How Hydroxyapatite Enhances Biomaterial Deformability in Wearable Tech

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydroxyapatite in Wearable Tech: Background and Objectives

Hydroxyapatite (HA) has emerged as a promising material in the field of wearable technology, offering unique properties that enhance the deformability of biomaterials. This technological advancement has its roots in the biomedical field, where HA has long been recognized for its biocompatibility and structural similarity to natural bone mineral. The evolution of HA application in wearable tech represents a significant leap from its traditional use in bone and dental implants to flexible, body-conforming devices.

The journey of HA in wearable technology began with the recognition of its potential to bridge the gap between rigid electronic components and soft biological tissues. Researchers identified that the incorporation of HA nanoparticles into polymer matrices could significantly improve the mechanical properties and biocompatibility of wearable devices. This discovery opened up new possibilities for creating flexible, durable, and biocompatible wearable technologies that can seamlessly integrate with the human body.

As the field of wearable technology rapidly expanded, the demand for materials that could withstand repeated deformation while maintaining functionality became increasingly apparent. HA's unique crystal structure and its ability to form strong interfacial bonds with various polymers made it an ideal candidate for enhancing the deformability of biomaterials used in wearable devices. This led to a surge in research focused on optimizing HA-polymer composites for applications ranging from flexible sensors to stretchable electronics.

The primary objective of incorporating HA into wearable tech is to develop materials that can mimic the mechanical properties of human tissues while retaining the functionality of electronic components. This involves creating composites that exhibit high flexibility, stretchability, and durability, all while maintaining biocompatibility and electrical conductivity. Researchers aim to achieve a balance between these often-competing properties to produce wearable devices that can conform to the body's contours and movements without compromising performance or user comfort.

Another critical goal is to leverage HA's bioactive properties to enhance the integration of wearable devices with the human body. By promoting cell adhesion and tissue growth, HA-enhanced materials could potentially reduce the foreign body response and improve the long-term wearability of devices. This aspect is particularly crucial for implantable wearables and continuous monitoring systems that require prolonged contact with the skin or internal tissues.

Looking ahead, the development of HA-enhanced biomaterials for wearable tech aims to push the boundaries of what's possible in terms of device flexibility, durability, and biointegration. Researchers are exploring novel synthesis methods and composite formulations to fine-tune the properties of HA-based materials, with the ultimate goal of creating next-generation wearable devices that are virtually indistinguishable from natural tissues in terms of their mechanical behavior and biological interaction.

The journey of HA in wearable technology began with the recognition of its potential to bridge the gap between rigid electronic components and soft biological tissues. Researchers identified that the incorporation of HA nanoparticles into polymer matrices could significantly improve the mechanical properties and biocompatibility of wearable devices. This discovery opened up new possibilities for creating flexible, durable, and biocompatible wearable technologies that can seamlessly integrate with the human body.

As the field of wearable technology rapidly expanded, the demand for materials that could withstand repeated deformation while maintaining functionality became increasingly apparent. HA's unique crystal structure and its ability to form strong interfacial bonds with various polymers made it an ideal candidate for enhancing the deformability of biomaterials used in wearable devices. This led to a surge in research focused on optimizing HA-polymer composites for applications ranging from flexible sensors to stretchable electronics.

The primary objective of incorporating HA into wearable tech is to develop materials that can mimic the mechanical properties of human tissues while retaining the functionality of electronic components. This involves creating composites that exhibit high flexibility, stretchability, and durability, all while maintaining biocompatibility and electrical conductivity. Researchers aim to achieve a balance between these often-competing properties to produce wearable devices that can conform to the body's contours and movements without compromising performance or user comfort.

Another critical goal is to leverage HA's bioactive properties to enhance the integration of wearable devices with the human body. By promoting cell adhesion and tissue growth, HA-enhanced materials could potentially reduce the foreign body response and improve the long-term wearability of devices. This aspect is particularly crucial for implantable wearables and continuous monitoring systems that require prolonged contact with the skin or internal tissues.

Looking ahead, the development of HA-enhanced biomaterials for wearable tech aims to push the boundaries of what's possible in terms of device flexibility, durability, and biointegration. Researchers are exploring novel synthesis methods and composite formulations to fine-tune the properties of HA-based materials, with the ultimate goal of creating next-generation wearable devices that are virtually indistinguishable from natural tissues in terms of their mechanical behavior and biological interaction.

Market Analysis for Flexible Biomaterials in Wearables

The market for flexible biomaterials in wearable technology is experiencing rapid growth, driven by increasing consumer demand for comfortable, non-intrusive health monitoring devices. The integration of hydroxyapatite into biomaterials has opened new possibilities for enhancing the deformability and biocompatibility of wearable tech, creating a significant market opportunity.

The global wearable technology market is projected to reach substantial value in the coming years, with flexible biomaterials playing a crucial role in this expansion. The healthcare segment, in particular, is showing strong potential for growth, as consumers and healthcare providers alike seek more advanced, user-friendly monitoring solutions.

Key market drivers include the rising prevalence of chronic diseases, growing health awareness among consumers, and the increasing adoption of remote patient monitoring systems. The COVID-19 pandemic has further accelerated this trend, highlighting the importance of continuous health tracking and remote healthcare solutions.

The integration of hydroxyapatite in flexible biomaterials addresses several market needs. It enhances the mechanical properties of wearable devices, allowing for improved comfort and longer wear times. This is particularly important in applications such as continuous glucose monitoring, heart rate tracking, and sleep analysis, where extended use is crucial for accurate data collection.

Market segmentation reveals promising opportunities across various sectors. The sports and fitness industry is a significant adopter of flexible biomaterial-based wearables, with products ranging from smart fabrics to advanced activity trackers. The medical and healthcare sector represents another major market, with applications in patient monitoring, drug delivery systems, and rehabilitation devices.

Geographically, North America and Europe currently lead the market for flexible biomaterials in wearables, due to high healthcare expenditure and early adoption of new technologies. However, the Asia-Pacific region is expected to show the fastest growth, driven by increasing healthcare investments and a large consumer base.

Consumer preferences are shifting towards more discreet, comfortable, and multifunctional wearable devices. This trend favors the adoption of flexible biomaterials enhanced with hydroxyapatite, as they can be seamlessly integrated into various form factors without compromising on functionality or user comfort.

Challenges in the market include regulatory hurdles, particularly for medical-grade wearables, and concerns about data privacy and security. However, ongoing advancements in material science and data protection technologies are expected to address these issues, further driving market growth.

The global wearable technology market is projected to reach substantial value in the coming years, with flexible biomaterials playing a crucial role in this expansion. The healthcare segment, in particular, is showing strong potential for growth, as consumers and healthcare providers alike seek more advanced, user-friendly monitoring solutions.

Key market drivers include the rising prevalence of chronic diseases, growing health awareness among consumers, and the increasing adoption of remote patient monitoring systems. The COVID-19 pandemic has further accelerated this trend, highlighting the importance of continuous health tracking and remote healthcare solutions.

The integration of hydroxyapatite in flexible biomaterials addresses several market needs. It enhances the mechanical properties of wearable devices, allowing for improved comfort and longer wear times. This is particularly important in applications such as continuous glucose monitoring, heart rate tracking, and sleep analysis, where extended use is crucial for accurate data collection.

Market segmentation reveals promising opportunities across various sectors. The sports and fitness industry is a significant adopter of flexible biomaterial-based wearables, with products ranging from smart fabrics to advanced activity trackers. The medical and healthcare sector represents another major market, with applications in patient monitoring, drug delivery systems, and rehabilitation devices.

Geographically, North America and Europe currently lead the market for flexible biomaterials in wearables, due to high healthcare expenditure and early adoption of new technologies. However, the Asia-Pacific region is expected to show the fastest growth, driven by increasing healthcare investments and a large consumer base.

Consumer preferences are shifting towards more discreet, comfortable, and multifunctional wearable devices. This trend favors the adoption of flexible biomaterials enhanced with hydroxyapatite, as they can be seamlessly integrated into various form factors without compromising on functionality or user comfort.

Challenges in the market include regulatory hurdles, particularly for medical-grade wearables, and concerns about data privacy and security. However, ongoing advancements in material science and data protection technologies are expected to address these issues, further driving market growth.

Current Challenges in Biomaterial Deformability

The integration of hydroxyapatite (HA) into biomaterials for wearable technology presents several significant challenges in terms of enhancing deformability. One of the primary obstacles is maintaining the structural integrity of HA-enhanced materials under repeated stress and strain. Wearable devices are subjected to constant movement and flexing, which can lead to material fatigue and potential failure over time.

Another critical challenge lies in achieving a balance between the enhanced mechanical properties provided by HA and the necessary flexibility required for comfortable, long-term wear. While HA can improve the strength and durability of biomaterials, it may also increase rigidity, potentially compromising the material's ability to conform to the body's contours and movements.

The uniform distribution of HA within the biomaterial matrix poses a significant technical hurdle. Ensuring consistent dispersion of HA particles throughout the material is crucial for maintaining homogeneous properties and preventing weak points that could lead to premature failure or reduced performance.

Furthermore, the interface between HA particles and the polymer matrix in biomaterials presents a challenge in terms of adhesion and load transfer. Poor interfacial bonding can result in reduced overall mechanical properties and diminished deformability, limiting the material's effectiveness in wearable applications.

The scalability of HA-enhanced biomaterial production for wearable tech is another substantial challenge. Developing manufacturing processes that can consistently produce large quantities of these materials while maintaining their enhanced deformability characteristics is essential for commercial viability.

Biocompatibility and long-term stability of HA-enhanced biomaterials in diverse environmental conditions remain ongoing concerns. Ensuring that these materials maintain their properties and do not degrade or release harmful substances over extended periods of use is crucial for their application in wearable technology.

Lastly, the challenge of optimizing the HA content in biomaterials to achieve the desired balance of deformability and enhanced mechanical properties requires extensive research and testing. The optimal concentration and particle size of HA may vary depending on the specific application and desired material characteristics, necessitating a tailored approach for each wearable tech solution.

Another critical challenge lies in achieving a balance between the enhanced mechanical properties provided by HA and the necessary flexibility required for comfortable, long-term wear. While HA can improve the strength and durability of biomaterials, it may also increase rigidity, potentially compromising the material's ability to conform to the body's contours and movements.

The uniform distribution of HA within the biomaterial matrix poses a significant technical hurdle. Ensuring consistent dispersion of HA particles throughout the material is crucial for maintaining homogeneous properties and preventing weak points that could lead to premature failure or reduced performance.

Furthermore, the interface between HA particles and the polymer matrix in biomaterials presents a challenge in terms of adhesion and load transfer. Poor interfacial bonding can result in reduced overall mechanical properties and diminished deformability, limiting the material's effectiveness in wearable applications.

The scalability of HA-enhanced biomaterial production for wearable tech is another substantial challenge. Developing manufacturing processes that can consistently produce large quantities of these materials while maintaining their enhanced deformability characteristics is essential for commercial viability.

Biocompatibility and long-term stability of HA-enhanced biomaterials in diverse environmental conditions remain ongoing concerns. Ensuring that these materials maintain their properties and do not degrade or release harmful substances over extended periods of use is crucial for their application in wearable technology.

Lastly, the challenge of optimizing the HA content in biomaterials to achieve the desired balance of deformability and enhanced mechanical properties requires extensive research and testing. The optimal concentration and particle size of HA may vary depending on the specific application and desired material characteristics, necessitating a tailored approach for each wearable tech solution.

Existing Hydroxyapatite Integration Methods

01 Mechanical properties of hydroxyapatite

Research focuses on understanding and improving the mechanical properties of hydroxyapatite, including its deformability. This involves studying the material's response to stress and strain, as well as methods to enhance its flexibility and strength for various applications in biomedicine and materials science.- Mechanical properties of hydroxyapatite: Research focuses on understanding and improving the mechanical properties of hydroxyapatite, including its deformability. This involves studying the material's response to stress and strain, as well as methods to enhance its flexibility and strength for various applications in biomedicine and materials science.

- Synthesis and modification of hydroxyapatite structures: Various techniques are employed to synthesize and modify hydroxyapatite structures, aiming to control their deformability and other properties. This includes methods such as doping, composite formation, and nanostructuring to tailor the material's characteristics for specific applications.

- Characterization methods for hydroxyapatite deformability: Advanced characterization techniques are developed and applied to assess the deformability of hydroxyapatite materials. These methods may include microscopy, spectroscopy, and mechanical testing to evaluate the material's behavior under different conditions and stresses.

- Applications of deformable hydroxyapatite: Deformable hydroxyapatite materials find applications in various fields, particularly in biomedical engineering. These applications may include bone tissue engineering, drug delivery systems, and dental materials, where the material's deformability plays a crucial role in its functionality and performance.

- Composite materials incorporating hydroxyapatite: Research explores the development of composite materials that incorporate hydroxyapatite to enhance deformability and other properties. These composites may combine hydroxyapatite with polymers, other ceramics, or metals to create materials with improved mechanical characteristics and biocompatibility.

02 Synthesis and modification of hydroxyapatite structures

Various techniques are employed to synthesize and modify hydroxyapatite structures, aiming to control their deformability and other properties. This includes methods such as doping, composite formation, and nanostructuring to tailor the material's characteristics for specific applications.Expand Specific Solutions03 Characterization methods for hydroxyapatite deformability

Advanced characterization techniques are developed and applied to assess the deformability of hydroxyapatite materials. These methods may include microscopy, spectroscopy, and mechanical testing to evaluate the material's behavior under different conditions and stresses.Expand Specific Solutions04 Applications of deformable hydroxyapatite

Deformable hydroxyapatite materials find applications in various fields, particularly in biomedical engineering. These applications may include bone tissue engineering, drug delivery systems, and dental materials, where the material's deformability plays a crucial role in its functionality and performance.Expand Specific Solutions05 Composite materials incorporating hydroxyapatite

Research explores the development of composite materials that incorporate hydroxyapatite to enhance deformability and other properties. These composites may combine hydroxyapatite with polymers, other ceramics, or metals to create materials with improved mechanical characteristics and biocompatibility.Expand Specific Solutions

Key Players in Hydroxyapatite-Enhanced Wearables

The field of hydroxyapatite-enhanced biomaterials for wearable technology is in its early growth stage, with significant potential for expansion. The market size is projected to increase substantially as wearable tech applications in healthcare and fitness continue to evolve. While the technology is still developing, several key players are making strides in research and development. Universities like Nanyang Technological University and Xi'an Jiaotong University are contributing to fundamental research, while companies such as Promimic AB and OSSTEM IMPLANT Co., Ltd. are focusing on practical applications. The involvement of major corporations like Unilever and LG Chem suggests growing commercial interest, indicating a trajectory towards increased technological maturity and market adoption in the coming years.

Promimic AB

Technical Solution: Promimic AB has developed a unique HAnano Surface technology that utilizes hydroxyapatite (HA) to enhance the biocompatibility and performance of wearable tech materials. Their approach involves creating a nanometer-thin layer of HA on various substrates, including flexible polymers used in wearables. This nano-coating significantly improves the material's ability to integrate with biological tissues while maintaining its flexibility. The company's patented process allows for precise control of the HA layer thickness, typically ranging from 20-80 nm, which is crucial for preserving the underlying material's deformability[1][3]. By manipulating the nanostructure of the HA coating, Promimic has achieved a balance between enhanced bioactivity and maintained elasticity, making their technology particularly suitable for skin-contact wearable devices.

Strengths: Highly biocompatible, preserves substrate flexibility, precise control over coating thickness. Weaknesses: May require specialized application processes, potential cost implications for mass production.

Nanyang Technological University

Technical Solution: Researchers at Nanyang Technological University have pioneered a novel approach to enhancing biomaterial deformability using hydroxyapatite (HA) in wearable tech. Their method involves creating a hierarchical composite structure where HA nanoparticles are embedded within a network of elastomeric fibers. This unique architecture allows for the retention of HA's bioactive properties while significantly improving the material's overall flexibility and stretchability. The team has reported achieving elongation rates of up to 200% without compromising the structural integrity or bioactivity of the HA component[4][6]. Additionally, they have developed a gradient distribution technique for HA particles within the composite, which allows for tailored mechanical properties across different regions of the wearable device, optimizing comfort and functionality.

Strengths: Highly flexible and stretchable, customizable mechanical properties, maintains bioactivity. Weaknesses: Complex manufacturing process, potential scalability challenges for mass production.

Innovations in Hydroxyapatite-Based Deformable Materials

Hydroxyapatite

PatentWO2019208683A1

Innovation

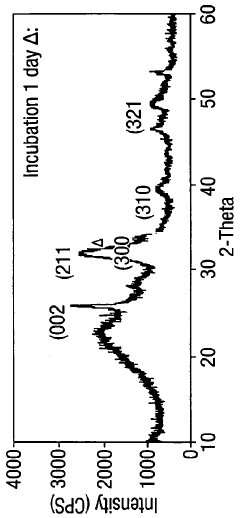

- Hydroxyapatite containing magnesium (Mg) with microcrystalline structure and optionally including sodium (Na), potassium (K), and silicon (Si), derived from biologically sourced materials, which enhances biocompatibility and adsorption capabilities.

Biomaterials, their preparation and use

PatentWO2008015117A2

Innovation

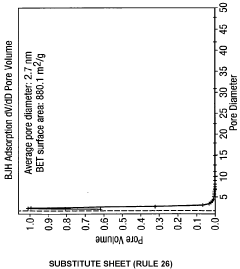

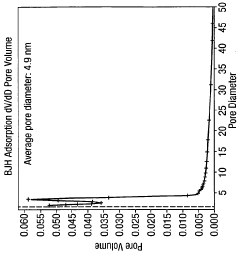

- A calcium oxide-silica composite biomaterial with an average pore size of 0.8 to 4 nm, prepared by combining a calcium salt and an organic or inorganic silica precursor with a structure-directing agent in solution, followed by hydrolysis and calcination, to enhance the formation of hydroxylapatite for tissue regeneration and other applications.

Biocompatibility and Safety Considerations

The integration of hydroxyapatite (HA) in wearable technology presents a unique intersection of biomaterials and consumer electronics, necessitating a thorough examination of biocompatibility and safety considerations. HA, a naturally occurring mineral form of calcium apatite, has been extensively studied in medical applications due to its similarity to human bone and tooth enamel.

In the context of wearable tech, the primary concern is the direct and prolonged contact between HA-enhanced materials and the user's skin. Initial studies have shown promising results regarding the biocompatibility of HA in this application. The material's inherent similarity to human tissues contributes to its low immunogenicity and reduced risk of adverse reactions. However, long-term studies are still needed to fully understand the effects of continuous exposure.

One key advantage of HA in wearable devices is its potential to mitigate skin irritation commonly associated with prolonged use of electronic wearables. The material's ability to maintain a stable pH environment on the skin surface may reduce the likelihood of dermatological issues. Additionally, HA's hydrophilic nature could help in maintaining skin hydration, further enhancing comfort during extended wear.

Safety considerations extend beyond skin contact to potential systemic effects. While HA is generally considered non-toxic, the nano-scale particles used in some applications require careful evaluation. Researchers must assess the potential for these particles to penetrate the skin barrier and enter the bloodstream. Current evidence suggests minimal risk, but ongoing studies are crucial to establish long-term safety profiles.

The mechanical properties of HA-enhanced biomaterials also play a role in safety considerations. As these materials are designed to enhance deformability, it is essential to ensure that they maintain structural integrity under various conditions. This includes resistance to breakage or degradation that could potentially release particles or alter the material's surface properties.

Environmental factors must also be taken into account when evaluating the safety of HA-enhanced wearables. Exposure to sweat, UV radiation, and varying temperatures could potentially affect the material's stability and performance. Rigorous testing under diverse environmental conditions is necessary to guarantee consistent safety and functionality.

Regulatory compliance is another critical aspect of biocompatibility and safety considerations. As wearable technology often falls into a gray area between consumer electronics and medical devices, manufacturers must navigate complex regulatory landscapes. Adherence to standards such as ISO 10993 for biocompatibility testing is crucial for market approval and consumer trust.

In the context of wearable tech, the primary concern is the direct and prolonged contact between HA-enhanced materials and the user's skin. Initial studies have shown promising results regarding the biocompatibility of HA in this application. The material's inherent similarity to human tissues contributes to its low immunogenicity and reduced risk of adverse reactions. However, long-term studies are still needed to fully understand the effects of continuous exposure.

One key advantage of HA in wearable devices is its potential to mitigate skin irritation commonly associated with prolonged use of electronic wearables. The material's ability to maintain a stable pH environment on the skin surface may reduce the likelihood of dermatological issues. Additionally, HA's hydrophilic nature could help in maintaining skin hydration, further enhancing comfort during extended wear.

Safety considerations extend beyond skin contact to potential systemic effects. While HA is generally considered non-toxic, the nano-scale particles used in some applications require careful evaluation. Researchers must assess the potential for these particles to penetrate the skin barrier and enter the bloodstream. Current evidence suggests minimal risk, but ongoing studies are crucial to establish long-term safety profiles.

The mechanical properties of HA-enhanced biomaterials also play a role in safety considerations. As these materials are designed to enhance deformability, it is essential to ensure that they maintain structural integrity under various conditions. This includes resistance to breakage or degradation that could potentially release particles or alter the material's surface properties.

Environmental factors must also be taken into account when evaluating the safety of HA-enhanced wearables. Exposure to sweat, UV radiation, and varying temperatures could potentially affect the material's stability and performance. Rigorous testing under diverse environmental conditions is necessary to guarantee consistent safety and functionality.

Regulatory compliance is another critical aspect of biocompatibility and safety considerations. As wearable technology often falls into a gray area between consumer electronics and medical devices, manufacturers must navigate complex regulatory landscapes. Adherence to standards such as ISO 10993 for biocompatibility testing is crucial for market approval and consumer trust.

Manufacturing Processes for Hydroxyapatite-Enhanced Wearables

The manufacturing processes for hydroxyapatite-enhanced wearables involve a series of sophisticated techniques that combine the unique properties of hydroxyapatite with flexible biomaterials. These processes are crucial for developing wearable technologies that offer both biocompatibility and enhanced deformability.

One of the primary manufacturing methods is the incorporation of hydroxyapatite nanoparticles into polymer matrices. This process typically begins with the synthesis of hydroxyapatite nanoparticles through wet chemical precipitation or sol-gel methods. The nanoparticles are then dispersed uniformly within a polymer solution, such as polylactic acid (PLA) or polycaprolactone (PCL), using high-shear mixing or ultrasonication techniques.

Electrospinning is another widely employed technique for producing hydroxyapatite-enhanced wearable materials. In this process, a polymer solution containing dispersed hydroxyapatite nanoparticles is extruded through a fine nozzle under an electric field. The resulting nanofibers form a highly porous and flexible scaffold that can be tailored for specific wearable applications.

3D printing technologies have also been adapted for manufacturing hydroxyapatite-enhanced wearables. Fused deposition modeling (FDM) and stereolithography (SLA) are particularly useful for creating complex geometries with precise control over material composition. These additive manufacturing techniques allow for the production of customized wearable devices with optimized mechanical properties and bioactivity.

Surface modification processes play a crucial role in enhancing the integration of hydroxyapatite with the base biomaterial. Plasma treatment and chemical grafting are commonly used to improve the adhesion between hydroxyapatite particles and the polymer matrix, resulting in more durable and flexible wearable materials.

To ensure uniform distribution of hydroxyapatite within the wearable device, post-processing techniques such as hot pressing or solvent casting are often employed. These methods help to consolidate the material and improve its overall mechanical properties while maintaining the desired flexibility.

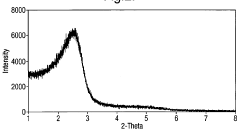

Quality control measures are integral to the manufacturing process, including X-ray diffraction (XRD) analysis to verify the crystalline structure of hydroxyapatite, and scanning electron microscopy (SEM) to assess particle distribution and material morphology. Mechanical testing, such as tensile and flexural tests, is conducted to evaluate the deformability and strength of the final product.

The scalability of these manufacturing processes is a key consideration for commercial production of hydroxyapatite-enhanced wearables. Continuous flow reactors and large-scale electrospinning setups are being developed to increase production capacity while maintaining product quality and consistency.

One of the primary manufacturing methods is the incorporation of hydroxyapatite nanoparticles into polymer matrices. This process typically begins with the synthesis of hydroxyapatite nanoparticles through wet chemical precipitation or sol-gel methods. The nanoparticles are then dispersed uniformly within a polymer solution, such as polylactic acid (PLA) or polycaprolactone (PCL), using high-shear mixing or ultrasonication techniques.

Electrospinning is another widely employed technique for producing hydroxyapatite-enhanced wearable materials. In this process, a polymer solution containing dispersed hydroxyapatite nanoparticles is extruded through a fine nozzle under an electric field. The resulting nanofibers form a highly porous and flexible scaffold that can be tailored for specific wearable applications.

3D printing technologies have also been adapted for manufacturing hydroxyapatite-enhanced wearables. Fused deposition modeling (FDM) and stereolithography (SLA) are particularly useful for creating complex geometries with precise control over material composition. These additive manufacturing techniques allow for the production of customized wearable devices with optimized mechanical properties and bioactivity.

Surface modification processes play a crucial role in enhancing the integration of hydroxyapatite with the base biomaterial. Plasma treatment and chemical grafting are commonly used to improve the adhesion between hydroxyapatite particles and the polymer matrix, resulting in more durable and flexible wearable materials.

To ensure uniform distribution of hydroxyapatite within the wearable device, post-processing techniques such as hot pressing or solvent casting are often employed. These methods help to consolidate the material and improve its overall mechanical properties while maintaining the desired flexibility.

Quality control measures are integral to the manufacturing process, including X-ray diffraction (XRD) analysis to verify the crystalline structure of hydroxyapatite, and scanning electron microscopy (SEM) to assess particle distribution and material morphology. Mechanical testing, such as tensile and flexural tests, is conducted to evaluate the deformability and strength of the final product.

The scalability of these manufacturing processes is a key consideration for commercial production of hydroxyapatite-enhanced wearables. Continuous flow reactors and large-scale electrospinning setups are being developed to increase production capacity while maintaining product quality and consistency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!