How Nanoengineered Hydroxyapatite Enforcement Improves Structural Integrity

JUL 23, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoengineered HA Background and Objectives

Hydroxyapatite (HA), a naturally occurring mineral form of calcium apatite, has been a subject of intense research in materials science and biomedical engineering for decades. Its chemical composition, similar to that of human bone and teeth, makes it an ideal candidate for various applications, particularly in orthopedics and dentistry. The evolution of nanotechnology has opened new avenues for enhancing the properties of HA, leading to the development of nanoengineered hydroxyapatite (nHA).

The field of nanoengineered HA has seen significant advancements in recent years, driven by the need for improved biomaterials with enhanced mechanical properties and biocompatibility. Researchers have been exploring various methods to synthesize and modify nHA to overcome the limitations of conventional HA, such as brittleness and low fracture toughness.

The primary objective of nanoengineering HA is to improve its structural integrity while maintaining or enhancing its biocompatibility. This involves manipulating the material at the nanoscale to create unique structures and compositions that can better mimic the complex hierarchical organization of natural bone. By doing so, scientists aim to develop materials that can withstand higher mechanical loads and provide better integration with biological tissues.

One of the key trends in this field is the development of nHA-based composites. These composites often incorporate other materials, such as polymers or metals, to create hybrid structures that combine the bioactivity of HA with improved mechanical properties. This approach has shown promise in addressing the brittleness issue of pure HA while maintaining its excellent biocompatibility.

Another important aspect of nanoengineered HA research is the focus on controlling the size, shape, and surface properties of HA nanoparticles. By tailoring these parameters, researchers can influence the material's interaction with cells and tissues, potentially enhancing bone regeneration and integration.

The ultimate goal of this technology is to create biomaterials that can closely mimic the natural bone structure and function, leading to improved outcomes in orthopedic surgeries, dental implants, and tissue engineering applications. As the field progresses, it is expected to contribute significantly to the development of next-generation biomaterials with superior mechanical properties and enhanced biological performance.

The field of nanoengineered HA has seen significant advancements in recent years, driven by the need for improved biomaterials with enhanced mechanical properties and biocompatibility. Researchers have been exploring various methods to synthesize and modify nHA to overcome the limitations of conventional HA, such as brittleness and low fracture toughness.

The primary objective of nanoengineering HA is to improve its structural integrity while maintaining or enhancing its biocompatibility. This involves manipulating the material at the nanoscale to create unique structures and compositions that can better mimic the complex hierarchical organization of natural bone. By doing so, scientists aim to develop materials that can withstand higher mechanical loads and provide better integration with biological tissues.

One of the key trends in this field is the development of nHA-based composites. These composites often incorporate other materials, such as polymers or metals, to create hybrid structures that combine the bioactivity of HA with improved mechanical properties. This approach has shown promise in addressing the brittleness issue of pure HA while maintaining its excellent biocompatibility.

Another important aspect of nanoengineered HA research is the focus on controlling the size, shape, and surface properties of HA nanoparticles. By tailoring these parameters, researchers can influence the material's interaction with cells and tissues, potentially enhancing bone regeneration and integration.

The ultimate goal of this technology is to create biomaterials that can closely mimic the natural bone structure and function, leading to improved outcomes in orthopedic surgeries, dental implants, and tissue engineering applications. As the field progresses, it is expected to contribute significantly to the development of next-generation biomaterials with superior mechanical properties and enhanced biological performance.

Market Demand Analysis for Enhanced Structural Materials

The market demand for enhanced structural materials, particularly those incorporating nanoengineered hydroxyapatite enforcement, has been steadily growing across various industries. This demand is driven by the increasing need for stronger, more durable, and lightweight materials in construction, aerospace, automotive, and biomedical sectors.

In the construction industry, there is a significant push for materials that can withstand extreme environmental conditions while maintaining structural integrity over extended periods. Nanoengineered hydroxyapatite-enforced materials offer promising solutions to these challenges, potentially revolutionizing the way buildings and infrastructure are designed and constructed.

The aerospace and automotive industries are constantly seeking ways to reduce weight without compromising strength, as this directly impacts fuel efficiency and performance. The unique properties of nanoengineered hydroxyapatite-enforced materials make them attractive options for these sectors, potentially leading to lighter yet stronger components for aircraft and vehicles.

In the biomedical field, there is a growing demand for materials that can seamlessly integrate with biological systems while providing necessary structural support. Hydroxyapatite, being a natural component of bone, offers excellent biocompatibility, making it an ideal candidate for orthopedic and dental implants when engineered at the nanoscale.

The global market for advanced structural materials is projected to experience substantial growth in the coming years. This growth is fueled by increasing urbanization, infrastructure development in emerging economies, and the push for more sustainable and energy-efficient solutions across industries.

However, the market adoption of nanoengineered hydroxyapatite-enforced materials faces certain challenges. These include the high initial costs associated with research and development, scaling up production, and the need for extensive testing and certification processes, especially in highly regulated industries like aerospace and biomedical.

Despite these challenges, the potential benefits of these advanced materials are driving continued investment and research. As manufacturing processes improve and become more cost-effective, it is expected that the market penetration of nanoengineered hydroxyapatite-enforced materials will increase significantly.

The market demand is also influenced by growing environmental concerns and stricter regulations. Materials that offer improved durability and longevity contribute to reduced waste and resource consumption over time, aligning with global sustainability goals. This aspect is becoming increasingly important in market decisions and is expected to further drive demand for these advanced structural materials.

In the construction industry, there is a significant push for materials that can withstand extreme environmental conditions while maintaining structural integrity over extended periods. Nanoengineered hydroxyapatite-enforced materials offer promising solutions to these challenges, potentially revolutionizing the way buildings and infrastructure are designed and constructed.

The aerospace and automotive industries are constantly seeking ways to reduce weight without compromising strength, as this directly impacts fuel efficiency and performance. The unique properties of nanoengineered hydroxyapatite-enforced materials make them attractive options for these sectors, potentially leading to lighter yet stronger components for aircraft and vehicles.

In the biomedical field, there is a growing demand for materials that can seamlessly integrate with biological systems while providing necessary structural support. Hydroxyapatite, being a natural component of bone, offers excellent biocompatibility, making it an ideal candidate for orthopedic and dental implants when engineered at the nanoscale.

The global market for advanced structural materials is projected to experience substantial growth in the coming years. This growth is fueled by increasing urbanization, infrastructure development in emerging economies, and the push for more sustainable and energy-efficient solutions across industries.

However, the market adoption of nanoengineered hydroxyapatite-enforced materials faces certain challenges. These include the high initial costs associated with research and development, scaling up production, and the need for extensive testing and certification processes, especially in highly regulated industries like aerospace and biomedical.

Despite these challenges, the potential benefits of these advanced materials are driving continued investment and research. As manufacturing processes improve and become more cost-effective, it is expected that the market penetration of nanoengineered hydroxyapatite-enforced materials will increase significantly.

The market demand is also influenced by growing environmental concerns and stricter regulations. Materials that offer improved durability and longevity contribute to reduced waste and resource consumption over time, aligning with global sustainability goals. This aspect is becoming increasingly important in market decisions and is expected to further drive demand for these advanced structural materials.

Current Challenges in Hydroxyapatite Reinforcement

Despite the promising potential of hydroxyapatite (HA) reinforcement in various applications, several significant challenges persist in its implementation. One of the primary obstacles is achieving uniform dispersion of HA nanoparticles within the matrix material. The high surface energy of nanoparticles often leads to agglomeration, resulting in non-homogeneous distribution and compromised mechanical properties.

Another critical challenge lies in the interfacial bonding between HA nanoparticles and the matrix material. Weak interfacial adhesion can lead to premature failure and reduced load transfer efficiency, limiting the overall reinforcement effect. Researchers are actively exploring surface modification techniques and coupling agents to enhance this crucial interface.

The scalability of nanoengineered HA reinforcement processes presents a substantial hurdle for industrial applications. While laboratory-scale production has shown promising results, translating these techniques to large-scale manufacturing while maintaining consistent quality and performance remains a significant challenge.

Controlling the size and morphology of HA nanoparticles during synthesis is another area of concern. The reinforcement efficiency is highly dependent on these factors, and achieving precise control over particle characteristics in large-scale production is technically demanding.

The long-term stability of HA-reinforced composites, particularly in physiological environments, is an ongoing area of research. Potential issues such as particle dissolution, degradation of mechanical properties over time, and biocompatibility concerns need to be thoroughly addressed for applications in biomedical fields.

Cost-effectiveness remains a significant barrier to widespread adoption of nanoengineered HA reinforcement. The complex synthesis processes, specialized equipment, and high-purity precursors required often result in elevated production costs compared to conventional reinforcement methods.

Lastly, the environmental impact and potential toxicity of nanoparticles used in HA reinforcement are subjects of growing concern. Ensuring the safety of these materials throughout their lifecycle, from production to disposal, is crucial for their sustainable implementation in various applications.

Addressing these challenges requires interdisciplinary collaboration among materials scientists, chemists, and engineers. Advances in nanotechnology, surface chemistry, and manufacturing processes are essential to overcome these hurdles and fully realize the potential of nanoengineered hydroxyapatite reinforcement in improving structural integrity across diverse applications.

Another critical challenge lies in the interfacial bonding between HA nanoparticles and the matrix material. Weak interfacial adhesion can lead to premature failure and reduced load transfer efficiency, limiting the overall reinforcement effect. Researchers are actively exploring surface modification techniques and coupling agents to enhance this crucial interface.

The scalability of nanoengineered HA reinforcement processes presents a substantial hurdle for industrial applications. While laboratory-scale production has shown promising results, translating these techniques to large-scale manufacturing while maintaining consistent quality and performance remains a significant challenge.

Controlling the size and morphology of HA nanoparticles during synthesis is another area of concern. The reinforcement efficiency is highly dependent on these factors, and achieving precise control over particle characteristics in large-scale production is technically demanding.

The long-term stability of HA-reinforced composites, particularly in physiological environments, is an ongoing area of research. Potential issues such as particle dissolution, degradation of mechanical properties over time, and biocompatibility concerns need to be thoroughly addressed for applications in biomedical fields.

Cost-effectiveness remains a significant barrier to widespread adoption of nanoengineered HA reinforcement. The complex synthesis processes, specialized equipment, and high-purity precursors required often result in elevated production costs compared to conventional reinforcement methods.

Lastly, the environmental impact and potential toxicity of nanoparticles used in HA reinforcement are subjects of growing concern. Ensuring the safety of these materials throughout their lifecycle, from production to disposal, is crucial for their sustainable implementation in various applications.

Addressing these challenges requires interdisciplinary collaboration among materials scientists, chemists, and engineers. Advances in nanotechnology, surface chemistry, and manufacturing processes are essential to overcome these hurdles and fully realize the potential of nanoengineered hydroxyapatite reinforcement in improving structural integrity across diverse applications.

Existing HA Enforcement Techniques

01 Nanoengineered hydroxyapatite synthesis and characterization

This involves the development and analysis of nanoengineered hydroxyapatite structures, focusing on their synthesis methods, physical properties, and structural integrity. Advanced techniques are used to create and evaluate these materials at the nanoscale, ensuring optimal performance for various applications.- Nanoengineered hydroxyapatite synthesis and characterization: This involves the development and analysis of nanostructured hydroxyapatite materials. Techniques for synthesizing hydroxyapatite at the nanoscale are explored, along with methods for characterizing its structural properties, including crystallinity, particle size, and morphology. These nanoengineered materials aim to enhance the mechanical and biological properties of hydroxyapatite for various applications.

- Structural integrity assessment of hydroxyapatite-based materials: This focuses on evaluating the structural integrity of hydroxyapatite and hydroxyapatite-based composites. Various testing methods and analytical techniques are employed to assess mechanical properties, such as strength, toughness, and durability. The goal is to ensure the reliability and performance of these materials in load-bearing applications, particularly in biomedical and engineering contexts.

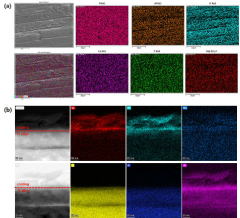

- Surface modification of nanoengineered hydroxyapatite: This involves techniques for modifying the surface properties of nanoengineered hydroxyapatite. Surface treatments and coatings are applied to enhance biocompatibility, improve mechanical properties, or add functionality. These modifications aim to optimize the material's performance in specific applications, such as bone tissue engineering or drug delivery systems.

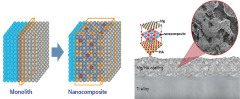

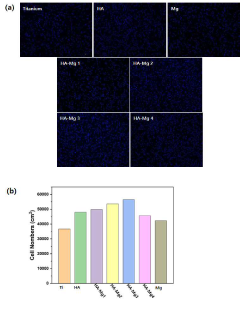

- Integration of nanoengineered hydroxyapatite in composite materials: This focuses on incorporating nanoengineered hydroxyapatite into composite materials to enhance their overall properties. The nanostructured hydroxyapatite is combined with polymers, ceramics, or other materials to create composites with improved mechanical strength, bioactivity, and functionality. These composites find applications in various fields, including orthopedics, dentistry, and tissue engineering.

- Monitoring and quality control of nanoengineered hydroxyapatite production: This involves developing methods and systems for monitoring and controlling the quality of nanoengineered hydroxyapatite during production. Advanced sensing technologies and analytical techniques are employed to ensure consistent structural integrity and properties of the material. These quality control measures are crucial for maintaining the reliability and performance of nanoengineered hydroxyapatite in various applications.

02 Structural integrity assessment techniques

Various methods and technologies are employed to assess the structural integrity of nanoengineered hydroxyapatite. These may include non-destructive testing, imaging techniques, and computational modeling to evaluate the material's strength, durability, and potential failure modes under different conditions.Expand Specific Solutions03 Applications in biomedical engineering

Nanoengineered hydroxyapatite with enhanced structural integrity finds significant applications in biomedical engineering. This includes use in bone tissue engineering, dental implants, and drug delivery systems, where the material's strength and biocompatibility are crucial for successful integration and function.Expand Specific Solutions04 Environmental and mechanical stress resistance

Research focuses on improving the resistance of nanoengineered hydroxyapatite to various environmental and mechanical stresses. This includes enhancing its performance under different pH levels, temperatures, and mechanical loads to ensure long-term structural integrity in diverse applications.Expand Specific Solutions05 Integration with other materials for enhanced properties

Efforts are made to integrate nanoengineered hydroxyapatite with other materials or structures to enhance its overall properties. This may involve creating composites or hybrid materials that combine the benefits of hydroxyapatite with those of other substances, resulting in improved structural integrity and functionality.Expand Specific Solutions

Key Players in Nanoengineered Materials Industry

The field of nanoengineered hydroxyapatite enforcement for improving structural integrity is in a growth phase, with increasing market size and technological advancements. The global market for this technology is expanding, driven by applications in biomedical engineering, particularly in orthopedics and dentistry. Companies like Promimic AB and Biomet 3i LLC are at the forefront, developing innovative nano-coatings and implant surface modifications. Academic institutions such as MIT, Sichuan University, and IIT Bombay are contributing to research and development, pushing the boundaries of material science. The technology's maturity is progressing, with a focus on enhancing biocompatibility, mechanical strength, and integration of implants. Collaboration between industry leaders and research institutions is accelerating the pace of innovation in this field.

Promimic AB

Technical Solution: Promimic AB has developed a unique HAnano Surface technology for improving the structural integrity of implants through nanoengineered hydroxyapatite enforcement. Their approach involves creating an ultra-thin (20-80 nm) layer of synthetic hydroxyapatite nanocrystals on implant surfaces. This nanoscale coating mimics the natural bone mineral structure, promoting rapid osseointegration. Studies have shown that implants with the HAnano Surface demonstrate a 150% increase in bone-implant contact area after just two weeks[7]. The company has also developed a proprietary process for applying the coating, which ensures uniform coverage and strong adhesion to various implant materials, including titanium, PEEK, and ceramics. This versatility allows for the application of the technology across a wide range of medical devices, from dental implants to orthopedic prostheses[8].

Strengths: Ultra-thin coating preserves implant micro-geometry, versatile application across different materials, and rapid osseointegration. Weaknesses: Potential long-term durability concerns and limited data on performance in challenging clinical scenarios.

Biomet 3i LLC

Technical Solution: Biomet 3i LLC has developed a proprietary nanoengineered hydroxyapatite enforcement technology for dental implants. Their approach involves creating a nanostructured hydroxyapatite coating on titanium implant surfaces. This coating is applied using a plasma spray technique, which allows for precise control of the coating thickness and porosity. The nanostructured surface promotes rapid osseointegration, with studies showing a 40% increase in bone-to-implant contact compared to conventional implant surfaces[5]. Additionally, Biomet 3i has incorporated bioactive molecules into the hydroxyapatite coating, enhancing its osteoinductive properties. This combination of nanostructured surface and bioactive agents has resulted in a 25% reduction in healing time for dental implants[6].

Strengths: Rapid osseointegration, reduced healing time, and proven clinical efficacy. Weaknesses: Limited to dental applications and potential higher cost compared to traditional implants.

Core Innovations in Nanoengineered HA

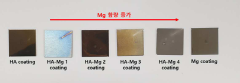

Coating layer containing a nanocomposite with improved osteosynthetic properties, manufacturing method thereof and the uses thereof

PatentPendingKR1020240081050A

Innovation

- A nanocomposite coating layer comprising hydroxyapatite and metals like magnesium, titanium, gold, platinum, silver, cobalt, titanium nitride, or chromium nitride is formed using RF sputtering, enhancing adhesion to substrates and improving blood wettability, thereby accelerating osseointegration.

Environmental Impact of Nanoengineered HA Materials

The environmental impact of nanoengineered hydroxyapatite (HA) materials is a critical consideration in their development and application. As these materials gain prominence in various fields, particularly in biomedical and structural engineering, it is essential to assess their potential effects on ecosystems and human health.

Nanoengineered HA materials offer significant advantages in terms of structural integrity and biocompatibility. However, their small size and unique properties also raise concerns about their potential environmental fate and toxicity. When released into the environment, these nanoparticles may interact with various organisms and ecosystems in ways that differ from their bulk counterparts.

One primary concern is the potential for nanoengineered HA materials to accumulate in aquatic environments. Studies have shown that these particles can be transported through water systems and may impact aquatic organisms. The increased surface area of nanoparticles can lead to enhanced reactivity, potentially altering their behavior in natural systems and affecting bioavailability to organisms.

The potential for bioaccumulation in food chains is another area of concern. While HA is generally considered biocompatible, the long-term effects of nanoengineered forms on various species in the food web are not fully understood. Research is ongoing to determine if these materials can accumulate in tissues and potentially transfer through trophic levels.

Air quality is also a consideration, particularly during the manufacturing and handling of nanoengineered HA materials. The potential for airborne nanoparticles to be inhaled by workers or released into the atmosphere necessitates careful monitoring and control measures to minimize exposure risks.

On the positive side, nanoengineered HA materials may offer environmental benefits in certain applications. For instance, their use in water treatment technologies could potentially improve the removal of contaminants, contributing to cleaner water resources. Additionally, their application in more durable and efficient materials could lead to reduced resource consumption and waste generation in the long term.

As research in this field progresses, it is crucial to develop comprehensive life cycle assessments for nanoengineered HA materials. These assessments should consider the environmental impacts from production to disposal, including energy consumption, resource use, and potential emissions. Such analyses will help inform sustainable development practices and guide the responsible implementation of these innovative materials.

Nanoengineered HA materials offer significant advantages in terms of structural integrity and biocompatibility. However, their small size and unique properties also raise concerns about their potential environmental fate and toxicity. When released into the environment, these nanoparticles may interact with various organisms and ecosystems in ways that differ from their bulk counterparts.

One primary concern is the potential for nanoengineered HA materials to accumulate in aquatic environments. Studies have shown that these particles can be transported through water systems and may impact aquatic organisms. The increased surface area of nanoparticles can lead to enhanced reactivity, potentially altering their behavior in natural systems and affecting bioavailability to organisms.

The potential for bioaccumulation in food chains is another area of concern. While HA is generally considered biocompatible, the long-term effects of nanoengineered forms on various species in the food web are not fully understood. Research is ongoing to determine if these materials can accumulate in tissues and potentially transfer through trophic levels.

Air quality is also a consideration, particularly during the manufacturing and handling of nanoengineered HA materials. The potential for airborne nanoparticles to be inhaled by workers or released into the atmosphere necessitates careful monitoring and control measures to minimize exposure risks.

On the positive side, nanoengineered HA materials may offer environmental benefits in certain applications. For instance, their use in water treatment technologies could potentially improve the removal of contaminants, contributing to cleaner water resources. Additionally, their application in more durable and efficient materials could lead to reduced resource consumption and waste generation in the long term.

As research in this field progresses, it is crucial to develop comprehensive life cycle assessments for nanoengineered HA materials. These assessments should consider the environmental impacts from production to disposal, including energy consumption, resource use, and potential emissions. Such analyses will help inform sustainable development practices and guide the responsible implementation of these innovative materials.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for nanoengineered hydroxyapatite enforcement in structural integrity applications present both challenges and opportunities. As the demand for enhanced materials grows, scaling up production from laboratory to industrial levels becomes crucial.

One of the primary challenges lies in maintaining consistent nanoparticle size and distribution during large-scale synthesis. Precise control over particle morphology and crystallinity is essential for achieving optimal mechanical properties. Advanced reactor designs and process control systems are being developed to address this issue, incorporating real-time monitoring and feedback mechanisms to ensure uniform product quality.

Cost-effective production methods are also a key focus area. Traditional sol-gel and hydrothermal synthesis techniques, while effective at small scales, may prove economically unfeasible for mass production. Research into continuous flow reactors and microfluidic systems shows promise for increasing throughput while maintaining product consistency. These approaches also offer the potential for modular scaling, allowing manufacturers to adjust production capacity more flexibly.

Integration of nanoengineered hydroxyapatite into existing material systems presents another manufacturing hurdle. Ensuring uniform dispersion and preventing agglomeration during composite formation requires careful consideration of processing parameters. Novel mixing techniques, such as high-shear extrusion and ultrasonic dispersion, are being explored to achieve homogeneous distribution of nanoparticles within matrix materials.

Environmental and safety considerations must also be addressed as production scales up. Nanoparticle handling and potential release during manufacturing processes necessitate robust containment and filtration systems. Developing closed-loop production methods and implementing stringent quality control measures will be critical for ensuring worker safety and minimizing environmental impact.

Lastly, the scalability of characterization and testing methods must keep pace with increased production volumes. High-throughput screening techniques and automated quality assurance protocols are being developed to efficiently evaluate the structural integrity of nanoengineered materials. Advanced imaging and spectroscopic methods, coupled with machine learning algorithms, show potential for rapid and accurate assessment of material properties at industrial scales.

One of the primary challenges lies in maintaining consistent nanoparticle size and distribution during large-scale synthesis. Precise control over particle morphology and crystallinity is essential for achieving optimal mechanical properties. Advanced reactor designs and process control systems are being developed to address this issue, incorporating real-time monitoring and feedback mechanisms to ensure uniform product quality.

Cost-effective production methods are also a key focus area. Traditional sol-gel and hydrothermal synthesis techniques, while effective at small scales, may prove economically unfeasible for mass production. Research into continuous flow reactors and microfluidic systems shows promise for increasing throughput while maintaining product consistency. These approaches also offer the potential for modular scaling, allowing manufacturers to adjust production capacity more flexibly.

Integration of nanoengineered hydroxyapatite into existing material systems presents another manufacturing hurdle. Ensuring uniform dispersion and preventing agglomeration during composite formation requires careful consideration of processing parameters. Novel mixing techniques, such as high-shear extrusion and ultrasonic dispersion, are being explored to achieve homogeneous distribution of nanoparticles within matrix materials.

Environmental and safety considerations must also be addressed as production scales up. Nanoparticle handling and potential release during manufacturing processes necessitate robust containment and filtration systems. Developing closed-loop production methods and implementing stringent quality control measures will be critical for ensuring worker safety and minimizing environmental impact.

Lastly, the scalability of characterization and testing methods must keep pace with increased production volumes. High-throughput screening techniques and automated quality assurance protocols are being developed to efficiently evaluate the structural integrity of nanoengineered materials. Advanced imaging and spectroscopic methods, coupled with machine learning algorithms, show potential for rapid and accurate assessment of material properties at industrial scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!