How V8 Engines Contribute to Global Technological Progress?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine, a marvel of automotive engineering, has played a pivotal role in shaping the global technological landscape since its inception. This powerful and efficient engine design has undergone significant evolution over the years, continuously pushing the boundaries of performance and fuel efficiency. The journey of V8 engines began in the early 20th century, with the first mass-produced V8 engine introduced by Cadillac in 1914.

As the automotive industry progressed, V8 engines became synonymous with power and prestige. The post-World War II era saw a surge in V8 engine development, particularly in the United States, where muscle cars and high-performance vehicles dominated the market. This period marked a significant milestone in V8 engine evolution, with manufacturers competing to produce more powerful and efficient designs.

The 1970s brought new challenges to V8 engine development, as concerns over fuel efficiency and emissions regulations forced manufacturers to rethink their approach. This led to the introduction of electronic fuel injection systems and computer-controlled engine management, marking the beginning of a new era in V8 engine technology. These advancements not only improved fuel efficiency but also paved the way for more precise control over engine performance.

In recent decades, the focus of V8 engine evolution has shifted towards achieving a balance between power and environmental responsibility. Technologies such as variable valve timing, cylinder deactivation, and direct fuel injection have been incorporated to enhance efficiency without compromising performance. The integration of turbocharging and supercharging has allowed manufacturers to downsize V8 engines while maintaining or even increasing power output.

The objectives of modern V8 engine development are multifaceted. Manufacturers aim to push the boundaries of performance while meeting increasingly stringent emissions standards. This has led to the exploration of hybrid and electric technologies in conjunction with V8 engines, creating powerful yet environmentally conscious powertrains. Additionally, there is a growing emphasis on lightweight materials and advanced manufacturing techniques to improve overall vehicle efficiency.

Looking ahead, the future of V8 engines lies in their ability to adapt to changing market demands and environmental regulations. The development of sustainable fuels and advanced combustion technologies presents new opportunities for V8 engines to remain relevant in an increasingly electrified automotive landscape. As such, the ongoing evolution of V8 engines continues to contribute significantly to global technological progress, driving innovation across various industries and inspiring new generations of engineers and enthusiasts alike.

As the automotive industry progressed, V8 engines became synonymous with power and prestige. The post-World War II era saw a surge in V8 engine development, particularly in the United States, where muscle cars and high-performance vehicles dominated the market. This period marked a significant milestone in V8 engine evolution, with manufacturers competing to produce more powerful and efficient designs.

The 1970s brought new challenges to V8 engine development, as concerns over fuel efficiency and emissions regulations forced manufacturers to rethink their approach. This led to the introduction of electronic fuel injection systems and computer-controlled engine management, marking the beginning of a new era in V8 engine technology. These advancements not only improved fuel efficiency but also paved the way for more precise control over engine performance.

In recent decades, the focus of V8 engine evolution has shifted towards achieving a balance between power and environmental responsibility. Technologies such as variable valve timing, cylinder deactivation, and direct fuel injection have been incorporated to enhance efficiency without compromising performance. The integration of turbocharging and supercharging has allowed manufacturers to downsize V8 engines while maintaining or even increasing power output.

The objectives of modern V8 engine development are multifaceted. Manufacturers aim to push the boundaries of performance while meeting increasingly stringent emissions standards. This has led to the exploration of hybrid and electric technologies in conjunction with V8 engines, creating powerful yet environmentally conscious powertrains. Additionally, there is a growing emphasis on lightweight materials and advanced manufacturing techniques to improve overall vehicle efficiency.

Looking ahead, the future of V8 engines lies in their ability to adapt to changing market demands and environmental regulations. The development of sustainable fuels and advanced combustion technologies presents new opportunities for V8 engines to remain relevant in an increasingly electrified automotive landscape. As such, the ongoing evolution of V8 engines continues to contribute significantly to global technological progress, driving innovation across various industries and inspiring new generations of engineers and enthusiasts alike.

Market Demand Analysis for V8 Engines

The global market for V8 engines has experienced significant growth and transformation in recent years, driven by various factors across different sectors. In the automotive industry, V8 engines continue to be in high demand for luxury vehicles, sports cars, and high-performance SUVs. This demand is particularly strong in North America and the Middle East, where consumers value the power and prestige associated with V8-powered vehicles.

The marine sector also contributes substantially to the V8 engine market. Large boats and yachts often utilize V8 engines for their superior power-to-weight ratio and reliability. As the global tourism industry recovers and luxury marine travel increases, the demand for V8 engines in this sector is expected to grow.

In the industrial sector, V8 engines find applications in heavy machinery, generators, and agricultural equipment. The need for robust and powerful engines in construction and farming activities, especially in developing economies, fuels the demand for V8 engines in these areas.

The aviation industry, although a smaller market segment, also contributes to V8 engine demand. Some small aircraft and unmanned aerial vehicles (UAVs) utilize V8 engines for their power and efficiency characteristics.

However, the market for V8 engines faces challenges due to increasing environmental regulations and a global shift towards electrification. Many countries have implemented stricter emissions standards, pushing manufacturers to develop more fuel-efficient and cleaner V8 engines. This has led to innovations such as cylinder deactivation technology and the integration of hybrid systems with V8 engines.

Despite these challenges, the market for V8 engines remains resilient. Manufacturers are adapting by developing more efficient and environmentally friendly V8 engines. The integration of advanced technologies like direct injection, turbocharging, and variable valve timing has allowed V8 engines to maintain their appeal while meeting stricter emissions standards.

The aftermarket and performance tuning sectors also contribute significantly to the V8 engine market. Enthusiasts and racing teams continue to modify and enhance V8 engines, creating a robust ecosystem of parts and services.

Looking ahead, the V8 engine market is expected to evolve. While traditional applications may face pressure from electrification, new opportunities are emerging in specialized sectors. The development of synthetic fuels and hydrogen combustion technologies may also provide new avenues for V8 engines to remain relevant in a changing technological landscape.

The marine sector also contributes substantially to the V8 engine market. Large boats and yachts often utilize V8 engines for their superior power-to-weight ratio and reliability. As the global tourism industry recovers and luxury marine travel increases, the demand for V8 engines in this sector is expected to grow.

In the industrial sector, V8 engines find applications in heavy machinery, generators, and agricultural equipment. The need for robust and powerful engines in construction and farming activities, especially in developing economies, fuels the demand for V8 engines in these areas.

The aviation industry, although a smaller market segment, also contributes to V8 engine demand. Some small aircraft and unmanned aerial vehicles (UAVs) utilize V8 engines for their power and efficiency characteristics.

However, the market for V8 engines faces challenges due to increasing environmental regulations and a global shift towards electrification. Many countries have implemented stricter emissions standards, pushing manufacturers to develop more fuel-efficient and cleaner V8 engines. This has led to innovations such as cylinder deactivation technology and the integration of hybrid systems with V8 engines.

Despite these challenges, the market for V8 engines remains resilient. Manufacturers are adapting by developing more efficient and environmentally friendly V8 engines. The integration of advanced technologies like direct injection, turbocharging, and variable valve timing has allowed V8 engines to maintain their appeal while meeting stricter emissions standards.

The aftermarket and performance tuning sectors also contribute significantly to the V8 engine market. Enthusiasts and racing teams continue to modify and enhance V8 engines, creating a robust ecosystem of parts and services.

Looking ahead, the V8 engine market is expected to evolve. While traditional applications may face pressure from electrification, new opportunities are emerging in specialized sectors. The development of synthetic fuels and hydrogen combustion technologies may also provide new avenues for V8 engines to remain relevant in a changing technological landscape.

V8 Engine Technology Status and Challenges

V8 engine technology has made significant strides in recent years, but it still faces several challenges in its quest for further advancement. Currently, V8 engines are widely used in various applications, from automotive to industrial sectors, due to their high power output and efficiency. However, the technology is at a critical juncture where it must adapt to meet increasingly stringent environmental regulations and market demands for improved performance.

One of the primary challenges facing V8 engine technology is the need to reduce emissions while maintaining or improving performance. As global environmental standards become more stringent, manufacturers are under pressure to develop cleaner V8 engines. This has led to the implementation of advanced fuel injection systems, improved combustion chamber designs, and the integration of hybrid technologies. Despite these efforts, achieving the perfect balance between power output and emissions reduction remains a significant hurdle.

Another major challenge is the optimization of fuel efficiency. While V8 engines are known for their power, they have traditionally been less fuel-efficient compared to smaller engine configurations. Engineers are working on various solutions, including cylinder deactivation technologies, which allow the engine to operate on fewer cylinders under light load conditions. However, perfecting these systems to ensure seamless operation and long-term reliability is an ongoing challenge.

The integration of advanced materials and manufacturing techniques presents both opportunities and challenges for V8 engine development. Lightweight materials such as aluminum and carbon fiber composites are being explored to reduce engine weight and improve efficiency. However, these materials often come with higher costs and require new manufacturing processes, which can be a barrier to widespread adoption.

Electrification is another area that is reshaping the landscape of V8 engine technology. As the automotive industry moves towards electrification, there is a growing need to develop hybrid V8 systems that can complement electric powertrains. This integration poses significant technical challenges, particularly in terms of packaging, thermal management, and overall system complexity.

From a geographical perspective, V8 engine technology development is primarily concentrated in regions with strong automotive industries, such as North America, Europe, and parts of Asia. However, there is an increasing trend of global collaboration, with research and development efforts spanning across continents to leverage diverse expertise and resources.

In conclusion, while V8 engine technology continues to evolve and adapt to changing market and regulatory demands, it faces multifaceted challenges. The path forward requires innovative solutions that address emissions, fuel efficiency, materials science, and electrification, all while maintaining the power and performance characteristics that have made V8 engines iconic in the automotive world.

One of the primary challenges facing V8 engine technology is the need to reduce emissions while maintaining or improving performance. As global environmental standards become more stringent, manufacturers are under pressure to develop cleaner V8 engines. This has led to the implementation of advanced fuel injection systems, improved combustion chamber designs, and the integration of hybrid technologies. Despite these efforts, achieving the perfect balance between power output and emissions reduction remains a significant hurdle.

Another major challenge is the optimization of fuel efficiency. While V8 engines are known for their power, they have traditionally been less fuel-efficient compared to smaller engine configurations. Engineers are working on various solutions, including cylinder deactivation technologies, which allow the engine to operate on fewer cylinders under light load conditions. However, perfecting these systems to ensure seamless operation and long-term reliability is an ongoing challenge.

The integration of advanced materials and manufacturing techniques presents both opportunities and challenges for V8 engine development. Lightweight materials such as aluminum and carbon fiber composites are being explored to reduce engine weight and improve efficiency. However, these materials often come with higher costs and require new manufacturing processes, which can be a barrier to widespread adoption.

Electrification is another area that is reshaping the landscape of V8 engine technology. As the automotive industry moves towards electrification, there is a growing need to develop hybrid V8 systems that can complement electric powertrains. This integration poses significant technical challenges, particularly in terms of packaging, thermal management, and overall system complexity.

From a geographical perspective, V8 engine technology development is primarily concentrated in regions with strong automotive industries, such as North America, Europe, and parts of Asia. However, there is an increasing trend of global collaboration, with research and development efforts spanning across continents to leverage diverse expertise and resources.

In conclusion, while V8 engine technology continues to evolve and adapt to changing market and regulatory demands, it faces multifaceted challenges. The path forward requires innovative solutions that address emissions, fuel efficiency, materials science, and electrification, all while maintaining the power and performance characteristics that have made V8 engines iconic in the automotive world.

Current V8 Engine Solutions

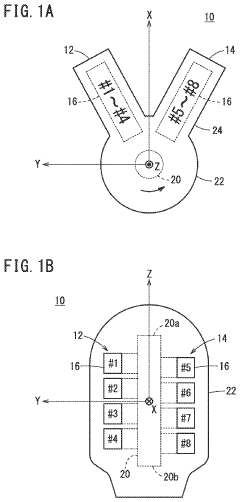

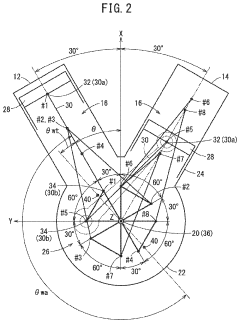

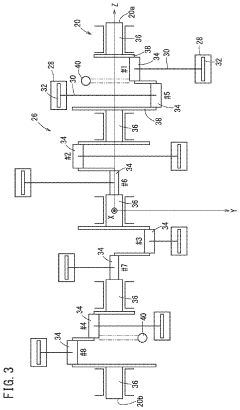

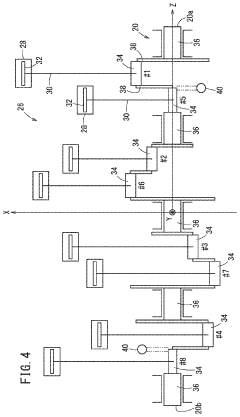

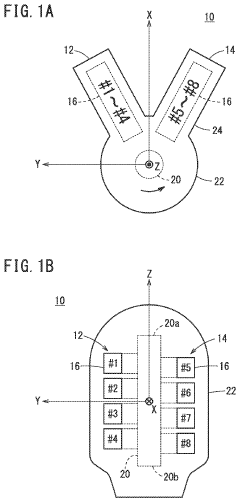

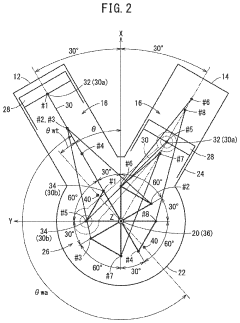

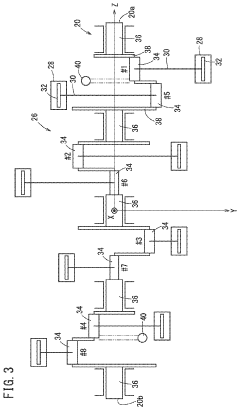

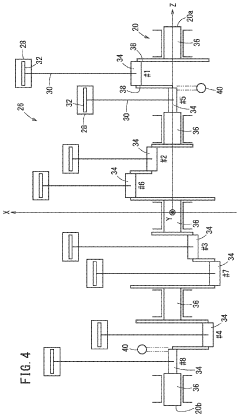

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved balance, and higher power output compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are continuously optimized to enhance performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design while providing high power output. The design often includes features for improved performance, fuel efficiency, and reduced emissions.

- Valve Train and Cylinder Head Improvements: Advancements in V8 engine valve trains and cylinder heads focus on optimizing airflow, combustion efficiency, and overall engine performance. These improvements may include variable valve timing, multi-valve configurations, and innovative cylinder head designs.

- Fuel Injection and Combustion Optimization: Modern V8 engines incorporate advanced fuel injection systems and combustion chamber designs to enhance fuel efficiency and power output. This includes direct injection technology, improved fuel atomization, and optimized combustion chamber geometry.

- Engine Block and Crankshaft Innovations: Innovations in V8 engine blocks and crankshafts focus on reducing weight, improving strength, and enhancing overall engine durability. This may involve the use of advanced materials, optimized casting techniques, and innovative crankshaft designs for better balance and reduced vibration.

- Cooling and Lubrication System Enhancements: Improvements in V8 engine cooling and lubrication systems aim to enhance thermal management, reduce friction, and increase overall engine efficiency. This includes advanced coolant flow designs, oil pump innovations, and the integration of thermal management systems.

02 Fuel Injection Systems for V8 Engines

Advanced fuel injection systems are crucial for optimizing V8 engine performance. These systems include direct injection, port fuel injection, and dual-injection technologies. Innovations in fuel injector design, fuel pressure regulation, and electronic control units contribute to improved fuel efficiency, reduced emissions, and enhanced power output in V8 engines.Expand Specific Solutions03 Turbocharging and Supercharging V8 Engines

Forced induction systems, such as turbochargers and superchargers, are frequently used to boost the power output of V8 engines. These systems compress the intake air, allowing for more fuel to be burned and resulting in increased horsepower. Innovations in turbocharger and supercharger design, including variable geometry turbos and electric superchargers, continue to improve V8 engine performance.Expand Specific Solutions04 V8 Engine Cooling and Lubrication Systems

Efficient cooling and lubrication systems are essential for maintaining V8 engine performance and longevity. Innovations in coolant flow design, oil pump technology, and thermal management systems help regulate engine temperature and reduce friction. Advanced materials and coatings are also employed to enhance heat dissipation and improve overall engine efficiency.Expand Specific Solutions05 Emissions Control Technologies for V8 Engines

To meet increasingly stringent emissions regulations, V8 engines incorporate various emissions control technologies. These include advanced catalytic converters, exhaust gas recirculation systems, and particulate filters. Innovations in combustion chamber design, variable valve timing, and engine control strategies also contribute to reducing harmful emissions while maintaining performance.Expand Specific Solutions

Major Players in V8 Engine Industry

The V8 engine technology landscape is characterized by intense competition among established automotive giants and emerging players. The market is in a mature phase, with global demand driven by the automotive and industrial sectors. The technology's maturity is evident in the advanced offerings from key players like GM Global Technology Operations, Hyundai Motor, BMW, Honda, and Toyota. These companies have invested heavily in R&D to improve V8 engine efficiency, performance, and emissions. However, the industry is also witnessing a shift towards alternative powertrains, with companies like Great Wall Motor and Xiaomi exploring hybrid and electric technologies. This transition is reshaping the competitive landscape, pushing traditional V8 manufacturers to innovate and adapt to changing market demands and regulatory pressures.

GM Global Technology Operations LLC

Technical Solution: General Motors has been a pioneer in V8 engine technology, with innovations that have significantly impacted global automotive progress. Their Active Fuel Management (AFM) system, which deactivates cylinders under light load conditions, has greatly improved fuel efficiency in V8 engines[8]. GM's Direct Injection technology, combined with Variable Valve Timing, has enhanced both power output and fuel economy across their V8 lineup[9]. The company's development of the LT4 supercharged V8 engine showcases their ability to produce high-performance powerplants with advanced thermal management and lubrication systems[10]. GM has also made strides in materials science, utilizing aluminum block and head construction to reduce weight while maintaining strength. Their recent focus on Dynamic Fuel Management, an evolution of AFM that allows for 17 different cylinder activation combinations, represents a significant leap in V8 efficiency and responsiveness[11].

Strengths: Advanced cylinder deactivation technology, high-performance capabilities, innovative materials usage. Weaknesses: Complexity of some systems leading to potential long-term reliability concerns, slower adaptation to full electrification compared to some competitors.

Bayerische Motoren Werke AG

Technical Solution: BMW has made substantial contributions to V8 engine technology, focusing on performance, efficiency, and refinement. Their TwinPower Turbo V8 engines feature advanced technologies such as High Precision Injection, VALVETRONIC variable valve timing, and Double-VANOS camshaft control[12]. BMW's use of a "hot V" configuration, placing turbochargers within the V of the engine, has improved throttle response and overall engine packaging[13]. The company has also developed a water injection system for their M V8 engines, which cools intake temperatures, allowing for higher boost pressures and increased power output[14]. BMW's integration of lightweight materials and advanced manufacturing techniques, such as 3D-printed cylinder heads for prototype engines, showcases their commitment to pushing the boundaries of V8 technology[15]. Their recent V8 engines also incorporate mild hybrid technology, demonstrating BMW's approach to bridging traditional internal combustion with electrification.

Strengths: Advanced turbocharging technology, innovative engine layouts, integration of cutting-edge manufacturing techniques. Weaknesses: Higher complexity leading to potential increased maintenance costs, focus on performance sometimes at the expense of ultimate efficiency.

Key V8 Engine Innovations

V8 engine

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Environmental Impact of V8 Engines

The environmental impact of V8 engines has been a subject of increasing concern as global awareness of climate change and air pollution continues to grow. These powerful engines, known for their high performance and distinctive sound, have long been associated with luxury vehicles and sports cars. However, their significant fuel consumption and emissions output have placed them at the center of debates surrounding automotive sustainability.

V8 engines typically produce higher levels of carbon dioxide (CO2) emissions compared to smaller, more fuel-efficient engines. This contributes to the overall greenhouse gas effect, which is a primary driver of global warming. The increased fuel consumption of V8 engines also leads to greater depletion of fossil fuel resources, raising questions about long-term sustainability in the automotive industry.

Nitrogen oxides (NOx) and particulate matter emissions from V8 engines, particularly in older models, have been linked to air quality issues in urban areas. These pollutants can have severe health implications, including respiratory problems and cardiovascular diseases. As a result, many cities worldwide have implemented stricter emissions regulations, challenging the continued use of traditional V8 engines in densely populated areas.

Despite these environmental concerns, V8 engine technology has not remained stagnant. Manufacturers have made significant strides in improving the efficiency and reducing the environmental impact of V8 engines. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation have been implemented to enhance fuel economy and reduce emissions without sacrificing performance.

Furthermore, the development of hybrid V8 systems has emerged as a compromise between performance and environmental responsibility. These systems combine the power of a V8 engine with electric motors, allowing for reduced fuel consumption and emissions during city driving while maintaining high performance capabilities when needed.

The automotive industry's shift towards electrification has also influenced the future of V8 engines. As electric vehicles gain market share, the role of V8 engines in personal transportation is likely to diminish. However, their use in specialized applications, such as high-performance vehicles and certain industrial settings, may continue, albeit with increasing pressure to adopt cleaner technologies.

In conclusion, while V8 engines have contributed significantly to automotive performance and technological advancement, their environmental impact remains a critical concern. The industry's response through technological improvements and the gradual transition to alternative powertrains reflects the ongoing balance between performance demands and environmental responsibility in the global automotive sector.

V8 engines typically produce higher levels of carbon dioxide (CO2) emissions compared to smaller, more fuel-efficient engines. This contributes to the overall greenhouse gas effect, which is a primary driver of global warming. The increased fuel consumption of V8 engines also leads to greater depletion of fossil fuel resources, raising questions about long-term sustainability in the automotive industry.

Nitrogen oxides (NOx) and particulate matter emissions from V8 engines, particularly in older models, have been linked to air quality issues in urban areas. These pollutants can have severe health implications, including respiratory problems and cardiovascular diseases. As a result, many cities worldwide have implemented stricter emissions regulations, challenging the continued use of traditional V8 engines in densely populated areas.

Despite these environmental concerns, V8 engine technology has not remained stagnant. Manufacturers have made significant strides in improving the efficiency and reducing the environmental impact of V8 engines. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation have been implemented to enhance fuel economy and reduce emissions without sacrificing performance.

Furthermore, the development of hybrid V8 systems has emerged as a compromise between performance and environmental responsibility. These systems combine the power of a V8 engine with electric motors, allowing for reduced fuel consumption and emissions during city driving while maintaining high performance capabilities when needed.

The automotive industry's shift towards electrification has also influenced the future of V8 engines. As electric vehicles gain market share, the role of V8 engines in personal transportation is likely to diminish. However, their use in specialized applications, such as high-performance vehicles and certain industrial settings, may continue, albeit with increasing pressure to adopt cleaner technologies.

In conclusion, while V8 engines have contributed significantly to automotive performance and technological advancement, their environmental impact remains a critical concern. The industry's response through technological improvements and the gradual transition to alternative powertrains reflects the ongoing balance between performance demands and environmental responsibility in the global automotive sector.

V8 Engine Global Economic Influence

The global economic influence of V8 engines extends far beyond the automotive industry, shaping various sectors and driving technological advancements worldwide. These powerful and efficient engines have become a cornerstone of modern transportation, logistics, and industrial applications, contributing significantly to economic growth and productivity.

In the automotive sector, V8 engines have long been associated with high-performance vehicles, luxury cars, and heavy-duty trucks. Their widespread adoption has fueled the growth of automotive manufacturing, creating jobs and stimulating economic activity in numerous countries. The demand for V8-powered vehicles has led to the development of specialized production facilities, supply chains, and aftermarket industries, further amplifying their economic impact.

Beyond automobiles, V8 engines have found applications in marine vessels, construction equipment, and power generation systems. This versatility has expanded their influence across multiple industries, driving innovation and efficiency improvements in sectors such as shipping, construction, and energy production. The adaptability of V8 engines has enabled businesses to optimize their operations and reduce costs, contributing to overall economic productivity.

The development and production of V8 engines have also spurred technological advancements in materials science, manufacturing processes, and engineering. This has led to the creation of high-skilled jobs in research and development, design, and advanced manufacturing. The continuous pursuit of improved performance and efficiency in V8 engines has resulted in spillover effects, benefiting other areas of technology and industry.

Furthermore, the global trade of V8 engines and related components has become a significant contributor to international commerce. Countries with strong automotive and engine manufacturing capabilities have leveraged this expertise to boost their exports and strengthen their economic positions. This has led to the formation of complex global supply chains and strategic partnerships between nations and corporations.

The influence of V8 engines on the global economy also extends to environmental considerations. As regulations on emissions and fuel efficiency have become more stringent, manufacturers have invested heavily in developing cleaner and more efficient V8 engines. This has driven innovation in areas such as fuel injection systems, exhaust treatment technologies, and lightweight materials, creating new markets and economic opportunities in the green technology sector.

In conclusion, V8 engines have played a pivotal role in shaping the global economy, influencing industries far beyond their original automotive applications. Their impact on job creation, technological innovation, international trade, and environmental advancements underscores their significance as a driver of economic growth and progress worldwide.

In the automotive sector, V8 engines have long been associated with high-performance vehicles, luxury cars, and heavy-duty trucks. Their widespread adoption has fueled the growth of automotive manufacturing, creating jobs and stimulating economic activity in numerous countries. The demand for V8-powered vehicles has led to the development of specialized production facilities, supply chains, and aftermarket industries, further amplifying their economic impact.

Beyond automobiles, V8 engines have found applications in marine vessels, construction equipment, and power generation systems. This versatility has expanded their influence across multiple industries, driving innovation and efficiency improvements in sectors such as shipping, construction, and energy production. The adaptability of V8 engines has enabled businesses to optimize their operations and reduce costs, contributing to overall economic productivity.

The development and production of V8 engines have also spurred technological advancements in materials science, manufacturing processes, and engineering. This has led to the creation of high-skilled jobs in research and development, design, and advanced manufacturing. The continuous pursuit of improved performance and efficiency in V8 engines has resulted in spillover effects, benefiting other areas of technology and industry.

Furthermore, the global trade of V8 engines and related components has become a significant contributor to international commerce. Countries with strong automotive and engine manufacturing capabilities have leveraged this expertise to boost their exports and strengthen their economic positions. This has led to the formation of complex global supply chains and strategic partnerships between nations and corporations.

The influence of V8 engines on the global economy also extends to environmental considerations. As regulations on emissions and fuel efficiency have become more stringent, manufacturers have invested heavily in developing cleaner and more efficient V8 engines. This has driven innovation in areas such as fuel injection systems, exhaust treatment technologies, and lightweight materials, creating new markets and economic opportunities in the green technology sector.

In conclusion, V8 engines have played a pivotal role in shaping the global economy, influencing industries far beyond their original automotive applications. Their impact on job creation, technological innovation, international trade, and environmental advancements underscores their significance as a driver of economic growth and progress worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!