V8 Engine Role in Renewable Energy Vehicles: An Overview

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception, adapting to changing market demands and technological advancements. Initially designed for high-performance vehicles, the V8 engine has found its way into various applications, including renewable energy vehicles.

In the early stages of V8 engine development, the focus was primarily on increasing power output and improving efficiency. Engineers worked on optimizing combustion processes, enhancing fuel delivery systems, and refining engine block designs. These efforts resulted in more powerful and reliable V8 engines, which became popular in luxury cars and sports vehicles.

As environmental concerns grew, the automotive industry faced pressure to reduce emissions and improve fuel economy. This led to a shift in V8 engine development, with manufacturers exploring ways to make these engines more environmentally friendly without sacrificing performance. Technologies such as variable valve timing, direct fuel injection, and cylinder deactivation were introduced to improve efficiency and reduce fuel consumption.

The advent of hybrid technology marked a significant milestone in V8 engine evolution. Manufacturers began integrating electric motors with V8 engines, creating hybrid powertrains that offered improved fuel economy and reduced emissions while maintaining the power and performance associated with V8 engines. This hybrid approach allowed V8 engines to remain relevant in an increasingly eco-conscious market.

In recent years, the role of V8 engines in renewable energy vehicles has expanded beyond traditional hybrid systems. Some manufacturers have explored the use of V8 engines as range extenders in plug-in hybrid electric vehicles (PHEVs). In this configuration, the V8 engine serves as a generator to charge the battery pack, allowing for extended driving range and improved overall efficiency.

Furthermore, advancements in alternative fuels have opened new possibilities for V8 engines in renewable energy vehicles. Researchers have been exploring the use of biofuels, hydrogen, and synthetic fuels in V8 engines, aiming to reduce their carbon footprint while maintaining their performance characteristics. These developments have led to the creation of flex-fuel V8 engines capable of running on various renewable fuel sources.

The integration of advanced materials and manufacturing techniques has also played a crucial role in V8 engine evolution. Lightweight alloys, 3D printing, and advanced coatings have enabled the production of more efficient and durable V8 engines, further enhancing their suitability for renewable energy applications.

As the automotive industry continues to push towards electrification, the future of V8 engines in renewable energy vehicles remains uncertain. However, ongoing research and development efforts suggest that V8 engines may continue to evolve, potentially finding new roles in niche applications or serving as transitional technologies in the shift towards fully renewable energy-powered vehicles.

In the early stages of V8 engine development, the focus was primarily on increasing power output and improving efficiency. Engineers worked on optimizing combustion processes, enhancing fuel delivery systems, and refining engine block designs. These efforts resulted in more powerful and reliable V8 engines, which became popular in luxury cars and sports vehicles.

As environmental concerns grew, the automotive industry faced pressure to reduce emissions and improve fuel economy. This led to a shift in V8 engine development, with manufacturers exploring ways to make these engines more environmentally friendly without sacrificing performance. Technologies such as variable valve timing, direct fuel injection, and cylinder deactivation were introduced to improve efficiency and reduce fuel consumption.

The advent of hybrid technology marked a significant milestone in V8 engine evolution. Manufacturers began integrating electric motors with V8 engines, creating hybrid powertrains that offered improved fuel economy and reduced emissions while maintaining the power and performance associated with V8 engines. This hybrid approach allowed V8 engines to remain relevant in an increasingly eco-conscious market.

In recent years, the role of V8 engines in renewable energy vehicles has expanded beyond traditional hybrid systems. Some manufacturers have explored the use of V8 engines as range extenders in plug-in hybrid electric vehicles (PHEVs). In this configuration, the V8 engine serves as a generator to charge the battery pack, allowing for extended driving range and improved overall efficiency.

Furthermore, advancements in alternative fuels have opened new possibilities for V8 engines in renewable energy vehicles. Researchers have been exploring the use of biofuels, hydrogen, and synthetic fuels in V8 engines, aiming to reduce their carbon footprint while maintaining their performance characteristics. These developments have led to the creation of flex-fuel V8 engines capable of running on various renewable fuel sources.

The integration of advanced materials and manufacturing techniques has also played a crucial role in V8 engine evolution. Lightweight alloys, 3D printing, and advanced coatings have enabled the production of more efficient and durable V8 engines, further enhancing their suitability for renewable energy applications.

As the automotive industry continues to push towards electrification, the future of V8 engines in renewable energy vehicles remains uncertain. However, ongoing research and development efforts suggest that V8 engines may continue to evolve, potentially finding new roles in niche applications or serving as transitional technologies in the shift towards fully renewable energy-powered vehicles.

Market Demand Analysis

The market demand for V8 engines in renewable energy vehicles is undergoing a significant transformation. As the automotive industry shifts towards more sustainable solutions, there's a growing interest in adapting traditional high-performance engines to work with renewable energy sources. This trend is driven by consumers who desire the power and prestige associated with V8 engines but also want to reduce their environmental impact.

The global market for renewable energy vehicles is expanding rapidly, with electric and hybrid vehicles leading the charge. However, a niche market is emerging for high-performance vehicles that can offer the excitement of a V8 engine while utilizing renewable energy sources. This segment is particularly attractive to luxury and sports car manufacturers who are looking to maintain their brand identity while meeting increasingly stringent environmental regulations.

Market research indicates that there's a substantial demand from automotive enthusiasts who are reluctant to give up the distinctive sound and feel of a V8 engine. These consumers are willing to pay a premium for vehicles that can deliver both performance and eco-friendliness. As a result, several major automakers are investing in research and development to create V8 engines that can run on biofuels, hydrogen, or in hybrid configurations.

The potential market size for V8-powered renewable energy vehicles is significant, especially in regions with a strong car culture and high disposable incomes. North America, Europe, and parts of Asia are expected to be the primary markets for these vehicles. Industry analysts project that this niche could represent a multi-billion dollar opportunity within the next decade, as technology advances and production scales up.

However, the market faces several challenges. The high cost of developing and producing these specialized engines may limit their accessibility to a broader consumer base. Additionally, the availability of renewable fuels and the necessary infrastructure to support them varies greatly across different regions, which could impact market growth.

Despite these challenges, the industry trend is clear: there's a growing demand for vehicles that can reconcile high performance with environmental responsibility. This has led to increased collaboration between traditional engine manufacturers and renewable energy specialists to develop innovative solutions. As technology progresses and economies of scale are achieved, the market for V8 engines in renewable energy vehicles is expected to expand, potentially reshaping the landscape of high-performance automotive engineering.

The global market for renewable energy vehicles is expanding rapidly, with electric and hybrid vehicles leading the charge. However, a niche market is emerging for high-performance vehicles that can offer the excitement of a V8 engine while utilizing renewable energy sources. This segment is particularly attractive to luxury and sports car manufacturers who are looking to maintain their brand identity while meeting increasingly stringent environmental regulations.

Market research indicates that there's a substantial demand from automotive enthusiasts who are reluctant to give up the distinctive sound and feel of a V8 engine. These consumers are willing to pay a premium for vehicles that can deliver both performance and eco-friendliness. As a result, several major automakers are investing in research and development to create V8 engines that can run on biofuels, hydrogen, or in hybrid configurations.

The potential market size for V8-powered renewable energy vehicles is significant, especially in regions with a strong car culture and high disposable incomes. North America, Europe, and parts of Asia are expected to be the primary markets for these vehicles. Industry analysts project that this niche could represent a multi-billion dollar opportunity within the next decade, as technology advances and production scales up.

However, the market faces several challenges. The high cost of developing and producing these specialized engines may limit their accessibility to a broader consumer base. Additionally, the availability of renewable fuels and the necessary infrastructure to support them varies greatly across different regions, which could impact market growth.

Despite these challenges, the industry trend is clear: there's a growing demand for vehicles that can reconcile high performance with environmental responsibility. This has led to increased collaboration between traditional engine manufacturers and renewable energy specialists to develop innovative solutions. As technology progresses and economies of scale are achieved, the market for V8 engines in renewable energy vehicles is expected to expand, potentially reshaping the landscape of high-performance automotive engineering.

Technical Challenges

The integration of V8 engines in renewable energy vehicles presents several significant technical challenges. One of the primary obstacles is the inherent conflict between the high fuel consumption of V8 engines and the eco-friendly goals of renewable energy vehicles. This discrepancy necessitates innovative solutions to improve fuel efficiency without compromising the power output that V8 engines are known for.

Another major challenge lies in the adaptation of V8 engines to alternative fuel sources. While traditional V8 engines are designed to run on gasoline or diesel, their use in renewable energy vehicles requires modifications to accommodate biofuels, hydrogen, or other sustainable energy sources. This adaptation process involves complex engineering tasks, including redesigning fuel injection systems, adjusting combustion chamber geometries, and developing new engine management software.

The weight of V8 engines poses a significant hurdle in the context of renewable energy vehicles. These engines are typically heavier than their smaller counterparts, which can negatively impact the overall efficiency and range of the vehicle. Engineers must find ways to reduce engine weight without sacrificing durability or performance, possibly through the use of advanced materials or innovative design techniques.

Emissions control represents another critical challenge. V8 engines, known for their high power output, also tend to produce more emissions compared to smaller engines. Meeting increasingly stringent environmental regulations while maintaining the characteristic performance of V8 engines requires advanced exhaust after-treatment systems and sophisticated engine control strategies.

The integration of V8 engines with hybrid or electric powertrains presents additional complexities. Balancing the power delivery between the V8 engine and electric motors, managing thermal issues, and optimizing energy recovery systems are all areas that demand innovative solutions. This integration must be seamless to ensure smooth operation and maximize overall system efficiency.

Noise and vibration control is another area of concern. V8 engines are often valued for their distinctive sound, but this can be at odds with the quiet operation expected from renewable energy vehicles. Developing effective noise cancellation technologies and vibration damping systems without compromising the engine's character is a delicate balance to achieve.

Lastly, the cost factor cannot be overlooked. Incorporating V8 engines into renewable energy vehicles while keeping the final product affordable and competitive in the market is a significant challenge. This requires careful consideration of manufacturing processes, material selection, and overall vehicle design to ensure economic viability.

Another major challenge lies in the adaptation of V8 engines to alternative fuel sources. While traditional V8 engines are designed to run on gasoline or diesel, their use in renewable energy vehicles requires modifications to accommodate biofuels, hydrogen, or other sustainable energy sources. This adaptation process involves complex engineering tasks, including redesigning fuel injection systems, adjusting combustion chamber geometries, and developing new engine management software.

The weight of V8 engines poses a significant hurdle in the context of renewable energy vehicles. These engines are typically heavier than their smaller counterparts, which can negatively impact the overall efficiency and range of the vehicle. Engineers must find ways to reduce engine weight without sacrificing durability or performance, possibly through the use of advanced materials or innovative design techniques.

Emissions control represents another critical challenge. V8 engines, known for their high power output, also tend to produce more emissions compared to smaller engines. Meeting increasingly stringent environmental regulations while maintaining the characteristic performance of V8 engines requires advanced exhaust after-treatment systems and sophisticated engine control strategies.

The integration of V8 engines with hybrid or electric powertrains presents additional complexities. Balancing the power delivery between the V8 engine and electric motors, managing thermal issues, and optimizing energy recovery systems are all areas that demand innovative solutions. This integration must be seamless to ensure smooth operation and maximize overall system efficiency.

Noise and vibration control is another area of concern. V8 engines are often valued for their distinctive sound, but this can be at odds with the quiet operation expected from renewable energy vehicles. Developing effective noise cancellation technologies and vibration damping systems without compromising the engine's character is a delicate balance to achieve.

Lastly, the cost factor cannot be overlooked. Incorporating V8 engines into renewable energy vehicles while keeping the final product affordable and competitive in the market is a significant challenge. This requires careful consideration of manufacturing processes, material selection, and overall vehicle design to ensure economic viability.

Current V8 Solutions

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously improved to enhance performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously improved to enhance performance and efficiency.

- Fuel Efficiency and Emissions Control: Modern V8 engines incorporate advanced technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Innovations in these areas aim to meet stringent environmental regulations while maintaining the power and performance characteristics of V8 engines.

- Performance Enhancement and Tuning: Various methods and components are developed to enhance the performance of V8 engines. These include turbocharging, supercharging, intake and exhaust system optimization, and engine management system tuning. Performance enhancements focus on increasing horsepower, torque, and overall engine efficiency across different operating conditions.

- Cooling and Lubrication Systems: Effective cooling and lubrication are crucial for V8 engine reliability and longevity. Innovations in cooling systems, including advanced radiator designs, electric water pumps, and precision-controlled thermostats, help maintain optimal operating temperatures. Improved lubrication systems ensure proper oil distribution to all critical engine components, reducing wear and extending engine life.

- Manufacturing and Assembly Techniques: Advancements in manufacturing and assembly techniques for V8 engines focus on improving precision, reducing weight, and enhancing durability. These may include the use of lightweight materials, advanced casting and machining processes, and innovative assembly methods. Improved manufacturing techniques contribute to better engine performance, reliability, and cost-effectiveness in production.

02 Fuel Efficiency and Emissions Control

Modern V8 engines incorporate advanced technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Innovations in engine management systems and combustion processes aim to optimize fuel consumption while maintaining high performance levels and meeting stringent emission standards.Expand Specific Solutions03 Performance Enhancement and Tuning

Various methods and components are developed to enhance V8 engine performance. These include turbocharging, supercharging, intercooling, and high-flow intake and exhaust systems. Advanced materials and manufacturing techniques are employed to reduce weight, improve thermal efficiency, and increase durability. Engine tuning software and hardware modifications allow for customization of power output and torque characteristics.Expand Specific Solutions04 Cooling and Lubrication Systems

Efficient cooling and lubrication are crucial for V8 engine performance and longevity. Innovations in coolant flow design, oil circulation systems, and heat management contribute to improved engine efficiency and reliability. Advanced cooling technologies, such as precision cooling and integrated thermal management systems, help maintain optimal operating temperatures under various conditions.Expand Specific Solutions05 Integration with Hybrid and Electric Systems

As automotive technology evolves, V8 engines are being integrated with hybrid and electric systems to meet future performance and efficiency demands. This includes the development of mild hybrid systems, plug-in hybrid powertrains, and advanced start-stop technologies specifically designed for V8 engines. These integrations aim to combine the power of V8 engines with the efficiency benefits of electrification.Expand Specific Solutions

Key Industry Players

The V8 engine's role in renewable energy vehicles presents a complex competitive landscape. The industry is in a transitional phase, with traditional automotive giants like GM, Honda, BMW, and Toyota competing against newer entrants focused on electric and hybrid technologies. The market size is expanding rapidly as governments worldwide push for cleaner transportation solutions. Technologically, companies are at varying stages of maturity. Established players like Ford and Hyundai are leveraging their expertise to develop more efficient V8 engines, while firms like Ballard Power Systems and Turntide Technologies are pioneering alternative powertrains. This diversity in approaches reflects the industry's ongoing evolution towards sustainable mobility solutions.

GM Global Technology Operations LLC

Technical Solution: GM has developed a novel V8 engine design for hybrid electric vehicles, focusing on improving fuel efficiency and reducing emissions. The engine incorporates advanced technologies such as variable valve timing, direct fuel injection, and cylinder deactivation. GM's V8 engine for renewable energy vehicles uses a 48-volt mild hybrid system, which allows for improved start-stop functionality and energy recuperation during braking[1]. The engine also features a compact design that allows for easier integration with electric powertrains, making it suitable for various hybrid configurations[2].

Strengths: Improved fuel efficiency, reduced emissions, and compatibility with hybrid systems. Weaknesses: Still relies on fossil fuels, may be less efficient than full electric powertrains in certain scenarios.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a unique V8 engine concept for renewable energy vehicles, focusing on hydrogen fuel cell technology. Their V8 engine design incorporates a hydrogen fuel cell stack that generates electricity to power electric motors. The system combines the high power output of a V8 configuration with zero-emission hydrogen fuel technology. Honda's V8 fuel cell engine utilizes advanced materials for hydrogen storage and a high-efficiency fuel cell stack, achieving a power density comparable to traditional V8 engines[3]. The system also integrates regenerative braking and energy recovery systems to maximize overall efficiency[4].

Strengths: Zero emissions, high power output, and potential for long-range driving. Weaknesses: Limited hydrogen infrastructure, high production costs, and complexity of fuel cell systems.

Core V8 Innovations

Flame-retardant molded articles for electrical devices

PatentPendingUS20240059867A1

Innovation

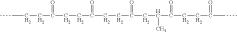

- A flame-retardant molded article comprising a polymer matrix of crosslinked aliphatic polyketone (PK) combined with a special diamine source as a crosslinking agent to form imine groups, along with a flame retardant, enhancing mechanical and thermal properties while maintaining processability.

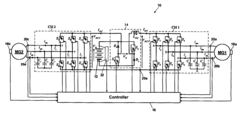

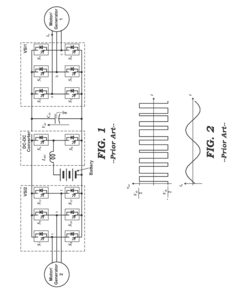

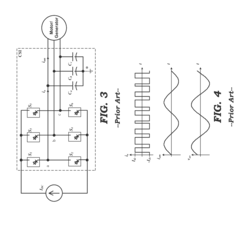

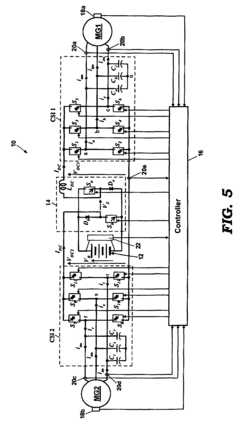

Power conversion apparatus and method

PatentInactiveUS8110948B2

Innovation

- A power conversion apparatus using a voltage-to-current converter to enable a current source inverter to operate from a voltage energy storage device, eliminating the need for DC bus capacitors and allowing for efficient current control and charging during dynamic braking, while reducing electromagnetic interference.

Emissions Regulations

Emissions regulations play a crucial role in shaping the automotive industry's approach to vehicle design and powertrain development. As governments worldwide strive to reduce greenhouse gas emissions and improve air quality, stringent regulations have been implemented to limit vehicle emissions. These regulations have a significant impact on the role of V8 engines in renewable energy vehicles.

In recent years, many countries have adopted increasingly strict emissions standards. The European Union's Euro 6 standards, for instance, set limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. Similarly, the United States Environmental Protection Agency (EPA) has established Corporate Average Fuel Economy (CAFE) standards, which require automakers to improve their fleet-wide fuel efficiency over time.

These regulations have led to a shift in the automotive industry towards more fuel-efficient and environmentally friendly technologies. As a result, traditional V8 engines, known for their high power output but relatively poor fuel economy, have faced challenges in meeting these stringent requirements. Manufacturers have been forced to explore alternative solutions, such as downsizing engines, implementing turbocharging, and integrating hybrid powertrains.

However, the V8 engine's role in renewable energy vehicles is not entirely obsolete. Some manufacturers have adapted V8 engines to meet emissions regulations by incorporating advanced technologies. For example, cylinder deactivation systems allow V8 engines to operate on fewer cylinders during low-load conditions, improving fuel efficiency. Additionally, the integration of start-stop systems and mild hybrid technology has helped reduce emissions during idle and low-speed driving.

Furthermore, the development of renewable fuels has opened up new possibilities for V8 engines in the context of emissions regulations. Biofuels and synthetic fuels, when used in V8 engines, can significantly reduce carbon emissions compared to traditional fossil fuels. This approach allows manufacturers to maintain the performance characteristics of V8 engines while meeting increasingly stringent emissions standards.

Despite these advancements, the long-term viability of V8 engines in renewable energy vehicles remains uncertain. As emissions regulations continue to tighten, manufacturers may need to explore more radical solutions, such as full electrification or hydrogen fuel cell technology. The future of V8 engines in this context will largely depend on their ability to adapt to evolving regulatory landscapes and compete with emerging zero-emission technologies.

In recent years, many countries have adopted increasingly strict emissions standards. The European Union's Euro 6 standards, for instance, set limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. Similarly, the United States Environmental Protection Agency (EPA) has established Corporate Average Fuel Economy (CAFE) standards, which require automakers to improve their fleet-wide fuel efficiency over time.

These regulations have led to a shift in the automotive industry towards more fuel-efficient and environmentally friendly technologies. As a result, traditional V8 engines, known for their high power output but relatively poor fuel economy, have faced challenges in meeting these stringent requirements. Manufacturers have been forced to explore alternative solutions, such as downsizing engines, implementing turbocharging, and integrating hybrid powertrains.

However, the V8 engine's role in renewable energy vehicles is not entirely obsolete. Some manufacturers have adapted V8 engines to meet emissions regulations by incorporating advanced technologies. For example, cylinder deactivation systems allow V8 engines to operate on fewer cylinders during low-load conditions, improving fuel efficiency. Additionally, the integration of start-stop systems and mild hybrid technology has helped reduce emissions during idle and low-speed driving.

Furthermore, the development of renewable fuels has opened up new possibilities for V8 engines in the context of emissions regulations. Biofuels and synthetic fuels, when used in V8 engines, can significantly reduce carbon emissions compared to traditional fossil fuels. This approach allows manufacturers to maintain the performance characteristics of V8 engines while meeting increasingly stringent emissions standards.

Despite these advancements, the long-term viability of V8 engines in renewable energy vehicles remains uncertain. As emissions regulations continue to tighten, manufacturers may need to explore more radical solutions, such as full electrification or hydrogen fuel cell technology. The future of V8 engines in this context will largely depend on their ability to adapt to evolving regulatory landscapes and compete with emerging zero-emission technologies.

Hybrid V8 Technologies

Hybrid V8 technologies represent a significant advancement in the automotive industry, combining the power and performance of traditional V8 engines with the efficiency and environmental benefits of hybrid systems. These technologies aim to bridge the gap between high-performance vehicles and eco-friendly transportation solutions.

The core concept of hybrid V8 technologies involves integrating electric motors and battery systems with conventional V8 internal combustion engines. This combination allows for improved fuel efficiency, reduced emissions, and enhanced performance characteristics. The electric components can provide additional power during acceleration, enable regenerative braking, and allow for short-distance electric-only driving.

One of the key advantages of hybrid V8 systems is the ability to maintain the iconic V8 engine sound and driving experience while significantly reducing fuel consumption and emissions. This makes them particularly attractive for luxury and performance vehicle manufacturers who want to meet increasingly stringent environmental regulations without compromising on brand identity and customer expectations.

Several approaches have been developed to implement hybrid V8 technologies. Parallel hybrid systems, where both the V8 engine and electric motor can directly power the wheels, are common. This configuration allows for seamless transitions between electric and combustion power, optimizing efficiency across various driving conditions. Another approach is the series hybrid system, where the V8 engine primarily serves as a generator to charge the battery pack, which in turn powers the electric motors driving the wheels.

Advanced energy management systems play a crucial role in hybrid V8 technologies. These systems continuously optimize the power distribution between the V8 engine and electric motors, ensuring maximum efficiency and performance. They take into account factors such as battery charge level, driving conditions, and driver input to determine the most appropriate power source at any given moment.

Regenerative braking is another essential feature of hybrid V8 systems. This technology captures kinetic energy during deceleration and braking, converting it into electrical energy to recharge the battery pack. This process not only improves overall efficiency but also reduces wear on traditional braking components.

The integration of hybrid technologies with V8 engines has led to the development of new materials and manufacturing processes. Lightweight materials are increasingly used to offset the additional weight of battery packs and electric motors, helping to maintain the vehicle's performance characteristics. Advanced thermal management systems have also been developed to handle the heat generated by both the V8 engine and the electric components, ensuring optimal operating conditions for all systems.

The core concept of hybrid V8 technologies involves integrating electric motors and battery systems with conventional V8 internal combustion engines. This combination allows for improved fuel efficiency, reduced emissions, and enhanced performance characteristics. The electric components can provide additional power during acceleration, enable regenerative braking, and allow for short-distance electric-only driving.

One of the key advantages of hybrid V8 systems is the ability to maintain the iconic V8 engine sound and driving experience while significantly reducing fuel consumption and emissions. This makes them particularly attractive for luxury and performance vehicle manufacturers who want to meet increasingly stringent environmental regulations without compromising on brand identity and customer expectations.

Several approaches have been developed to implement hybrid V8 technologies. Parallel hybrid systems, where both the V8 engine and electric motor can directly power the wheels, are common. This configuration allows for seamless transitions between electric and combustion power, optimizing efficiency across various driving conditions. Another approach is the series hybrid system, where the V8 engine primarily serves as a generator to charge the battery pack, which in turn powers the electric motors driving the wheels.

Advanced energy management systems play a crucial role in hybrid V8 technologies. These systems continuously optimize the power distribution between the V8 engine and electric motors, ensuring maximum efficiency and performance. They take into account factors such as battery charge level, driving conditions, and driver input to determine the most appropriate power source at any given moment.

Regenerative braking is another essential feature of hybrid V8 systems. This technology captures kinetic energy during deceleration and braking, converting it into electrical energy to recharge the battery pack. This process not only improves overall efficiency but also reduces wear on traditional braking components.

The integration of hybrid technologies with V8 engines has led to the development of new materials and manufacturing processes. Lightweight materials are increasingly used to offset the additional weight of battery packs and electric motors, helping to maintain the vehicle's performance characteristics. Advanced thermal management systems have also been developed to handle the heat generated by both the V8 engine and the electric components, ensuring optimal operating conditions for all systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!