V8 Engine Applications in Military Vehicles: Strategic Insights

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution in Military Vehicles

The evolution of V8 engines in military vehicles represents a significant chapter in the advancement of military technology. Initially developed for high-performance aircraft during World War II, V8 engines found their way into ground vehicles due to their impressive power-to-weight ratio and reliability. The 1950s marked the beginning of widespread adoption in military vehicles, with the U.S. Army's M48 Patton tank featuring a Continental AV-1790 V8 gasoline engine.

Throughout the 1960s and 1970s, military vehicle manufacturers focused on improving fuel efficiency and durability. This led to the development of more robust V8 diesel engines, capable of withstanding harsh battlefield conditions while providing superior torque for heavy armored vehicles. The introduction of turbocharging and intercooling technologies in the 1980s further enhanced engine performance, allowing for increased power output without sacrificing fuel economy.

The 1990s saw a shift towards modular engine designs, enabling easier maintenance and parts replacement in the field. This period also witnessed the integration of electronic engine management systems, improving overall engine efficiency and reducing emissions. As environmental concerns grew, military organizations began exploring alternative fuel options for V8 engines, including biodiesel and synthetic fuels.

In the early 2000s, the focus shifted to power density and thermal management. Advanced materials such as high-strength alloys and ceramics were incorporated into engine designs, allowing for higher operating temperatures and increased power output. Concurrently, the development of advanced cooling systems helped maintain engine reliability under extreme conditions.

The past decade has seen a renewed emphasis on fuel efficiency and reduced logistical footprint. Hybrid V8 powertrains have emerged, combining traditional internal combustion engines with electric motors to optimize power delivery and fuel consumption. Additionally, advancements in 3D printing and additive manufacturing have revolutionized the production of complex engine components, enabling rapid prototyping and field repairs.

Looking forward, the evolution of V8 engines in military vehicles is likely to focus on further integration of smart technologies. This includes predictive maintenance systems, real-time performance optimization, and adaptive power management. Research into alternative fuels and propulsion systems continues, with hydrogen-powered V8 engines and fully electric powertrains being explored for future military applications.

Throughout the 1960s and 1970s, military vehicle manufacturers focused on improving fuel efficiency and durability. This led to the development of more robust V8 diesel engines, capable of withstanding harsh battlefield conditions while providing superior torque for heavy armored vehicles. The introduction of turbocharging and intercooling technologies in the 1980s further enhanced engine performance, allowing for increased power output without sacrificing fuel economy.

The 1990s saw a shift towards modular engine designs, enabling easier maintenance and parts replacement in the field. This period also witnessed the integration of electronic engine management systems, improving overall engine efficiency and reducing emissions. As environmental concerns grew, military organizations began exploring alternative fuel options for V8 engines, including biodiesel and synthetic fuels.

In the early 2000s, the focus shifted to power density and thermal management. Advanced materials such as high-strength alloys and ceramics were incorporated into engine designs, allowing for higher operating temperatures and increased power output. Concurrently, the development of advanced cooling systems helped maintain engine reliability under extreme conditions.

The past decade has seen a renewed emphasis on fuel efficiency and reduced logistical footprint. Hybrid V8 powertrains have emerged, combining traditional internal combustion engines with electric motors to optimize power delivery and fuel consumption. Additionally, advancements in 3D printing and additive manufacturing have revolutionized the production of complex engine components, enabling rapid prototyping and field repairs.

Looking forward, the evolution of V8 engines in military vehicles is likely to focus on further integration of smart technologies. This includes predictive maintenance systems, real-time performance optimization, and adaptive power management. Research into alternative fuels and propulsion systems continues, with hydrogen-powered V8 engines and fully electric powertrains being explored for future military applications.

Military Vehicle Market Demand Analysis

The military vehicle market has been experiencing significant growth and transformation in recent years, driven by evolving global security challenges and technological advancements. The demand for military vehicles equipped with V8 engines has shown a notable increase, particularly in regions with complex terrains and harsh operating conditions.

Market analysis indicates that the global military vehicle sector is projected to expand at a steady rate over the next decade. This growth is primarily fueled by increasing defense budgets in several countries, modernization initiatives of existing military fleets, and the need for more versatile and powerful vehicles capable of multi-role operations.

The V8 engine, known for its robust power output and reliability, has become a preferred choice for many military vehicle applications. Its ability to deliver high torque at low RPMs makes it particularly suitable for heavy-duty military vehicles that require substantial pulling power and off-road capabilities.

In terms of regional demand, North America and Europe continue to be the largest markets for military vehicles with V8 engines. However, emerging economies in Asia-Pacific and the Middle East are showing rapid growth in demand, driven by regional security concerns and efforts to strengthen military capabilities.

The market for armored personnel carriers (APCs) and infantry fighting vehicles (IFVs) equipped with V8 engines has seen particularly strong growth. These vehicles require powerful engines to maintain mobility while carrying heavy armor and weapon systems. Light tactical vehicles and logistics trucks are also increasingly adopting V8 engines to improve performance in challenging environments.

Environmental considerations are influencing market trends, with a growing emphasis on fuel efficiency and reduced emissions. This has led to the development of more advanced V8 engine designs that offer improved fuel economy without compromising on power output.

The aftermarket and maintenance sector for V8 engines in military vehicles is also expanding, driven by the need for regular servicing and upgrades of existing fleets. This presents additional opportunities for engine manufacturers and service providers in the military vehicle ecosystem.

Overall, the market demand for V8 engines in military vehicles remains robust, with a clear trend towards more powerful, efficient, and versatile engine solutions to meet the evolving needs of modern armed forces.

Market analysis indicates that the global military vehicle sector is projected to expand at a steady rate over the next decade. This growth is primarily fueled by increasing defense budgets in several countries, modernization initiatives of existing military fleets, and the need for more versatile and powerful vehicles capable of multi-role operations.

The V8 engine, known for its robust power output and reliability, has become a preferred choice for many military vehicle applications. Its ability to deliver high torque at low RPMs makes it particularly suitable for heavy-duty military vehicles that require substantial pulling power and off-road capabilities.

In terms of regional demand, North America and Europe continue to be the largest markets for military vehicles with V8 engines. However, emerging economies in Asia-Pacific and the Middle East are showing rapid growth in demand, driven by regional security concerns and efforts to strengthen military capabilities.

The market for armored personnel carriers (APCs) and infantry fighting vehicles (IFVs) equipped with V8 engines has seen particularly strong growth. These vehicles require powerful engines to maintain mobility while carrying heavy armor and weapon systems. Light tactical vehicles and logistics trucks are also increasingly adopting V8 engines to improve performance in challenging environments.

Environmental considerations are influencing market trends, with a growing emphasis on fuel efficiency and reduced emissions. This has led to the development of more advanced V8 engine designs that offer improved fuel economy without compromising on power output.

The aftermarket and maintenance sector for V8 engines in military vehicles is also expanding, driven by the need for regular servicing and upgrades of existing fleets. This presents additional opportunities for engine manufacturers and service providers in the military vehicle ecosystem.

Overall, the market demand for V8 engines in military vehicles remains robust, with a clear trend towards more powerful, efficient, and versatile engine solutions to meet the evolving needs of modern armed forces.

V8 Engine Challenges in Military Applications

The application of V8 engines in military vehicles presents several unique challenges that must be addressed to ensure optimal performance and reliability in demanding operational environments. One of the primary concerns is the need for enhanced durability and longevity. Military vehicles often operate in extreme conditions, including harsh terrains, extreme temperatures, and prolonged periods of use. This necessitates the development of V8 engines with reinforced components and advanced materials capable of withstanding increased stress and wear.

Another significant challenge lies in the power-to-weight ratio optimization. Military vehicles require substantial power output to overcome obstacles and maintain mobility in diverse terrains. However, excessive weight can hinder maneuverability and transportability. Engineers must strike a delicate balance between maximizing engine power and minimizing overall vehicle weight, often through the use of lightweight alloys and innovative design techniques.

Fuel efficiency and range extension pose additional hurdles in military V8 engine applications. Extended operational range is crucial for military missions, yet the high power demands of these engines can lead to increased fuel consumption. Developing fuel-efficient V8 engines that maintain performance standards while reducing fuel usage is a complex engineering task, often involving advanced fuel injection systems and combustion optimization techniques.

Thermal management presents another critical challenge in military V8 applications. The high-output nature of these engines, combined with operation in extreme environments, can lead to significant heat generation. Effective cooling systems must be designed to prevent overheating and ensure consistent performance, even in the most demanding conditions. This often requires innovative approaches to heat dissipation and the integration of advanced thermal management technologies.

Noise and vibration reduction are also key considerations in military V8 engine development. Excessive noise and vibration can compromise vehicle stealth, crew comfort, and long-term structural integrity. Engineers must implement advanced noise dampening technologies and vibration isolation systems to mitigate these issues without sacrificing engine performance or reliability.

Lastly, the integration of modern electronic systems and engine management technologies poses a unique challenge in military applications. While these systems can significantly enhance engine performance and efficiency, they must be ruggedized to withstand electromagnetic interference, cyber threats, and physical damage in combat situations. Developing robust, secure, and easily maintainable electronic systems for V8 engines in military vehicles is an ongoing challenge that requires continuous innovation and rigorous testing protocols.

Another significant challenge lies in the power-to-weight ratio optimization. Military vehicles require substantial power output to overcome obstacles and maintain mobility in diverse terrains. However, excessive weight can hinder maneuverability and transportability. Engineers must strike a delicate balance between maximizing engine power and minimizing overall vehicle weight, often through the use of lightweight alloys and innovative design techniques.

Fuel efficiency and range extension pose additional hurdles in military V8 engine applications. Extended operational range is crucial for military missions, yet the high power demands of these engines can lead to increased fuel consumption. Developing fuel-efficient V8 engines that maintain performance standards while reducing fuel usage is a complex engineering task, often involving advanced fuel injection systems and combustion optimization techniques.

Thermal management presents another critical challenge in military V8 applications. The high-output nature of these engines, combined with operation in extreme environments, can lead to significant heat generation. Effective cooling systems must be designed to prevent overheating and ensure consistent performance, even in the most demanding conditions. This often requires innovative approaches to heat dissipation and the integration of advanced thermal management technologies.

Noise and vibration reduction are also key considerations in military V8 engine development. Excessive noise and vibration can compromise vehicle stealth, crew comfort, and long-term structural integrity. Engineers must implement advanced noise dampening technologies and vibration isolation systems to mitigate these issues without sacrificing engine performance or reliability.

Lastly, the integration of modern electronic systems and engine management technologies poses a unique challenge in military applications. While these systems can significantly enhance engine performance and efficiency, they must be ruggedized to withstand electromagnetic interference, cyber threats, and physical damage in combat situations. Developing robust, secure, and easily maintainable electronic systems for V8 engines in military vehicles is an ongoing challenge that requires continuous innovation and rigorous testing protocols.

Current V8 Engine Solutions for Military Vehicles

01 V8 Engine Design and Configuration

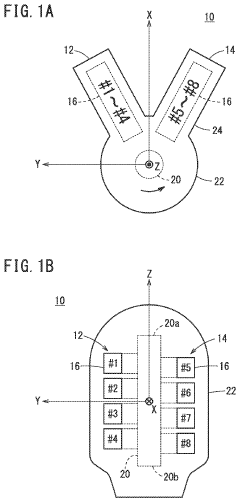

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are continuously optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and balanced operation. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems may include direct injection, variable valve timing, and advanced ignition control. Innovations in this area focus on improving fuel efficiency, reducing emissions, and enhancing power output across different operating conditions.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often used in V8 engines to increase power output and efficiency. These systems compress the intake air, allowing more fuel to be burned and generating more power. Innovations in this area include variable geometry turbochargers and electric superchargers for improved response and efficiency.

- Engine Block and Component Materials: The choice of materials for V8 engine components significantly impacts performance, durability, and weight. Advanced materials such as aluminum alloys, high-strength steel, and composite materials are used in engine blocks, cylinder heads, and other components to reduce weight while maintaining strength and heat dissipation properties.

- Cooling and Lubrication Systems: Efficient cooling and lubrication systems are essential for V8 engine performance and longevity. Innovations in this area include advanced coolant formulations, precision oil delivery systems, and integrated thermal management solutions. These systems help maintain optimal operating temperatures and reduce friction, improving overall engine efficiency and durability.

02 Fuel Injection and Combustion Systems

Modern V8 engines employ advanced fuel injection and combustion systems to enhance performance and reduce emissions. These systems may include direct injection, variable valve timing, and cylinder deactivation technologies. Innovations in this area focus on improving fuel efficiency, power output, and meeting stringent emission standards.Expand Specific Solutions03 Turbocharging and Supercharging

To increase power output and efficiency, many V8 engines incorporate forced induction systems such as turbochargers or superchargers. These systems compress the intake air, allowing more fuel to be burned and generating more power from the same engine displacement. Advancements in this area include twin-turbo setups, electric superchargers, and variable geometry turbochargers.Expand Specific Solutions04 Engine Block and Component Materials

The choice of materials for V8 engine components significantly impacts performance, durability, and weight. Innovations in this area include the use of lightweight alloys for engine blocks, high-strength materials for pistons and connecting rods, and advanced coatings to reduce friction and wear. These material advancements contribute to improved power-to-weight ratios and engine longevity.Expand Specific Solutions05 Cooling and Lubrication Systems

Effective cooling and lubrication are crucial for V8 engine performance and longevity. Innovations in this area include advanced coolant formulations, precision oil delivery systems, and improved heat management techniques. These developments aim to maintain optimal operating temperatures, reduce friction, and extend engine life under high-performance conditions.Expand Specific Solutions

Key Military Vehicle Manufacturers and Engine Suppliers

The V8 engine applications in military vehicles market is in a mature stage, with established players and proven technologies. The market size is substantial, driven by ongoing military modernization programs and the need for powerful, reliable engines in armored vehicles and heavy-duty military trucks. Technologically, V8 engines for military use are highly advanced, with companies like GM Global Technology Operations, Oshkosh Defense, and Rolls-Royce leading innovation. These firms, along with others such as FCA US and Ford Global Technologies, have developed specialized V8 engines that meet stringent military requirements for performance, durability, and fuel efficiency in harsh operational environments. The competitive landscape is characterized by a mix of traditional automotive manufacturers and defense-focused companies, each leveraging their expertise to gain market share.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced V8 engine applications for military vehicles, focusing on improved fuel efficiency and power output. Their technology incorporates direct injection, variable valve timing, and cylinder deactivation to optimize performance in demanding military environments. GM's V8 engines for military use feature reinforced components to withstand extreme conditions and provide enhanced durability. The company has also integrated advanced cooling systems to maintain optimal engine temperature in harsh operating conditions[1][3]. Additionally, GM has implemented sophisticated engine control units (ECUs) that allow for real-time adjustments to engine parameters based on terrain and mission requirements, enhancing overall vehicle performance and adaptability[5].

Strengths: Extensive experience in V8 engine development, advanced fuel efficiency technologies, and robust design for military applications. Weaknesses: Potential higher initial costs due to specialized military-grade components and systems.

Oshkosh Defense LLC

Technical Solution: Oshkosh Defense has developed proprietary V8 engine solutions specifically tailored for military vehicles. Their approach focuses on integrating high-performance V8 engines with advanced drivetrain systems to maximize mobility and survivability. Oshkosh's V8 engines feature enhanced power-to-weight ratios, allowing for improved acceleration and climbing capabilities in tactical situations[2]. The company has also implemented advanced thermal management systems to ensure optimal engine performance in extreme temperatures. Oshkosh's V8 engines are designed with modular components for easy field maintenance and rapid replacement, reducing vehicle downtime in combat zones[4]. Furthermore, they have incorporated smart diagnostics and prognostics systems that provide real-time engine health monitoring and predictive maintenance capabilities[6].

Strengths: Specialized military vehicle expertise, focus on mobility and survivability, and advanced maintenance features. Weaknesses: Potentially limited applicability outside of military contexts.

Core V8 Engine Innovations for Military Use

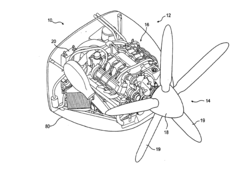

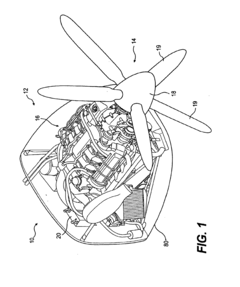

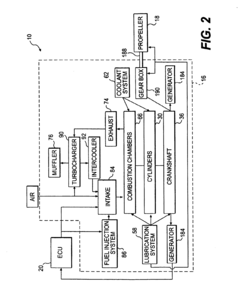

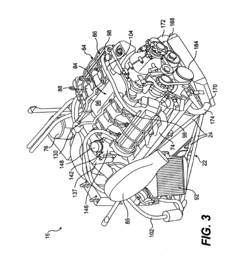

Piston Type Aircraft Engine

PatentInactiveUS20080027620A1

Innovation

- A compact, lightweight piston-type internal combustion engine with a V-type configuration, featuring a closed-loop liquid cooling system, electronic control unit, and a propeller shaft, designed to meet FAA and RTCA guidelines, with a displacement of less than 19.6 liters and a power output of 140 to 600 horsepower, optimized for efficient operation at high altitudes and duty cycles.

V8 engine

PatentActiveUS20230109196A1

Innovation

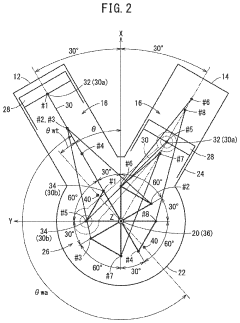

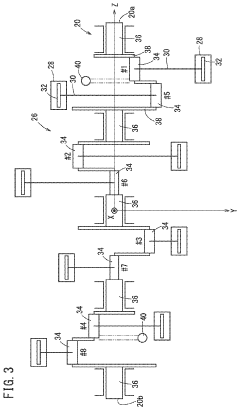

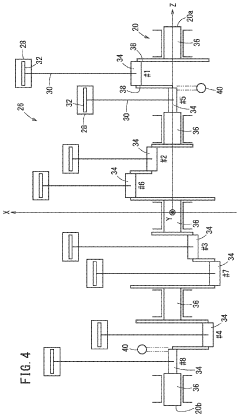

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Military Vehicle Powertrain Regulations

Military vehicle powertrain regulations play a crucial role in shaping the development and deployment of V8 engines in military applications. These regulations encompass a wide range of requirements, including performance standards, emissions controls, fuel efficiency targets, and durability specifications. The primary objective of these regulations is to ensure that military vehicles meet operational needs while adhering to environmental and safety standards.

One of the key aspects of military vehicle powertrain regulations is the emphasis on performance under extreme conditions. V8 engines used in military vehicles must demonstrate reliable operation in diverse environments, from arctic tundras to scorching deserts. Regulations often specify minimum power output, torque requirements, and acceleration capabilities to ensure vehicles can navigate challenging terrains and carry heavy payloads.

Emissions standards for military vehicles, while generally less stringent than civilian counterparts, are becoming increasingly important. Many armed forces worldwide are adopting stricter emissions controls to reduce their environmental impact and improve operational efficiency. These regulations often set limits on particulate matter, nitrogen oxides, and carbon dioxide emissions, pushing manufacturers to develop cleaner V8 engine technologies for military applications.

Fuel efficiency is another critical aspect addressed by military vehicle powertrain regulations. With the high cost and logistical challenges associated with fuel supply in combat zones, regulations often mandate minimum fuel economy standards for different vehicle classes. This has led to the development of advanced fuel management systems and the exploration of alternative fuels compatible with V8 engines.

Durability and reliability requirements are particularly stringent in military vehicle regulations. V8 engines must demonstrate extended service life under harsh conditions, with regulations specifying minimum operating hours between major overhauls and strict maintenance schedules. These requirements drive innovations in materials science and engine design to enhance longevity and reduce maintenance needs.

Interoperability and standardization are also key components of military vehicle powertrain regulations. Many armed forces require compatibility with standardized fuel types and maintenance procedures across their vehicle fleets. This has implications for V8 engine design, often necessitating adaptable fuel systems and modular components to facilitate maintenance and repairs in the field.

As military operations evolve, regulations are increasingly focusing on power generation capabilities of vehicle engines. Modern military vehicles often serve as mobile power stations for electronic systems and weaponry. Consequently, regulations now frequently include specifications for auxiliary power output from V8 engines, driving the integration of advanced alternators and power management systems.

One of the key aspects of military vehicle powertrain regulations is the emphasis on performance under extreme conditions. V8 engines used in military vehicles must demonstrate reliable operation in diverse environments, from arctic tundras to scorching deserts. Regulations often specify minimum power output, torque requirements, and acceleration capabilities to ensure vehicles can navigate challenging terrains and carry heavy payloads.

Emissions standards for military vehicles, while generally less stringent than civilian counterparts, are becoming increasingly important. Many armed forces worldwide are adopting stricter emissions controls to reduce their environmental impact and improve operational efficiency. These regulations often set limits on particulate matter, nitrogen oxides, and carbon dioxide emissions, pushing manufacturers to develop cleaner V8 engine technologies for military applications.

Fuel efficiency is another critical aspect addressed by military vehicle powertrain regulations. With the high cost and logistical challenges associated with fuel supply in combat zones, regulations often mandate minimum fuel economy standards for different vehicle classes. This has led to the development of advanced fuel management systems and the exploration of alternative fuels compatible with V8 engines.

Durability and reliability requirements are particularly stringent in military vehicle regulations. V8 engines must demonstrate extended service life under harsh conditions, with regulations specifying minimum operating hours between major overhauls and strict maintenance schedules. These requirements drive innovations in materials science and engine design to enhance longevity and reduce maintenance needs.

Interoperability and standardization are also key components of military vehicle powertrain regulations. Many armed forces require compatibility with standardized fuel types and maintenance procedures across their vehicle fleets. This has implications for V8 engine design, often necessitating adaptable fuel systems and modular components to facilitate maintenance and repairs in the field.

As military operations evolve, regulations are increasingly focusing on power generation capabilities of vehicle engines. Modern military vehicles often serve as mobile power stations for electronic systems and weaponry. Consequently, regulations now frequently include specifications for auxiliary power output from V8 engines, driving the integration of advanced alternators and power management systems.

V8 Engine Sustainability in Military Applications

The sustainability of V8 engines in military applications is a critical consideration for armed forces worldwide. These powerful engines have long been favored for their high torque output and reliability, which are essential in military vehicles operating in challenging environments. However, the increasing focus on environmental sustainability and fuel efficiency has raised questions about the long-term viability of V8 engines in military applications.

One of the primary challenges facing V8 engines in military use is their relatively high fuel consumption. As armed forces seek to reduce their carbon footprint and operational costs, there is growing pressure to find more fuel-efficient alternatives. This has led to the exploration of hybrid and electric powertrains, as well as the development of more efficient internal combustion engines.

Despite these challenges, V8 engines continue to offer several advantages that make them valuable in military applications. Their robust design and ability to operate in extreme conditions make them well-suited for military vehicles that must function reliably in diverse and hostile environments. Additionally, the high power output of V8 engines is crucial for heavy-duty military vehicles that require significant torque for off-road capabilities and towing capacity.

To address sustainability concerns, manufacturers are developing more efficient V8 engines that incorporate advanced technologies such as direct injection, variable valve timing, and cylinder deactivation. These innovations help to improve fuel economy and reduce emissions without sacrificing the power and reliability that military applications demand.

Another approach to enhancing the sustainability of V8 engines in military use is the adoption of alternative fuels. Research is ongoing into the use of biofuels and synthetic fuels that can reduce the carbon footprint of V8-powered vehicles while maintaining their performance characteristics. This strategy allows armed forces to leverage existing V8 engine technology while moving towards more sustainable fuel sources.

The long-term sustainability of V8 engines in military applications will likely depend on a combination of technological advancements and strategic planning. As armed forces balance the need for powerful, reliable vehicles with environmental and economic considerations, the role of V8 engines may evolve. This could involve the selective use of V8 engines in specific applications where their advantages are most critical, while adopting alternative powertrains for other vehicles in the military fleet.

One of the primary challenges facing V8 engines in military use is their relatively high fuel consumption. As armed forces seek to reduce their carbon footprint and operational costs, there is growing pressure to find more fuel-efficient alternatives. This has led to the exploration of hybrid and electric powertrains, as well as the development of more efficient internal combustion engines.

Despite these challenges, V8 engines continue to offer several advantages that make them valuable in military applications. Their robust design and ability to operate in extreme conditions make them well-suited for military vehicles that must function reliably in diverse and hostile environments. Additionally, the high power output of V8 engines is crucial for heavy-duty military vehicles that require significant torque for off-road capabilities and towing capacity.

To address sustainability concerns, manufacturers are developing more efficient V8 engines that incorporate advanced technologies such as direct injection, variable valve timing, and cylinder deactivation. These innovations help to improve fuel economy and reduce emissions without sacrificing the power and reliability that military applications demand.

Another approach to enhancing the sustainability of V8 engines in military use is the adoption of alternative fuels. Research is ongoing into the use of biofuels and synthetic fuels that can reduce the carbon footprint of V8-powered vehicles while maintaining their performance characteristics. This strategy allows armed forces to leverage existing V8 engine technology while moving towards more sustainable fuel sources.

The long-term sustainability of V8 engines in military applications will likely depend on a combination of technological advancements and strategic planning. As armed forces balance the need for powerful, reliable vehicles with environmental and economic considerations, the role of V8 engines may evolve. This could involve the selective use of V8 engines in specific applications where their advantages are most critical, while adopting alternative powertrains for other vehicles in the military fleet.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!