V8 Engine Acoustic Control: Latest Developments Explained

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Noise Control Background and Objectives

V8 engines have been a cornerstone of automotive engineering for decades, renowned for their power and performance. However, the inherent noise generated by these engines has long been a challenge for manufacturers and a concern for consumers. The evolution of V8 engine noise control technology reflects the industry's ongoing commitment to balancing performance with environmental and comfort considerations.

The primary objective of V8 engine acoustic control is to mitigate unwanted noise while preserving the characteristic sound that enthusiasts associate with high-performance vehicles. This goal has become increasingly important as regulatory bodies worldwide implement stricter noise emission standards for vehicles. Manufacturers must now navigate the complex task of reducing overall noise levels without compromising the engine's power output or the vehicle's auditory appeal.

Historically, V8 engine noise control focused on passive methods such as sound-absorbing materials and exhaust system modifications. However, as technology has advanced, the approach has shifted towards more sophisticated, active noise control systems. These modern solutions utilize electronic sensors, actuators, and advanced algorithms to dynamically manage engine acoustics in real-time.

The development of V8 engine acoustic control technology has been driven by several factors. Consumer demand for quieter, more refined vehicles has pushed manufacturers to innovate. Additionally, the rise of electric and hybrid vehicles has raised the bar for noise reduction in internal combustion engines, as they must now compete with the near-silent operation of electric powertrains.

Recent technological advancements have opened new avenues for V8 engine noise control. These include adaptive exhaust systems that can alter the engine's sound profile based on driving conditions, active noise cancellation technologies that use sound waves to counteract unwanted frequencies, and advanced materials science that has produced more effective sound-dampening components.

The objectives of current V8 engine acoustic control research and development are multifaceted. Engineers aim to create systems that can selectively reduce harmful or unpleasant frequencies while enhancing desirable sound characteristics. There is also a focus on developing solutions that are lightweight and energy-efficient, to avoid negatively impacting vehicle performance or fuel economy.

As the automotive industry continues to evolve, the future of V8 engine acoustic control lies in the integration of artificial intelligence and machine learning. These technologies promise to deliver more personalized and adaptive noise control solutions, capable of learning driver preferences and adjusting the engine's acoustic profile accordingly.

The primary objective of V8 engine acoustic control is to mitigate unwanted noise while preserving the characteristic sound that enthusiasts associate with high-performance vehicles. This goal has become increasingly important as regulatory bodies worldwide implement stricter noise emission standards for vehicles. Manufacturers must now navigate the complex task of reducing overall noise levels without compromising the engine's power output or the vehicle's auditory appeal.

Historically, V8 engine noise control focused on passive methods such as sound-absorbing materials and exhaust system modifications. However, as technology has advanced, the approach has shifted towards more sophisticated, active noise control systems. These modern solutions utilize electronic sensors, actuators, and advanced algorithms to dynamically manage engine acoustics in real-time.

The development of V8 engine acoustic control technology has been driven by several factors. Consumer demand for quieter, more refined vehicles has pushed manufacturers to innovate. Additionally, the rise of electric and hybrid vehicles has raised the bar for noise reduction in internal combustion engines, as they must now compete with the near-silent operation of electric powertrains.

Recent technological advancements have opened new avenues for V8 engine noise control. These include adaptive exhaust systems that can alter the engine's sound profile based on driving conditions, active noise cancellation technologies that use sound waves to counteract unwanted frequencies, and advanced materials science that has produced more effective sound-dampening components.

The objectives of current V8 engine acoustic control research and development are multifaceted. Engineers aim to create systems that can selectively reduce harmful or unpleasant frequencies while enhancing desirable sound characteristics. There is also a focus on developing solutions that are lightweight and energy-efficient, to avoid negatively impacting vehicle performance or fuel economy.

As the automotive industry continues to evolve, the future of V8 engine acoustic control lies in the integration of artificial intelligence and machine learning. These technologies promise to deliver more personalized and adaptive noise control solutions, capable of learning driver preferences and adjusting the engine's acoustic profile accordingly.

Market Demand for Quieter V8 Engines

The market demand for quieter V8 engines has been steadily increasing in recent years, driven by a combination of consumer preferences, regulatory pressures, and technological advancements. Luxury vehicle manufacturers and performance car enthusiasts have long valued the power and prestige associated with V8 engines. However, the traditional roar of these engines has become less desirable in urban environments and for daily driving scenarios.

Consumer surveys indicate a growing preference for vehicles that offer a balance between performance and comfort. Many buyers now seek the power of a V8 engine without the associated noise levels, particularly in premium and luxury segments. This shift in consumer behavior has prompted automakers to invest heavily in acoustic control technologies for their V8 powertrains.

Environmental regulations and noise pollution laws in various countries have also played a significant role in driving the demand for quieter engines. Urban areas, in particular, have implemented stricter noise limits for vehicles, pushing manufacturers to develop innovative solutions for engine sound reduction. The European Union, for instance, has set progressively lower noise limits for new vehicles, with specific targets for high-performance cars.

The automotive industry has responded to this market demand by developing advanced acoustic control systems for V8 engines. These technologies aim to reduce unwanted noise while preserving the characteristic V8 sound that enthusiasts appreciate. Active noise control systems, adaptive exhaust systems, and advanced engine mounts are among the solutions being implemented to meet this demand.

Market analysis shows that the global market for automotive acoustic materials is expected to grow significantly in the coming years, with a substantial portion attributed to high-performance engines like V8s. This growth is not limited to traditional automotive markets but is also seen in emerging economies where luxury vehicle sales are on the rise.

The demand for quieter V8 engines has also spurred innovation in related fields, such as materials science and digital sound processing. Companies specializing in acoustic materials and noise cancellation technologies have found new opportunities in the automotive sector, leading to partnerships and collaborations with engine manufacturers.

As the automotive industry continues its transition towards electrification, the demand for refined internal combustion engines, including quieter V8s, remains strong in certain market segments. This demand is particularly evident in the high-end sports car and luxury SUV markets, where the V8 engine's performance characteristics are still highly valued.

Consumer surveys indicate a growing preference for vehicles that offer a balance between performance and comfort. Many buyers now seek the power of a V8 engine without the associated noise levels, particularly in premium and luxury segments. This shift in consumer behavior has prompted automakers to invest heavily in acoustic control technologies for their V8 powertrains.

Environmental regulations and noise pollution laws in various countries have also played a significant role in driving the demand for quieter engines. Urban areas, in particular, have implemented stricter noise limits for vehicles, pushing manufacturers to develop innovative solutions for engine sound reduction. The European Union, for instance, has set progressively lower noise limits for new vehicles, with specific targets for high-performance cars.

The automotive industry has responded to this market demand by developing advanced acoustic control systems for V8 engines. These technologies aim to reduce unwanted noise while preserving the characteristic V8 sound that enthusiasts appreciate. Active noise control systems, adaptive exhaust systems, and advanced engine mounts are among the solutions being implemented to meet this demand.

Market analysis shows that the global market for automotive acoustic materials is expected to grow significantly in the coming years, with a substantial portion attributed to high-performance engines like V8s. This growth is not limited to traditional automotive markets but is also seen in emerging economies where luxury vehicle sales are on the rise.

The demand for quieter V8 engines has also spurred innovation in related fields, such as materials science and digital sound processing. Companies specializing in acoustic materials and noise cancellation technologies have found new opportunities in the automotive sector, leading to partnerships and collaborations with engine manufacturers.

As the automotive industry continues its transition towards electrification, the demand for refined internal combustion engines, including quieter V8s, remains strong in certain market segments. This demand is particularly evident in the high-end sports car and luxury SUV markets, where the V8 engine's performance characteristics are still highly valued.

Current Challenges in V8 Engine Acoustic Management

V8 engine acoustic management faces several significant challenges in the current automotive landscape. One of the primary issues is the increasing demand for quieter vehicle interiors, which puts pressure on engineers to reduce engine noise without compromising performance. This challenge is particularly acute in high-performance vehicles where the engine sound is an integral part of the driving experience.

Another major hurdle is the complex nature of V8 engine acoustics. The firing order, cylinder arrangement, and exhaust system all contribute to the engine's sound signature. Balancing these elements to achieve the desired acoustic profile while meeting stringent emissions and fuel efficiency standards presents a formidable engineering task.

The advent of electric and hybrid vehicles has also raised the bar for combustion engine acoustics. Consumers accustomed to the near-silent operation of electric motors now expect similar levels of refinement from traditional powertrains. This shift in expectations necessitates more sophisticated noise cancellation and sound design techniques for V8 engines.

Regulatory pressures pose another significant challenge. Increasingly strict noise pollution laws in many countries require automakers to limit external engine noise, particularly in urban areas. This often conflicts with the desire for a powerful and emotive engine sound, forcing engineers to develop innovative solutions that can adapt to different driving conditions and environments.

The integration of active noise control systems presents its own set of challenges. While these systems can effectively reduce unwanted noise, they add complexity, weight, and cost to the vehicle. Ensuring seamless operation and natural sound reproduction across various driving conditions requires advanced algorithms and precise calibration.

Material selection and design optimization for engine components also play a crucial role in acoustic management. Engineers must balance the need for lightweight materials to improve fuel efficiency with the acoustic properties required for effective noise and vibration damping. This often involves compromises and innovative material solutions.

Lastly, the subjective nature of sound appreciation adds another layer of complexity to V8 engine acoustic management. What sounds pleasing to one consumer may be undesirable to another, making it challenging to create a universally appealing acoustic profile. This subjectivity necessitates extensive market research and fine-tuning of engine sound characteristics to meet diverse consumer preferences across different markets and vehicle segments.

Another major hurdle is the complex nature of V8 engine acoustics. The firing order, cylinder arrangement, and exhaust system all contribute to the engine's sound signature. Balancing these elements to achieve the desired acoustic profile while meeting stringent emissions and fuel efficiency standards presents a formidable engineering task.

The advent of electric and hybrid vehicles has also raised the bar for combustion engine acoustics. Consumers accustomed to the near-silent operation of electric motors now expect similar levels of refinement from traditional powertrains. This shift in expectations necessitates more sophisticated noise cancellation and sound design techniques for V8 engines.

Regulatory pressures pose another significant challenge. Increasingly strict noise pollution laws in many countries require automakers to limit external engine noise, particularly in urban areas. This often conflicts with the desire for a powerful and emotive engine sound, forcing engineers to develop innovative solutions that can adapt to different driving conditions and environments.

The integration of active noise control systems presents its own set of challenges. While these systems can effectively reduce unwanted noise, they add complexity, weight, and cost to the vehicle. Ensuring seamless operation and natural sound reproduction across various driving conditions requires advanced algorithms and precise calibration.

Material selection and design optimization for engine components also play a crucial role in acoustic management. Engineers must balance the need for lightweight materials to improve fuel efficiency with the acoustic properties required for effective noise and vibration damping. This often involves compromises and innovative material solutions.

Lastly, the subjective nature of sound appreciation adds another layer of complexity to V8 engine acoustic management. What sounds pleasing to one consumer may be undesirable to another, making it challenging to create a universally appealing acoustic profile. This subjectivity necessitates extensive market research and fine-tuning of engine sound characteristics to meet diverse consumer preferences across different markets and vehicle segments.

Existing V8 Engine Noise Reduction Solutions

01 Active noise control systems for V8 engines

Implementation of active noise control systems specifically designed for V8 engines to reduce unwanted noise and vibrations. These systems use advanced algorithms and sensors to detect and counteract engine noise, improving overall acoustic comfort in the vehicle cabin.- Active noise control systems: Active noise control systems are used to reduce engine noise by generating sound waves that cancel out unwanted noise. These systems typically involve microphones to detect noise, processors to analyze and generate counter-signals, and speakers to emit canceling sound waves. This technology can be particularly effective for controlling low-frequency noise produced by V8 engines.

- Passive acoustic treatments: Passive acoustic treatments involve the use of sound-absorbing materials and structures to reduce engine noise. This can include specially designed engine covers, acoustic insulation, and resonators. These treatments are often used in combination with active noise control systems to achieve comprehensive noise reduction in V8 engines.

- Engine design optimization: Optimizing the design of V8 engines can significantly reduce noise generation at the source. This includes modifications to the engine block, crankshaft, and valve train to minimize vibrations and acoustic emissions. Advanced computer modeling and simulation techniques are often used to identify and address noise sources in the engine design phase.

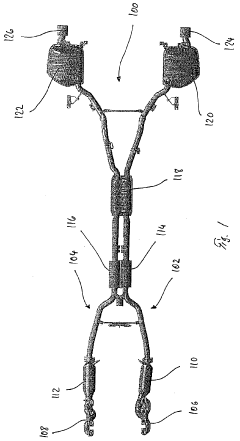

- Exhaust system modifications: Modifications to the exhaust system play a crucial role in controlling V8 engine acoustics. This can involve the use of specially designed mufflers, resonators, and catalytic converters to reduce exhaust noise while maintaining engine performance. Some systems also incorporate active exhaust valves that can alter the exhaust flow and sound characteristics based on driving conditions.

- Electronic sound enhancement: Electronic sound enhancement systems are used to improve the perceived sound quality of V8 engines. These systems can amplify desirable engine sounds while masking unwanted noise. They often involve the use of audio processors and in-cabin speakers to create a more pleasing and controlled acoustic environment for the vehicle occupants.

02 Exhaust system modifications for acoustic control

Modifications to the exhaust system of V8 engines to control and optimize acoustic output. This includes the use of specially designed mufflers, resonators, and exhaust pipes to manage sound levels and enhance the engine's auditory characteristics.Expand Specific Solutions03 Engine block and cylinder head design for noise reduction

Innovative designs for V8 engine blocks and cylinder heads that incorporate acoustic dampening features. These designs aim to reduce noise at the source by minimizing vibrations and resonances within the engine structure.Expand Specific Solutions04 Electronic sound enhancement for V8 engines

Implementation of electronic sound enhancement systems that augment or modify the natural sound of V8 engines. These systems can be used to create a more desirable engine note or to mask unwanted frequencies, improving the overall acoustic experience.Expand Specific Solutions05 Adaptive engine mounts for vibration control

Development of adaptive engine mounting systems that actively control and reduce vibrations transmitted from the V8 engine to the vehicle chassis. These mounts use sensors and actuators to dynamically adjust their stiffness and damping characteristics based on engine operating conditions.Expand Specific Solutions

Key Players in V8 Engine Acoustic Control Industry

The V8 Engine Acoustic Control market is in a growth phase, with increasing demand for quieter and more efficient engines. The global market size is estimated to be in the billions, driven by stringent noise regulations and consumer preferences for smoother rides. Technologically, the field is rapidly evolving, with companies like GM, Toyota, and Honda leading innovations. Hyundai and Kia are also making significant strides, while BMW and Ford are investing heavily in acoustic control technologies. Emerging players like Weichai Power and Mazda are contributing to the competitive landscape, pushing for more advanced solutions in engine noise reduction and vibration control.

GM Global Technology Operations LLC

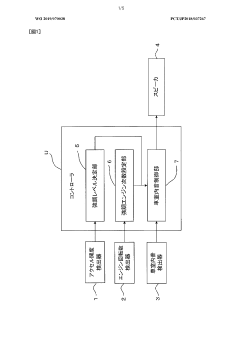

Technical Solution: GM has developed an advanced V8 Engine Acoustic Control system that utilizes active noise cancellation and sound enhancement technologies. The system employs strategically placed microphones and accelerometers to detect engine noise and vibration[1]. A sophisticated algorithm processes this data in real-time, generating counter-waves through the vehicle's audio system to neutralize unwanted sounds[3]. Additionally, GM's system can selectively enhance desirable engine notes, creating a more refined and sporty auditory experience. The technology also incorporates adaptive tuning based on driving conditions and user preferences, allowing for a customizable acoustic environment[5].

Strengths: Highly effective noise reduction, customizable sound profiles, and integration with existing audio systems. Weaknesses: Complexity may lead to higher costs and potential reliability issues in the long term.

Toyota Motor Corp.

Technical Solution: Toyota's V8 Engine Acoustic Control system focuses on a holistic approach combining passive and active noise control methods. Their latest developments include advanced engine encapsulation using multi-layer sound-absorbing materials[2]. This is complemented by an active noise control system that uses engine-mounted actuators to generate anti-noise vibrations, effectively cancelling out engine-induced vibrations at their source[4]. Toyota has also implemented a unique exhaust valve control system that modulates the exhaust note based on engine load and driver input, providing a more engaging driving experience while maintaining compliance with noise regulations[6].

Strengths: Comprehensive approach addressing both noise and vibration, effective at source control. Weaknesses: Potential increase in engine complexity and weight due to additional components.

Core Innovations in V8 Engine Acoustic Control

Exhaust system for an internal combustion engine

PatentWO2005033485A1

Innovation

- The exhaust system features a first silencer with a short outlet pipe and a second silencer with a longer outlet pipe, along with internal structures divided into partial spaces for gas exchange, to maintain the acoustically effective length and phase relationship, ensuring the preservation of odd-order frequency components and harmonics.

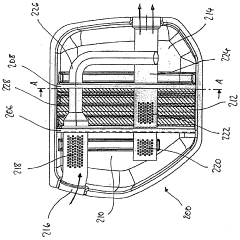

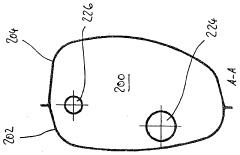

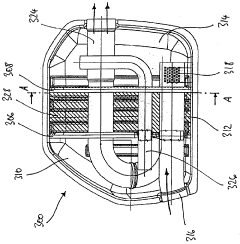

Sound control device for vehicle

PatentWO2019070038A1

Innovation

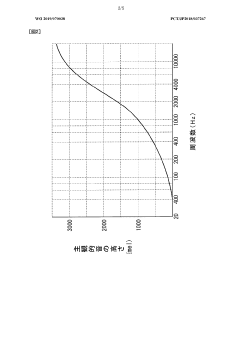

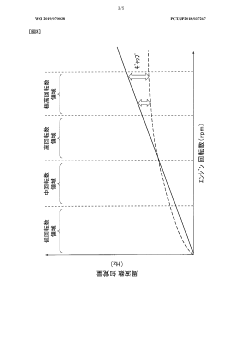

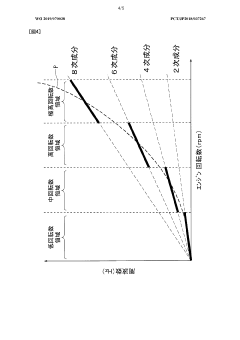

- A vehicle acoustic control device that includes a prime mover rotation speed detector and an emphasis order setting section to emphasize higher-order components of the prime mover sound as the rotation speed increases, allowing the vehicle interior sound control unit to adjust and control the sound generated by the speaker, ensuring that higher-order components are emphasized and other components are attenuated to improve the driver's perception of engine sound changes.

Environmental Regulations Impact on V8 Engine Design

Environmental regulations have significantly impacted V8 engine design, particularly in the realm of acoustic control. As governments worldwide implement stricter emissions and noise pollution standards, manufacturers have been compelled to adapt their V8 engines to meet these requirements while maintaining performance and consumer appeal.

One of the primary challenges faced by V8 engine designers is the reduction of noise emissions. Traditional V8 engines are known for their distinctive, powerful sound, which has long been a selling point for enthusiasts. However, this characteristic rumble often exceeds modern noise limits, necessitating innovative solutions in acoustic management.

To address these regulatory challenges, manufacturers have implemented various technologies and design modifications. Active noise control systems have become increasingly prevalent in V8-equipped vehicles. These systems use sound-canceling technology to reduce engine noise inside the cabin, allowing for a quieter ride while maintaining the engine's performance characteristics.

Exhaust system redesigns have also played a crucial role in meeting environmental regulations. Variable exhaust valves and resonators are now commonly employed to modulate exhaust noise based on driving conditions and engine load. These systems can provide a more subdued sound during normal operation while still allowing for a sportier note when desired.

Engine encapsulation has emerged as another effective method for controlling V8 acoustic emissions. By surrounding the engine with sound-absorbing materials, manufacturers can significantly reduce noise pollution without compromising engine performance. This approach has the added benefit of improving thermal efficiency, which aligns with fuel economy regulations.

The push for cleaner emissions has led to the widespread adoption of direct injection and turbocharging in V8 engines. While these technologies primarily address fuel efficiency and emissions, they also impact the engine's acoustic profile. The higher-pressure fuel injection and forced induction systems introduce new sound characteristics that must be carefully managed to meet noise regulations.

Cylinder deactivation technology, which allows V8 engines to operate on fewer cylinders under light load conditions, has become more sophisticated in response to environmental regulations. This not only improves fuel economy but also reduces noise emissions during cruising, helping vehicles comply with urban noise limits.

As environmental regulations continue to evolve, the future of V8 engine design is likely to see further innovations in acoustic control. Advanced materials, improved computational fluid dynamics for exhaust flow optimization, and integration with hybrid powertrains are all areas of ongoing development aimed at preserving the V8 engine's place in the market while meeting increasingly stringent environmental standards.

One of the primary challenges faced by V8 engine designers is the reduction of noise emissions. Traditional V8 engines are known for their distinctive, powerful sound, which has long been a selling point for enthusiasts. However, this characteristic rumble often exceeds modern noise limits, necessitating innovative solutions in acoustic management.

To address these regulatory challenges, manufacturers have implemented various technologies and design modifications. Active noise control systems have become increasingly prevalent in V8-equipped vehicles. These systems use sound-canceling technology to reduce engine noise inside the cabin, allowing for a quieter ride while maintaining the engine's performance characteristics.

Exhaust system redesigns have also played a crucial role in meeting environmental regulations. Variable exhaust valves and resonators are now commonly employed to modulate exhaust noise based on driving conditions and engine load. These systems can provide a more subdued sound during normal operation while still allowing for a sportier note when desired.

Engine encapsulation has emerged as another effective method for controlling V8 acoustic emissions. By surrounding the engine with sound-absorbing materials, manufacturers can significantly reduce noise pollution without compromising engine performance. This approach has the added benefit of improving thermal efficiency, which aligns with fuel economy regulations.

The push for cleaner emissions has led to the widespread adoption of direct injection and turbocharging in V8 engines. While these technologies primarily address fuel efficiency and emissions, they also impact the engine's acoustic profile. The higher-pressure fuel injection and forced induction systems introduce new sound characteristics that must be carefully managed to meet noise regulations.

Cylinder deactivation technology, which allows V8 engines to operate on fewer cylinders under light load conditions, has become more sophisticated in response to environmental regulations. This not only improves fuel economy but also reduces noise emissions during cruising, helping vehicles comply with urban noise limits.

As environmental regulations continue to evolve, the future of V8 engine design is likely to see further innovations in acoustic control. Advanced materials, improved computational fluid dynamics for exhaust flow optimization, and integration with hybrid powertrains are all areas of ongoing development aimed at preserving the V8 engine's place in the market while meeting increasingly stringent environmental standards.

Performance vs. Noise Trade-offs in V8 Engines

The trade-off between performance and noise in V8 engines represents a significant challenge for automotive engineers and manufacturers. As V8 engines are renowned for their power and distinctive sound, balancing these attributes with increasingly stringent noise regulations and consumer preferences for quieter vehicles has become a critical focus in engine development.

Performance enhancements in V8 engines often lead to increased noise levels. Higher compression ratios, larger displacement, and more aggressive camshaft profiles contribute to improved power output but also result in greater mechanical noise and exhaust sound. This creates a dilemma for engineers who must maintain the engine's performance characteristics while adhering to noise regulations and meeting customer expectations for comfort.

Recent advancements in acoustic control technologies have provided new avenues for addressing this trade-off. Active noise control systems, which use sound waves to cancel out unwanted engine noise, have been implemented in some high-end vehicles. These systems can selectively reduce certain frequencies, allowing manufacturers to preserve the desirable aspects of the V8 sound while minimizing less pleasant tones.

Material science has also played a crucial role in noise reduction efforts. The development of advanced sound-absorbing materials and improved engine bay insulation has helped to contain engine noise without significantly impacting performance. Additionally, precision manufacturing techniques have reduced tolerances in engine components, minimizing mechanical noise sources.

Exhaust system design has evolved to incorporate variable valve systems and adaptive mufflers. These technologies allow for dynamic control of exhaust flow and sound, enabling a quieter operation during normal driving conditions while preserving the ability to produce a more aggressive sound when desired or when operating at higher performance levels.

Engine management systems have become increasingly sophisticated, allowing for real-time adjustments to engine parameters based on driving conditions and noise targets. This includes variable valve timing and lift systems that can alter the engine's breathing characteristics to optimize performance while managing noise output.

Despite these advancements, the fundamental challenge remains: preserving the iconic V8 sound and performance while meeting ever-tightening noise regulations. This has led some manufacturers to explore artificial sound enhancement technologies, which can augment or modify the engine sound heard inside the vehicle cabin. While controversial among purists, these systems offer a potential solution to maintain the perceived performance characteristics of V8 engines while adhering to noise limitations.

Performance enhancements in V8 engines often lead to increased noise levels. Higher compression ratios, larger displacement, and more aggressive camshaft profiles contribute to improved power output but also result in greater mechanical noise and exhaust sound. This creates a dilemma for engineers who must maintain the engine's performance characteristics while adhering to noise regulations and meeting customer expectations for comfort.

Recent advancements in acoustic control technologies have provided new avenues for addressing this trade-off. Active noise control systems, which use sound waves to cancel out unwanted engine noise, have been implemented in some high-end vehicles. These systems can selectively reduce certain frequencies, allowing manufacturers to preserve the desirable aspects of the V8 sound while minimizing less pleasant tones.

Material science has also played a crucial role in noise reduction efforts. The development of advanced sound-absorbing materials and improved engine bay insulation has helped to contain engine noise without significantly impacting performance. Additionally, precision manufacturing techniques have reduced tolerances in engine components, minimizing mechanical noise sources.

Exhaust system design has evolved to incorporate variable valve systems and adaptive mufflers. These technologies allow for dynamic control of exhaust flow and sound, enabling a quieter operation during normal driving conditions while preserving the ability to produce a more aggressive sound when desired or when operating at higher performance levels.

Engine management systems have become increasingly sophisticated, allowing for real-time adjustments to engine parameters based on driving conditions and noise targets. This includes variable valve timing and lift systems that can alter the engine's breathing characteristics to optimize performance while managing noise output.

Despite these advancements, the fundamental challenge remains: preserving the iconic V8 sound and performance while meeting ever-tightening noise regulations. This has led some manufacturers to explore artificial sound enhancement technologies, which can augment or modify the engine sound heard inside the vehicle cabin. While controversial among purists, these systems offer a potential solution to maintain the perceived performance characteristics of V8 engines while adhering to noise limitations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!