How V8 Engines are Essential in Heavy Duty Applications?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The evolution of V8 engines in heavy-duty applications has been marked by significant technological advancements and innovations over the years. Initially developed for high-performance automobiles, V8 engines have found their way into various heavy-duty applications due to their power, efficiency, and reliability.

In the early stages, V8 engines were primarily used in large trucks and construction equipment. These early iterations were characterized by their robust design and ability to generate substantial torque at low RPMs, making them ideal for heavy-duty tasks. However, they were often criticized for their high fuel consumption and emissions.

As environmental concerns grew and fuel efficiency became a priority, manufacturers began to focus on improving the V8 engine's performance while reducing its environmental impact. This led to the introduction of advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies. These innovations allowed V8 engines to maintain their power output while significantly improving fuel economy and reducing emissions.

The integration of turbocharging and supercharging technologies marked another significant milestone in V8 engine evolution for heavy-duty applications. These forced induction systems enabled engines to produce more power from smaller displacements, leading to improved efficiency without sacrificing performance. This development was particularly crucial for heavy-duty applications where power-to-weight ratio is a critical factor.

In recent years, the focus has shifted towards hybridization and electrification. Many manufacturers have begun incorporating electric motors alongside V8 engines in heavy-duty vehicles, creating hybrid powertrains that offer improved fuel efficiency and reduced emissions while maintaining the power and torque characteristics that make V8 engines essential in these applications.

The latest advancements in materials science and manufacturing techniques have also played a crucial role in V8 engine evolution. The use of lightweight materials such as aluminum and composite materials has helped reduce engine weight, improving overall vehicle efficiency. Additionally, precision manufacturing techniques have allowed for tighter tolerances and improved engine designs, further enhancing performance and reliability.

Looking ahead, the evolution of V8 engines in heavy-duty applications is likely to continue, with a focus on further improving efficiency, reducing emissions, and integrating with advanced powertrain technologies. While alternative power sources are gaining traction, the V8 engine's combination of power, reliability, and adaptability ensures its continued relevance in heavy-duty applications for the foreseeable future.

In the early stages, V8 engines were primarily used in large trucks and construction equipment. These early iterations were characterized by their robust design and ability to generate substantial torque at low RPMs, making them ideal for heavy-duty tasks. However, they were often criticized for their high fuel consumption and emissions.

As environmental concerns grew and fuel efficiency became a priority, manufacturers began to focus on improving the V8 engine's performance while reducing its environmental impact. This led to the introduction of advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies. These innovations allowed V8 engines to maintain their power output while significantly improving fuel economy and reducing emissions.

The integration of turbocharging and supercharging technologies marked another significant milestone in V8 engine evolution for heavy-duty applications. These forced induction systems enabled engines to produce more power from smaller displacements, leading to improved efficiency without sacrificing performance. This development was particularly crucial for heavy-duty applications where power-to-weight ratio is a critical factor.

In recent years, the focus has shifted towards hybridization and electrification. Many manufacturers have begun incorporating electric motors alongside V8 engines in heavy-duty vehicles, creating hybrid powertrains that offer improved fuel efficiency and reduced emissions while maintaining the power and torque characteristics that make V8 engines essential in these applications.

The latest advancements in materials science and manufacturing techniques have also played a crucial role in V8 engine evolution. The use of lightweight materials such as aluminum and composite materials has helped reduce engine weight, improving overall vehicle efficiency. Additionally, precision manufacturing techniques have allowed for tighter tolerances and improved engine designs, further enhancing performance and reliability.

Looking ahead, the evolution of V8 engines in heavy-duty applications is likely to continue, with a focus on further improving efficiency, reducing emissions, and integrating with advanced powertrain technologies. While alternative power sources are gaining traction, the V8 engine's combination of power, reliability, and adaptability ensures its continued relevance in heavy-duty applications for the foreseeable future.

Heavy Duty Market Needs

The heavy-duty market has been experiencing significant growth and transformation, driven by increasing demand for robust and efficient machinery across various industries. This sector encompasses a wide range of applications, including construction, mining, agriculture, and transportation, all of which rely heavily on powerful and durable engines to perform demanding tasks.

In recent years, there has been a notable shift in market needs, with customers seeking engines that not only deliver high performance but also meet stringent environmental regulations and offer improved fuel efficiency. This demand is particularly evident in the construction industry, where large-scale projects require machinery capable of operating continuously under extreme conditions.

The mining sector, another key player in the heavy-duty market, has been pushing for engines that can withstand harsh environments while maintaining optimal performance. These industries require engines that can generate substantial torque and power output to move heavy loads and operate complex machinery efficiently.

Agricultural applications have also seen a surge in demand for advanced engine technologies. As farms grow larger and more mechanized, there is an increasing need for tractors and other agricultural equipment powered by engines that can work long hours with minimal downtime. This has led to a focus on reliability and durability as key factors in engine selection for heavy-duty agricultural machinery.

The transportation sector, particularly in long-haul trucking, has been driving innovation in engine technology. Fleet operators are seeking engines that can deliver improved fuel economy without compromising on power, as fuel costs represent a significant portion of their operational expenses. This has led to a growing interest in V8 engines that can provide the necessary power while offering better fuel efficiency compared to larger displacement engines.

Furthermore, there is an increasing emphasis on reducing emissions and meeting global environmental standards. This has created a demand for engines that incorporate advanced technologies such as improved combustion systems, exhaust after-treatment, and electronic control units to minimize environmental impact while maintaining high performance levels.

The heavy-duty market is also seeing a trend towards engines with longer service intervals and easier maintenance procedures. This is driven by the need to reduce downtime and lower total cost of ownership, which are critical factors for businesses operating in competitive industries.

As urbanization continues and infrastructure development projects expand globally, the demand for heavy-duty engines is expected to grow further. This presents both challenges and opportunities for engine manufacturers to innovate and develop solutions that meet the evolving needs of the market while addressing environmental concerns and operational efficiency requirements.

In recent years, there has been a notable shift in market needs, with customers seeking engines that not only deliver high performance but also meet stringent environmental regulations and offer improved fuel efficiency. This demand is particularly evident in the construction industry, where large-scale projects require machinery capable of operating continuously under extreme conditions.

The mining sector, another key player in the heavy-duty market, has been pushing for engines that can withstand harsh environments while maintaining optimal performance. These industries require engines that can generate substantial torque and power output to move heavy loads and operate complex machinery efficiently.

Agricultural applications have also seen a surge in demand for advanced engine technologies. As farms grow larger and more mechanized, there is an increasing need for tractors and other agricultural equipment powered by engines that can work long hours with minimal downtime. This has led to a focus on reliability and durability as key factors in engine selection for heavy-duty agricultural machinery.

The transportation sector, particularly in long-haul trucking, has been driving innovation in engine technology. Fleet operators are seeking engines that can deliver improved fuel economy without compromising on power, as fuel costs represent a significant portion of their operational expenses. This has led to a growing interest in V8 engines that can provide the necessary power while offering better fuel efficiency compared to larger displacement engines.

Furthermore, there is an increasing emphasis on reducing emissions and meeting global environmental standards. This has created a demand for engines that incorporate advanced technologies such as improved combustion systems, exhaust after-treatment, and electronic control units to minimize environmental impact while maintaining high performance levels.

The heavy-duty market is also seeing a trend towards engines with longer service intervals and easier maintenance procedures. This is driven by the need to reduce downtime and lower total cost of ownership, which are critical factors for businesses operating in competitive industries.

As urbanization continues and infrastructure development projects expand globally, the demand for heavy-duty engines is expected to grow further. This presents both challenges and opportunities for engine manufacturers to innovate and develop solutions that meet the evolving needs of the market while addressing environmental concerns and operational efficiency requirements.

V8 Tech Challenges

V8 engines, while renowned for their power and performance, face several significant challenges in heavy-duty applications. One of the primary issues is fuel efficiency. These engines typically consume more fuel compared to their smaller counterparts, which can lead to increased operational costs for businesses relying on heavy-duty vehicles. This challenge is particularly pronounced in long-haul transportation and construction sectors where fuel expenses constitute a substantial portion of operational costs.

Another major hurdle is the stringent emission regulations that V8 engines must comply with. As environmental concerns grow, governments worldwide are implementing stricter emission standards. V8 engines, known for their higher output, often struggle to meet these standards without compromising performance. This necessitates the development and integration of advanced emission control technologies, which can add complexity and cost to the engine design.

Heat management presents another significant challenge for V8 engines in heavy-duty applications. The high power output generates substantial heat, which needs to be efficiently dissipated to prevent engine damage and maintain optimal performance. This is especially critical in demanding environments such as construction sites or mining operations where engines are subjected to prolonged periods of high-load operation.

Durability and reliability are also key concerns. Heavy-duty applications often involve continuous operation under extreme conditions. V8 engines must be engineered to withstand these harsh environments while maintaining consistent performance over extended periods. This requires advanced materials and robust design principles, which can increase manufacturing costs.

Weight is another factor that engineers must contend with. V8 engines are inherently heavier than smaller engine configurations, which can impact the overall weight distribution and payload capacity of heavy-duty vehicles. This challenge becomes more pronounced in applications where weight restrictions are critical, such as in certain types of construction equipment or specialized transportation vehicles.

Lastly, the complexity of V8 engines poses challenges in maintenance and repair. These engines often require specialized knowledge and tools for servicing, which can lead to increased downtime and maintenance costs. This complexity can be a significant drawback for businesses operating in remote areas or with limited access to specialized mechanical expertise.

Another major hurdle is the stringent emission regulations that V8 engines must comply with. As environmental concerns grow, governments worldwide are implementing stricter emission standards. V8 engines, known for their higher output, often struggle to meet these standards without compromising performance. This necessitates the development and integration of advanced emission control technologies, which can add complexity and cost to the engine design.

Heat management presents another significant challenge for V8 engines in heavy-duty applications. The high power output generates substantial heat, which needs to be efficiently dissipated to prevent engine damage and maintain optimal performance. This is especially critical in demanding environments such as construction sites or mining operations where engines are subjected to prolonged periods of high-load operation.

Durability and reliability are also key concerns. Heavy-duty applications often involve continuous operation under extreme conditions. V8 engines must be engineered to withstand these harsh environments while maintaining consistent performance over extended periods. This requires advanced materials and robust design principles, which can increase manufacturing costs.

Weight is another factor that engineers must contend with. V8 engines are inherently heavier than smaller engine configurations, which can impact the overall weight distribution and payload capacity of heavy-duty vehicles. This challenge becomes more pronounced in applications where weight restrictions are critical, such as in certain types of construction equipment or specialized transportation vehicles.

Lastly, the complexity of V8 engines poses challenges in maintenance and repair. These engines often require specialized knowledge and tools for servicing, which can lead to increased downtime and maintenance costs. This complexity can be a significant drawback for businesses operating in remote areas or with limited access to specialized mechanical expertise.

Current V8 Solutions

01 V8 Engine Design and Configuration

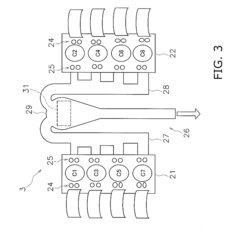

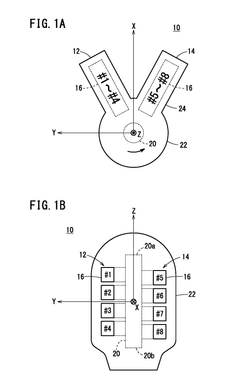

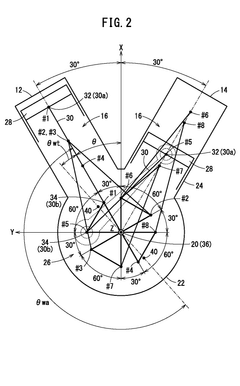

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design while providing high power output. The design often includes features for improved performance, fuel efficiency, and reduced emissions.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously improved to enhance performance and efficiency.

- Fuel Efficiency and Emissions Control: Modern V8 engines incorporate advanced technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Innovations in engine management systems and combustion processes aim to optimize performance while meeting stringent environmental regulations.

- Performance Enhancement and Tuning: Various methods and components are developed to enhance the performance of V8 engines. These include turbocharging, supercharging, intercooling, and the use of high-performance camshafts and pistons. Aftermarket tuning solutions and engine management systems allow for customization of power output and torque characteristics to suit different applications.

- Cooling and Lubrication Systems: Effective cooling and lubrication are crucial for V8 engine reliability and longevity. Innovations in coolant flow design, oil pump efficiency, and the use of advanced materials in cooling components help manage the high heat output of V8 engines. Improved oil circulation and filtration systems contribute to reduced wear and extended engine life.

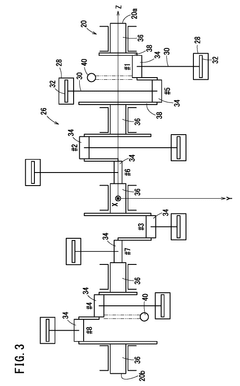

- Integration with Hybrid and Electric Systems: As automotive technology evolves, V8 engines are being integrated with hybrid and electric systems to improve overall vehicle efficiency. This includes the development of mild hybrid systems, regenerative braking, and start-stop technology specifically designed for V8 engines. These innovations aim to combine the power of V8 engines with the efficiency benefits of electrification.

02 Fuel Injection Systems for V8 Engines

Advanced fuel injection systems are developed for V8 engines to optimize fuel delivery and combustion. These systems may include direct injection, multi-port injection, or a combination of both, aimed at improving engine efficiency and reducing fuel consumption while maintaining high performance.Expand Specific Solutions03 Valve Train and Camshaft Innovations

Innovations in valve train and camshaft designs for V8 engines focus on improving engine breathing and overall efficiency. This may include variable valve timing, cylinder deactivation systems, and advanced camshaft profiles to enhance performance across different engine speeds and loads.Expand Specific Solutions04 Turbocharging and Supercharging V8 Engines

Forced induction systems, such as turbochargers and superchargers, are increasingly used in V8 engines to boost power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and resulting in increased power from a smaller displacement engine.Expand Specific Solutions05 Cooling and Lubrication Systems for V8 Engines

Advanced cooling and lubrication systems are developed to manage the high heat output and mechanical stresses in V8 engines. These may include precision oil cooling, advanced coolant formulations, and optimized oil circulation paths to ensure engine longevity and maintain performance under various operating conditions.Expand Specific Solutions

Key V8 Manufacturers

The V8 engine market in heavy-duty applications is in a mature stage, with established players dominating the landscape. The global market size for V8 engines in this sector is substantial, driven by demand in construction, agriculture, and transportation industries. Technologically, V8 engines have reached a high level of sophistication, with companies like BMW, Honda, and GM leading innovation. These firms, along with others such as Yamaha and Mitsubishi, are focusing on improving fuel efficiency, reducing emissions, and enhancing power output. The competitive landscape is characterized by ongoing R&D efforts to meet stringent environmental regulations while maintaining performance standards, with a gradual shift towards hybrid and alternative fuel technologies in heavy-duty applications.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced V8 engines for heavy-duty applications, focusing on improved fuel efficiency and power output. Their latest V8 engines incorporate direct fuel injection, variable valve timing, and cylinder deactivation technologies. These innovations allow for precise fuel control, optimized combustion, and reduced fuel consumption under varying load conditions [1][3]. GM's V8 engines also feature advanced materials such as aluminum block and heads to reduce weight while maintaining durability. The company has implemented a sophisticated engine management system that continuously monitors and adjusts engine parameters to ensure optimal performance and efficiency in heavy-duty scenarios [2].

Strengths: High power output, improved fuel efficiency, and advanced technologies. Weaknesses: Complexity may lead to higher maintenance costs, and the focus on efficiency might slightly compromise maximum power output in some scenarios.

Deere & Co.

Technical Solution: John Deere has developed V8 engines for heavy-duty applications in agricultural and construction equipment. Their V8 engines feature a robust design with wet cylinder liners and four-valve cylinder heads for improved durability and performance [13]. John Deere has implemented advanced electronic fuel injection systems in their V8 engines, allowing for precise fuel control and optimized combustion across various operating conditions. The company's engines also incorporate variable geometry turbochargers to enhance low-end torque and overall engine responsiveness [14]. John Deere has focused on improving the cooling system in their V8 engines, implementing advanced fan drive systems and optimized coolant flow to maintain optimal operating temperatures under heavy loads. Additionally, their engines feature an integrated exhaust aftertreatment system to meet stringent emissions regulations while maintaining performance [15].

Strengths: Excellent durability in harsh environments, high torque output for agricultural and construction applications, and advanced emissions control systems. Weaknesses: Potentially higher fuel consumption compared to smaller engine options, and may have limited applications outside of specialized equipment.

V8 Core Innovations

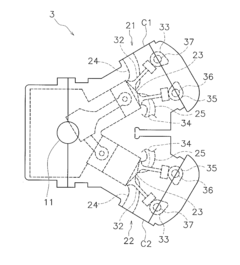

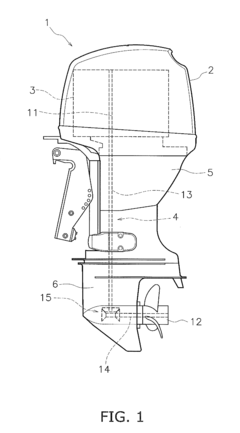

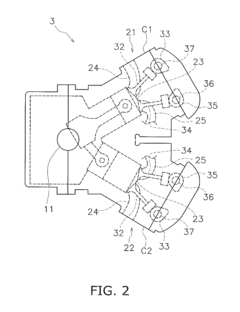

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

V8 engine

PatentWO2021171405A1

Innovation

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

Emissions Regulations

Emissions regulations have become increasingly stringent for heavy-duty vehicles, significantly impacting the design and performance of V8 engines in these applications. The Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have been at the forefront of implementing strict emission standards, particularly focusing on reducing nitrogen oxides (NOx) and particulate matter (PM) emissions.

These regulations have evolved over time, with each new tier setting more challenging targets for engine manufacturers. The introduction of Tier 4 Final standards in 2014 marked a significant milestone, requiring a 90% reduction in PM and NOx emissions compared to previous tiers. This has led to the widespread adoption of advanced emission control technologies in V8 engines for heavy-duty applications.

To meet these stringent requirements, V8 engine manufacturers have implemented various technologies. Selective Catalytic Reduction (SCR) systems have become a standard feature, using a urea-based solution (DEF) to convert NOx into harmless nitrogen and water. Diesel Particulate Filters (DPF) have also been integrated to capture and eliminate PM emissions.

The implementation of these emission control systems has necessitated significant changes in V8 engine design. Engineers have had to optimize combustion processes, improve fuel injection systems, and enhance engine control units to ensure efficient operation while meeting emission standards. This has resulted in more complex and sophisticated V8 engines for heavy-duty applications.

However, the pursuit of lower emissions has often come at the cost of fuel efficiency and performance. Engine manufacturers have had to balance the trade-offs between emission reduction, fuel economy, and power output. This challenge has driven innovation in areas such as turbocharging, variable valve timing, and advanced materials to maintain or improve engine performance while adhering to regulations.

Looking ahead, upcoming emission standards are set to become even more stringent. The EPA's Cleaner Trucks Initiative aims to further reduce NOx emissions from heavy-duty trucks starting in 2027. This will likely necessitate additional technological advancements in V8 engines, potentially including more advanced aftertreatment systems, improved thermal management, and even hybrid powertrains.

The global nature of emission regulations adds another layer of complexity for V8 engine manufacturers. Different regions have varying standards and implementation timelines, requiring adaptable engine designs that can meet diverse regulatory requirements. This has led to increased research and development efforts to create flexible engine platforms capable of meeting global emission standards.

These regulations have evolved over time, with each new tier setting more challenging targets for engine manufacturers. The introduction of Tier 4 Final standards in 2014 marked a significant milestone, requiring a 90% reduction in PM and NOx emissions compared to previous tiers. This has led to the widespread adoption of advanced emission control technologies in V8 engines for heavy-duty applications.

To meet these stringent requirements, V8 engine manufacturers have implemented various technologies. Selective Catalytic Reduction (SCR) systems have become a standard feature, using a urea-based solution (DEF) to convert NOx into harmless nitrogen and water. Diesel Particulate Filters (DPF) have also been integrated to capture and eliminate PM emissions.

The implementation of these emission control systems has necessitated significant changes in V8 engine design. Engineers have had to optimize combustion processes, improve fuel injection systems, and enhance engine control units to ensure efficient operation while meeting emission standards. This has resulted in more complex and sophisticated V8 engines for heavy-duty applications.

However, the pursuit of lower emissions has often come at the cost of fuel efficiency and performance. Engine manufacturers have had to balance the trade-offs between emission reduction, fuel economy, and power output. This challenge has driven innovation in areas such as turbocharging, variable valve timing, and advanced materials to maintain or improve engine performance while adhering to regulations.

Looking ahead, upcoming emission standards are set to become even more stringent. The EPA's Cleaner Trucks Initiative aims to further reduce NOx emissions from heavy-duty trucks starting in 2027. This will likely necessitate additional technological advancements in V8 engines, potentially including more advanced aftertreatment systems, improved thermal management, and even hybrid powertrains.

The global nature of emission regulations adds another layer of complexity for V8 engine manufacturers. Different regions have varying standards and implementation timelines, requiring adaptable engine designs that can meet diverse regulatory requirements. This has led to increased research and development efforts to create flexible engine platforms capable of meeting global emission standards.

Fuel Efficiency Trends

The fuel efficiency of V8 engines in heavy-duty applications has seen significant improvements over the past decades. This trend is driven by a combination of technological advancements, regulatory pressures, and market demands for more economical operations. Modern V8 engines used in heavy-duty vehicles have achieved remarkable gains in fuel economy without compromising performance or reliability.

One of the key factors contributing to improved fuel efficiency is the implementation of advanced fuel injection systems. Direct injection technology, coupled with precise electronic control units, allows for more accurate fuel metering and better combustion efficiency. This results in reduced fuel consumption and lower emissions, addressing both economic and environmental concerns.

Turbocharging and supercharging technologies have also played a crucial role in enhancing fuel efficiency. These forced induction systems enable V8 engines to produce more power from smaller displacements, effectively downsizing engines without sacrificing performance. The ability to maintain high power outputs with reduced engine sizes leads to improved fuel economy, especially under partial load conditions common in many heavy-duty applications.

Variable valve timing (VVT) systems have further contributed to fuel efficiency gains. By optimizing valve operation based on engine speed and load, VVT allows for better control of the combustion process, resulting in improved fuel economy across a wide range of operating conditions. This technology is particularly beneficial in heavy-duty applications where engines often operate under varying loads and speeds.

The integration of advanced materials and manufacturing techniques has also impacted fuel efficiency trends. Lightweight components, such as aluminum cylinder heads and composite materials, reduce overall engine weight while maintaining strength and durability. This weight reduction translates to improved fuel economy, especially in applications where the engine's weight is a significant factor in the vehicle's total mass.

Sophisticated engine management systems have emerged as a critical component in the quest for better fuel efficiency. These systems utilize complex algorithms and real-time data to optimize engine performance continuously. By adjusting parameters such as fuel injection timing, air-fuel ratios, and boost pressure, these management systems ensure that V8 engines operate at peak efficiency under diverse conditions.

The trend towards hybridization has also begun to influence V8 engines in heavy-duty applications. While full electrification may not be feasible for all heavy-duty tasks, hybrid systems that combine V8 engines with electric motors offer promising fuel efficiency improvements. These systems can recover energy during braking and provide electric assistance during acceleration, reducing the overall fuel consumption of the vehicle.

As environmental regulations become increasingly stringent, the focus on fuel efficiency in V8 engines for heavy-duty applications is expected to intensify. Future trends may include further refinements in combustion technology, increased use of alternative fuels, and more widespread adoption of hybrid powertrains. These developments will continue to push the boundaries of what is possible in terms of fuel efficiency for V8 engines in demanding heavy-duty scenarios.

One of the key factors contributing to improved fuel efficiency is the implementation of advanced fuel injection systems. Direct injection technology, coupled with precise electronic control units, allows for more accurate fuel metering and better combustion efficiency. This results in reduced fuel consumption and lower emissions, addressing both economic and environmental concerns.

Turbocharging and supercharging technologies have also played a crucial role in enhancing fuel efficiency. These forced induction systems enable V8 engines to produce more power from smaller displacements, effectively downsizing engines without sacrificing performance. The ability to maintain high power outputs with reduced engine sizes leads to improved fuel economy, especially under partial load conditions common in many heavy-duty applications.

Variable valve timing (VVT) systems have further contributed to fuel efficiency gains. By optimizing valve operation based on engine speed and load, VVT allows for better control of the combustion process, resulting in improved fuel economy across a wide range of operating conditions. This technology is particularly beneficial in heavy-duty applications where engines often operate under varying loads and speeds.

The integration of advanced materials and manufacturing techniques has also impacted fuel efficiency trends. Lightweight components, such as aluminum cylinder heads and composite materials, reduce overall engine weight while maintaining strength and durability. This weight reduction translates to improved fuel economy, especially in applications where the engine's weight is a significant factor in the vehicle's total mass.

Sophisticated engine management systems have emerged as a critical component in the quest for better fuel efficiency. These systems utilize complex algorithms and real-time data to optimize engine performance continuously. By adjusting parameters such as fuel injection timing, air-fuel ratios, and boost pressure, these management systems ensure that V8 engines operate at peak efficiency under diverse conditions.

The trend towards hybridization has also begun to influence V8 engines in heavy-duty applications. While full electrification may not be feasible for all heavy-duty tasks, hybrid systems that combine V8 engines with electric motors offer promising fuel efficiency improvements. These systems can recover energy during braking and provide electric assistance during acceleration, reducing the overall fuel consumption of the vehicle.

As environmental regulations become increasingly stringent, the focus on fuel efficiency in V8 engines for heavy-duty applications is expected to intensify. Future trends may include further refinements in combustion technology, increased use of alternative fuels, and more widespread adoption of hybrid powertrains. These developments will continue to push the boundaries of what is possible in terms of fuel efficiency for V8 engines in demanding heavy-duty scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!