How V8 Engines are Transforming Highway Transport Dynamics?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine has been a cornerstone of automotive engineering since its inception in the early 20th century. Initially developed to provide more power and smoother operation for luxury vehicles, V8 engines have evolved significantly over the decades, becoming a transformative force in highway transport dynamics. The evolution of V8 engines has been driven by the continuous pursuit of increased power output, improved fuel efficiency, and reduced emissions.

In the context of highway transport, V8 engines have played a crucial role in shaping the performance and capabilities of heavy-duty trucks and commercial vehicles. The primary objective of V8 engine development in this sector has been to enhance the power-to-weight ratio, enabling trucks to haul heavier loads over longer distances while maintaining optimal fuel consumption. This has led to a series of technological advancements, including turbocharging, direct fuel injection, and variable valve timing.

The evolution of V8 engines for highway transport has also been influenced by increasingly stringent environmental regulations. Engine manufacturers have had to balance the demand for power with the need to reduce emissions and improve fuel economy. This has resulted in the development of more sophisticated engine management systems, advanced materials for lighter engine components, and the integration of hybrid technologies in some applications.

Another significant objective in V8 engine evolution has been the improvement of durability and reliability. Long-haul trucking demands engines that can operate continuously for extended periods under varying load conditions. This has led to advancements in engine cooling systems, lubrication technologies, and the use of more robust materials in engine construction.

The digital revolution has also played a pivotal role in V8 engine development. The integration of electronic control units (ECUs) and sophisticated sensors has enabled real-time monitoring and adjustment of engine parameters, optimizing performance and efficiency across a wide range of operating conditions. This has not only improved engine performance but also facilitated predictive maintenance, reducing downtime and operational costs for fleet operators.

Looking forward, the objectives for V8 engine development in highway transport are increasingly focused on sustainability and adaptability. There is a growing emphasis on developing engines that can operate on alternative fuels, such as biodiesel or hydrogen, without compromising on power output or reliability. Additionally, research is being conducted to further enhance engine efficiency through technologies like waste heat recovery systems and advanced combustion strategies.

In the context of highway transport, V8 engines have played a crucial role in shaping the performance and capabilities of heavy-duty trucks and commercial vehicles. The primary objective of V8 engine development in this sector has been to enhance the power-to-weight ratio, enabling trucks to haul heavier loads over longer distances while maintaining optimal fuel consumption. This has led to a series of technological advancements, including turbocharging, direct fuel injection, and variable valve timing.

The evolution of V8 engines for highway transport has also been influenced by increasingly stringent environmental regulations. Engine manufacturers have had to balance the demand for power with the need to reduce emissions and improve fuel economy. This has resulted in the development of more sophisticated engine management systems, advanced materials for lighter engine components, and the integration of hybrid technologies in some applications.

Another significant objective in V8 engine evolution has been the improvement of durability and reliability. Long-haul trucking demands engines that can operate continuously for extended periods under varying load conditions. This has led to advancements in engine cooling systems, lubrication technologies, and the use of more robust materials in engine construction.

The digital revolution has also played a pivotal role in V8 engine development. The integration of electronic control units (ECUs) and sophisticated sensors has enabled real-time monitoring and adjustment of engine parameters, optimizing performance and efficiency across a wide range of operating conditions. This has not only improved engine performance but also facilitated predictive maintenance, reducing downtime and operational costs for fleet operators.

Looking forward, the objectives for V8 engine development in highway transport are increasingly focused on sustainability and adaptability. There is a growing emphasis on developing engines that can operate on alternative fuels, such as biodiesel or hydrogen, without compromising on power output or reliability. Additionally, research is being conducted to further enhance engine efficiency through technologies like waste heat recovery systems and advanced combustion strategies.

Market Demand Analysis

The market demand for V8 engines in highway transport is undergoing significant transformation, driven by a complex interplay of economic, environmental, and technological factors. The trucking industry, a major consumer of V8 engines, continues to seek powerful and efficient propulsion systems to meet the growing demands of freight transportation. This demand is particularly pronounced in long-haul operations where high torque and sustained power output are crucial.

Despite increasing pressure from environmental regulations and the push towards electrification, V8 engines maintain a strong presence in the heavy-duty truck segment. Their ability to deliver robust performance under heavy loads and across diverse terrains makes them indispensable for many fleet operators. The market for V8-powered trucks is especially resilient in regions with extensive highway networks and where alternative fuel infrastructure is still developing.

However, the landscape is evolving rapidly. Stricter emission standards and fuel efficiency requirements are reshaping the demand dynamics. Manufacturers are investing heavily in developing V8 engines that comply with these regulations while maintaining the power output that customers expect. This has led to innovations in engine design, including advanced fuel injection systems, turbocharging technologies, and improved thermal management.

The aftermarket sector also plays a significant role in sustaining demand for V8 engines. Many operators opt to retrofit or upgrade existing vehicles with newer, more efficient V8 engines rather than investing in entirely new fleets. This trend is particularly evident in emerging markets where the cost of new vehicles can be prohibitive.

Interestingly, the performance car segment continues to influence the development of V8 engines for highway transport. Advancements in materials and engineering techniques, often pioneered in high-performance applications, are finding their way into commercial V8 engines, enhancing durability and efficiency.

The global supply chain disruptions and economic uncertainties have had a mixed impact on the V8 engine market. While they have slowed down new vehicle purchases in some sectors, they have also increased the value of existing V8-powered vehicles, driving up demand for maintenance and upgrades.

Looking ahead, the market for V8 engines in highway transport faces both challenges and opportunities. The push towards alternative powertrains, including electric and hydrogen fuel cells, is gaining momentum. However, the transition is likely to be gradual, especially in heavy-duty long-haul applications where V8 engines still offer unmatched performance characteristics. This creates a window of opportunity for V8 engine manufacturers to innovate and adapt, potentially extending the relevance of these powerplants in the evolving landscape of highway transport dynamics.

Despite increasing pressure from environmental regulations and the push towards electrification, V8 engines maintain a strong presence in the heavy-duty truck segment. Their ability to deliver robust performance under heavy loads and across diverse terrains makes them indispensable for many fleet operators. The market for V8-powered trucks is especially resilient in regions with extensive highway networks and where alternative fuel infrastructure is still developing.

However, the landscape is evolving rapidly. Stricter emission standards and fuel efficiency requirements are reshaping the demand dynamics. Manufacturers are investing heavily in developing V8 engines that comply with these regulations while maintaining the power output that customers expect. This has led to innovations in engine design, including advanced fuel injection systems, turbocharging technologies, and improved thermal management.

The aftermarket sector also plays a significant role in sustaining demand for V8 engines. Many operators opt to retrofit or upgrade existing vehicles with newer, more efficient V8 engines rather than investing in entirely new fleets. This trend is particularly evident in emerging markets where the cost of new vehicles can be prohibitive.

Interestingly, the performance car segment continues to influence the development of V8 engines for highway transport. Advancements in materials and engineering techniques, often pioneered in high-performance applications, are finding their way into commercial V8 engines, enhancing durability and efficiency.

The global supply chain disruptions and economic uncertainties have had a mixed impact on the V8 engine market. While they have slowed down new vehicle purchases in some sectors, they have also increased the value of existing V8-powered vehicles, driving up demand for maintenance and upgrades.

Looking ahead, the market for V8 engines in highway transport faces both challenges and opportunities. The push towards alternative powertrains, including electric and hydrogen fuel cells, is gaining momentum. However, the transition is likely to be gradual, especially in heavy-duty long-haul applications where V8 engines still offer unmatched performance characteristics. This creates a window of opportunity for V8 engine manufacturers to innovate and adapt, potentially extending the relevance of these powerplants in the evolving landscape of highway transport dynamics.

Technical Challenges

The integration of V8 engines into highway transport vehicles presents several significant technical challenges that require innovative solutions. One of the primary hurdles is the need for enhanced cooling systems to manage the increased heat generation from these powerful engines. The higher operating temperatures of V8 engines demand more efficient radiators, advanced coolant formulations, and improved airflow management to prevent overheating during long-haul journeys.

Another critical challenge lies in optimizing fuel efficiency without compromising performance. V8 engines are known for their high power output, but this often comes at the cost of increased fuel consumption. Engineers must develop sophisticated fuel injection systems, implement advanced combustion chamber designs, and utilize cutting-edge engine management software to strike a balance between power delivery and fuel economy.

The increased weight of V8 engines compared to smaller powerplants poses challenges for vehicle dynamics and handling. This necessitates redesigning suspension systems, adjusting weight distribution, and potentially incorporating active suspension technologies to maintain stability and maneuverability, especially for large trucks navigating diverse road conditions.

Emissions control represents a significant technical hurdle for V8-powered transport vehicles. Stricter environmental regulations require the development of more effective catalytic converters, particulate filters, and exhaust gas recirculation systems. Additionally, engineers must explore innovative solutions such as selective catalytic reduction (SCR) technology to reduce nitrogen oxide emissions without sacrificing engine performance.

Durability and longevity are crucial factors in highway transport, and V8 engines must be engineered to withstand the rigors of extended high-load operation. This involves developing more robust internal components, such as forged crankshafts and pistons, as well as implementing advanced lubrication systems to minimize wear and extend service intervals.

The integration of V8 engines with modern transmission systems presents another set of challenges. Engineers must design and calibrate transmissions capable of handling the increased torque output while optimizing gear ratios for both performance and efficiency. This may involve the development of advanced multi-speed automatic transmissions or even continuously variable transmissions (CVTs) specifically tailored for V8 applications in heavy-duty transport.

Lastly, the incorporation of V8 engines into highway transport vehicles necessitates advancements in noise, vibration, and harshness (NVH) control. The inherent characteristics of V8 engines can lead to increased cabin noise and vibration, potentially affecting driver comfort and fatigue levels during long journeys. Addressing this challenge requires innovative sound dampening materials, active noise cancellation technologies, and refined engine mounting systems to isolate vibrations effectively.

Another critical challenge lies in optimizing fuel efficiency without compromising performance. V8 engines are known for their high power output, but this often comes at the cost of increased fuel consumption. Engineers must develop sophisticated fuel injection systems, implement advanced combustion chamber designs, and utilize cutting-edge engine management software to strike a balance between power delivery and fuel economy.

The increased weight of V8 engines compared to smaller powerplants poses challenges for vehicle dynamics and handling. This necessitates redesigning suspension systems, adjusting weight distribution, and potentially incorporating active suspension technologies to maintain stability and maneuverability, especially for large trucks navigating diverse road conditions.

Emissions control represents a significant technical hurdle for V8-powered transport vehicles. Stricter environmental regulations require the development of more effective catalytic converters, particulate filters, and exhaust gas recirculation systems. Additionally, engineers must explore innovative solutions such as selective catalytic reduction (SCR) technology to reduce nitrogen oxide emissions without sacrificing engine performance.

Durability and longevity are crucial factors in highway transport, and V8 engines must be engineered to withstand the rigors of extended high-load operation. This involves developing more robust internal components, such as forged crankshafts and pistons, as well as implementing advanced lubrication systems to minimize wear and extend service intervals.

The integration of V8 engines with modern transmission systems presents another set of challenges. Engineers must design and calibrate transmissions capable of handling the increased torque output while optimizing gear ratios for both performance and efficiency. This may involve the development of advanced multi-speed automatic transmissions or even continuously variable transmissions (CVTs) specifically tailored for V8 applications in heavy-duty transport.

Lastly, the incorporation of V8 engines into highway transport vehicles necessitates advancements in noise, vibration, and harshness (NVH) control. The inherent characteristics of V8 engines can lead to increased cabin noise and vibration, potentially affecting driver comfort and fatigue levels during long journeys. Addressing this challenge requires innovative sound dampening materials, active noise cancellation technologies, and refined engine mounting systems to isolate vibrations effectively.

Current V8 Solutions

01 V8 Engine Design and Optimization

This category focuses on the design and optimization of V8 engines, including improvements in engine block structure, cylinder configuration, and overall performance. Innovations in this area aim to enhance power output, fuel efficiency, and reduce emissions while maintaining the characteristic V8 engine dynamics.- V8 Engine Design and Performance: V8 engines are known for their power and performance in transportation. The design of these engines, including cylinder arrangement and combustion dynamics, plays a crucial role in their efficiency and output. Advancements in V8 engine technology focus on improving fuel efficiency, reducing emissions, and enhancing overall performance for various transport applications.

- Transport Dynamics and Vehicle Control Systems: The integration of V8 engines with advanced vehicle control systems is essential for optimizing transport dynamics. These systems manage engine performance, transmission, and vehicle stability to enhance handling and safety. Innovations in this area include adaptive suspension systems, traction control, and electronic stability programs tailored for V8-powered vehicles.

- Fuel Efficiency and Emission Control: Improving fuel efficiency and reducing emissions are key challenges in V8 engine development for transport applications. Technologies such as direct injection, variable valve timing, and cylinder deactivation are employed to optimize fuel consumption. Advanced emission control systems, including catalytic converters and exhaust gas recirculation, are integrated to meet stringent environmental regulations.

- Cooling and Thermal Management: Effective cooling and thermal management are critical for maintaining optimal performance and longevity of V8 engines in transport applications. Advanced cooling systems, including precision-controlled coolant flow and innovative radiator designs, help manage the high heat output of these powerful engines. Thermal management strategies also contribute to improved fuel efficiency and reduced emissions.

- Transmission and Drivetrain Integration: The integration of V8 engines with advanced transmission and drivetrain systems is crucial for optimizing power delivery and overall vehicle dynamics. This includes the development of high-performance automatic transmissions, advanced all-wheel-drive systems, and electronic differentials. These components work in harmony with the V8 engine to enhance acceleration, handling, and overall driving experience in various transport scenarios.

02 Fuel Injection and Combustion Systems

Advancements in fuel injection and combustion systems for V8 engines are covered in this category. This includes developments in direct injection technology, variable valve timing, and combustion chamber design to improve fuel atomization, mixture formation, and overall combustion efficiency in V8 engines.Expand Specific Solutions03 Exhaust and Emissions Control

This category encompasses innovations in exhaust systems and emissions control technologies specifically designed for V8 engines. It includes advancements in catalytic converters, exhaust gas recirculation systems, and noise reduction techniques to meet stringent environmental regulations while maintaining engine performance.Expand Specific Solutions04 Cooling and Lubrication Systems

Improvements in cooling and lubrication systems for V8 engines are covered in this category. This includes innovations in oil circulation, coolant flow management, and thermal management techniques to enhance engine efficiency, longevity, and performance under various operating conditions.Expand Specific Solutions05 Engine Control and Management Systems

This category focuses on advanced control and management systems for V8 engines. It includes developments in engine control units (ECUs), sensors, and software algorithms to optimize engine performance, fuel economy, and emissions control in real-time across various driving conditions.Expand Specific Solutions

Key Industry Players

The V8 engine market in highway transport is in a mature stage, with established players like GM, Honda, Toyota, and Nissan dominating the landscape. The market size is substantial, driven by the continued demand for powerful engines in heavy-duty trucks and luxury vehicles. Technologically, V8 engines are well-developed, but innovations focus on improving fuel efficiency and reducing emissions. Companies like Valeo Systèmes de Contrôle Moteur and Schaeffler Technologies are at the forefront of developing advanced engine control systems and components to enhance V8 performance. Emerging players such as ePower Engine Systems are exploring hybrid V8 solutions, indicating a shift towards more sustainable technologies in this segment.

GM Global Technology Operations LLC

Technical Solution: GM's V8 engine technology focuses on Dynamic Fuel Management (DFM) system, which can deactivate cylinders in 17 different patterns to optimize fuel efficiency and performance. The latest generation of GM's V8 engines, such as the 6.2L V8 in the Chevrolet Silverado, incorporates advanced technologies like direct injection, variable valve timing, and a high compression ratio of 11.5:1 to deliver improved power output and fuel economy[1][3]. GM has also developed a new electrical architecture to support these advanced engine technologies, enabling faster data processing and more precise control over engine operations[5].

Strengths: Improved fuel efficiency, high power output, and advanced cylinder deactivation technology. Weaknesses: Complexity of the DFM system may lead to higher maintenance costs and potential reliability issues in the long term.

Toyota Motor Corp.

Technical Solution: Toyota's approach to V8 engine technology in highway transport focuses on balancing power and efficiency. Their latest V8 engines, such as the 5.7L i-FORCE V8 used in the Toyota Tundra, feature Dual Independent Variable Valve Timing with intelligence (VVT-i) and an Acoustic Control Induction System (ACIS) to optimize performance across a wide range of driving conditions[2]. Toyota has also implemented D-4S direct injection technology, which combines port and direct injection methods to improve fuel efficiency and reduce emissions[4]. Additionally, Toyota is exploring hybrid V8 powertrains for larger vehicles, integrating electric motors with traditional V8 engines to further enhance fuel economy and reduce environmental impact[6].

Strengths: Balanced performance and efficiency, proven reliability, and integration of hybrid technology. Weaknesses: Relatively conservative approach may lag behind competitors in terms of cutting-edge innovations.

Core V8 Innovations

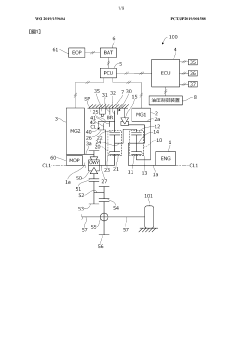

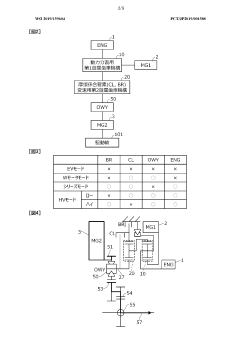

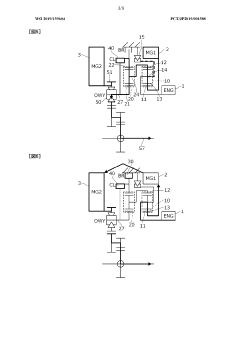

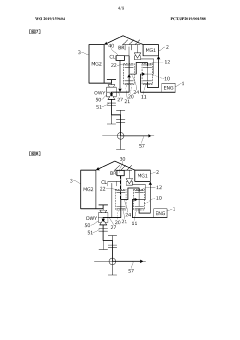

Hybrid vehicle driving device

PatentWO2019159604A1

Innovation

- A hybrid vehicle drive system with a simplified configuration using a first and second planetary gear mechanism, a one-way clutch, a brake mechanism, and a clutch mechanism, allowing for easy control of power transmission and gear shifting between EV, series, HV low, and HV high modes by controlling the engagement operations of the brake and clutch mechanisms.

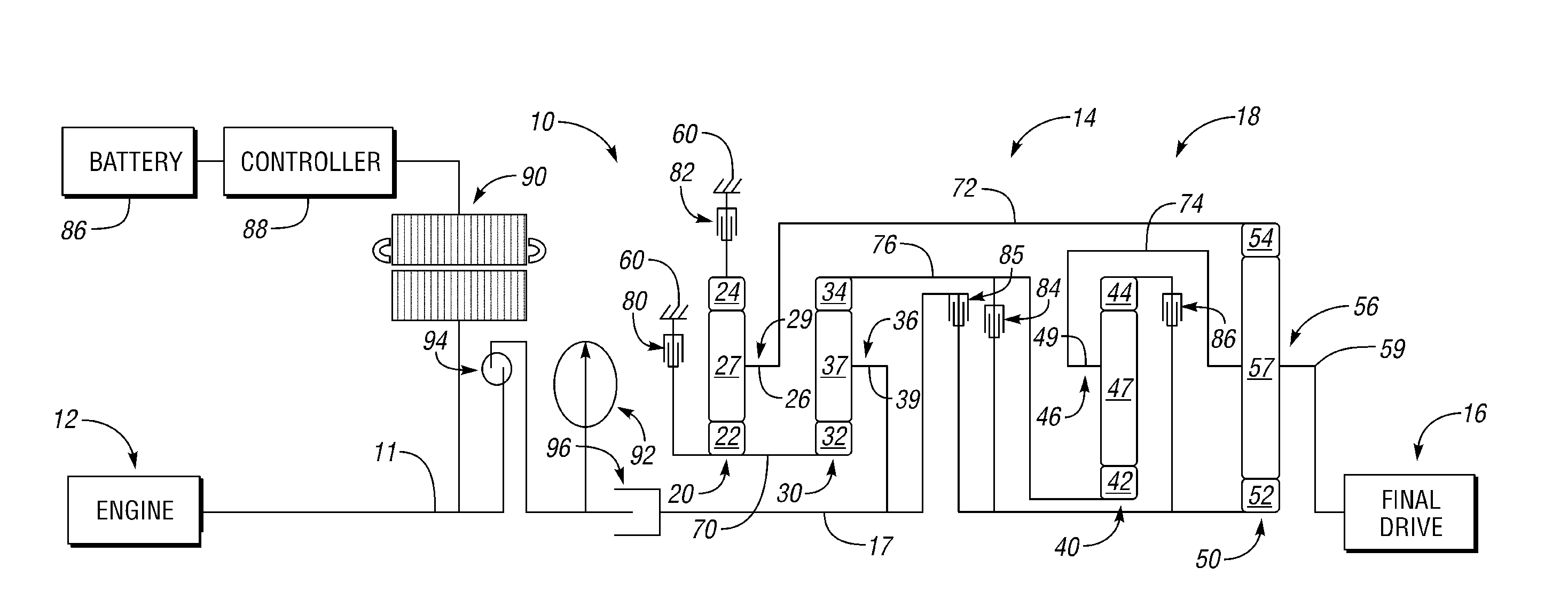

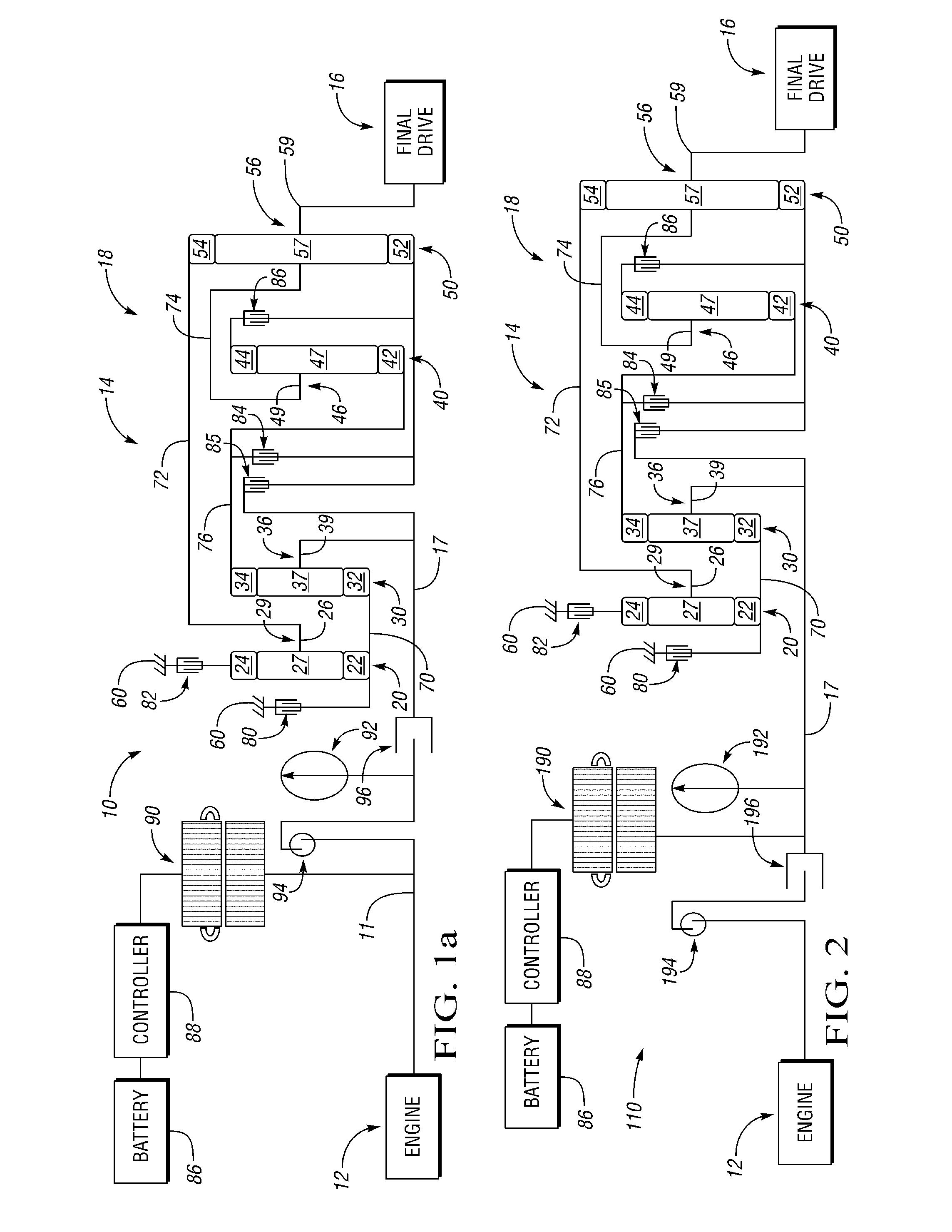

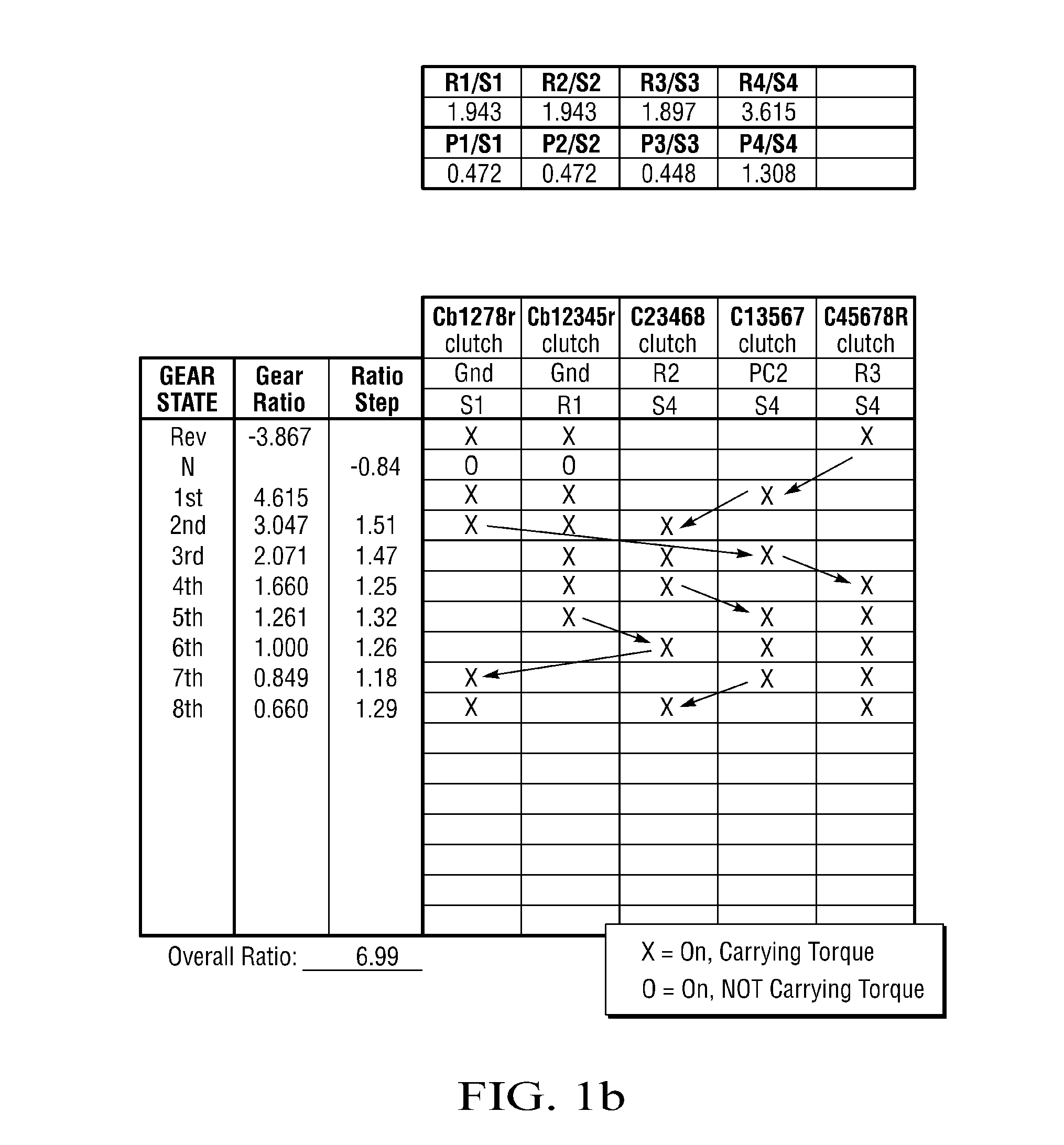

8-Speed Hybrid Transmission Architectures

PatentInactiveUS20100069191A1

Innovation

- A hybrid powertrain with four planetary gear sets and five torque-transmitting devices is used to provide eight forward speed ratios and one reverse speed ratio, allowing for efficient engine operation by combining electric motor assistance and regenerative braking, enabling the engine to be downsized without reducing performance.

Fuel Efficiency Impact

The impact of V8 engines on fuel efficiency in highway transport dynamics is significant and multifaceted. These powerful engines have undergone substantial improvements over the years, leading to enhanced fuel economy without compromising performance.

V8 engines, known for their high power output, have traditionally been associated with higher fuel consumption. However, recent advancements in engine technology have dramatically improved their efficiency. Modern V8 engines incorporate sophisticated fuel injection systems, variable valve timing, and cylinder deactivation technologies, all of which contribute to optimized fuel utilization.

One of the key factors in improving fuel efficiency is the implementation of direct fuel injection. This technology allows for precise control over fuel delivery, ensuring that only the necessary amount of fuel is used at any given moment. By optimizing the fuel-air mixture, direct injection systems significantly reduce fuel waste and improve overall engine efficiency.

Variable valve timing is another crucial innovation that has enhanced the fuel efficiency of V8 engines. This technology allows for dynamic adjustment of valve opening and closing times, optimizing engine performance across different operating conditions. As a result, the engine can maintain peak efficiency at various speeds and loads, leading to improved fuel economy during highway driving.

Cylinder deactivation, also known as variable displacement, is a feature that has revolutionized V8 engine efficiency. This technology allows the engine to shut down a portion of its cylinders when full power is not required, such as during highway cruising. By operating on fewer cylinders, the engine consumes less fuel while still providing sufficient power for maintaining highway speeds.

The integration of advanced materials and manufacturing techniques has also contributed to improved fuel efficiency. Lightweight components and reduced friction within the engine have led to decreased energy losses and better overall performance. These improvements translate directly into reduced fuel consumption during long-distance highway transport.

Furthermore, the development of sophisticated engine management systems has played a crucial role in optimizing fuel efficiency. These systems continuously monitor and adjust various engine parameters to ensure optimal performance and fuel economy under different driving conditions. By leveraging real-time data and adaptive algorithms, modern V8 engines can achieve remarkable fuel efficiency improvements compared to their predecessors.

In the context of highway transport dynamics, these advancements in V8 engine technology have had a profound impact. Long-haul trucks and heavy-duty vehicles equipped with modern V8 engines can now achieve significantly better fuel economy while maintaining the power and torque necessary for demanding transport operations. This improvement in efficiency not only reduces operational costs for transport companies but also contributes to lower emissions and a reduced environmental impact of highway transportation.

V8 engines, known for their high power output, have traditionally been associated with higher fuel consumption. However, recent advancements in engine technology have dramatically improved their efficiency. Modern V8 engines incorporate sophisticated fuel injection systems, variable valve timing, and cylinder deactivation technologies, all of which contribute to optimized fuel utilization.

One of the key factors in improving fuel efficiency is the implementation of direct fuel injection. This technology allows for precise control over fuel delivery, ensuring that only the necessary amount of fuel is used at any given moment. By optimizing the fuel-air mixture, direct injection systems significantly reduce fuel waste and improve overall engine efficiency.

Variable valve timing is another crucial innovation that has enhanced the fuel efficiency of V8 engines. This technology allows for dynamic adjustment of valve opening and closing times, optimizing engine performance across different operating conditions. As a result, the engine can maintain peak efficiency at various speeds and loads, leading to improved fuel economy during highway driving.

Cylinder deactivation, also known as variable displacement, is a feature that has revolutionized V8 engine efficiency. This technology allows the engine to shut down a portion of its cylinders when full power is not required, such as during highway cruising. By operating on fewer cylinders, the engine consumes less fuel while still providing sufficient power for maintaining highway speeds.

The integration of advanced materials and manufacturing techniques has also contributed to improved fuel efficiency. Lightweight components and reduced friction within the engine have led to decreased energy losses and better overall performance. These improvements translate directly into reduced fuel consumption during long-distance highway transport.

Furthermore, the development of sophisticated engine management systems has played a crucial role in optimizing fuel efficiency. These systems continuously monitor and adjust various engine parameters to ensure optimal performance and fuel economy under different driving conditions. By leveraging real-time data and adaptive algorithms, modern V8 engines can achieve remarkable fuel efficiency improvements compared to their predecessors.

In the context of highway transport dynamics, these advancements in V8 engine technology have had a profound impact. Long-haul trucks and heavy-duty vehicles equipped with modern V8 engines can now achieve significantly better fuel economy while maintaining the power and torque necessary for demanding transport operations. This improvement in efficiency not only reduces operational costs for transport companies but also contributes to lower emissions and a reduced environmental impact of highway transportation.

Environmental Regulations

The implementation of V8 engines in highway transport has significant implications for environmental regulations. As these powerful engines gain prominence in the trucking industry, regulatory bodies are compelled to reassess and adapt their policies to address the evolving landscape of emissions and fuel efficiency.

V8 engines, known for their high performance and torque output, have traditionally been associated with higher fuel consumption and emissions. However, recent advancements in engine technology have led to more efficient V8 designs, prompting a reevaluation of existing environmental standards. Regulatory agencies are now tasked with balancing the benefits of increased power and payload capacity against the potential environmental impact.

One key area of focus is the revision of emissions standards to accommodate the unique characteristics of V8-powered trucks. These regulations aim to ensure that the increased power output does not come at the cost of excessive pollutant emissions. As a result, manufacturers are investing in advanced emission control technologies, such as selective catalytic reduction (SCR) systems and diesel particulate filters (DPF), to meet stringent requirements.

Fuel efficiency standards are also undergoing scrutiny in light of V8 engine adoption. While these engines have historically been less fuel-efficient than their smaller counterparts, recent innovations have narrowed this gap. Regulatory bodies are now considering new metrics that take into account the improved ton-mile efficiency of V8-powered trucks, potentially leading to more nuanced fuel economy standards for heavy-duty vehicles.

The shift towards V8 engines in highway transport has also sparked discussions about lifecycle emissions and sustainability. Environmental regulations are expanding to encompass not only tailpipe emissions but also the overall carbon footprint of vehicle production and operation. This holistic approach is driving manufacturers to explore alternative materials and manufacturing processes to offset the potential increase in emissions associated with larger engines.

Furthermore, the adoption of V8 engines is influencing noise pollution regulations. The distinctive sound profile of these engines has led to the development of new noise reduction technologies and the implementation of stricter sound level limits for heavy-duty vehicles. These regulations aim to mitigate the impact of increased engine power on roadside communities and wildlife.

As V8 engines continue to transform highway transport dynamics, environmental regulations are evolving to address the complex interplay between performance, efficiency, and sustainability. This ongoing regulatory adaptation reflects the industry's commitment to balancing technological advancement with environmental stewardship, ensuring that the benefits of V8 engines are realized without compromising ecological goals.

V8 engines, known for their high performance and torque output, have traditionally been associated with higher fuel consumption and emissions. However, recent advancements in engine technology have led to more efficient V8 designs, prompting a reevaluation of existing environmental standards. Regulatory agencies are now tasked with balancing the benefits of increased power and payload capacity against the potential environmental impact.

One key area of focus is the revision of emissions standards to accommodate the unique characteristics of V8-powered trucks. These regulations aim to ensure that the increased power output does not come at the cost of excessive pollutant emissions. As a result, manufacturers are investing in advanced emission control technologies, such as selective catalytic reduction (SCR) systems and diesel particulate filters (DPF), to meet stringent requirements.

Fuel efficiency standards are also undergoing scrutiny in light of V8 engine adoption. While these engines have historically been less fuel-efficient than their smaller counterparts, recent innovations have narrowed this gap. Regulatory bodies are now considering new metrics that take into account the improved ton-mile efficiency of V8-powered trucks, potentially leading to more nuanced fuel economy standards for heavy-duty vehicles.

The shift towards V8 engines in highway transport has also sparked discussions about lifecycle emissions and sustainability. Environmental regulations are expanding to encompass not only tailpipe emissions but also the overall carbon footprint of vehicle production and operation. This holistic approach is driving manufacturers to explore alternative materials and manufacturing processes to offset the potential increase in emissions associated with larger engines.

Furthermore, the adoption of V8 engines is influencing noise pollution regulations. The distinctive sound profile of these engines has led to the development of new noise reduction technologies and the implementation of stricter sound level limits for heavy-duty vehicles. These regulations aim to mitigate the impact of increased engine power on roadside communities and wildlife.

As V8 engines continue to transform highway transport dynamics, environmental regulations are evolving to address the complex interplay between performance, efficiency, and sustainability. This ongoing regulatory adaptation reflects the industry's commitment to balancing technological advancement with environmental stewardship, ensuring that the benefits of V8 engines are realized without compromising ecological goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!