How do mild hybrids influence battery recycling practices

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Evolution

The evolution of mild hybrid technology has been a significant development in the automotive industry, marking a transitional phase between conventional internal combustion engines and fully electric vehicles. This progression has had notable implications for battery recycling practices, as the integration of electric components into traditional powertrains introduces new challenges and opportunities.

Mild hybrid systems, first introduced in the late 1990s, have undergone substantial refinements over the past two decades. Initially, these systems were primarily focused on improving fuel efficiency through start-stop functionality and regenerative braking. As the technology matured, manufacturers began incorporating more advanced features, such as electric torque assistance and energy recovery during deceleration.

The evolution of mild hybrid systems has been characterized by a gradual increase in battery capacity and voltage. Early systems typically utilized 12V batteries, which limited their electric capabilities. However, the industry has since shifted towards 48V systems, allowing for more substantial electric assistance and energy recuperation. This transition has necessitated changes in battery composition and design, influencing recycling practices.

With the proliferation of mild hybrid vehicles, the automotive industry has seen a diversification in battery chemistries. While lead-acid batteries remain common in 12V systems, lithium-ion batteries have become increasingly prevalent in 48V configurations. This shift has implications for recycling processes, as different battery chemistries require distinct handling and recycling methods.

The integration of electric components in mild hybrid systems has also led to the development of more complex battery management systems (BMS). These sophisticated BMS units are designed to optimize battery performance and longevity, potentially extending the lifespan of batteries in mild hybrid vehicles. This increased durability may impact the frequency and volume of batteries entering the recycling stream.

As mild hybrid technology has evolved, so too have the strategies for battery recycling. The industry has had to adapt to handle the increased variety of battery types and chemistries found in mild hybrid vehicles. This has led to the development of more advanced sorting and processing techniques to efficiently recycle the diverse range of materials present in these batteries.

The evolution of mild hybrid systems has also influenced the design of vehicles for end-of-life considerations. Manufacturers have increasingly focused on designing battery systems that are more easily removable and recyclable, facilitating more efficient recycling processes. This trend towards design for recyclability is likely to continue as mild hybrid technology becomes more widespread.

Mild hybrid systems, first introduced in the late 1990s, have undergone substantial refinements over the past two decades. Initially, these systems were primarily focused on improving fuel efficiency through start-stop functionality and regenerative braking. As the technology matured, manufacturers began incorporating more advanced features, such as electric torque assistance and energy recovery during deceleration.

The evolution of mild hybrid systems has been characterized by a gradual increase in battery capacity and voltage. Early systems typically utilized 12V batteries, which limited their electric capabilities. However, the industry has since shifted towards 48V systems, allowing for more substantial electric assistance and energy recuperation. This transition has necessitated changes in battery composition and design, influencing recycling practices.

With the proliferation of mild hybrid vehicles, the automotive industry has seen a diversification in battery chemistries. While lead-acid batteries remain common in 12V systems, lithium-ion batteries have become increasingly prevalent in 48V configurations. This shift has implications for recycling processes, as different battery chemistries require distinct handling and recycling methods.

The integration of electric components in mild hybrid systems has also led to the development of more complex battery management systems (BMS). These sophisticated BMS units are designed to optimize battery performance and longevity, potentially extending the lifespan of batteries in mild hybrid vehicles. This increased durability may impact the frequency and volume of batteries entering the recycling stream.

As mild hybrid technology has evolved, so too have the strategies for battery recycling. The industry has had to adapt to handle the increased variety of battery types and chemistries found in mild hybrid vehicles. This has led to the development of more advanced sorting and processing techniques to efficiently recycle the diverse range of materials present in these batteries.

The evolution of mild hybrid systems has also influenced the design of vehicles for end-of-life considerations. Manufacturers have increasingly focused on designing battery systems that are more easily removable and recyclable, facilitating more efficient recycling processes. This trend towards design for recyclability is likely to continue as mild hybrid technology becomes more widespread.

Market Demand Analysis

The market demand for mild hybrid vehicles has been steadily increasing in recent years, driven by growing environmental concerns and stricter emissions regulations worldwide. This trend has significant implications for battery recycling practices, as mild hybrid systems utilize smaller battery packs compared to full hybrid or electric vehicles.

The global mild hybrid market is experiencing rapid growth, with a projected compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This expansion is primarily fueled by automotive manufacturers' efforts to meet increasingly stringent fuel efficiency and emissions standards while offering improved performance and cost-effectiveness to consumers.

As mild hybrid technology becomes more prevalent, the demand for batteries in this segment is expected to rise substantially. However, the impact on battery recycling practices differs from that of full electric vehicles due to the unique characteristics of mild hybrid systems. These systems typically employ smaller, less energy-dense batteries, often using lead-acid or lithium-ion chemistries.

The increased adoption of mild hybrids is creating new challenges and opportunities in the battery recycling industry. On one hand, the smaller battery sizes may lead to a higher volume of batteries entering the recycling stream, potentially straining existing recycling infrastructure. On the other hand, the less complex nature of mild hybrid batteries compared to those in full electric vehicles may simplify some aspects of the recycling process.

Market analysis indicates that the growth of mild hybrids is likely to drive innovation in battery recycling technologies specifically tailored to these systems. This includes the development of more efficient recycling processes for smaller battery packs and the exploration of new recycling methods for the diverse range of battery chemistries used in mild hybrid vehicles.

The increasing market penetration of mild hybrids is also expected to influence the overall battery supply chain. As demand for these vehicles grows, there will be a corresponding increase in the need for recycled battery materials to support sustainable production practices. This trend aligns with the circular economy principles being adopted by many automotive manufacturers and battery producers.

Furthermore, the market demand for mild hybrids is likely to impact regulatory frameworks surrounding battery recycling. Policymakers and industry stakeholders are expected to develop new guidelines and standards specifically addressing the unique recycling requirements of mild hybrid batteries, potentially leading to more specialized recycling facilities and processes.

In conclusion, the growing market demand for mild hybrid vehicles is set to significantly influence battery recycling practices. This influence will manifest in various ways, from driving technological innovations in recycling processes to shaping regulatory landscapes and supply chain dynamics in the automotive and battery industries.

The global mild hybrid market is experiencing rapid growth, with a projected compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This expansion is primarily fueled by automotive manufacturers' efforts to meet increasingly stringent fuel efficiency and emissions standards while offering improved performance and cost-effectiveness to consumers.

As mild hybrid technology becomes more prevalent, the demand for batteries in this segment is expected to rise substantially. However, the impact on battery recycling practices differs from that of full electric vehicles due to the unique characteristics of mild hybrid systems. These systems typically employ smaller, less energy-dense batteries, often using lead-acid or lithium-ion chemistries.

The increased adoption of mild hybrids is creating new challenges and opportunities in the battery recycling industry. On one hand, the smaller battery sizes may lead to a higher volume of batteries entering the recycling stream, potentially straining existing recycling infrastructure. On the other hand, the less complex nature of mild hybrid batteries compared to those in full electric vehicles may simplify some aspects of the recycling process.

Market analysis indicates that the growth of mild hybrids is likely to drive innovation in battery recycling technologies specifically tailored to these systems. This includes the development of more efficient recycling processes for smaller battery packs and the exploration of new recycling methods for the diverse range of battery chemistries used in mild hybrid vehicles.

The increasing market penetration of mild hybrids is also expected to influence the overall battery supply chain. As demand for these vehicles grows, there will be a corresponding increase in the need for recycled battery materials to support sustainable production practices. This trend aligns with the circular economy principles being adopted by many automotive manufacturers and battery producers.

Furthermore, the market demand for mild hybrids is likely to impact regulatory frameworks surrounding battery recycling. Policymakers and industry stakeholders are expected to develop new guidelines and standards specifically addressing the unique recycling requirements of mild hybrid batteries, potentially leading to more specialized recycling facilities and processes.

In conclusion, the growing market demand for mild hybrid vehicles is set to significantly influence battery recycling practices. This influence will manifest in various ways, from driving technological innovations in recycling processes to shaping regulatory landscapes and supply chain dynamics in the automotive and battery industries.

Technical Challenges

The integration of mild hybrid technology into vehicles presents several technical challenges for battery recycling practices. One of the primary issues is the diversity of battery chemistries and configurations used in mild hybrid systems. Unlike full electric vehicles, which typically use lithium-ion batteries, mild hybrids may employ a variety of battery types, including lead-acid, nickel-metal hydride, and lithium-ion. This heterogeneity complicates the recycling process, as each battery type requires different handling and recycling techniques.

Another significant challenge is the smaller size and lower capacity of mild hybrid batteries compared to those in full electric vehicles. These smaller batteries often contain less valuable materials, potentially making the recycling process less economically viable. The lower material content may not justify the energy and resources required for recycling, leading to potential environmental trade-offs.

The integration of mild hybrid batteries into the vehicle's structure also poses technical difficulties for recycling. These batteries are often more tightly integrated with other vehicle components, making their removal and isolation more complex and time-consuming. This integration can increase the risk of damage during the disassembly process, potentially reducing the recyclable content of the battery.

Furthermore, the rapid evolution of mild hybrid technology presents a moving target for recycling practices. As manufacturers continually improve battery designs and chemistries to enhance performance and reduce costs, recycling facilities must adapt their processes to handle these evolving technologies. This constant change can lead to inefficiencies in the recycling process and may require frequent updates to recycling equipment and methodologies.

The presence of hybrid-specific components, such as power electronics and control units, adds another layer of complexity to the recycling process. These components often contain valuable materials but are challenging to separate and process efficiently. The intricate nature of these systems requires specialized knowledge and equipment for proper recycling, which may not be widely available in current recycling facilities.

Additionally, the relatively low market penetration of mild hybrids compared to conventional vehicles means that the volume of batteries available for recycling is still limited. This low volume can make it difficult to establish efficient, large-scale recycling operations specifically tailored to mild hybrid batteries. The lack of economies of scale may result in higher recycling costs per unit, further challenging the economic viability of the recycling process.

Lastly, the lack of standardization in mild hybrid battery designs across different manufacturers complicates the development of universal recycling processes. Each manufacturer may use proprietary designs and materials, requiring recyclers to develop multiple processes to handle various battery types effectively. This diversity increases the complexity and cost of recycling operations, potentially limiting the number of facilities capable of processing mild hybrid batteries efficiently.

Another significant challenge is the smaller size and lower capacity of mild hybrid batteries compared to those in full electric vehicles. These smaller batteries often contain less valuable materials, potentially making the recycling process less economically viable. The lower material content may not justify the energy and resources required for recycling, leading to potential environmental trade-offs.

The integration of mild hybrid batteries into the vehicle's structure also poses technical difficulties for recycling. These batteries are often more tightly integrated with other vehicle components, making their removal and isolation more complex and time-consuming. This integration can increase the risk of damage during the disassembly process, potentially reducing the recyclable content of the battery.

Furthermore, the rapid evolution of mild hybrid technology presents a moving target for recycling practices. As manufacturers continually improve battery designs and chemistries to enhance performance and reduce costs, recycling facilities must adapt their processes to handle these evolving technologies. This constant change can lead to inefficiencies in the recycling process and may require frequent updates to recycling equipment and methodologies.

The presence of hybrid-specific components, such as power electronics and control units, adds another layer of complexity to the recycling process. These components often contain valuable materials but are challenging to separate and process efficiently. The intricate nature of these systems requires specialized knowledge and equipment for proper recycling, which may not be widely available in current recycling facilities.

Additionally, the relatively low market penetration of mild hybrids compared to conventional vehicles means that the volume of batteries available for recycling is still limited. This low volume can make it difficult to establish efficient, large-scale recycling operations specifically tailored to mild hybrid batteries. The lack of economies of scale may result in higher recycling costs per unit, further challenging the economic viability of the recycling process.

Lastly, the lack of standardization in mild hybrid battery designs across different manufacturers complicates the development of universal recycling processes. Each manufacturer may use proprietary designs and materials, requiring recyclers to develop multiple processes to handle various battery types effectively. This diversity increases the complexity and cost of recycling operations, potentially limiting the number of facilities capable of processing mild hybrid batteries efficiently.

Current Recycling Methods

01 Battery recycling processes for mild hybrid vehicles

Specialized recycling processes have been developed for mild hybrid vehicle batteries. These processes involve disassembling the battery packs, separating different components, and recovering valuable materials such as lithium, cobalt, and nickel. The recycling methods aim to maximize material recovery while minimizing environmental impact.- Battery recycling processes for mild hybrid vehicles: Specialized recycling processes have been developed for mild hybrid vehicle batteries. These processes involve disassembling the battery packs, separating different components, and recovering valuable materials such as lithium, cobalt, and nickel. The recycling methods aim to maximize material recovery while minimizing environmental impact.

- Integration of battery recycling with vehicle maintenance: Some approaches integrate battery recycling practices with regular vehicle maintenance procedures. This involves collecting and processing used batteries during routine service visits, ensuring a steady stream of recyclable materials and improving overall recycling efficiency for mild hybrid batteries.

- Advanced sorting and material recovery techniques: Innovative sorting and material recovery techniques have been developed specifically for mild hybrid batteries. These methods use advanced technologies such as automated sorting systems, chemical separation processes, and thermal treatment to efficiently extract and purify valuable materials from the batteries.

- Eco-friendly battery disposal and recycling methods: Environmentally friendly disposal and recycling methods have been created for mild hybrid batteries. These approaches focus on reducing the carbon footprint of the recycling process, minimizing waste, and ensuring safe handling of potentially hazardous materials throughout the recycling lifecycle.

- Collaboration between automakers and recycling facilities: Partnerships between automotive manufacturers and specialized recycling facilities have been established to improve the efficiency and effectiveness of mild hybrid battery recycling. These collaborations involve shared research and development efforts, standardized recycling protocols, and streamlined logistics for collecting and processing used batteries.

02 Integration of battery recycling with vehicle systems

Some mild hybrid systems incorporate built-in features to facilitate easier battery recycling at the end of the vehicle's life. These may include modular battery designs, easily removable components, or integrated recycling information systems that provide dismantling instructions to recyclers.Expand Specific Solutions03 Second-life applications for mild hybrid batteries

Before full recycling, mild hybrid batteries that no longer meet automotive standards may be repurposed for second-life applications. These can include use in stationary energy storage systems, backup power supplies, or less demanding vehicular applications, extending the useful life of the batteries and reducing waste.Expand Specific Solutions04 Automated battery sorting and recycling systems

Advanced automated systems have been developed to efficiently sort and process mild hybrid batteries for recycling. These systems use robotics, artificial intelligence, and machine vision to identify different battery types, separate components, and optimize the recycling process, improving efficiency and reducing human exposure to potentially hazardous materials.Expand Specific Solutions05 Eco-friendly recycling methods for mild hybrid batteries

Innovative, environmentally friendly recycling methods have been developed specifically for mild hybrid batteries. These may include hydrometallurgical processes, bioleaching techniques, or other novel approaches that aim to reduce energy consumption, minimize chemical use, and lower the overall environmental footprint of the recycling process.Expand Specific Solutions

Key Industry Players

The mild hybrid technology's impact on battery recycling practices is evolving within a competitive landscape characterized by various stages of industry development. The market for mild hybrid systems is expanding, driven by increasing demand for fuel-efficient vehicles and stricter emissions regulations. However, the technology's maturity varies across different companies. Established automotive manufacturers like Audi AG, Honda Motor Co., and Cummins, Inc. are at the forefront, integrating mild hybrid systems into their product lines. Emerging players such as Astemo Ltd. and HL Mando Co., Ltd. are also making strides in this field. The battery recycling sector is adapting to the unique challenges posed by mild hybrid batteries, with companies like Guangdong Bangpu Recycling Technology Co., Ltd. and Ascend Elements, Inc. developing specialized recycling processes to handle these components efficiently.

Cummins, Inc.

Technical Solution: Cummins has developed a mild hybrid system for commercial vehicles that utilizes a 48V battery pack. This system incorporates regenerative braking to capture energy during deceleration, which is then stored in the battery for later use. The mild hybrid technology allows for engine stop-start functionality, reducing idle time and fuel consumption. Cummins' approach focuses on integrating the mild hybrid system with their existing engine platforms, ensuring compatibility with current vehicle designs[1]. The company has also implemented a battery management system that optimizes the charge-discharge cycles, potentially extending the battery life and improving recycling efficiency[2].

Strengths: Seamless integration with existing engines, improved fuel efficiency, and potential for extended battery life. Weaknesses: Limited electric-only operation compared to full hybrids, and potential complexity in recycling due to integration with conventional engine components.

AUDI AG

Technical Solution: Audi has implemented mild hybrid technology across various models, utilizing a 48V electrical system. Their system includes a belt alternator starter (BAS) that enables energy recovery during braking and coasting. The recovered energy is stored in a compact lithium-ion battery. Audi's mild hybrid system allows for extended start-stop functionality, including coasting with the engine off at speeds up to 160 km/h[3]. In terms of battery recycling, Audi has partnered with recycling specialists to develop a closed-loop system for high-voltage batteries. While this primarily focuses on full hybrid and electric vehicle batteries, the principles and infrastructure developed could be applied to mild hybrid batteries as well[4].

Strengths: Advanced energy recovery system, extended engine-off coasting, and established recycling partnerships. Weaknesses: Potential for increased complexity in vehicle design and higher initial cost compared to conventional powertrains.

Innovative Recycling Tech

Hybrid battery system for electric and hybrid electric vehicles

PatentInactiveUS20130244061A1

Innovation

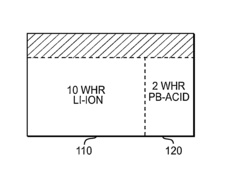

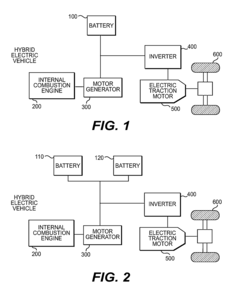

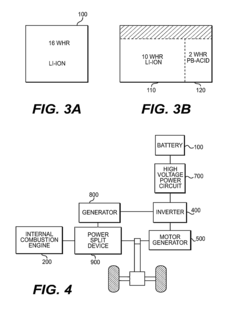

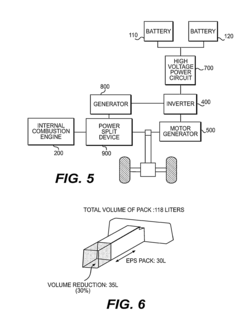

- A hybrid-battery system combining lead-acid batteries for high power and another electrochemistry, such as Li-ion or Ni-MH, to optimize energy and power requirements, reducing overall size, weight, and cost, while maintaining reliability and safety.

Method for controlling an energy storage device of a mild hybrid motor vehicle and state-of-charge control device for a mild hybrid motor vehicle

PatentActiveEP3448713A1

Innovation

- The method involves dividing the actively usable range of the energy storage device into three ranges: one for energy recovery and two for energy consumption, with dynamically determined upper and lower threshold values based on monitored and simulated charging and discharging processes to optimize the target state of charge range, ensuring efficient energy use and adaptation to specific vehicle parameters.

Environmental Regulations

Environmental regulations play a crucial role in shaping the landscape of battery recycling practices for mild hybrid vehicles. As these vehicles gain popularity, governments worldwide are implementing stricter guidelines to ensure sustainable end-of-life management of their battery systems. The European Union, for instance, has introduced the Battery Directive, which mandates specific recycling targets for automotive batteries, including those used in mild hybrids.

These regulations often require manufacturers to establish take-back programs for used batteries, ensuring a high percentage of materials are recovered and recycled. In the United States, individual states have enacted their own battery recycling laws, with California leading the way through its Advanced Clean Cars Program, which includes provisions for battery recycling and disposal.

The impact of these regulations on mild hybrid battery recycling is multifaceted. Firstly, they drive innovation in recycling technologies, as companies strive to meet increasingly stringent recovery rates for materials such as lithium, cobalt, and nickel. This has led to the development of more efficient recycling processes, including hydrometallurgical and pyrometallurgical methods tailored for mild hybrid batteries.

Furthermore, environmental regulations have spurred the growth of specialized recycling facilities equipped to handle the unique challenges posed by mild hybrid batteries. These facilities must comply with strict environmental and safety standards, often requiring significant investments in infrastructure and training.

The regulatory landscape also influences the design of mild hybrid batteries themselves. Manufacturers are increasingly adopting design-for-recycling principles, making batteries easier to disassemble and recycle at the end of their life cycle. This trend is partly driven by extended producer responsibility policies, which hold manufacturers accountable for the entire lifecycle of their products.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, further complicate the global landscape of mild hybrid battery recycling. These agreements regulate the international transport of used batteries, impacting the development of global recycling networks and supply chains.

As mild hybrid technology continues to evolve, environmental regulations are likely to adapt accordingly. Future regulations may focus on increasing the recyclability of specific battery components, promoting the use of recycled materials in new battery production, or incentivizing the development of more environmentally friendly battery chemistries. The interplay between these regulations and technological advancements will continue to shape the future of mild hybrid battery recycling practices.

These regulations often require manufacturers to establish take-back programs for used batteries, ensuring a high percentage of materials are recovered and recycled. In the United States, individual states have enacted their own battery recycling laws, with California leading the way through its Advanced Clean Cars Program, which includes provisions for battery recycling and disposal.

The impact of these regulations on mild hybrid battery recycling is multifaceted. Firstly, they drive innovation in recycling technologies, as companies strive to meet increasingly stringent recovery rates for materials such as lithium, cobalt, and nickel. This has led to the development of more efficient recycling processes, including hydrometallurgical and pyrometallurgical methods tailored for mild hybrid batteries.

Furthermore, environmental regulations have spurred the growth of specialized recycling facilities equipped to handle the unique challenges posed by mild hybrid batteries. These facilities must comply with strict environmental and safety standards, often requiring significant investments in infrastructure and training.

The regulatory landscape also influences the design of mild hybrid batteries themselves. Manufacturers are increasingly adopting design-for-recycling principles, making batteries easier to disassemble and recycle at the end of their life cycle. This trend is partly driven by extended producer responsibility policies, which hold manufacturers accountable for the entire lifecycle of their products.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, further complicate the global landscape of mild hybrid battery recycling. These agreements regulate the international transport of used batteries, impacting the development of global recycling networks and supply chains.

As mild hybrid technology continues to evolve, environmental regulations are likely to adapt accordingly. Future regulations may focus on increasing the recyclability of specific battery components, promoting the use of recycled materials in new battery production, or incentivizing the development of more environmentally friendly battery chemistries. The interplay between these regulations and technological advancements will continue to shape the future of mild hybrid battery recycling practices.

Economic Feasibility

The economic feasibility of mild hybrid battery recycling practices is influenced by several factors that impact the overall cost-effectiveness and sustainability of the process. As mild hybrid vehicles become more prevalent in the automotive market, the volume of batteries requiring recycling is expected to increase, potentially creating economies of scale for recycling operations.

One of the primary economic considerations is the composition of mild hybrid batteries, which typically contain less valuable materials compared to full hybrid or electric vehicle batteries. This lower material value may initially reduce the economic incentive for recycling. However, as recycling technologies advance and become more efficient, the cost of processing these batteries is likely to decrease, improving the economic viability of recycling practices.

The integration of mild hybrid systems into conventional vehicles also presents unique challenges and opportunities for recycling. The smaller battery size and lower voltage of mild hybrid systems may require less complex recycling processes, potentially reducing the overall cost of recycling operations. This could lead to a more favorable economic outlook for recycling facilities specializing in mild hybrid batteries.

Furthermore, the increased adoption of mild hybrid technology across various vehicle models and manufacturers may lead to standardization of battery designs and chemistries. Such standardization could streamline recycling processes, reducing costs and improving the economic feasibility of large-scale recycling operations.

The economic viability of mild hybrid battery recycling is also influenced by regulatory frameworks and government incentives. As environmental regulations become more stringent, automotive manufacturers may face increased pressure to implement comprehensive recycling programs for all types of hybrid batteries, including those from mild hybrid systems. This regulatory push could create new market opportunities and drive investment in recycling infrastructure, potentially improving the economic landscape for mild hybrid battery recycling.

Additionally, the potential for second-life applications of mild hybrid batteries could significantly impact the economic feasibility of recycling practices. While these batteries may have reduced capacity for automotive use, they could still be repurposed for stationary energy storage applications, creating additional value streams and extending the economic lifecycle of the batteries before final recycling.

In conclusion, the economic feasibility of mild hybrid battery recycling practices is a complex interplay of factors including material value, processing costs, technological advancements, regulatory pressures, and potential second-life applications. As the mild hybrid market matures and recycling technologies evolve, the economic landscape for battery recycling is likely to become increasingly favorable, driving sustainable practices in the automotive industry.

One of the primary economic considerations is the composition of mild hybrid batteries, which typically contain less valuable materials compared to full hybrid or electric vehicle batteries. This lower material value may initially reduce the economic incentive for recycling. However, as recycling technologies advance and become more efficient, the cost of processing these batteries is likely to decrease, improving the economic viability of recycling practices.

The integration of mild hybrid systems into conventional vehicles also presents unique challenges and opportunities for recycling. The smaller battery size and lower voltage of mild hybrid systems may require less complex recycling processes, potentially reducing the overall cost of recycling operations. This could lead to a more favorable economic outlook for recycling facilities specializing in mild hybrid batteries.

Furthermore, the increased adoption of mild hybrid technology across various vehicle models and manufacturers may lead to standardization of battery designs and chemistries. Such standardization could streamline recycling processes, reducing costs and improving the economic feasibility of large-scale recycling operations.

The economic viability of mild hybrid battery recycling is also influenced by regulatory frameworks and government incentives. As environmental regulations become more stringent, automotive manufacturers may face increased pressure to implement comprehensive recycling programs for all types of hybrid batteries, including those from mild hybrid systems. This regulatory push could create new market opportunities and drive investment in recycling infrastructure, potentially improving the economic landscape for mild hybrid battery recycling.

Additionally, the potential for second-life applications of mild hybrid batteries could significantly impact the economic feasibility of recycling practices. While these batteries may have reduced capacity for automotive use, they could still be repurposed for stationary energy storage applications, creating additional value streams and extending the economic lifecycle of the batteries before final recycling.

In conclusion, the economic feasibility of mild hybrid battery recycling practices is a complex interplay of factors including material value, processing costs, technological advancements, regulatory pressures, and potential second-life applications. As the mild hybrid market matures and recycling technologies evolve, the economic landscape for battery recycling is likely to become increasingly favorable, driving sustainable practices in the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!