How Hydroxyapatite Incorporates into High-Tensile Aerospace Composites

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydroxyapatite Aerospace Integration Objectives

The integration of hydroxyapatite into high-tensile aerospace composites represents a significant leap in material science, aiming to enhance the performance and durability of aerospace structures. This technological advancement seeks to combine the biocompatibility and strength of hydroxyapatite with the lightweight and high-strength properties of aerospace composites.

The primary objective is to develop a novel composite material that exhibits superior mechanical properties, particularly in terms of tensile strength and impact resistance, while maintaining or reducing overall weight. By incorporating hydroxyapatite, researchers aim to improve the material's resistance to fatigue, corrosion, and thermal stress, which are critical factors in aerospace applications.

Another key goal is to enhance the material's ability to withstand extreme environmental conditions encountered during flight, including rapid temperature changes, high-altitude pressure variations, and exposure to cosmic radiation. The integration of hydroxyapatite is expected to contribute to the material's thermal stability and radiation shielding capabilities.

Researchers are also focusing on optimizing the manufacturing processes to ensure uniform distribution of hydroxyapatite within the composite matrix. This involves developing new techniques for nano-scale integration and exploring various binding mechanisms to achieve strong interfacial bonding between the hydroxyapatite particles and the composite matrix.

Furthermore, the technology aims to address the growing demand for sustainable and environmentally friendly materials in the aerospace industry. Hydroxyapatite, being a naturally occurring mineral, aligns with this objective and could potentially lead to more recyclable and biodegradable composite materials.

The long-term vision for this technology includes the development of self-healing composites, where hydroxyapatite could play a role in initiating and facilitating the repair of micro-cracks and damages in the material structure. This would significantly extend the lifespan of aerospace components and reduce maintenance costs.

Ultimately, the successful integration of hydroxyapatite into high-tensile aerospace composites is expected to revolutionize aircraft design and performance. It could enable the creation of lighter, stronger, and more durable aircraft structures, leading to improved fuel efficiency, increased payload capacity, and enhanced safety in aerospace applications.

The primary objective is to develop a novel composite material that exhibits superior mechanical properties, particularly in terms of tensile strength and impact resistance, while maintaining or reducing overall weight. By incorporating hydroxyapatite, researchers aim to improve the material's resistance to fatigue, corrosion, and thermal stress, which are critical factors in aerospace applications.

Another key goal is to enhance the material's ability to withstand extreme environmental conditions encountered during flight, including rapid temperature changes, high-altitude pressure variations, and exposure to cosmic radiation. The integration of hydroxyapatite is expected to contribute to the material's thermal stability and radiation shielding capabilities.

Researchers are also focusing on optimizing the manufacturing processes to ensure uniform distribution of hydroxyapatite within the composite matrix. This involves developing new techniques for nano-scale integration and exploring various binding mechanisms to achieve strong interfacial bonding between the hydroxyapatite particles and the composite matrix.

Furthermore, the technology aims to address the growing demand for sustainable and environmentally friendly materials in the aerospace industry. Hydroxyapatite, being a naturally occurring mineral, aligns with this objective and could potentially lead to more recyclable and biodegradable composite materials.

The long-term vision for this technology includes the development of self-healing composites, where hydroxyapatite could play a role in initiating and facilitating the repair of micro-cracks and damages in the material structure. This would significantly extend the lifespan of aerospace components and reduce maintenance costs.

Ultimately, the successful integration of hydroxyapatite into high-tensile aerospace composites is expected to revolutionize aircraft design and performance. It could enable the creation of lighter, stronger, and more durable aircraft structures, leading to improved fuel efficiency, increased payload capacity, and enhanced safety in aerospace applications.

Market Demand Analysis

The market demand for incorporating hydroxyapatite into high-tensile aerospace composites has been steadily growing in recent years. This trend is driven by the aerospace industry's continuous pursuit of lighter, stronger, and more durable materials to enhance aircraft performance and fuel efficiency. Hydroxyapatite, a naturally occurring mineral form of calcium apatite, has shown promising potential in reinforcing composite materials, particularly in applications where high strength-to-weight ratios are crucial.

The aerospace sector, including commercial aviation, military aircraft, and space exploration, represents the primary market for these advanced composites. As global air traffic continues to increase and space exploration missions become more ambitious, the demand for innovative materials that can withstand extreme conditions while reducing overall weight is expected to surge. Industry analysts project that the market for high-performance aerospace composites will experience significant growth over the next decade.

One of the key drivers of market demand is the potential for hydroxyapatite-incorporated composites to address specific challenges in aerospace engineering. These materials offer improved mechanical properties, including enhanced tensile strength, fracture toughness, and fatigue resistance. Additionally, the biocompatibility of hydroxyapatite opens up possibilities for developing multifunctional composites that could have applications beyond structural components, such as in advanced sensor systems or radiation shielding.

The increasing focus on sustainability and environmental regulations in the aviation industry also contributes to the growing interest in these composites. As airlines and manufacturers seek to reduce carbon emissions, materials that can contribute to lighter aircraft structures without compromising safety and performance are highly sought after. Hydroxyapatite-reinforced composites align well with these objectives, potentially offering a more eco-friendly alternative to some traditional aerospace materials.

Furthermore, the defense sector's ongoing modernization efforts and the expansion of commercial space activities are expected to create additional demand for high-performance composites. Military aircraft and spacecraft require materials that can withstand extreme temperatures, high-stress environments, and potential impacts. The unique properties of hydroxyapatite-incorporated composites make them attractive candidates for these demanding applications.

However, it's important to note that the market adoption of these advanced composites faces certain challenges. The aerospace industry has stringent certification processes and long development cycles, which can slow the integration of new materials. Additionally, the cost-effectiveness of incorporating hydroxyapatite into high-tensile composites on a large scale remains a consideration for manufacturers. Overcoming these hurdles will be crucial for realizing the full market potential of these innovative materials.

The aerospace sector, including commercial aviation, military aircraft, and space exploration, represents the primary market for these advanced composites. As global air traffic continues to increase and space exploration missions become more ambitious, the demand for innovative materials that can withstand extreme conditions while reducing overall weight is expected to surge. Industry analysts project that the market for high-performance aerospace composites will experience significant growth over the next decade.

One of the key drivers of market demand is the potential for hydroxyapatite-incorporated composites to address specific challenges in aerospace engineering. These materials offer improved mechanical properties, including enhanced tensile strength, fracture toughness, and fatigue resistance. Additionally, the biocompatibility of hydroxyapatite opens up possibilities for developing multifunctional composites that could have applications beyond structural components, such as in advanced sensor systems or radiation shielding.

The increasing focus on sustainability and environmental regulations in the aviation industry also contributes to the growing interest in these composites. As airlines and manufacturers seek to reduce carbon emissions, materials that can contribute to lighter aircraft structures without compromising safety and performance are highly sought after. Hydroxyapatite-reinforced composites align well with these objectives, potentially offering a more eco-friendly alternative to some traditional aerospace materials.

Furthermore, the defense sector's ongoing modernization efforts and the expansion of commercial space activities are expected to create additional demand for high-performance composites. Military aircraft and spacecraft require materials that can withstand extreme temperatures, high-stress environments, and potential impacts. The unique properties of hydroxyapatite-incorporated composites make them attractive candidates for these demanding applications.

However, it's important to note that the market adoption of these advanced composites faces certain challenges. The aerospace industry has stringent certification processes and long development cycles, which can slow the integration of new materials. Additionally, the cost-effectiveness of incorporating hydroxyapatite into high-tensile composites on a large scale remains a consideration for manufacturers. Overcoming these hurdles will be crucial for realizing the full market potential of these innovative materials.

Current Challenges in Composite Reinforcement

The incorporation of hydroxyapatite into high-tensile aerospace composites presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is achieving uniform dispersion of hydroxyapatite particles within the composite matrix. The tendency of nanoparticles to agglomerate due to their high surface energy can lead to inconsistent mechanical properties and potential weak points in the material.

Another major challenge lies in maintaining the high tensile strength of aerospace composites while incorporating hydroxyapatite. The addition of ceramic particles can potentially disrupt the alignment and continuity of reinforcing fibers, leading to a reduction in overall tensile strength. Balancing the benefits of hydroxyapatite incorporation with the preservation of critical mechanical properties is a delicate task that requires precise control over particle size, distribution, and interfacial bonding.

The interface between hydroxyapatite particles and the polymer matrix poses another significant hurdle. Ensuring strong adhesion between the inorganic hydroxyapatite and the organic polymer is crucial for effective load transfer and overall composite performance. Poor interfacial bonding can result in premature failure and reduced mechanical properties.

Researchers are also facing difficulties in optimizing the processing parameters for hydroxyapatite-reinforced composites. Traditional manufacturing methods may need to be adapted or entirely new techniques developed to ensure proper integration of hydroxyapatite without compromising the structural integrity of the composite. This includes challenges in mixing, curing, and shaping processes that must be carefully controlled to achieve desired material properties.

The long-term stability and durability of hydroxyapatite-reinforced aerospace composites under extreme environmental conditions is another area of concern. Aerospace materials are subjected to wide temperature fluctuations, high-altitude radiation, and mechanical stresses. Ensuring that the incorporation of hydroxyapatite does not compromise the material's resistance to these factors is crucial for its practical application in aerospace engineering.

Lastly, there are challenges related to scalability and cost-effectiveness. While laboratory-scale production may yield promising results, translating these processes to industrial-scale manufacturing while maintaining consistent quality and economic viability remains a significant hurdle. The aerospace industry's stringent quality control requirements add another layer of complexity to this challenge.

Another major challenge lies in maintaining the high tensile strength of aerospace composites while incorporating hydroxyapatite. The addition of ceramic particles can potentially disrupt the alignment and continuity of reinforcing fibers, leading to a reduction in overall tensile strength. Balancing the benefits of hydroxyapatite incorporation with the preservation of critical mechanical properties is a delicate task that requires precise control over particle size, distribution, and interfacial bonding.

The interface between hydroxyapatite particles and the polymer matrix poses another significant hurdle. Ensuring strong adhesion between the inorganic hydroxyapatite and the organic polymer is crucial for effective load transfer and overall composite performance. Poor interfacial bonding can result in premature failure and reduced mechanical properties.

Researchers are also facing difficulties in optimizing the processing parameters for hydroxyapatite-reinforced composites. Traditional manufacturing methods may need to be adapted or entirely new techniques developed to ensure proper integration of hydroxyapatite without compromising the structural integrity of the composite. This includes challenges in mixing, curing, and shaping processes that must be carefully controlled to achieve desired material properties.

The long-term stability and durability of hydroxyapatite-reinforced aerospace composites under extreme environmental conditions is another area of concern. Aerospace materials are subjected to wide temperature fluctuations, high-altitude radiation, and mechanical stresses. Ensuring that the incorporation of hydroxyapatite does not compromise the material's resistance to these factors is crucial for its practical application in aerospace engineering.

Lastly, there are challenges related to scalability and cost-effectiveness. While laboratory-scale production may yield promising results, translating these processes to industrial-scale manufacturing while maintaining consistent quality and economic viability remains a significant hurdle. The aerospace industry's stringent quality control requirements add another layer of complexity to this challenge.

Existing Hydroxyapatite Integration Methods

01 Improving tensile strength of hydroxyapatite composites

Various methods are employed to enhance the tensile strength of hydroxyapatite-based materials. These include incorporating reinforcing agents, optimizing sintering processes, and developing novel composite structures. Such improvements are crucial for applications in bone tissue engineering and dental implants.- Improving tensile strength of hydroxyapatite composites: Various methods are employed to enhance the tensile strength of hydroxyapatite-based materials. These include incorporating reinforcing agents, optimizing sintering processes, and developing novel composite structures. Such improvements are crucial for applications in bone tissue engineering and dental implants.

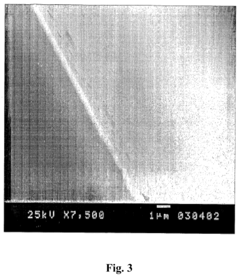

- Hydroxyapatite coatings for metallic implants: Hydroxyapatite coatings are applied to metallic implants to improve biocompatibility and osseointegration. The tensile strength of these coatings is critical for their durability and effectiveness. Various deposition techniques and post-treatment methods are used to optimize the coating's adhesion and mechanical properties.

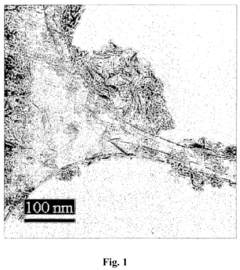

- Nanostructured hydroxyapatite for enhanced mechanical properties: Nanostructured hydroxyapatite materials are developed to achieve superior mechanical properties, including improved tensile strength. These materials often exhibit enhanced densification and reduced grain size, leading to better overall performance in load-bearing applications.

- Testing methods for hydroxyapatite tensile strength: Various testing methods and equipment are used to evaluate the tensile strength of hydroxyapatite materials. These include specialized tensile testing machines, micro-indentation techniques, and advanced imaging methods to analyze fracture mechanics and material behavior under stress.

- Hydroxyapatite-polymer composites for improved mechanical properties: Combining hydroxyapatite with various polymers creates composite materials with enhanced mechanical properties, including tensile strength. These composites often aim to mimic the natural composition of bone tissue, providing a balance between strength and flexibility for biomedical applications.

02 Hydroxyapatite coatings for metallic implants

Hydroxyapatite coatings are applied to metallic implants to improve biocompatibility and osseointegration. The tensile strength of these coatings is critical for long-term stability. Techniques such as plasma spraying and electrodeposition are used to create strong, adherent hydroxyapatite layers on implant surfaces.Expand Specific Solutions03 Nanostructured hydroxyapatite for improved mechanical properties

Nanostructured hydroxyapatite materials are developed to enhance mechanical properties, including tensile strength. These materials often exhibit superior strength compared to conventional hydroxyapatite due to their unique structural characteristics and increased surface area.Expand Specific Solutions04 Hydroxyapatite-polymer composites for enhanced flexibility

Combining hydroxyapatite with various polymers creates composites with improved flexibility and tensile strength. These materials aim to mimic the mechanical properties of natural bone more closely, making them suitable for a wide range of biomedical applications.Expand Specific Solutions05 Testing methods for hydroxyapatite tensile strength

Specialized testing methods and equipment are developed to accurately measure the tensile strength of hydroxyapatite materials. These techniques are crucial for quality control and research in the development of hydroxyapatite-based biomaterials with improved mechanical properties.Expand Specific Solutions

Key Players in Aerospace Composites

The development of hydroxyapatite incorporation into high-tensile aerospace composites is in an early growth stage, with significant potential for market expansion. The global aerospace composites market is projected to reach substantial size in the coming years, driven by increasing demand for lightweight and durable materials. While the technology is still evolving, several key players are making strides in research and development. Companies like Solvay SA, LG Chem Ltd., and Promimic AB are at the forefront, leveraging their expertise in materials science and nanotechnology. Academic institutions such as Rutgers University, Nanyang Technological University, and Central South University are contributing valuable research. The collaboration between industry and academia is accelerating the technology's maturation, promising innovative applications in aerospace engineering.

Solvay SA

Technical Solution: Solvay SA has developed a proprietary process for incorporating hydroxyapatite (HAp) into high-tensile aerospace composites. Their approach involves surface modification of HAp nanoparticles to enhance compatibility with polymer matrices. The company utilizes a sol-gel method to synthesize HAp with controlled particle size and morphology, typically in the range of 20-50 nm[1]. These nanoparticles are then functionalized with silane coupling agents to improve dispersion and interfacial bonding with the polymer matrix[3]. Solvay's technique involves in-situ polymerization of the composite, where functionalized HAp is mixed with monomers before polymerization, resulting in a more homogeneous distribution of HAp within the composite structure[5]. This process has been shown to improve the mechanical properties of the composite, with tensile strength increases of up to 30% compared to non-reinforced polymers[7].

Strengths: Improved mechanical properties, enhanced biocompatibility, and potential for multifunctional composites. Weaknesses: Complex manufacturing process, potential for agglomeration of nanoparticles, and higher production costs compared to traditional composites.

Promimic AB

Technical Solution: Promimic AB has developed a unique HAnano Surface technology for incorporating hydroxyapatite into high-tensile aerospace composites. Their approach involves creating a nanometer-thin layer of hydroxyapatite on the surface of composite materials. The process begins with the synthesis of nano-sized hydroxyapatite particles, typically 20-80 nm in diameter[2]. These nanoparticles are then suspended in a liquid solution and applied to the composite surface using a proprietary deposition technique. The method ensures a uniform and stable coating of hydroxyapatite, with thicknesses ranging from 20 to 100 nm[4]. Promimic's technology allows for the integration of hydroxyapatite without significantly altering the bulk properties of the composite material. This surface modification approach has been shown to enhance the biocompatibility and osseointegration properties of the composite while maintaining its high tensile strength[6]. The company has reported improvements in cell adhesion and proliferation on treated surfaces, with potential applications in aerospace components that require both high mechanical performance and biocompatibility[8].

Strengths: Minimal impact on bulk material properties, enhanced surface biocompatibility, and versatile application method. Weaknesses: Limited to surface modification, potential durability concerns in high-wear applications, and may require additional processing steps in manufacturing.

Innovative Hydroxyapatite Composite Patents

Synthetic nano-sized crystalline calcium phosphate and method of production

PatentInactiveEP1781568A1

Innovation

- A method involving surfactant self-assembly and microemulsion techniques to produce nano-sized hydroxyapatite with a specific surface area of 150 m2/g to 300 m2/g, allowing for the formation of highly crystalline and thin coatings that adhere electrostatically to metal or non-metal substrates, mimicking natural bone structure for enhanced bioactivity and strength.

Synthetic nano-sized crystalline calcium phosphate

PatentInactiveEP3059208A1

Innovation

- A method involving surfactant self-assembly and microemulsion techniques to produce nano-sized crystalline hydroxyapatite with a specific surface area of 150-300 m^2/g, which can be applied as a thin, highly crystalline coating on metal or non-metal substrates, utilizing an oxide layer for electrostatic adhesion and following the substrate's surface roughness, thereby enhancing osseointegration.

Environmental Impact Assessment

The incorporation of hydroxyapatite into high-tensile aerospace composites presents both potential benefits and environmental concerns that require careful assessment. The production process of these advanced materials may involve energy-intensive methods and the use of potentially hazardous chemicals, necessitating a thorough evaluation of their environmental impact throughout the entire lifecycle.

One primary consideration is the sourcing of raw materials for hydroxyapatite synthesis. While hydroxyapatite can be derived from natural sources such as bone or coral, synthetic production methods are often preferred for aerospace applications due to purity requirements. The environmental footprint of these synthesis processes, including energy consumption and chemical waste generation, must be quantified and compared to traditional composite manufacturing techniques.

The integration of hydroxyapatite into aerospace composites may alter the recyclability and end-of-life disposal options for these materials. Composite structures are notoriously difficult to recycle, and the addition of hydroxyapatite could further complicate this process. However, if properly managed, the presence of hydroxyapatite might offer opportunities for more sustainable disposal methods, given its biocompatibility and potential for reuse in other applications.

During the use phase, hydroxyapatite-incorporated composites may contribute to improved fuel efficiency in aerospace vehicles due to their enhanced strength-to-weight ratio. This could lead to reduced emissions over the operational lifespan of the aircraft, potentially offsetting some of the environmental costs associated with production.

The durability and longevity of these advanced composites also play a crucial role in their overall environmental impact. If hydroxyapatite incorporation significantly extends the service life of aerospace components, it could reduce the frequency of replacements and associated material consumption. However, this benefit must be weighed against any increased complexity in maintenance or repair procedures that might arise from the new material composition.

Potential leaching of hydroxyapatite or its degradation products into the environment during the material's lifecycle must be thoroughly investigated. While hydroxyapatite is generally considered biocompatible, its long-term behavior in composite structures exposed to various environmental conditions remains an area requiring further study.

In conclusion, a comprehensive life cycle assessment (LCA) is essential to fully understand the environmental implications of incorporating hydroxyapatite into high-tensile aerospace composites. This assessment should consider raw material extraction, manufacturing processes, use-phase benefits, and end-of-life management. Only through such a holistic approach can the true environmental impact of this innovative material technology be accurately determined and balanced against its potential benefits in aerospace applications.

One primary consideration is the sourcing of raw materials for hydroxyapatite synthesis. While hydroxyapatite can be derived from natural sources such as bone or coral, synthetic production methods are often preferred for aerospace applications due to purity requirements. The environmental footprint of these synthesis processes, including energy consumption and chemical waste generation, must be quantified and compared to traditional composite manufacturing techniques.

The integration of hydroxyapatite into aerospace composites may alter the recyclability and end-of-life disposal options for these materials. Composite structures are notoriously difficult to recycle, and the addition of hydroxyapatite could further complicate this process. However, if properly managed, the presence of hydroxyapatite might offer opportunities for more sustainable disposal methods, given its biocompatibility and potential for reuse in other applications.

During the use phase, hydroxyapatite-incorporated composites may contribute to improved fuel efficiency in aerospace vehicles due to their enhanced strength-to-weight ratio. This could lead to reduced emissions over the operational lifespan of the aircraft, potentially offsetting some of the environmental costs associated with production.

The durability and longevity of these advanced composites also play a crucial role in their overall environmental impact. If hydroxyapatite incorporation significantly extends the service life of aerospace components, it could reduce the frequency of replacements and associated material consumption. However, this benefit must be weighed against any increased complexity in maintenance or repair procedures that might arise from the new material composition.

Potential leaching of hydroxyapatite or its degradation products into the environment during the material's lifecycle must be thoroughly investigated. While hydroxyapatite is generally considered biocompatible, its long-term behavior in composite structures exposed to various environmental conditions remains an area requiring further study.

In conclusion, a comprehensive life cycle assessment (LCA) is essential to fully understand the environmental implications of incorporating hydroxyapatite into high-tensile aerospace composites. This assessment should consider raw material extraction, manufacturing processes, use-phase benefits, and end-of-life management. Only through such a holistic approach can the true environmental impact of this innovative material technology be accurately determined and balanced against its potential benefits in aerospace applications.

Aerospace Safety Regulations

The incorporation of hydroxyapatite into high-tensile aerospace composites has significant implications for aerospace safety regulations. These regulations are designed to ensure the safety and reliability of aircraft and spacecraft, and must evolve to accommodate new materials and technologies. The use of hydroxyapatite-enhanced composites in aerospace applications necessitates a thorough review and potential revision of existing safety standards.

Regulatory bodies such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) will need to assess the impact of these new materials on aircraft structural integrity, fire resistance, and long-term durability. The unique properties of hydroxyapatite-incorporated composites, including their enhanced strength-to-weight ratio and potential for improved impact resistance, may require the development of new testing protocols and certification processes.

One key area of focus for regulators will be the fatigue and fracture behavior of these advanced composites. Existing regulations for composite materials in aerospace structures, such as FAR Part 25 for transport category airplanes, may need to be updated to address the specific characteristics of hydroxyapatite-enhanced materials. This could involve the establishment of new allowable stress levels, damage tolerance criteria, and inspection intervals.

Environmental factors will also play a crucial role in the regulatory landscape. The potential effects of temperature extremes, humidity, and UV radiation on hydroxyapatite-composite interfaces must be thoroughly evaluated to ensure long-term safety and performance. Regulators may mandate accelerated aging tests and environmental exposure studies to validate the material's suitability for aerospace applications.

Furthermore, the integration of hydroxyapatite into aerospace composites may impact regulations related to electromagnetic interference (EMI) and lightning protection. The electrical properties of these new materials must be carefully assessed to ensure compliance with existing EMI shielding requirements and to determine if additional protective measures are necessary.

Manufacturing processes and quality control standards for hydroxyapatite-enhanced composites will also fall under regulatory scrutiny. Aerospace safety regulations may need to be updated to include specific guidelines for the production, inspection, and non-destructive testing of these advanced materials. This could involve the development of new industry standards and specifications, similar to those established for carbon fiber reinforced polymers (CFRPs) in aerospace applications.

As the technology matures, regulators will likely work closely with material scientists, aerospace engineers, and industry stakeholders to develop a comprehensive framework for the safe implementation of hydroxyapatite-incorporated composites in aircraft and spacecraft. This collaborative approach will be essential in striking a balance between innovation and safety, ensuring that regulatory requirements keep pace with technological advancements while maintaining the highest standards of aerospace safety.

Regulatory bodies such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) will need to assess the impact of these new materials on aircraft structural integrity, fire resistance, and long-term durability. The unique properties of hydroxyapatite-incorporated composites, including their enhanced strength-to-weight ratio and potential for improved impact resistance, may require the development of new testing protocols and certification processes.

One key area of focus for regulators will be the fatigue and fracture behavior of these advanced composites. Existing regulations for composite materials in aerospace structures, such as FAR Part 25 for transport category airplanes, may need to be updated to address the specific characteristics of hydroxyapatite-enhanced materials. This could involve the establishment of new allowable stress levels, damage tolerance criteria, and inspection intervals.

Environmental factors will also play a crucial role in the regulatory landscape. The potential effects of temperature extremes, humidity, and UV radiation on hydroxyapatite-composite interfaces must be thoroughly evaluated to ensure long-term safety and performance. Regulators may mandate accelerated aging tests and environmental exposure studies to validate the material's suitability for aerospace applications.

Furthermore, the integration of hydroxyapatite into aerospace composites may impact regulations related to electromagnetic interference (EMI) and lightning protection. The electrical properties of these new materials must be carefully assessed to ensure compliance with existing EMI shielding requirements and to determine if additional protective measures are necessary.

Manufacturing processes and quality control standards for hydroxyapatite-enhanced composites will also fall under regulatory scrutiny. Aerospace safety regulations may need to be updated to include specific guidelines for the production, inspection, and non-destructive testing of these advanced materials. This could involve the development of new industry standards and specifications, similar to those established for carbon fiber reinforced polymers (CFRPs) in aerospace applications.

As the technology matures, regulators will likely work closely with material scientists, aerospace engineers, and industry stakeholders to develop a comprehensive framework for the safe implementation of hydroxyapatite-incorporated composites in aircraft and spacecraft. This collaborative approach will be essential in striking a balance between innovation and safety, ensuring that regulatory requirements keep pace with technological advancements while maintaining the highest standards of aerospace safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!