors. Technological maturity is high, with companies like ZF Friedrichshafen, BorgWarner, and AVL List contributing specialized expertise in drivetrain and powertrain solutions. Emerging players such as Hyliion are introducing innovative approaches, particularly in electrification and hybrid technologies, challenging traditional V8 optimization methods and pushing the industry towards more fuel-efficient and environmentally friendly solutions.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced V8 engine technologies to optimize performance for towing. Their EcoBoost V8 engines utilize direct fuel injection and twin turbochargers to increase power output while maintaining fuel efficiency[1]. Ford's Dynamic Boost system adjusts turbocharger output based on load conditions, providing optimal torque for towing[2]. The company has also implemented advanced cooling systems, including larger radiators and transmission oil coolers, to manage heat during heavy towing[3]. Ford's Pro Trailer Backup Assist technology integrates with the V8 engine management system to provide seamless control when maneuvering with a trailer[4].

Strengths: High torque output, advanced cooling systems, and integrated towing technologies. Weaknesses: Potentially higher fuel consumption compared to smaller engines, and increased complexity of turbocharged systems.

GM Global Technology Operations LLC

Technical Solution: GM's approach to optimizing V8 performance for towing focuses on their Dynamic Fuel Management (DFM) system. This technology allows for 17 different cylinder deactivation combinations, enabling the engine to operate in various cylinder configurations based on load demands[5]. For towing, the system ensures full V8 power when needed while conserving fuel during lighter loads. GM has also developed an enhanced cooling package for their V8 engines, including a heavy-duty engine oil cooler and a more efficient cooling fan[6]. Their Tow/Haul mode recalibrates transmission shift points to optimize power delivery and engine braking when towing[7]. Additionally, GM's V8 engines feature variable valve timing and direct injection to improve overall efficiency and power output[8].

Strengths: Flexible cylinder deactivation system, advanced cooling solutions, and specialized towing modes. Weaknesses: Complexity of the DFM system may lead to higher maintenance costs, and potential reliability concerns with frequent towing.

Key V8 Towing Innovations

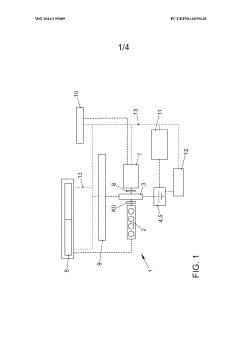

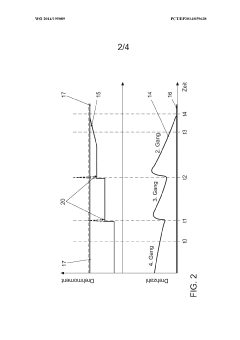

Method for performing open-loop and/or closed-loop control of a hybrid drive arrangement of a motor vehicle

PatentWO2014195089A1

Innovation

- Towing the internal combustion engine during the deceleration phase, particularly during braking, reduces the electrical energy needed and minimizes rotational irregularities by using the disconnect clutch to couple and uncouple the engine efficiently, thereby reducing wear and enhancing comfort.

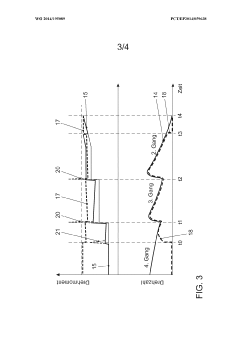

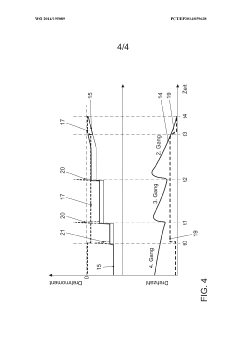

Method for operating a hybrid propulsion unit

PatentWO2015071053A1

Innovation

- The method involves switching off all cylinders of the internal combustion engine during towing, utilizing a planetary gear set to maintain engine speed and minimize drag losses, and alternately operating the engine at an optimum point for energy storage and retrieval, allowing for immediate torque delivery without conventional starting processes.

Fuel Efficiency in Towing

Fuel efficiency in towing is a critical aspect of V8 engine performance optimization. When towing heavy loads, vehicles equipped with V8 engines face increased fuel consumption due to the additional weight and resistance. To address this challenge, engine manufacturers have developed various strategies to enhance fuel efficiency without compromising towing capacity.

One of the primary approaches to improving fuel efficiency in towing scenarios is the implementation of advanced fuel injection systems. Direct fuel injection technology allows for precise control over fuel delivery, optimizing combustion and reducing waste. This results in improved fuel economy, especially under heavy load conditions. Additionally, variable valve timing systems contribute to better fuel efficiency by adjusting valve operation based on engine load and speed, ensuring optimal air-fuel mixture across different towing conditions.

Cylinder deactivation technology has also proven effective in enhancing fuel efficiency during towing. This system allows the engine to temporarily shut down a portion of its cylinders when full power is not required, such as during highway cruising. By reducing the active displacement, fuel consumption is significantly decreased without affecting the engine's ability to quickly respond to increased power demands when necessary.

Turbocharging and supercharging technologies play a crucial role in optimizing V8 engines for towing performance and fuel efficiency. These forced induction systems increase the engine's power output without necessarily increasing displacement, allowing for smaller, more fuel-efficient engines to maintain high towing capacities. The ability to generate more power from a smaller engine volume contributes to overall weight reduction and improved fuel economy.

Advanced transmission systems, such as 8-speed or 10-speed automatic transmissions, further enhance fuel efficiency in towing applications. These transmissions provide a wider range of gear ratios, allowing the engine to operate in its most efficient RPM range more frequently. Additionally, lock-up torque converters and intelligent shift patterns optimize power delivery and reduce fuel consumption during towing operations.

Engine management systems have become increasingly sophisticated, utilizing real-time data and adaptive algorithms to optimize fuel efficiency. These systems continuously monitor various parameters such as engine load, vehicle speed, and terrain conditions to adjust engine performance dynamically. This results in improved fuel economy across a wide range of towing scenarios, from city driving to long-distance highway hauling.

One of the primary approaches to improving fuel efficiency in towing scenarios is the implementation of advanced fuel injection systems. Direct fuel injection technology allows for precise control over fuel delivery, optimizing combustion and reducing waste. This results in improved fuel economy, especially under heavy load conditions. Additionally, variable valve timing systems contribute to better fuel efficiency by adjusting valve operation based on engine load and speed, ensuring optimal air-fuel mixture across different towing conditions.

Cylinder deactivation technology has also proven effective in enhancing fuel efficiency during towing. This system allows the engine to temporarily shut down a portion of its cylinders when full power is not required, such as during highway cruising. By reducing the active displacement, fuel consumption is significantly decreased without affecting the engine's ability to quickly respond to increased power demands when necessary.

Turbocharging and supercharging technologies play a crucial role in optimizing V8 engines for towing performance and fuel efficiency. These forced induction systems increase the engine's power output without necessarily increasing displacement, allowing for smaller, more fuel-efficient engines to maintain high towing capacities. The ability to generate more power from a smaller engine volume contributes to overall weight reduction and improved fuel economy.

Advanced transmission systems, such as 8-speed or 10-speed automatic transmissions, further enhance fuel efficiency in towing applications. These transmissions provide a wider range of gear ratios, allowing the engine to operate in its most efficient RPM range more frequently. Additionally, lock-up torque converters and intelligent shift patterns optimize power delivery and reduce fuel consumption during towing operations.

Engine management systems have become increasingly sophisticated, utilizing real-time data and adaptive algorithms to optimize fuel efficiency. These systems continuously monitor various parameters such as engine load, vehicle speed, and terrain conditions to adjust engine performance dynamically. This results in improved fuel economy across a wide range of towing scenarios, from city driving to long-distance highway hauling.

Towing Safety Technologies

Towing safety technologies have become increasingly sophisticated in recent years, enhancing the performance and safety of V8 engines when towing heavy loads. These advancements address various aspects of towing, from stability control to brake assistance and trailer monitoring systems.

One of the key safety technologies is the Trailer Sway Control (TSC) system. This technology works in conjunction with the vehicle's electronic stability control to detect trailer sway and automatically apply individual wheel braking or reduce engine torque to stabilize the trailer. TSC significantly improves the driver's ability to maintain control of the vehicle-trailer combination, especially in challenging driving conditions such as strong crosswinds or sudden lane changes.

Another critical safety feature is the Integrated Trailer Brake Controller (ITBC). This system synchronizes the vehicle's brakes with the trailer's electric brakes, providing seamless and proportional braking. The ITBC can be adjusted based on trailer weight and road conditions, ensuring optimal braking performance and reducing the risk of jackknifing or skidding during sudden stops.

Advanced camera systems have also been incorporated to enhance towing safety. Surround-view cameras provide a 360-degree view around the vehicle and trailer, making it easier for drivers to maneuver in tight spaces or when backing up. Some systems even offer a "transparent trailer" view, which uses cameras to create a virtual see-through effect of the trailer, significantly improving visibility and reducing blind spots.

Trailer Reverse Guidance systems have revolutionized the often challenging task of backing up with a trailer. These systems use multiple cameras and sensors to provide real-time guidance to the driver, displaying the trailer's trajectory on the infotainment screen and offering steering suggestions to achieve the desired path.

Weight distribution and leveling systems have also seen significant improvements. Dynamic load-leveling suspensions automatically adjust to maintain optimal vehicle height and weight distribution, regardless of the load being towed. This not only improves stability and handling but also ensures proper alignment of the headlights, enhancing visibility and safety for both the driver and other road users.

Tire Pressure Monitoring Systems (TPMS) have been extended to include trailer tires, allowing drivers to monitor the pressure of all tires in real-time. This helps prevent blowouts and ensures optimal traction and fuel efficiency. Some advanced systems can even detect and alert the driver to potential wheel bearing issues on the trailer, preventing potentially dangerous situations on the road.

These towing safety technologies, when integrated with V8 engines, not only optimize performance but also significantly enhance the overall safety of towing operations. As these systems continue to evolve, they promise to make towing safer, more efficient, and less stressful for drivers.

One of the key safety technologies is the Trailer Sway Control (TSC) system. This technology works in conjunction with the vehicle's electronic stability control to detect trailer sway and automatically apply individual wheel braking or reduce engine torque to stabilize the trailer. TSC significantly improves the driver's ability to maintain control of the vehicle-trailer combination, especially in challenging driving conditions such as strong crosswinds or sudden lane changes.

Another critical safety feature is the Integrated Trailer Brake Controller (ITBC). This system synchronizes the vehicle's brakes with the trailer's electric brakes, providing seamless and proportional braking. The ITBC can be adjusted based on trailer weight and road conditions, ensuring optimal braking performance and reducing the risk of jackknifing or skidding during sudden stops.

Advanced camera systems have also been incorporated to enhance towing safety. Surround-view cameras provide a 360-degree view around the vehicle and trailer, making it easier for drivers to maneuver in tight spaces or when backing up. Some systems even offer a "transparent trailer" view, which uses cameras to create a virtual see-through effect of the trailer, significantly improving visibility and reducing blind spots.

Trailer Reverse Guidance systems have revolutionized the often challenging task of backing up with a trailer. These systems use multiple cameras and sensors to provide real-time guidance to the driver, displaying the trailer's trajectory on the infotainment screen and offering steering suggestions to achieve the desired path.

Weight distribution and leveling systems have also seen significant improvements. Dynamic load-leveling suspensions automatically adjust to maintain optimal vehicle height and weight distribution, regardless of the load being towed. This not only improves stability and handling but also ensures proper alignment of the headlights, enhancing visibility and safety for both the driver and other road users.

Tire Pressure Monitoring Systems (TPMS) have been extended to include trailer tires, allowing drivers to monitor the pressure of all tires in real-time. This helps prevent blowouts and ensures optimal traction and fuel efficiency. Some advanced systems can even detect and alert the driver to potential wheel bearing issues on the trailer, preventing potentially dangerous situations on the road.

These towing safety technologies, when integrated with V8 engines, not only optimize performance but also significantly enhance the overall safety of towing operations. As these systems continue to evolve, they promise to make towing safer, more efficient, and less stressful for drivers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!