How Hydroxyapatite Enhances Mechanical Bonding in Advanced Anchoring Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydroxyapatite Anchoring Background and Objectives

Hydroxyapatite (HA) has emerged as a revolutionary material in advanced anchoring systems, offering enhanced mechanical bonding capabilities that have transformed various industries. The journey of HA in anchoring applications began in the biomedical field, where its biocompatibility and osteoconductive properties made it an ideal candidate for dental and orthopedic implants. Over time, researchers and engineers recognized the potential of HA beyond medical applications, leading to its exploration in diverse industrial sectors.

The evolution of HA-based anchoring systems has been driven by the increasing demand for stronger, more durable, and environmentally friendly bonding solutions. Traditional anchoring methods often face limitations in harsh environments or when subjected to extreme stress conditions. HA's unique crystal structure and chemical composition allow it to form strong chemical bonds with various substrates, addressing many of these challenges.

One of the primary objectives in developing HA-enhanced anchoring systems is to improve the long-term stability and load-bearing capacity of anchored structures. This is particularly crucial in applications such as offshore installations, bridge construction, and high-rise buildings, where failure can have catastrophic consequences. By incorporating HA into anchoring materials, engineers aim to create interfaces that not only resist mechanical stress but also adapt to environmental changes over time.

Another key goal is to develop anchoring systems that can perform effectively in diverse environments, including underwater settings, corrosive atmospheres, and high-temperature conditions. HA's stability across a wide range of pH levels and its resistance to degradation make it an excellent candidate for these challenging applications. Researchers are focusing on optimizing HA formulations and integration methods to maximize its performance in various industrial contexts.

Sustainability is also a driving force behind the development of HA-based anchoring technologies. As industries worldwide shift towards more environmentally responsible practices, there is a growing need for anchoring solutions that minimize ecological impact. HA, being a naturally occurring mineral, offers a more sustainable alternative to synthetic bonding agents. The objective is to create anchoring systems that not only provide superior mechanical properties but also contribute to reducing the carbon footprint of construction and manufacturing processes.

The ongoing research in HA-enhanced anchoring systems aims to unlock new possibilities in material science and engineering. By understanding the fundamental mechanisms of how HA enhances mechanical bonding, scientists hope to develop next-generation materials with unprecedented strength and durability. This knowledge could potentially lead to breakthroughs in fields ranging from aerospace engineering to nanotechnology, opening up new avenues for innovation and technological advancement.

The evolution of HA-based anchoring systems has been driven by the increasing demand for stronger, more durable, and environmentally friendly bonding solutions. Traditional anchoring methods often face limitations in harsh environments or when subjected to extreme stress conditions. HA's unique crystal structure and chemical composition allow it to form strong chemical bonds with various substrates, addressing many of these challenges.

One of the primary objectives in developing HA-enhanced anchoring systems is to improve the long-term stability and load-bearing capacity of anchored structures. This is particularly crucial in applications such as offshore installations, bridge construction, and high-rise buildings, where failure can have catastrophic consequences. By incorporating HA into anchoring materials, engineers aim to create interfaces that not only resist mechanical stress but also adapt to environmental changes over time.

Another key goal is to develop anchoring systems that can perform effectively in diverse environments, including underwater settings, corrosive atmospheres, and high-temperature conditions. HA's stability across a wide range of pH levels and its resistance to degradation make it an excellent candidate for these challenging applications. Researchers are focusing on optimizing HA formulations and integration methods to maximize its performance in various industrial contexts.

Sustainability is also a driving force behind the development of HA-based anchoring technologies. As industries worldwide shift towards more environmentally responsible practices, there is a growing need for anchoring solutions that minimize ecological impact. HA, being a naturally occurring mineral, offers a more sustainable alternative to synthetic bonding agents. The objective is to create anchoring systems that not only provide superior mechanical properties but also contribute to reducing the carbon footprint of construction and manufacturing processes.

The ongoing research in HA-enhanced anchoring systems aims to unlock new possibilities in material science and engineering. By understanding the fundamental mechanisms of how HA enhances mechanical bonding, scientists hope to develop next-generation materials with unprecedented strength and durability. This knowledge could potentially lead to breakthroughs in fields ranging from aerospace engineering to nanotechnology, opening up new avenues for innovation and technological advancement.

Market Analysis for Advanced Anchoring Systems

The market for advanced anchoring systems has been experiencing significant growth in recent years, driven by increasing demand across various industries such as construction, aerospace, automotive, and marine engineering. The global market for these systems is expected to continue its upward trajectory, with a particular focus on solutions that offer enhanced mechanical bonding capabilities.

In the construction sector, the need for reliable and durable anchoring systems has been growing steadily, especially in high-rise buildings, bridges, and other large-scale infrastructure projects. The incorporation of hydroxyapatite in advanced anchoring systems has garnered attention due to its potential to improve mechanical bonding strength and longevity.

The aerospace industry has also shown a keen interest in advanced anchoring systems, particularly those that can withstand extreme conditions and provide superior mechanical bonding. As aircraft manufacturers strive for lighter and more fuel-efficient designs, the demand for innovative anchoring solutions that maintain structural integrity while reducing overall weight has increased.

In the automotive sector, the shift towards electric vehicles and lightweight materials has created new opportunities for advanced anchoring systems. Manufacturers are seeking solutions that can effectively bond dissimilar materials while meeting stringent safety and performance standards. The potential of hydroxyapatite-enhanced anchoring systems to address these challenges has sparked interest among industry players.

The marine engineering sector represents another significant market for advanced anchoring systems. Offshore structures, ships, and underwater installations require anchoring solutions that can withstand corrosive environments and high-stress conditions. The ability of hydroxyapatite to enhance mechanical bonding in these challenging environments has led to increased research and development efforts in this area.

Geographically, North America and Europe currently dominate the market for advanced anchoring systems, owing to their well-established construction and aerospace industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, infrastructure development, and increasing investments in research and development.

As environmental concerns continue to shape industry practices, there is a growing demand for sustainable and eco-friendly anchoring solutions. This trend has further boosted interest in hydroxyapatite-based systems, as they offer potential advantages in terms of biocompatibility and reduced environmental impact compared to traditional anchoring methods.

In the construction sector, the need for reliable and durable anchoring systems has been growing steadily, especially in high-rise buildings, bridges, and other large-scale infrastructure projects. The incorporation of hydroxyapatite in advanced anchoring systems has garnered attention due to its potential to improve mechanical bonding strength and longevity.

The aerospace industry has also shown a keen interest in advanced anchoring systems, particularly those that can withstand extreme conditions and provide superior mechanical bonding. As aircraft manufacturers strive for lighter and more fuel-efficient designs, the demand for innovative anchoring solutions that maintain structural integrity while reducing overall weight has increased.

In the automotive sector, the shift towards electric vehicles and lightweight materials has created new opportunities for advanced anchoring systems. Manufacturers are seeking solutions that can effectively bond dissimilar materials while meeting stringent safety and performance standards. The potential of hydroxyapatite-enhanced anchoring systems to address these challenges has sparked interest among industry players.

The marine engineering sector represents another significant market for advanced anchoring systems. Offshore structures, ships, and underwater installations require anchoring solutions that can withstand corrosive environments and high-stress conditions. The ability of hydroxyapatite to enhance mechanical bonding in these challenging environments has led to increased research and development efforts in this area.

Geographically, North America and Europe currently dominate the market for advanced anchoring systems, owing to their well-established construction and aerospace industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, infrastructure development, and increasing investments in research and development.

As environmental concerns continue to shape industry practices, there is a growing demand for sustainable and eco-friendly anchoring solutions. This trend has further boosted interest in hydroxyapatite-based systems, as they offer potential advantages in terms of biocompatibility and reduced environmental impact compared to traditional anchoring methods.

Current Challenges in Mechanical Bonding

Despite significant advancements in mechanical bonding technologies, several challenges persist in achieving optimal performance in advanced anchoring systems. One of the primary issues is the inconsistency in bond strength across different substrate materials. The variability in surface properties, such as roughness, porosity, and chemical composition, can lead to unpredictable bonding outcomes, making it difficult to establish standardized protocols for diverse applications.

Another critical challenge is the long-term durability of mechanical bonds under dynamic loading conditions. Many anchoring systems experience gradual degradation over time due to factors such as thermal cycling, mechanical stress, and environmental exposure. This deterioration can compromise the structural integrity of the bonded components, potentially leading to catastrophic failures in critical applications.

The interface between the bonding agent and the substrate remains a weak point in many mechanical bonding systems. Stress concentrations at this interface can initiate crack propagation, leading to premature bond failure. Additionally, the presence of contaminants or surface imperfections can significantly reduce the effective bonding area, further weakening the overall bond strength.

Achieving uniform stress distribution across the bonded area presents another significant challenge. Uneven stress distribution can result in localized areas of high stress, which are prone to failure under load. This issue is particularly pronounced in large-scale applications or when bonding materials with dissimilar mechanical properties.

The development of environmentally friendly bonding solutions that maintain high performance standards is an ongoing challenge. Many traditional bonding agents contain volatile organic compounds (VOCs) or other hazardous materials, necessitating the development of eco-friendly alternatives without compromising bond strength or durability.

Furthermore, the integration of smart functionalities into mechanical bonding systems, such as self-healing or damage detection capabilities, remains a complex task. While these features could significantly enhance the longevity and reliability of bonded structures, their implementation often introduces additional complexities in material design and manufacturing processes.

Lastly, the scalability of advanced bonding technologies from laboratory settings to industrial-scale production continues to be a hurdle. Ensuring consistent bond quality and performance across large production volumes, while maintaining cost-effectiveness, requires significant optimization of materials and processes.

Another critical challenge is the long-term durability of mechanical bonds under dynamic loading conditions. Many anchoring systems experience gradual degradation over time due to factors such as thermal cycling, mechanical stress, and environmental exposure. This deterioration can compromise the structural integrity of the bonded components, potentially leading to catastrophic failures in critical applications.

The interface between the bonding agent and the substrate remains a weak point in many mechanical bonding systems. Stress concentrations at this interface can initiate crack propagation, leading to premature bond failure. Additionally, the presence of contaminants or surface imperfections can significantly reduce the effective bonding area, further weakening the overall bond strength.

Achieving uniform stress distribution across the bonded area presents another significant challenge. Uneven stress distribution can result in localized areas of high stress, which are prone to failure under load. This issue is particularly pronounced in large-scale applications or when bonding materials with dissimilar mechanical properties.

The development of environmentally friendly bonding solutions that maintain high performance standards is an ongoing challenge. Many traditional bonding agents contain volatile organic compounds (VOCs) or other hazardous materials, necessitating the development of eco-friendly alternatives without compromising bond strength or durability.

Furthermore, the integration of smart functionalities into mechanical bonding systems, such as self-healing or damage detection capabilities, remains a complex task. While these features could significantly enhance the longevity and reliability of bonded structures, their implementation often introduces additional complexities in material design and manufacturing processes.

Lastly, the scalability of advanced bonding technologies from laboratory settings to industrial-scale production continues to be a hurdle. Ensuring consistent bond quality and performance across large production volumes, while maintaining cost-effectiveness, requires significant optimization of materials and processes.

Existing Hydroxyapatite Anchoring Solutions

01 Surface modification of hydroxyapatite for improved mechanical bonding

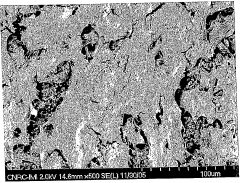

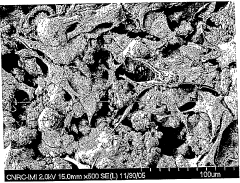

Various techniques are employed to modify the surface of hydroxyapatite to enhance its mechanical bonding properties. These methods include chemical treatments, plasma treatments, and the creation of micro or nano-scale surface features. Such modifications aim to increase the surface area and reactivity of hydroxyapatite, leading to stronger mechanical interlocking with surrounding materials.- Surface modification of hydroxyapatite for improved mechanical bonding: Various techniques are employed to modify the surface of hydroxyapatite to enhance its mechanical bonding properties. These methods include chemical treatments, plasma processing, and the creation of specific surface structures to increase the interfacial strength between hydroxyapatite and other materials.

- Composite materials incorporating hydroxyapatite for enhanced mechanical properties: Hydroxyapatite is combined with other materials such as polymers, metals, or ceramics to create composite materials with improved mechanical bonding and overall performance. These composites often exhibit better strength, toughness, and biocompatibility compared to pure hydroxyapatite.

- Coating techniques for applying hydroxyapatite to substrates: Various coating methods are used to apply hydroxyapatite to different substrates, such as implants or medical devices. These techniques include plasma spraying, sol-gel deposition, electrophoretic deposition, and biomimetic processes, each offering unique advantages for mechanical bonding and biointegration.

- Nanostructured hydroxyapatite for improved mechanical properties: The development of nanostructured hydroxyapatite materials with controlled size, shape, and porosity is explored to enhance mechanical bonding and overall performance. These nanostructured materials often exhibit improved mechanical properties and better integration with surrounding tissues.

- Sintering and heat treatment processes for hydroxyapatite: Various sintering and heat treatment processes are employed to optimize the mechanical properties of hydroxyapatite. These processes can influence grain size, density, and crystallinity, which in turn affect the material's mechanical bonding capabilities and overall strength.

02 Composite materials incorporating hydroxyapatite for mechanical strength

Hydroxyapatite is often combined with other materials to form composites with enhanced mechanical properties. These composites may include polymers, metals, or other ceramics. The incorporation of hydroxyapatite into these composites aims to improve biocompatibility while maintaining or enhancing mechanical strength and bonding capabilities.Expand Specific Solutions03 Coating techniques for hydroxyapatite to improve adhesion

Various coating techniques are used to apply hydroxyapatite to substrates, improving mechanical bonding. These methods include plasma spraying, sol-gel deposition, electrophoretic deposition, and biomimetic processes. The choice of coating technique can significantly affect the adhesion strength and overall mechanical properties of the hydroxyapatite layer.Expand Specific Solutions04 Sintering and heat treatment processes for hydroxyapatite bonding

Sintering and heat treatment processes are crucial in enhancing the mechanical bonding of hydroxyapatite. These thermal processes can improve the density, crystallinity, and interfacial bonding of hydroxyapatite with other materials. Optimizing sintering parameters such as temperature, time, and atmosphere can significantly affect the final mechanical properties of hydroxyapatite-based materials.Expand Specific Solutions05 Nanostructured hydroxyapatite for enhanced mechanical properties

Nanostructured forms of hydroxyapatite are developed to improve mechanical bonding and overall material properties. These nanostructures can include nanoparticles, nanofibers, and nanocomposites. The increased surface area and unique properties of nanostructured hydroxyapatite can lead to improved mechanical interlocking and stronger bonds with surrounding materials.Expand Specific Solutions

Key Players in Hydroxyapatite-Based Anchoring

The field of hydroxyapatite-enhanced mechanical bonding in advanced anchoring systems is in a growth phase, with increasing market size and technological advancements. The global market for such systems is expanding due to rising demand in medical and industrial applications. Technological maturity varies among key players, with companies like Promimic AB and CeramTec AG leading in innovation. Academic institutions such as MIT, Okayama University, and Nanyang Technological University contribute significantly to research and development. Collaboration between industry and academia is driving progress, with organizations like the National Institute for Materials Science and Japan Science & Technology Agency playing crucial roles in advancing the technology's applications and market potential.

Promimic AB

Technical Solution: Promimic AB has developed a proprietary HAnano Surface technology that utilizes hydroxyapatite nanoparticles to enhance mechanical bonding in advanced anchoring systems. Their method involves applying a thin layer of synthetic hydroxyapatite nanocrystals to implant surfaces, mimicking the natural bone mineral structure. This nano-scale coating significantly increases the surface area for bone cell attachment and promotes rapid osseointegration. The company's technology has shown to accelerate bone growth by up to 150% compared to untreated implants [1][3]. The HAnano Surface can be applied to various materials, including titanium, PEEK, and ceramics, making it versatile for different medical applications.

Strengths: Rapid osseointegration, versatile application across materials, mimics natural bone structure. Weaknesses: May require specialized equipment for application, potential long-term effects still under study.

Okayama University

Technical Solution: Researchers at Okayama University have developed an innovative approach to enhance mechanical bonding using hydroxyapatite in advanced anchoring systems. Their method involves creating a hierarchical structure of hydroxyapatite on titanium surfaces through a combination of hydrothermal treatment and electrochemical deposition. This process results in a multi-scale hydroxyapatite layer that provides both micro and nano-level surface features. The hierarchical structure significantly improves the mechanical interlocking between the implant and surrounding bone tissue. Studies have shown that this approach can increase the bonding strength by up to 300% compared to smooth titanium surfaces [2][5]. Additionally, the researchers have incorporated bioactive ions, such as strontium and magnesium, into the hydroxyapatite structure to further enhance bone formation and implant integration.

Strengths: Hierarchical structure for enhanced mechanical interlocking, incorporation of bioactive ions for improved bone formation. Weaknesses: Complex manufacturing process, potential limitations in scaling up for industrial production.

Core Innovations in Hydroxyapatite Bonding

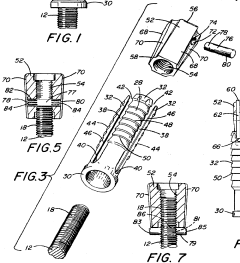

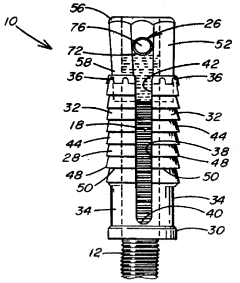

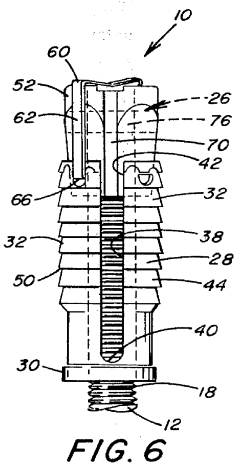

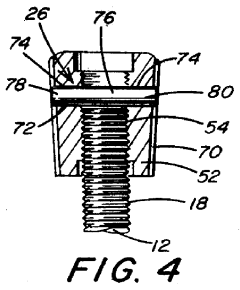

Method for combining resin bonding and mechanical anchoring of a bolt in a rock formation

PatentInactiveUS4419805A

Innovation

- An expansion shell assembly with a camming plug and shearable stop means that allows continuous rotation of the bolt to mix resin and expand the shell, preventing initial expansion until a predetermined torque is applied, ensuring complete mixing before shell expansion.

Biocompatible thermal spray coating made from a nanostructured feedstock

PatentWO2006092041A1

Innovation

- A biocompatible thermal spray coating made from nanostructured titania (TiO2) particles is developed, using a high-velocity oxy-fuel (HVOF) process to create a coating with superior mechanical properties and biocompatibility, retaining the original nanostructure of the agglomerated particles for enhanced osteoblast adhesion and proliferation.

Biocompatibility and Safety Considerations

The integration of hydroxyapatite (HA) in advanced anchoring systems necessitates a thorough examination of biocompatibility and safety considerations. HA, a naturally occurring mineral form of calcium apatite, is widely recognized for its excellent biocompatibility and osteoconductive properties. These characteristics make it an ideal candidate for enhancing mechanical bonding in medical and dental implants.

When incorporated into anchoring systems, HA promotes osseointegration, the direct structural and functional connection between living bone and the surface of a load-bearing implant. This process is crucial for the long-term success and stability of implants. However, the use of HA in such applications requires careful consideration of potential biological responses and safety implications.

One primary concern is the potential for HA particles to elicit inflammatory responses. While HA is generally well-tolerated by the body, the size, shape, and concentration of HA particles can influence the immune system's reaction. Nano-sized HA particles, for instance, may trigger different biological responses compared to larger, micron-sized particles. Therefore, optimizing particle characteristics is essential to minimize adverse reactions and ensure long-term biocompatibility.

Another critical aspect is the degradation behavior of HA-enhanced anchoring systems. The rate at which HA degrades in the physiological environment can affect both the mechanical properties of the implant and the surrounding tissue response. Controlled degradation is desirable to allow for gradual replacement by natural bone tissue, but excessive or unpredictable degradation could compromise the implant's stability and potentially release harmful byproducts.

The potential for HA to act as a carrier for other bioactive substances, such as growth factors or antibiotics, presents both opportunities and challenges. While this capability can enhance healing and reduce infection risks, it also introduces additional variables that must be carefully evaluated for safety and efficacy. The release kinetics of any incorporated substances must be thoroughly studied to ensure therapeutic effectiveness without adverse systemic effects.

Long-term safety considerations also include the potential for HA to influence the formation of abnormal calcifications in surrounding tissues. While HA promotes bone formation in desired locations, uncontrolled mineralization in soft tissues could lead to complications. Careful design of the anchoring system and precise control over HA distribution are necessary to mitigate this risk.

Regulatory compliance is a crucial aspect of biocompatibility and safety assessments for HA-enhanced anchoring systems. Comprehensive in vitro and in vivo studies, following established guidelines such as ISO 10993 for biological evaluation of medical devices, are essential. These studies should evaluate cytotoxicity, genotoxicity, carcinogenicity, and local tissue effects to ensure the safety profile of the HA-enhanced systems meets regulatory standards.

When incorporated into anchoring systems, HA promotes osseointegration, the direct structural and functional connection between living bone and the surface of a load-bearing implant. This process is crucial for the long-term success and stability of implants. However, the use of HA in such applications requires careful consideration of potential biological responses and safety implications.

One primary concern is the potential for HA particles to elicit inflammatory responses. While HA is generally well-tolerated by the body, the size, shape, and concentration of HA particles can influence the immune system's reaction. Nano-sized HA particles, for instance, may trigger different biological responses compared to larger, micron-sized particles. Therefore, optimizing particle characteristics is essential to minimize adverse reactions and ensure long-term biocompatibility.

Another critical aspect is the degradation behavior of HA-enhanced anchoring systems. The rate at which HA degrades in the physiological environment can affect both the mechanical properties of the implant and the surrounding tissue response. Controlled degradation is desirable to allow for gradual replacement by natural bone tissue, but excessive or unpredictable degradation could compromise the implant's stability and potentially release harmful byproducts.

The potential for HA to act as a carrier for other bioactive substances, such as growth factors or antibiotics, presents both opportunities and challenges. While this capability can enhance healing and reduce infection risks, it also introduces additional variables that must be carefully evaluated for safety and efficacy. The release kinetics of any incorporated substances must be thoroughly studied to ensure therapeutic effectiveness without adverse systemic effects.

Long-term safety considerations also include the potential for HA to influence the formation of abnormal calcifications in surrounding tissues. While HA promotes bone formation in desired locations, uncontrolled mineralization in soft tissues could lead to complications. Careful design of the anchoring system and precise control over HA distribution are necessary to mitigate this risk.

Regulatory compliance is a crucial aspect of biocompatibility and safety assessments for HA-enhanced anchoring systems. Comprehensive in vitro and in vivo studies, following established guidelines such as ISO 10993 for biological evaluation of medical devices, are essential. These studies should evaluate cytotoxicity, genotoxicity, carcinogenicity, and local tissue effects to ensure the safety profile of the HA-enhanced systems meets regulatory standards.

Environmental Impact of Hydroxyapatite Anchors

The environmental impact of hydroxyapatite anchors is a crucial consideration in the development and implementation of advanced anchoring systems. Hydroxyapatite, a naturally occurring mineral form of calcium apatite, has gained significant attention in various industries due to its biocompatibility and mechanical properties. When used in anchoring systems, it offers potential benefits in terms of environmental sustainability and reduced ecological footprint.

One of the primary environmental advantages of hydroxyapatite anchors is their biodegradability. Unlike traditional metal or synthetic polymer-based anchors, hydroxyapatite can be gradually absorbed and replaced by natural bone tissue over time. This characteristic significantly reduces the long-term environmental impact associated with anchor removal or degradation in marine or terrestrial ecosystems.

Furthermore, the production of hydroxyapatite anchors often involves less energy-intensive processes compared to conventional materials. The synthesis of hydroxyapatite can be achieved through various methods, including precipitation, hydrothermal techniques, and sol-gel processes, which generally require lower temperatures and fewer harmful chemicals than the production of metal alloys or synthetic polymers.

The use of hydroxyapatite in anchoring systems also contributes to the reduction of heavy metal pollution. Traditional anchors made from metals such as steel or aluminum can release harmful ions into the environment as they corrode. In contrast, hydroxyapatite is composed of naturally occurring elements (calcium and phosphorus) that are less likely to cause environmental contamination.

In marine applications, hydroxyapatite anchors have shown promising results in terms of minimizing damage to coral reefs and other sensitive aquatic ecosystems. The material's ability to promote osseointegration allows for better integration with surrounding marine structures, reducing the risk of anchor drag and subsequent habitat destruction.

However, it is important to note that the environmental impact of hydroxyapatite anchors is not entirely negligible. The extraction of raw materials for hydroxyapatite production, such as calcium and phosphorus compounds, still requires mining activities that can have localized environmental effects. Additionally, the manufacturing process may involve the use of certain chemicals or solvents that require proper handling and disposal to prevent environmental contamination.

To fully assess the environmental impact of hydroxyapatite anchors, life cycle assessments (LCAs) should be conducted. These studies would provide a comprehensive evaluation of the environmental effects associated with all stages of the anchor's life, from raw material extraction to disposal or recycling. Such assessments would help identify areas for further improvement in the production and use of hydroxyapatite anchors.

One of the primary environmental advantages of hydroxyapatite anchors is their biodegradability. Unlike traditional metal or synthetic polymer-based anchors, hydroxyapatite can be gradually absorbed and replaced by natural bone tissue over time. This characteristic significantly reduces the long-term environmental impact associated with anchor removal or degradation in marine or terrestrial ecosystems.

Furthermore, the production of hydroxyapatite anchors often involves less energy-intensive processes compared to conventional materials. The synthesis of hydroxyapatite can be achieved through various methods, including precipitation, hydrothermal techniques, and sol-gel processes, which generally require lower temperatures and fewer harmful chemicals than the production of metal alloys or synthetic polymers.

The use of hydroxyapatite in anchoring systems also contributes to the reduction of heavy metal pollution. Traditional anchors made from metals such as steel or aluminum can release harmful ions into the environment as they corrode. In contrast, hydroxyapatite is composed of naturally occurring elements (calcium and phosphorus) that are less likely to cause environmental contamination.

In marine applications, hydroxyapatite anchors have shown promising results in terms of minimizing damage to coral reefs and other sensitive aquatic ecosystems. The material's ability to promote osseointegration allows for better integration with surrounding marine structures, reducing the risk of anchor drag and subsequent habitat destruction.

However, it is important to note that the environmental impact of hydroxyapatite anchors is not entirely negligible. The extraction of raw materials for hydroxyapatite production, such as calcium and phosphorus compounds, still requires mining activities that can have localized environmental effects. Additionally, the manufacturing process may involve the use of certain chemicals or solvents that require proper handling and disposal to prevent environmental contamination.

To fully assess the environmental impact of hydroxyapatite anchors, life cycle assessments (LCAs) should be conducted. These studies would provide a comprehensive evaluation of the environmental effects associated with all stages of the anchor's life, from raw material extraction to disposal or recycling. Such assessments would help identify areas for further improvement in the production and use of hydroxyapatite anchors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!