V8 Engine Cylinder Deactivation: Exploring Inner Workings

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception in the early 20th century. Initially designed for high-performance applications, V8 engines have become synonymous with power and efficiency in automotive engineering. The journey of V8 engine development has been marked by continuous improvements in design, materials, and technology.

In the early stages, V8 engines were primarily focused on raw power output. The 1930s and 1940s saw the introduction of overhead valve designs, which improved engine breathing and increased power potential. The post-war era brought about a surge in V8 popularity, particularly in American automobiles, where they became a symbol of performance and luxury.

The 1960s and 1970s marked a golden age for V8 engines, with manufacturers pushing the boundaries of displacement and power output. However, this era also saw the beginning of a shift towards efficiency, prompted by rising fuel costs and emerging environmental concerns. This led to the development of smaller, more efficient V8 designs and the introduction of electronic fuel injection systems.

The 1980s and 1990s witnessed a significant leap in V8 technology with the widespread adoption of computer-controlled engine management systems. These advancements allowed for precise control over fuel delivery and ignition timing, resulting in improved performance and reduced emissions. During this period, manufacturers also began experimenting with lightweight materials and advanced manufacturing techniques to reduce engine weight and improve efficiency.

The turn of the millennium brought about a new focus on balancing performance with fuel efficiency and emissions reduction. This led to the development of technologies such as variable valve timing, direct fuel injection, and turbocharging for V8 engines. These innovations allowed V8s to maintain their performance characteristics while meeting increasingly stringent environmental regulations.

In recent years, the evolution of V8 engines has been driven by the need for even greater efficiency without sacrificing power. This has resulted in the development of cylinder deactivation technology, which allows engines to operate on fewer cylinders under light load conditions, significantly improving fuel economy. Additionally, hybrid and mild-hybrid systems have been integrated with V8 engines to further enhance efficiency and performance.

The latest advancements in V8 engine technology include the use of advanced materials such as carbon fiber and 3D-printed components, as well as the integration of artificial intelligence for optimized engine management. These developments are pushing the boundaries of what is possible with V8 engines, ensuring their continued relevance in an era of increasing electrification and environmental consciousness.

In the early stages, V8 engines were primarily focused on raw power output. The 1930s and 1940s saw the introduction of overhead valve designs, which improved engine breathing and increased power potential. The post-war era brought about a surge in V8 popularity, particularly in American automobiles, where they became a symbol of performance and luxury.

The 1960s and 1970s marked a golden age for V8 engines, with manufacturers pushing the boundaries of displacement and power output. However, this era also saw the beginning of a shift towards efficiency, prompted by rising fuel costs and emerging environmental concerns. This led to the development of smaller, more efficient V8 designs and the introduction of electronic fuel injection systems.

The 1980s and 1990s witnessed a significant leap in V8 technology with the widespread adoption of computer-controlled engine management systems. These advancements allowed for precise control over fuel delivery and ignition timing, resulting in improved performance and reduced emissions. During this period, manufacturers also began experimenting with lightweight materials and advanced manufacturing techniques to reduce engine weight and improve efficiency.

The turn of the millennium brought about a new focus on balancing performance with fuel efficiency and emissions reduction. This led to the development of technologies such as variable valve timing, direct fuel injection, and turbocharging for V8 engines. These innovations allowed V8s to maintain their performance characteristics while meeting increasingly stringent environmental regulations.

In recent years, the evolution of V8 engines has been driven by the need for even greater efficiency without sacrificing power. This has resulted in the development of cylinder deactivation technology, which allows engines to operate on fewer cylinders under light load conditions, significantly improving fuel economy. Additionally, hybrid and mild-hybrid systems have been integrated with V8 engines to further enhance efficiency and performance.

The latest advancements in V8 engine technology include the use of advanced materials such as carbon fiber and 3D-printed components, as well as the integration of artificial intelligence for optimized engine management. These developments are pushing the boundaries of what is possible with V8 engines, ensuring their continued relevance in an era of increasing electrification and environmental consciousness.

Market Demand Analysis

The market demand for V8 engine cylinder deactivation technology has been steadily growing in recent years, driven by increasing fuel efficiency regulations and consumer preferences for more economical vehicles without sacrificing performance. This technology allows V8 engines to operate on fewer cylinders during low-load conditions, significantly reducing fuel consumption and emissions.

The automotive industry has seen a shift towards more fuel-efficient vehicles, with many manufacturers incorporating cylinder deactivation systems into their V8 engines. This trend is particularly prominent in the North American market, where large V8-powered vehicles remain popular. The technology has found applications in various vehicle segments, including full-size trucks, SUVs, and high-performance cars.

Market research indicates that the global cylinder deactivation system market is expected to grow substantially over the next decade. This growth is attributed to the increasing adoption of the technology by major automakers and the rising demand for fuel-efficient vehicles. The market is segmented by vehicle type, with passenger cars and light commercial vehicles being the primary adopters of cylinder deactivation technology.

Consumer awareness and acceptance of cylinder deactivation technology have improved, with many buyers now actively seeking vehicles equipped with this fuel-saving feature. This shift in consumer behavior has prompted automakers to expand the availability of cylinder deactivation across their product lines, further driving market growth.

The technology's appeal extends beyond personal vehicles, with commercial fleet operators showing interest in cylinder deactivation as a means to reduce operating costs. This expansion into the commercial sector represents a significant opportunity for market growth and technological advancement.

Despite the growing demand, challenges remain in the widespread adoption of cylinder deactivation technology. These include the initial cost of implementation, complexity in engine management systems, and the need for precise control to maintain smooth operation. However, ongoing research and development efforts are addressing these challenges, potentially leading to more cost-effective and efficient solutions.

The market for V8 engine cylinder deactivation is also influenced by regional factors, with stricter emissions regulations in Europe and North America driving adoption, while emerging markets show increasing interest as they seek to improve air quality and reduce fuel consumption. This global perspective underscores the technology's potential for continued growth and innovation in the automotive industry.

The automotive industry has seen a shift towards more fuel-efficient vehicles, with many manufacturers incorporating cylinder deactivation systems into their V8 engines. This trend is particularly prominent in the North American market, where large V8-powered vehicles remain popular. The technology has found applications in various vehicle segments, including full-size trucks, SUVs, and high-performance cars.

Market research indicates that the global cylinder deactivation system market is expected to grow substantially over the next decade. This growth is attributed to the increasing adoption of the technology by major automakers and the rising demand for fuel-efficient vehicles. The market is segmented by vehicle type, with passenger cars and light commercial vehicles being the primary adopters of cylinder deactivation technology.

Consumer awareness and acceptance of cylinder deactivation technology have improved, with many buyers now actively seeking vehicles equipped with this fuel-saving feature. This shift in consumer behavior has prompted automakers to expand the availability of cylinder deactivation across their product lines, further driving market growth.

The technology's appeal extends beyond personal vehicles, with commercial fleet operators showing interest in cylinder deactivation as a means to reduce operating costs. This expansion into the commercial sector represents a significant opportunity for market growth and technological advancement.

Despite the growing demand, challenges remain in the widespread adoption of cylinder deactivation technology. These include the initial cost of implementation, complexity in engine management systems, and the need for precise control to maintain smooth operation. However, ongoing research and development efforts are addressing these challenges, potentially leading to more cost-effective and efficient solutions.

The market for V8 engine cylinder deactivation is also influenced by regional factors, with stricter emissions regulations in Europe and North America driving adoption, while emerging markets show increasing interest as they seek to improve air quality and reduce fuel consumption. This global perspective underscores the technology's potential for continued growth and innovation in the automotive industry.

Technical Challenges

Cylinder deactivation in V8 engines presents several technical challenges that engineers must overcome to ensure optimal performance, efficiency, and reliability. One of the primary hurdles is maintaining smooth engine operation during the transition between full cylinder operation and deactivated mode. This requires precise control of valve timing, fuel injection, and ignition systems to prevent noticeable vibrations or power fluctuations that could compromise driver comfort and vehicle drivability.

Another significant challenge lies in the thermal management of the engine. When cylinders are deactivated, the temperature distribution across the engine block becomes uneven, potentially leading to thermal stress and accelerated wear on components. Engineers must develop sophisticated cooling systems and materials that can withstand these temperature variations without compromising the engine's longevity or performance.

The complexity of the control systems required for cylinder deactivation poses yet another technical hurdle. Advanced sensors, actuators, and electronic control units must work in perfect harmony to determine the optimal moments for cylinder deactivation and reactivation based on various factors such as engine load, speed, and driver input. Developing robust algorithms and fail-safe mechanisms to manage these systems reliably under diverse operating conditions is a formidable task.

Noise, vibration, and harshness (NVH) management presents an additional challenge in cylinder deactivation systems. The altered firing order and reduced number of active cylinders can lead to increased engine vibrations and changes in the acoustic signature. Engineers must employ innovative solutions, such as active engine mounts and exhaust system tuning, to mitigate these NVH issues and maintain the expected level of refinement in luxury V8-powered vehicles.

Emissions control is another critical area that demands attention in cylinder deactivation systems. The intermittent operation of cylinders can affect the catalytic converter's efficiency and the overall emissions profile of the engine. Developing strategies to maintain optimal catalyst temperatures and ensure consistent emissions performance across all operating modes requires extensive research and testing.

Lastly, the mechanical complexity introduced by cylinder deactivation systems poses challenges in terms of reliability and maintenance. The additional components, such as switchable hydraulic lash adjusters and oil control valves, increase the potential points of failure within the engine. Designing these components for durability and developing comprehensive diagnostic systems to detect and prevent malfunctions are essential aspects of overcoming the technical challenges associated with V8 engine cylinder deactivation technology.

Another significant challenge lies in the thermal management of the engine. When cylinders are deactivated, the temperature distribution across the engine block becomes uneven, potentially leading to thermal stress and accelerated wear on components. Engineers must develop sophisticated cooling systems and materials that can withstand these temperature variations without compromising the engine's longevity or performance.

The complexity of the control systems required for cylinder deactivation poses yet another technical hurdle. Advanced sensors, actuators, and electronic control units must work in perfect harmony to determine the optimal moments for cylinder deactivation and reactivation based on various factors such as engine load, speed, and driver input. Developing robust algorithms and fail-safe mechanisms to manage these systems reliably under diverse operating conditions is a formidable task.

Noise, vibration, and harshness (NVH) management presents an additional challenge in cylinder deactivation systems. The altered firing order and reduced number of active cylinders can lead to increased engine vibrations and changes in the acoustic signature. Engineers must employ innovative solutions, such as active engine mounts and exhaust system tuning, to mitigate these NVH issues and maintain the expected level of refinement in luxury V8-powered vehicles.

Emissions control is another critical area that demands attention in cylinder deactivation systems. The intermittent operation of cylinders can affect the catalytic converter's efficiency and the overall emissions profile of the engine. Developing strategies to maintain optimal catalyst temperatures and ensure consistent emissions performance across all operating modes requires extensive research and testing.

Lastly, the mechanical complexity introduced by cylinder deactivation systems poses challenges in terms of reliability and maintenance. The additional components, such as switchable hydraulic lash adjusters and oil control valves, increase the potential points of failure within the engine. Designing these components for durability and developing comprehensive diagnostic systems to detect and prevent malfunctions are essential aspects of overcoming the technical challenges associated with V8 engine cylinder deactivation technology.

Current Solutions

01 Cylinder deactivation control systems

Advanced control systems are implemented to manage cylinder deactivation in V8 engines. These systems monitor various engine parameters and driving conditions to determine when to activate or deactivate cylinders, optimizing fuel efficiency and performance. The control systems may include electronic control units, sensors, and actuators to seamlessly transition between full and partial cylinder operation.- Cylinder deactivation control systems: Advanced control systems are implemented to manage cylinder deactivation in V8 engines. These systems monitor engine conditions and driver inputs to determine when to activate or deactivate cylinders, optimizing fuel efficiency and performance. The control systems may include electronic control units, sensors, and actuators to seamlessly transition between full and partial cylinder operation.

- Valve train mechanisms for cylinder deactivation: Specialized valve train mechanisms are developed to enable cylinder deactivation in V8 engines. These mechanisms may include switchable hydraulic lash adjusters, cam profile switching systems, or variable valve lift systems. Such designs allow for selective deactivation of intake and exhaust valves in specific cylinders, effectively shutting them down during partial load conditions.

- Oil management systems for deactivated cylinders: Innovative oil management systems are designed to maintain proper lubrication in deactivated cylinders. These systems ensure that oil continues to circulate and protect engine components even when certain cylinders are not firing. Special oil galleries, pressure control valves, and oil pumps may be incorporated to manage oil flow and prevent issues such as oil starvation or excessive accumulation in deactivated cylinders.

- NVH reduction techniques for cylinder deactivation: Various noise, vibration, and harshness (NVH) reduction techniques are employed to maintain smooth operation during cylinder deactivation. These may include active engine mounts, tuned exhaust systems, and refined combustion strategies. Such techniques help mitigate the potential imbalances and vibrations that can occur when transitioning between full and partial cylinder operation in V8 engines.

- Integration with other fuel-saving technologies: Cylinder deactivation systems in V8 engines are often integrated with other fuel-saving technologies to maximize efficiency gains. This may include variable valve timing, direct fuel injection, turbocharging, or hybrid powertrains. The combination of these technologies allows for a wider range of operating conditions where cylinder deactivation can be effectively utilized, further improving overall engine efficiency and performance.

02 Valve train mechanisms for cylinder deactivation

Specialized valve train mechanisms are developed to enable cylinder deactivation in V8 engines. These mechanisms may include switchable rocker arms, hydraulic lash adjusters, or camshaft designs that allow for selective valve actuation. The systems are designed to quickly and reliably deactivate and reactivate cylinders as needed, ensuring smooth engine operation and transitions.Expand Specific Solutions03 Lubrication and thermal management in deactivated cylinders

Innovative solutions are implemented to address lubrication and thermal management challenges in deactivated cylinders. These may include oil circulation systems, temperature sensors, and cooling strategies to prevent oil degradation and maintain optimal operating temperatures in both active and inactive cylinders, ensuring engine longevity and reliability.Expand Specific Solutions04 Integration with other engine technologies

Cylinder deactivation systems are integrated with other advanced engine technologies to further enhance efficiency and performance. This may include variable valve timing, direct fuel injection, turbocharging, or hybrid powertrains. The integration allows for more sophisticated engine management strategies that can adapt to various driving conditions and requirements.Expand Specific Solutions05 Noise, vibration, and harshness (NVH) mitigation

Techniques are developed to mitigate noise, vibration, and harshness issues associated with cylinder deactivation in V8 engines. These may include active engine mounts, sound insulation materials, or exhaust system modifications. The goal is to maintain a smooth and quiet driving experience even when operating with fewer active cylinders.Expand Specific Solutions

Key Industry Players

The V8 engine cylinder deactivation technology market is in a mature stage, with widespread adoption across major automotive manufacturers. The global market size for this technology is estimated to be in the billions of dollars, driven by increasing demand for fuel-efficient vehicles and stringent emissions regulations. Key players like GM, Ford, Mercedes-Benz, and Volkswagen have achieved high levels of technical maturity in implementing cylinder deactivation systems. Companies such as Delphi, BorgWarner, and Tula Technology are also contributing innovative solutions, further advancing the technology's capabilities and efficiency gains in modern V8 engines.

GM Global Technology Operations LLC

Technical Solution: GM's Dynamic Fuel Management (DFM) system is an advanced cylinder deactivation technology that can disable up to seven cylinders in a V8 engine. The system uses sophisticated software algorithms to continuously evaluate driving conditions and determine the optimal number of active cylinders needed. DFM can switch between 17 different firing patterns in real-time, providing seamless transitions between cylinder configurations[1]. The system incorporates advanced valvetrain components, including two-piece oil control valves and upgraded lifters, to enable rapid cylinder activation and deactivation[2]. GM's DFM technology has been shown to improve fuel efficiency by up to 15% in certain driving conditions, particularly during highway cruising[3].

Strengths: Highly flexible cylinder deactivation, seamless operation, significant fuel efficiency improvements. Weaknesses: Increased complexity, potential for higher maintenance costs, may require premium fuel for optimal performance.

Ford Global Technologies LLC

Technical Solution: Ford's cylinder deactivation system for V8 engines, known as Variable Displacement Engine (VDE) technology, focuses on deactivating four cylinders during light load conditions. The system utilizes specialized two-step roller finger followers in the valvetrain, which can be locked or unlocked to activate or deactivate cylinders[4]. Ford's VDE employs a unique oil pressure-controlled mechanism to switch between full cylinder operation and partial cylinder deactivation. The system is integrated with the engine control module, which monitors various parameters such as throttle position, vehicle speed, and engine load to determine when to engage cylinder deactivation[5]. Ford has reported fuel economy improvements of up to 20% in city driving conditions with their VDE technology[6].

Strengths: Proven fuel economy benefits, relatively simple implementation compared to more complex systems. Weaknesses: Less flexible than systems that can deactivate individual cylinders, potential for noticeable transitions between modes.

Core Technologies

Valve deactivation system

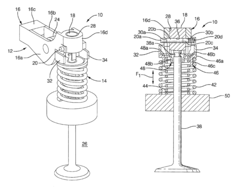

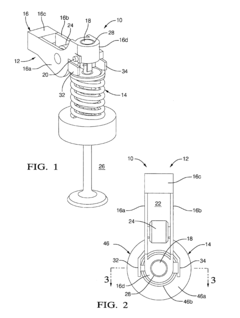

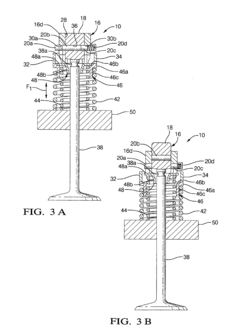

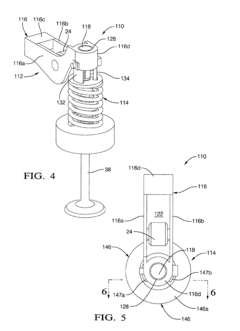

PatentInactiveEP1221541A3

Innovation

- A valve deactivation system comprising a deactivation rocker arm assembly with a sliding center post and a free motion spring assembly that utilizes existing space and conventional valve train components, reducing the number of parts and enabling operation across a wide range of engine conditions.

Valve deactivation system with free motion spring

PatentInactiveUS6799543B2

Innovation

- A valve deactivation system utilizing a deactivation rocker arm assembly and a free motion spring assembly that fits within existing space, using fewer components and conventional valve train components, allowing for cylinder deactivation over a wide range of engine operations without the need for custom designs.

Fuel Efficiency Impact

Cylinder deactivation technology in V8 engines has a significant impact on fuel efficiency, offering substantial improvements in fuel economy without compromising performance. This innovative approach allows the engine to operate on fewer cylinders during low-load conditions, effectively reducing fuel consumption and emissions.

The fuel efficiency impact of cylinder deactivation is most pronounced during highway cruising and light-load city driving. Studies have shown that this technology can improve fuel economy by 5-15% in real-world driving conditions, with some manufacturers reporting even higher gains in specific scenarios. The exact improvement varies depending on factors such as vehicle weight, driving conditions, and engine design.

One of the key advantages of cylinder deactivation is its ability to maintain the power and torque capabilities of a larger engine while providing the fuel efficiency of a smaller one. When full power is not required, the system deactivates a set of cylinders, typically four in a V8 engine, by cutting off fuel supply and closing the valves. This reduces pumping losses and improves thermal efficiency, resulting in better fuel economy.

The fuel savings are particularly notable in larger displacement engines, where the difference in fuel consumption between full and partial cylinder operation is more pronounced. For example, a V8 engine operating on four cylinders during highway cruising can significantly reduce its fuel consumption compared to running all eight cylinders.

Moreover, cylinder deactivation technology contributes to reduced CO2 emissions, aligning with increasingly stringent environmental regulations. The lower fuel consumption directly translates to decreased carbon dioxide output, helping manufacturers meet emission standards without sacrificing the power and appeal of larger engines.

It's worth noting that the fuel efficiency benefits of cylinder deactivation are not limited to steady-state driving conditions. Advanced control systems allow for seamless transitions between full and partial cylinder operation, optimizing fuel economy across various driving scenarios. This dynamic adaptation ensures that the engine operates in its most efficient mode at all times, maximizing the overall fuel efficiency impact.

While the technology primarily focuses on improving fuel economy, it also indirectly enhances other aspects of vehicle performance. The reduced engine load during partial cylinder operation can lead to decreased engine wear, potentially extending engine life and reducing maintenance costs. Additionally, the smoother operation during cylinder deactivation can contribute to improved NVH (Noise, Vibration, and Harshness) characteristics, enhancing overall driving comfort.

The fuel efficiency impact of cylinder deactivation is most pronounced during highway cruising and light-load city driving. Studies have shown that this technology can improve fuel economy by 5-15% in real-world driving conditions, with some manufacturers reporting even higher gains in specific scenarios. The exact improvement varies depending on factors such as vehicle weight, driving conditions, and engine design.

One of the key advantages of cylinder deactivation is its ability to maintain the power and torque capabilities of a larger engine while providing the fuel efficiency of a smaller one. When full power is not required, the system deactivates a set of cylinders, typically four in a V8 engine, by cutting off fuel supply and closing the valves. This reduces pumping losses and improves thermal efficiency, resulting in better fuel economy.

The fuel savings are particularly notable in larger displacement engines, where the difference in fuel consumption between full and partial cylinder operation is more pronounced. For example, a V8 engine operating on four cylinders during highway cruising can significantly reduce its fuel consumption compared to running all eight cylinders.

Moreover, cylinder deactivation technology contributes to reduced CO2 emissions, aligning with increasingly stringent environmental regulations. The lower fuel consumption directly translates to decreased carbon dioxide output, helping manufacturers meet emission standards without sacrificing the power and appeal of larger engines.

It's worth noting that the fuel efficiency benefits of cylinder deactivation are not limited to steady-state driving conditions. Advanced control systems allow for seamless transitions between full and partial cylinder operation, optimizing fuel economy across various driving scenarios. This dynamic adaptation ensures that the engine operates in its most efficient mode at all times, maximizing the overall fuel efficiency impact.

While the technology primarily focuses on improving fuel economy, it also indirectly enhances other aspects of vehicle performance. The reduced engine load during partial cylinder operation can lead to decreased engine wear, potentially extending engine life and reducing maintenance costs. Additionally, the smoother operation during cylinder deactivation can contribute to improved NVH (Noise, Vibration, and Harshness) characteristics, enhancing overall driving comfort.

Emissions Regulations

Emissions regulations have become increasingly stringent worldwide, driving automotive manufacturers to develop innovative technologies to reduce fuel consumption and emissions. Cylinder deactivation, particularly in V8 engines, has emerged as a key strategy to meet these regulatory challenges. The implementation of cylinder deactivation technology directly addresses the need to improve fuel efficiency and reduce greenhouse gas emissions, especially in larger displacement engines.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a primary driver for the adoption of cylinder deactivation. These standards require automakers to achieve specific fleet-wide average fuel economy targets, with penalties for non-compliance. The Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly administer these regulations, which have become progressively more demanding over time.

Similarly, the European Union has implemented strict CO2 emissions targets for new vehicles. The Euro 6 standards, introduced in 2014 and subsequently updated, have set increasingly lower limits for various pollutants, including nitrogen oxides (NOx) and particulate matter. These regulations have spurred the development and adoption of cylinder deactivation technology across a range of vehicle segments.

China, the world's largest automotive market, has also introduced its own emissions standards modeled after European regulations. The China 6 standards, phased in from 2020, are comparable to Euro 6 in their stringency. This regulatory environment has created a significant market for cylinder deactivation technology in Chinese-manufactured vehicles, particularly in larger SUVs and luxury sedans.

The global nature of these emissions regulations has led to a harmonization of technology development across major automotive markets. Cylinder deactivation has become a critical tool for manufacturers to meet these standards while still offering powerful V8 engines in certain vehicle segments. The technology allows engines to operate more efficiently under light load conditions, effectively reducing fuel consumption and emissions without compromising performance when full power is needed.

As emissions regulations continue to evolve, the role of cylinder deactivation in V8 engines is likely to expand. Future iterations of this technology may include more advanced control systems, integration with hybrid powertrains, and the ability to deactivate cylinders more dynamically based on driving conditions. These advancements will be crucial in ensuring that V8 engines remain viable in an increasingly environmentally conscious regulatory landscape.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a primary driver for the adoption of cylinder deactivation. These standards require automakers to achieve specific fleet-wide average fuel economy targets, with penalties for non-compliance. The Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly administer these regulations, which have become progressively more demanding over time.

Similarly, the European Union has implemented strict CO2 emissions targets for new vehicles. The Euro 6 standards, introduced in 2014 and subsequently updated, have set increasingly lower limits for various pollutants, including nitrogen oxides (NOx) and particulate matter. These regulations have spurred the development and adoption of cylinder deactivation technology across a range of vehicle segments.

China, the world's largest automotive market, has also introduced its own emissions standards modeled after European regulations. The China 6 standards, phased in from 2020, are comparable to Euro 6 in their stringency. This regulatory environment has created a significant market for cylinder deactivation technology in Chinese-manufactured vehicles, particularly in larger SUVs and luxury sedans.

The global nature of these emissions regulations has led to a harmonization of technology development across major automotive markets. Cylinder deactivation has become a critical tool for manufacturers to meet these standards while still offering powerful V8 engines in certain vehicle segments. The technology allows engines to operate more efficiently under light load conditions, effectively reducing fuel consumption and emissions without compromising performance when full power is needed.

As emissions regulations continue to evolve, the role of cylinder deactivation in V8 engines is likely to expand. Future iterations of this technology may include more advanced control systems, integration with hybrid powertrains, and the ability to deactivate cylinders more dynamically based on driving conditions. These advancements will be crucial in ensuring that V8 engines remain viable in an increasingly environmentally conscious regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!