Turbocharging V8 Engines: Key Benefits Uncovered

JUL 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbocharging Evolution

The evolution of turbocharging technology for V8 engines has been a remarkable journey, spanning several decades of automotive engineering innovation. Initially developed for aircraft engines in the early 20th century, turbocharging found its way into automotive applications in the 1960s. The primary goal was to enhance engine performance without significantly increasing engine size or weight.

In the 1970s and 1980s, turbocharging gained prominence in motorsports, particularly in Formula 1 racing. This period saw rapid advancements in turbocharger design and materials, leading to improved reliability and performance. The technology began to trickle down to production vehicles, with luxury and sports car manufacturers adopting turbocharging to boost power output and efficiency.

The 1990s marked a significant shift in turbocharging technology for V8 engines. Engineers focused on reducing turbo lag and improving throttle response, addressing the primary criticisms of early turbocharged engines. This era saw the introduction of sequential turbocharging and variable geometry turbochargers, which provided more consistent power delivery across the engine's rev range.

As environmental concerns grew in the 2000s, turbocharging became a key strategy for engine downsizing. Automakers began replacing larger naturally aspirated V8 engines with smaller turbocharged V6 or even four-cylinder engines that could match or exceed the power output of their larger counterparts while improving fuel efficiency and reducing emissions.

The 2010s witnessed a renaissance for turbocharged V8 engines, particularly in high-performance and luxury vehicles. Advanced materials and precision manufacturing techniques allowed for the creation of more compact, efficient, and responsive turbochargers. Twin-scroll turbochargers and electric turbochargers emerged, further enhancing performance and reducing lag.

Today, turbocharging is an integral part of V8 engine design, offering a balance of power, efficiency, and environmental responsibility. Modern turbocharged V8 engines benefit from sophisticated engine management systems, advanced intercooling techniques, and integration with hybrid powertrains. These developments have enabled V8 engines to remain relevant in an era of stringent emissions regulations and increasing demand for fuel efficiency.

Looking ahead, the evolution of turbocharging for V8 engines is likely to continue with a focus on electrification and further efficiency gains. The integration of electric compressors and advanced heat recovery systems promises to push the boundaries of performance and efficiency even further, ensuring that turbocharged V8 engines remain at the forefront of automotive engineering for years to come.

In the 1970s and 1980s, turbocharging gained prominence in motorsports, particularly in Formula 1 racing. This period saw rapid advancements in turbocharger design and materials, leading to improved reliability and performance. The technology began to trickle down to production vehicles, with luxury and sports car manufacturers adopting turbocharging to boost power output and efficiency.

The 1990s marked a significant shift in turbocharging technology for V8 engines. Engineers focused on reducing turbo lag and improving throttle response, addressing the primary criticisms of early turbocharged engines. This era saw the introduction of sequential turbocharging and variable geometry turbochargers, which provided more consistent power delivery across the engine's rev range.

As environmental concerns grew in the 2000s, turbocharging became a key strategy for engine downsizing. Automakers began replacing larger naturally aspirated V8 engines with smaller turbocharged V6 or even four-cylinder engines that could match or exceed the power output of their larger counterparts while improving fuel efficiency and reducing emissions.

The 2010s witnessed a renaissance for turbocharged V8 engines, particularly in high-performance and luxury vehicles. Advanced materials and precision manufacturing techniques allowed for the creation of more compact, efficient, and responsive turbochargers. Twin-scroll turbochargers and electric turbochargers emerged, further enhancing performance and reducing lag.

Today, turbocharging is an integral part of V8 engine design, offering a balance of power, efficiency, and environmental responsibility. Modern turbocharged V8 engines benefit from sophisticated engine management systems, advanced intercooling techniques, and integration with hybrid powertrains. These developments have enabled V8 engines to remain relevant in an era of stringent emissions regulations and increasing demand for fuel efficiency.

Looking ahead, the evolution of turbocharging for V8 engines is likely to continue with a focus on electrification and further efficiency gains. The integration of electric compressors and advanced heat recovery systems promises to push the boundaries of performance and efficiency even further, ensuring that turbocharged V8 engines remain at the forefront of automotive engineering for years to come.

V8 Market Dynamics

The V8 engine market has experienced significant shifts in recent years, driven by evolving consumer preferences, regulatory pressures, and technological advancements. Despite the growing trend towards electrification and downsizing, V8 engines continue to maintain a strong presence in certain segments, particularly in high-performance vehicles, luxury cars, and heavy-duty trucks.

In the automotive sector, V8 engines have traditionally been associated with power, prestige, and performance. However, the market has seen a gradual decline in V8 engine adoption in mainstream vehicles due to increasing fuel efficiency standards and environmental concerns. This has led to a concentration of V8 engines in niche markets, where their unique characteristics are still highly valued.

The luxury car segment remains a stronghold for V8 engines, with brands like Mercedes-Benz, BMW, and Audi continuing to offer V8 options in their flagship models. These engines are often paired with turbocharging technology to enhance performance while improving fuel efficiency, catering to discerning customers who demand both power and refinement.

In the sports car and high-performance vehicle market, V8 engines maintain their popularity due to their distinctive sound and power delivery characteristics. Manufacturers such as Ferrari, Chevrolet (with the Corvette), and Ford (with the Mustang) continue to develop and refine V8 engines for their top-tier models, often incorporating advanced technologies like direct injection and variable valve timing.

The heavy-duty truck segment represents another significant market for V8 engines, particularly in North America. These engines are valued for their torque output and durability in demanding applications such as towing and hauling. Major players in this space include Ford, General Motors, and Ram, who continue to invest in V8 engine development for their pickup truck lines.

Geographically, North America remains the largest market for V8 engines, followed by Europe and Asia-Pacific. The Middle East also represents a notable market, particularly for luxury and high-performance vehicles equipped with V8 engines.

Looking ahead, the V8 engine market is expected to face challenges from increasingly stringent emissions regulations and the shift towards electrification. However, opportunities exist in the development of more efficient V8 engines through advanced turbocharging, hybridization, and alternative fuel technologies. These innovations may help extend the relevance of V8 engines in specific market segments, even as the broader automotive industry transitions towards more sustainable powertrains.

In the automotive sector, V8 engines have traditionally been associated with power, prestige, and performance. However, the market has seen a gradual decline in V8 engine adoption in mainstream vehicles due to increasing fuel efficiency standards and environmental concerns. This has led to a concentration of V8 engines in niche markets, where their unique characteristics are still highly valued.

The luxury car segment remains a stronghold for V8 engines, with brands like Mercedes-Benz, BMW, and Audi continuing to offer V8 options in their flagship models. These engines are often paired with turbocharging technology to enhance performance while improving fuel efficiency, catering to discerning customers who demand both power and refinement.

In the sports car and high-performance vehicle market, V8 engines maintain their popularity due to their distinctive sound and power delivery characteristics. Manufacturers such as Ferrari, Chevrolet (with the Corvette), and Ford (with the Mustang) continue to develop and refine V8 engines for their top-tier models, often incorporating advanced technologies like direct injection and variable valve timing.

The heavy-duty truck segment represents another significant market for V8 engines, particularly in North America. These engines are valued for their torque output and durability in demanding applications such as towing and hauling. Major players in this space include Ford, General Motors, and Ram, who continue to invest in V8 engine development for their pickup truck lines.

Geographically, North America remains the largest market for V8 engines, followed by Europe and Asia-Pacific. The Middle East also represents a notable market, particularly for luxury and high-performance vehicles equipped with V8 engines.

Looking ahead, the V8 engine market is expected to face challenges from increasingly stringent emissions regulations and the shift towards electrification. However, opportunities exist in the development of more efficient V8 engines through advanced turbocharging, hybridization, and alternative fuel technologies. These innovations may help extend the relevance of V8 engines in specific market segments, even as the broader automotive industry transitions towards more sustainable powertrains.

Turbo V8 Challenges

Turbocharging V8 engines presents several significant challenges that engineers and manufacturers must overcome to maximize performance and efficiency. One of the primary obstacles is managing the increased heat generated by the turbocharger system. The compressed air from the turbocharger can reach extremely high temperatures, which can lead to engine knock and reduced efficiency if not properly addressed.

Another major challenge is controlling turbo lag, the delay between throttle input and the turbocharger's response. This lag can negatively impact drivability and overall engine performance, particularly in high-performance applications where immediate power delivery is crucial. Engineers must carefully balance turbocharger size, engine displacement, and exhaust system design to minimize this effect.

Durability and reliability are also key concerns when turbocharging V8 engines. The increased pressure and temperature within the engine can accelerate wear on components such as pistons, valves, and gaskets. This necessitates the use of more robust materials and advanced cooling systems to ensure longevity and consistent performance under demanding conditions.

Integrating turbochargers with V8 engines also presents packaging challenges. The compact engine bays of many modern vehicles leave limited space for accommodating turbochargers and their associated plumbing. This constraint often requires creative solutions in turbocharger placement and exhaust manifold design to optimize performance while maintaining serviceability.

Emissions control is another significant hurdle in turbocharged V8 development. While turbocharging can improve fuel efficiency, it can also lead to increased NOx emissions due to higher combustion temperatures. Meeting stringent emissions regulations while maintaining performance targets requires sophisticated engine management systems and often the implementation of additional technologies such as direct fuel injection and variable valve timing.

The cost factor cannot be overlooked when discussing turbocharging challenges. The addition of turbochargers and their supporting systems significantly increases the complexity and cost of V8 engines. Manufacturers must balance the performance gains against the added expense to ensure market viability of their turbocharged V8 offerings.

Lastly, calibrating turbocharged V8 engines for optimal performance across a wide range of operating conditions is a complex task. Engineers must fine-tune boost pressure, fuel delivery, and ignition timing to achieve the desired balance of power, efficiency, and drivability. This process often requires extensive testing and refinement to ensure consistent performance in various climates and driving scenarios.

Another major challenge is controlling turbo lag, the delay between throttle input and the turbocharger's response. This lag can negatively impact drivability and overall engine performance, particularly in high-performance applications where immediate power delivery is crucial. Engineers must carefully balance turbocharger size, engine displacement, and exhaust system design to minimize this effect.

Durability and reliability are also key concerns when turbocharging V8 engines. The increased pressure and temperature within the engine can accelerate wear on components such as pistons, valves, and gaskets. This necessitates the use of more robust materials and advanced cooling systems to ensure longevity and consistent performance under demanding conditions.

Integrating turbochargers with V8 engines also presents packaging challenges. The compact engine bays of many modern vehicles leave limited space for accommodating turbochargers and their associated plumbing. This constraint often requires creative solutions in turbocharger placement and exhaust manifold design to optimize performance while maintaining serviceability.

Emissions control is another significant hurdle in turbocharged V8 development. While turbocharging can improve fuel efficiency, it can also lead to increased NOx emissions due to higher combustion temperatures. Meeting stringent emissions regulations while maintaining performance targets requires sophisticated engine management systems and often the implementation of additional technologies such as direct fuel injection and variable valve timing.

The cost factor cannot be overlooked when discussing turbocharging challenges. The addition of turbochargers and their supporting systems significantly increases the complexity and cost of V8 engines. Manufacturers must balance the performance gains against the added expense to ensure market viability of their turbocharged V8 offerings.

Lastly, calibrating turbocharged V8 engines for optimal performance across a wide range of operating conditions is a complex task. Engineers must fine-tune boost pressure, fuel delivery, and ignition timing to achieve the desired balance of power, efficiency, and drivability. This process often requires extensive testing and refinement to ensure consistent performance in various climates and driving scenarios.

Current Turbo Systems

01 Improved power output and performance

V8 engines offer enhanced power output and performance compared to smaller engine configurations. The V-shaped design allows for a compact layout while accommodating eight cylinders, resulting in increased horsepower and torque. This configuration is particularly beneficial for larger vehicles and high-performance applications.- Improved power output and performance: V8 engines offer enhanced power output and performance compared to smaller engine configurations. The V-shaped design allows for a compact layout while accommodating eight cylinders, resulting in increased horsepower and torque. This configuration is particularly beneficial for larger vehicles and high-performance applications.

- Enhanced fuel efficiency and emissions control: Modern V8 engines incorporate advanced technologies to improve fuel efficiency and reduce emissions. These may include variable valve timing, cylinder deactivation, and direct fuel injection systems. Such innovations help V8 engines meet stringent environmental regulations while maintaining their performance characteristics.

- Smooth operation and reduced vibration: The V8 configuration provides excellent balance and smooth operation due to its inherent design. The arrangement of cylinders helps to counteract vibrations, resulting in a more refined driving experience. This characteristic makes V8 engines popular in luxury vehicles and high-end sports cars.

- Versatility in automotive applications: V8 engines are versatile and can be used in a wide range of automotive applications. They are commonly found in trucks, SUVs, sports cars, and luxury vehicles. The adaptability of V8 engines allows manufacturers to meet diverse performance requirements across various vehicle segments.

- Durability and longevity: V8 engines are known for their durability and longevity when properly maintained. The robust design and construction of these engines allow them to withstand high stress and prolonged use, making them suitable for heavy-duty applications and long-term reliability in various vehicles.

02 Enhanced fuel efficiency and emissions control

Modern V8 engines incorporate advanced technologies to improve fuel efficiency and reduce emissions. These may include variable valve timing, cylinder deactivation, and direct fuel injection systems. Such innovations help V8 engines meet stringent environmental regulations while maintaining their performance characteristics.Expand Specific Solutions03 Smooth operation and reduced vibration

The V8 configuration provides excellent balance and smooth operation due to its inherent design. The arrangement of cylinders helps to counteract vibrations, resulting in a more refined driving experience. This characteristic makes V8 engines popular in luxury vehicles and high-end sports cars.Expand Specific Solutions04 Versatility in automotive applications

V8 engines are versatile and can be used in a wide range of automotive applications. They are commonly found in trucks, SUVs, sports cars, and luxury vehicles. The adaptability of V8 engines allows manufacturers to meet diverse performance requirements across various vehicle segments.Expand Specific Solutions05 Durability and longevity

V8 engines are known for their durability and longevity when properly maintained. The robust design and construction of these engines allow them to withstand high stress and prolonged use, making them suitable for heavy-duty applications and long-term reliability in various vehicles.Expand Specific Solutions

Turbo V8 Manufacturers

The turbocharging V8 engines market is in a mature stage, with established players and proven technologies. The global market size for turbochargers is projected to reach $24.1 billion by 2025, driven by increasing demand for fuel-efficient vehicles. Key players like BorgWarner, Ford, and Honeywell dominate the market with advanced technologies. Companies such as Toyota, Honda, and Audi are also investing heavily in turbocharging technologies for their high-performance V8 engines. The technology is well-developed, with ongoing innovations focusing on improving efficiency, reducing emissions, and enhancing power output. Emerging trends include electric turbochargers and integration with hybrid powertrains.

BorgWarner, Inc.

Technical Solution: BorgWarner's advanced turbocharging technology for V8 engines focuses on enhancing performance while improving fuel efficiency. Their dual-volute turbocharger design separates exhaust pulses, reducing interference and improving turbine efficiency[1]. The company's variable geometry turbocharger (VGT) technology allows for precise boost control across a wide range of engine speeds, optimizing power delivery and reducing turbo lag[2]. BorgWarner also implements advanced materials such as titanium aluminide in turbine wheels, enabling higher temperature operation and faster spool-up times[3]. Their innovative wastegate designs and electronic actuation systems provide more precise boost control, further enhancing engine performance and efficiency[4].

Strengths: Improved low-end torque, reduced turbo lag, and better fuel efficiency. Weaknesses: Potentially higher manufacturing costs and complexity in system integration.

Ford Global Technologies LLC

Technical Solution: Ford's approach to turbocharging V8 engines involves their EcoBoost technology, which combines direct fuel injection with turbocharging. For V8 applications, Ford utilizes twin-turbo setups to enhance power output while maintaining efficiency. Their system incorporates advanced intercooling techniques to reduce intake air temperature, allowing for higher boost pressures without risking engine knock[1]. Ford's turbocharging strategy also includes the use of low-inertia turbines for quicker response times and reduced lag[2]. The company has developed sophisticated engine management systems that optimize boost pressure, fuel injection timing, and valve timing to maximize performance across the entire RPM range[3]. Additionally, Ford implements advanced materials in their turbocharger designs, such as high-temperature alloys, to improve durability and longevity[4].

Strengths: Significant power increase while maintaining or improving fuel efficiency, broad torque curve. Weaknesses: Increased complexity in engine design and potential for higher maintenance costs.

Key Turbo Innovations

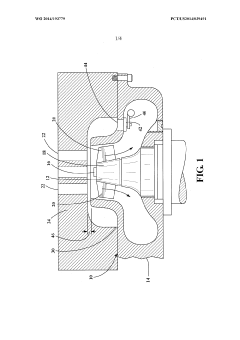

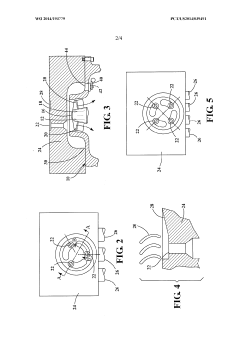

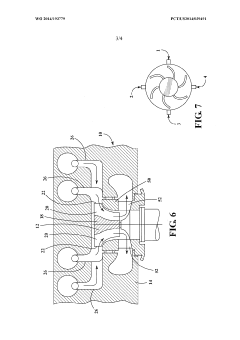

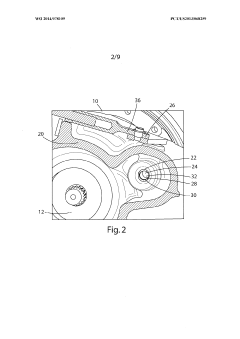

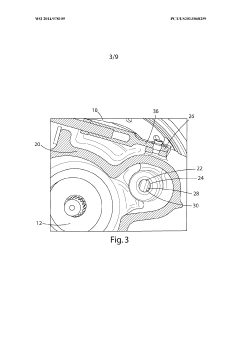

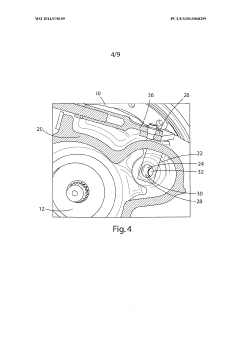

Pulse energy enhanced turbine for automotive turbochargers

PatentWO2014193779A1

Innovation

- A pulse energy enhanced turbine design with equidistant ports around the turbine wheel face to react to individual exhaust gas pulses, eliminating the need for a fixed stator and maintaining pulse energy, thereby enhancing efficiency and reducing inertia.

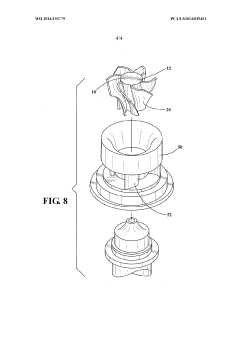

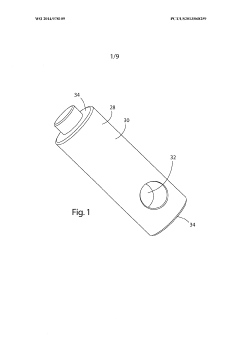

Valve assembly with cylinder having through holes

PatentWO2014078109A1

Innovation

- The implementation of a wastegate valve assembly featuring a moveable cylinder with through holes, allowing for precise control of exhaust gas flow through transverse or axial passages, reducing the need for large actuators and minimizing stress, with designs such as roller barrel and piston valves that can rotate or reciprocate within a tubular chamber.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, posing significant challenges for high-performance engines such as turbocharged V8s. These regulations aim to reduce harmful emissions and improve air quality, forcing manufacturers to adapt their engine designs and technologies.

The implementation of Euro 6 and Tier 3 standards in Europe and the United States, respectively, has set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. These standards have necessitated the development of advanced aftertreatment systems, including selective catalytic reduction (SCR) and diesel particulate filters (DPF) for diesel engines, and three-way catalytic converters for gasoline engines.

Turbocharged V8 engines, known for their power and performance, face particular scrutiny under these regulations. The high combustion temperatures associated with turbocharging can lead to increased NOx emissions, requiring manufacturers to implement sophisticated engine management systems and exhaust gas recirculation (EGR) technologies. Additionally, the use of direct fuel injection in many modern turbocharged V8 engines has raised concerns about particulate matter emissions, prompting the adoption of gasoline particulate filters (GPF) in some markets.

The Corporate Average Fuel Economy (CAFE) standards in the United States and similar fuel efficiency regulations worldwide have also impacted the development of turbocharged V8 engines. These standards encourage manufacturers to improve overall fleet fuel economy, leading to the downsizing of engines and increased adoption of turbocharging technology to maintain performance while reducing fuel consumption.

Despite these challenges, turbocharged V8 engines continue to evolve to meet emissions regulations while delivering impressive performance. Advanced technologies such as variable valve timing, cylinder deactivation, and integrated exhaust manifolds have been employed to optimize engine efficiency and reduce emissions. Furthermore, the integration of mild hybrid systems and 48-volt electrical architectures has allowed manufacturers to further improve fuel economy and reduce emissions during low-load conditions.

As emissions regulations continue to tighten, the future of turbocharged V8 engines will likely involve further advancements in combustion efficiency, electrification, and exhaust aftertreatment technologies. Manufacturers are exploring innovative solutions such as water injection, pre-chamber ignition systems, and advanced thermal management to ensure compliance with future emissions standards while preserving the performance characteristics that make turbocharged V8 engines desirable to enthusiasts and luxury vehicle buyers.

The implementation of Euro 6 and Tier 3 standards in Europe and the United States, respectively, has set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. These standards have necessitated the development of advanced aftertreatment systems, including selective catalytic reduction (SCR) and diesel particulate filters (DPF) for diesel engines, and three-way catalytic converters for gasoline engines.

Turbocharged V8 engines, known for their power and performance, face particular scrutiny under these regulations. The high combustion temperatures associated with turbocharging can lead to increased NOx emissions, requiring manufacturers to implement sophisticated engine management systems and exhaust gas recirculation (EGR) technologies. Additionally, the use of direct fuel injection in many modern turbocharged V8 engines has raised concerns about particulate matter emissions, prompting the adoption of gasoline particulate filters (GPF) in some markets.

The Corporate Average Fuel Economy (CAFE) standards in the United States and similar fuel efficiency regulations worldwide have also impacted the development of turbocharged V8 engines. These standards encourage manufacturers to improve overall fleet fuel economy, leading to the downsizing of engines and increased adoption of turbocharging technology to maintain performance while reducing fuel consumption.

Despite these challenges, turbocharged V8 engines continue to evolve to meet emissions regulations while delivering impressive performance. Advanced technologies such as variable valve timing, cylinder deactivation, and integrated exhaust manifolds have been employed to optimize engine efficiency and reduce emissions. Furthermore, the integration of mild hybrid systems and 48-volt electrical architectures has allowed manufacturers to further improve fuel economy and reduce emissions during low-load conditions.

As emissions regulations continue to tighten, the future of turbocharged V8 engines will likely involve further advancements in combustion efficiency, electrification, and exhaust aftertreatment technologies. Manufacturers are exploring innovative solutions such as water injection, pre-chamber ignition systems, and advanced thermal management to ensure compliance with future emissions standards while preserving the performance characteristics that make turbocharged V8 engines desirable to enthusiasts and luxury vehicle buyers.

Performance Metrics

Turbocharging V8 engines significantly enhances their performance metrics, offering substantial improvements across various key indicators. One of the most notable benefits is the increase in horsepower output. Turbocharged V8 engines can achieve power gains of up to 30-50% compared to their naturally aspirated counterparts, depending on the specific design and boost pressure. This translates to a considerable boost in acceleration and top speed capabilities.

Torque production is another area where turbocharged V8s excel. The forced induction system allows for a broader torque curve, with peak torque available at lower RPMs. This results in improved low-end and mid-range performance, enhancing drivability and responsiveness in everyday driving conditions. Typically, turbocharged V8s can produce 20-40% more torque than naturally aspirated versions of similar displacement.

Fuel efficiency is a somewhat counterintuitive benefit of turbocharging V8 engines. Despite the increased power output, these engines can often achieve better fuel economy under partial load conditions. This is due to the ability to downsize the engine while maintaining or improving performance, leading to reduced pumping losses and improved thermal efficiency. Studies have shown fuel economy improvements of 5-15% in real-world driving scenarios.

Emissions performance is another critical metric that sees improvement with turbocharging. The increased combustion efficiency and potential for engine downsizing contribute to lower CO2 emissions per unit of power produced. Many turbocharged V8 engines demonstrate a 10-20% reduction in CO2 emissions compared to their naturally aspirated equivalents, helping manufacturers meet increasingly stringent environmental regulations.

Power-to-weight ratio is significantly enhanced in turbocharged V8 engines. The ability to extract more power from a given engine size means that vehicles can achieve higher performance without the need for larger, heavier powerplants. This leads to improved handling characteristics and overall vehicle dynamics, as the weight distribution can be optimized more effectively.

Throttle response and turbo lag, historically considered drawbacks of turbocharged engines, have seen substantial improvements in modern designs. Advanced turbocharger technologies, such as twin-scroll turbos and electric compressors, have reduced lag times to near-imperceptible levels in many applications. Measurements show response times approaching those of naturally aspirated engines, with some high-performance turbocharged V8s achieving 0-60 mph times under 3 seconds.

Torque production is another area where turbocharged V8s excel. The forced induction system allows for a broader torque curve, with peak torque available at lower RPMs. This results in improved low-end and mid-range performance, enhancing drivability and responsiveness in everyday driving conditions. Typically, turbocharged V8s can produce 20-40% more torque than naturally aspirated versions of similar displacement.

Fuel efficiency is a somewhat counterintuitive benefit of turbocharging V8 engines. Despite the increased power output, these engines can often achieve better fuel economy under partial load conditions. This is due to the ability to downsize the engine while maintaining or improving performance, leading to reduced pumping losses and improved thermal efficiency. Studies have shown fuel economy improvements of 5-15% in real-world driving scenarios.

Emissions performance is another critical metric that sees improvement with turbocharging. The increased combustion efficiency and potential for engine downsizing contribute to lower CO2 emissions per unit of power produced. Many turbocharged V8 engines demonstrate a 10-20% reduction in CO2 emissions compared to their naturally aspirated equivalents, helping manufacturers meet increasingly stringent environmental regulations.

Power-to-weight ratio is significantly enhanced in turbocharged V8 engines. The ability to extract more power from a given engine size means that vehicles can achieve higher performance without the need for larger, heavier powerplants. This leads to improved handling characteristics and overall vehicle dynamics, as the weight distribution can be optimized more effectively.

Throttle response and turbo lag, historically considered drawbacks of turbocharged engines, have seen substantial improvements in modern designs. Advanced turbocharger technologies, such as twin-scroll turbos and electric compressors, have reduced lag times to near-imperceptible levels in many applications. Measurements show response times approaching those of naturally aspirated engines, with some high-performance turbocharged V8s achieving 0-60 mph times under 3 seconds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!