How Laminar Flow Enhances Smart Manufacturing Operations?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow in Manufacturing: Background and Objectives

Laminar flow, a fundamental concept in fluid dynamics, has emerged as a critical factor in enhancing smart manufacturing operations. This phenomenon, characterized by smooth and predictable fluid motion, has a rich history dating back to the early 20th century when scientists first began to understand and quantify fluid behavior. The evolution of laminar flow applications in manufacturing has been closely tied to advancements in materials science, process engineering, and automation technologies.

In recent years, the integration of laminar flow principles into smart manufacturing processes has gained significant traction. This integration is driven by the increasing demand for precision, efficiency, and quality in modern industrial production. The primary objective of leveraging laminar flow in smart manufacturing is to optimize fluid-based processes, ranging from coating and painting to chemical reactions and 3D printing.

The technological trajectory of laminar flow applications in manufacturing has been marked by several key milestones. Initially, the focus was on understanding and controlling laminar flow in simple systems. As computational fluid dynamics (CFD) and advanced sensing technologies developed, manufacturers gained the ability to model and manipulate laminar flow in complex industrial settings. This progress has led to the current era, where real-time monitoring and adaptive control of laminar flow conditions are becoming integral to smart manufacturing systems.

The adoption of laminar flow principles in smart manufacturing aims to address several critical challenges. These include reducing material waste, improving product uniformity, enhancing energy efficiency, and minimizing environmental impact. By precisely controlling fluid behavior, manufacturers can achieve unprecedented levels of process control, leading to higher quality products and more sustainable operations.

Looking forward, the integration of laminar flow with emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) presents exciting possibilities for further advancements in smart manufacturing. These technologies promise to enable predictive maintenance, autonomous process optimization, and even more sophisticated fluid control strategies.

As we explore the potential of laminar flow in smart manufacturing, it is essential to consider both the technological and economic implications. The successful implementation of laminar flow principles can lead to significant competitive advantages, including reduced production costs, improved product quality, and increased manufacturing flexibility. However, it also requires substantial investment in research, equipment, and workforce training.

In recent years, the integration of laminar flow principles into smart manufacturing processes has gained significant traction. This integration is driven by the increasing demand for precision, efficiency, and quality in modern industrial production. The primary objective of leveraging laminar flow in smart manufacturing is to optimize fluid-based processes, ranging from coating and painting to chemical reactions and 3D printing.

The technological trajectory of laminar flow applications in manufacturing has been marked by several key milestones. Initially, the focus was on understanding and controlling laminar flow in simple systems. As computational fluid dynamics (CFD) and advanced sensing technologies developed, manufacturers gained the ability to model and manipulate laminar flow in complex industrial settings. This progress has led to the current era, where real-time monitoring and adaptive control of laminar flow conditions are becoming integral to smart manufacturing systems.

The adoption of laminar flow principles in smart manufacturing aims to address several critical challenges. These include reducing material waste, improving product uniformity, enhancing energy efficiency, and minimizing environmental impact. By precisely controlling fluid behavior, manufacturers can achieve unprecedented levels of process control, leading to higher quality products and more sustainable operations.

Looking forward, the integration of laminar flow with emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) presents exciting possibilities for further advancements in smart manufacturing. These technologies promise to enable predictive maintenance, autonomous process optimization, and even more sophisticated fluid control strategies.

As we explore the potential of laminar flow in smart manufacturing, it is essential to consider both the technological and economic implications. The successful implementation of laminar flow principles can lead to significant competitive advantages, including reduced production costs, improved product quality, and increased manufacturing flexibility. However, it also requires substantial investment in research, equipment, and workforce training.

Market Demand for Smart Manufacturing Solutions

The demand for smart manufacturing solutions has been steadily increasing as industries seek to optimize their operations, reduce costs, and improve product quality. Laminar flow technology, a key component in smart manufacturing, has gained significant traction due to its ability to enhance precision, efficiency, and cleanliness in various manufacturing processes.

Market research indicates that the global smart manufacturing market is experiencing robust growth, driven by the adoption of Industry 4.0 technologies and the increasing need for automation. The integration of laminar flow systems into smart manufacturing operations has become a crucial factor in meeting the rising demand for high-quality products across industries such as pharmaceuticals, electronics, and aerospace.

In the pharmaceutical sector, laminar flow technology is essential for maintaining sterile environments during drug production and packaging. The stringent regulatory requirements and the need for contamination-free manufacturing processes have led to a surge in demand for advanced laminar flow solutions. This trend is expected to continue as pharmaceutical companies invest in upgrading their facilities to meet evolving quality standards and increase production efficiency.

The electronics industry has also witnessed a growing demand for laminar flow technology in smart manufacturing. As electronic components become smaller and more complex, the need for precision and cleanliness in manufacturing processes has intensified. Laminar flow systems play a crucial role in creating controlled environments for sensitive operations such as semiconductor fabrication and assembly of delicate electronic devices.

Aerospace manufacturing is another sector driving the demand for laminar flow solutions in smart manufacturing. The industry's requirements for high-precision manufacturing and stringent quality control have led to increased adoption of laminar flow technology in production facilities. This trend is particularly evident in the manufacturing of aircraft components and advanced materials, where even minor contamination can have significant consequences.

The market demand for smart manufacturing solutions incorporating laminar flow technology is further fueled by the growing emphasis on sustainability and energy efficiency. Laminar flow systems contribute to reduced energy consumption and waste generation in manufacturing processes, aligning with the global push for more environmentally friendly industrial practices.

As industries continue to embrace digital transformation and seek ways to improve their manufacturing capabilities, the demand for smart manufacturing solutions leveraging laminar flow technology is expected to grow. This trend is likely to drive innovation in laminar flow systems, leading to more advanced and integrated solutions that can address the evolving needs of modern manufacturing environments.

Market research indicates that the global smart manufacturing market is experiencing robust growth, driven by the adoption of Industry 4.0 technologies and the increasing need for automation. The integration of laminar flow systems into smart manufacturing operations has become a crucial factor in meeting the rising demand for high-quality products across industries such as pharmaceuticals, electronics, and aerospace.

In the pharmaceutical sector, laminar flow technology is essential for maintaining sterile environments during drug production and packaging. The stringent regulatory requirements and the need for contamination-free manufacturing processes have led to a surge in demand for advanced laminar flow solutions. This trend is expected to continue as pharmaceutical companies invest in upgrading their facilities to meet evolving quality standards and increase production efficiency.

The electronics industry has also witnessed a growing demand for laminar flow technology in smart manufacturing. As electronic components become smaller and more complex, the need for precision and cleanliness in manufacturing processes has intensified. Laminar flow systems play a crucial role in creating controlled environments for sensitive operations such as semiconductor fabrication and assembly of delicate electronic devices.

Aerospace manufacturing is another sector driving the demand for laminar flow solutions in smart manufacturing. The industry's requirements for high-precision manufacturing and stringent quality control have led to increased adoption of laminar flow technology in production facilities. This trend is particularly evident in the manufacturing of aircraft components and advanced materials, where even minor contamination can have significant consequences.

The market demand for smart manufacturing solutions incorporating laminar flow technology is further fueled by the growing emphasis on sustainability and energy efficiency. Laminar flow systems contribute to reduced energy consumption and waste generation in manufacturing processes, aligning with the global push for more environmentally friendly industrial practices.

As industries continue to embrace digital transformation and seek ways to improve their manufacturing capabilities, the demand for smart manufacturing solutions leveraging laminar flow technology is expected to grow. This trend is likely to drive innovation in laminar flow systems, leading to more advanced and integrated solutions that can address the evolving needs of modern manufacturing environments.

Current State and Challenges of Laminar Flow Implementation

Laminar flow technology has gained significant traction in smart manufacturing operations, yet its implementation faces several challenges. Currently, many industries are adopting laminar flow systems to enhance production efficiency and product quality. These systems are particularly prevalent in cleanroom environments, semiconductor manufacturing, and pharmaceutical production.

The primary advantage of laminar flow in smart manufacturing lies in its ability to maintain a controlled environment by minimizing turbulence and contamination. This is crucial for processes that require high precision and cleanliness. However, the widespread implementation of laminar flow technology is hindered by several factors.

One major challenge is the high initial cost of installing and maintaining laminar flow systems. The equipment, including HEPA filters, air handling units, and specialized enclosures, requires substantial investment. Additionally, ongoing maintenance and energy costs can be significant, making it difficult for smaller manufacturers to adopt this technology.

Another obstacle is the complexity of integrating laminar flow systems with existing manufacturing processes. Many facilities require extensive modifications to accommodate these systems, which can lead to production downtime and logistical challenges. The need for specialized training for operators and maintenance personnel further complicates implementation.

The effectiveness of laminar flow systems is highly dependent on proper design and operation. Achieving and maintaining optimal flow conditions across diverse manufacturing environments can be technically challenging. Factors such as equipment layout, personnel movement, and process heat generation can disrupt laminar flow, reducing its efficacy.

Regulatory compliance presents another hurdle, particularly in industries like pharmaceuticals and electronics. Stringent standards for air quality and particle control necessitate rigorous monitoring and documentation, adding to the operational complexity of laminar flow systems.

The scalability of laminar flow technology in large manufacturing facilities is also a significant challenge. As production areas increase in size, maintaining consistent laminar flow becomes more difficult and energy-intensive. This limitation can restrict the application of the technology in certain large-scale manufacturing operations.

Despite these challenges, ongoing research and development are addressing many of these issues. Innovations in energy-efficient designs, modular systems, and advanced control algorithms are making laminar flow technology more accessible and adaptable to various manufacturing environments. The integration of IoT and AI technologies is also enhancing the monitoring and optimization of laminar flow systems, contributing to their effectiveness in smart manufacturing operations.

The primary advantage of laminar flow in smart manufacturing lies in its ability to maintain a controlled environment by minimizing turbulence and contamination. This is crucial for processes that require high precision and cleanliness. However, the widespread implementation of laminar flow technology is hindered by several factors.

One major challenge is the high initial cost of installing and maintaining laminar flow systems. The equipment, including HEPA filters, air handling units, and specialized enclosures, requires substantial investment. Additionally, ongoing maintenance and energy costs can be significant, making it difficult for smaller manufacturers to adopt this technology.

Another obstacle is the complexity of integrating laminar flow systems with existing manufacturing processes. Many facilities require extensive modifications to accommodate these systems, which can lead to production downtime and logistical challenges. The need for specialized training for operators and maintenance personnel further complicates implementation.

The effectiveness of laminar flow systems is highly dependent on proper design and operation. Achieving and maintaining optimal flow conditions across diverse manufacturing environments can be technically challenging. Factors such as equipment layout, personnel movement, and process heat generation can disrupt laminar flow, reducing its efficacy.

Regulatory compliance presents another hurdle, particularly in industries like pharmaceuticals and electronics. Stringent standards for air quality and particle control necessitate rigorous monitoring and documentation, adding to the operational complexity of laminar flow systems.

The scalability of laminar flow technology in large manufacturing facilities is also a significant challenge. As production areas increase in size, maintaining consistent laminar flow becomes more difficult and energy-intensive. This limitation can restrict the application of the technology in certain large-scale manufacturing operations.

Despite these challenges, ongoing research and development are addressing many of these issues. Innovations in energy-efficient designs, modular systems, and advanced control algorithms are making laminar flow technology more accessible and adaptable to various manufacturing environments. The integration of IoT and AI technologies is also enhancing the monitoring and optimization of laminar flow systems, contributing to their effectiveness in smart manufacturing operations.

Existing Laminar Flow Solutions for Smart Manufacturing

01 Flow control devices for laminar flow enhancement

Various flow control devices are used to enhance laminar flow in fluid systems. These devices include specialized nozzles, valves, and flow straighteners that help to reduce turbulence and promote smooth, parallel fluid motion. By carefully designing and implementing these components, engineers can achieve more efficient and controlled fluid flow in various applications.- Flow control devices for laminar flow enhancement: Various flow control devices are used to enhance laminar flow in fluid systems. These devices include specialized nozzles, valves, and flow straighteners that help to reduce turbulence and promote smooth, parallel fluid motion. By carefully designing and implementing these components, engineers can achieve more efficient and controlled fluid flow in various applications.

- Surface modifications for laminar flow: Modifying surface characteristics of fluid-containing structures can significantly enhance laminar flow. This includes creating micro-textures, applying specialized coatings, or altering the geometry of flow channels. These modifications help to reduce friction and turbulence at the fluid-surface interface, promoting smoother and more laminar flow conditions.

- Measurement and analysis techniques for laminar flow: Advanced measurement and analysis techniques are crucial for understanding and optimizing laminar flow. This includes the use of flow meters, sensors, and imaging technologies to accurately measure flow characteristics. Data analysis and computational fluid dynamics (CFD) simulations are also employed to predict and enhance laminar flow behavior in various systems.

- Laminar flow enhancement in specific applications: Laminar flow enhancement techniques are tailored for specific applications such as aerodynamics, hydrodynamics, and microfluidics. This involves designing specialized structures, channels, or vessels that promote laminar flow conditions. Examples include streamlined vehicle bodies, optimized pipe systems, and microfluidic devices for precise fluid control in laboratory settings.

- Environmental control for laminar flow: Controlling environmental factors is essential for maintaining laminar flow conditions. This includes managing temperature, pressure, and humidity in the flow system. Specialized equipment such as clean rooms, pressure regulators, and temperature control systems are used to create and maintain optimal conditions for laminar flow in various industrial and research applications.

02 Surface modifications for laminar flow

Modifying surface characteristics of fluid-containing structures can significantly enhance laminar flow. This includes creating micro-textures, applying specialized coatings, or altering the geometry of flow channels. These modifications help to reduce friction and turbulence at the fluid-surface interface, promoting smoother and more laminar flow patterns.Expand Specific Solutions03 Measurement and analysis techniques for laminar flow

Advanced measurement and analysis techniques are crucial for understanding and optimizing laminar flow. This includes the use of flow meters, pressure sensors, and visualization methods to accurately characterize flow patterns. Data analysis and computational fluid dynamics (CFD) simulations are also employed to predict and improve laminar flow behavior in various systems.Expand Specific Solutions04 Laminar flow enhancement in specific applications

Laminar flow enhancement techniques are tailored for specific applications such as aerodynamics, hydrodynamics, and microfluidics. This involves designing specialized components and systems that take into account the unique requirements of each field. For example, in aeronautics, wing and fuselage designs are optimized to maintain laminar flow and reduce drag.Expand Specific Solutions05 Environmental control for laminar flow

Controlling environmental factors is essential for maintaining laminar flow conditions. This includes managing temperature, pressure, and humidity in the flow system. Additionally, vibration isolation and acoustic damping techniques are employed to minimize external disturbances that could disrupt laminar flow patterns.Expand Specific Solutions

Key Players in Smart Manufacturing and Fluid Dynamics

The laminar flow technology in smart manufacturing is in a growth phase, with increasing market size and evolving technical maturity. The global market for laminar flow solutions in manufacturing is expanding, driven by the demand for precision and efficiency in production processes. Companies like Robert Bosch GmbH, KUKA Systems GmbH, and Taiwan Semiconductor Manufacturing Co., Ltd. are at the forefront of implementing laminar flow technologies in their smart manufacturing operations. These industry leaders are continuously refining the technology, improving its application in various manufacturing scenarios, and integrating it with other advanced technologies like IoT and AI to enhance overall production efficiency and quality control.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced laminar flow control systems for smart manufacturing operations. Their technology utilizes precise sensors and actuators to maintain optimal laminar flow conditions in production environments. This includes adaptive air flow management systems that adjust in real-time based on production needs and environmental factors. Bosch's solution integrates with their Industry 4.0 platforms, allowing for data-driven optimization of laminar flow parameters across the manufacturing process[1][3]. The system employs machine learning algorithms to predict and prevent turbulence, ensuring consistent product quality and reducing contamination risks.

Strengths: Seamless integration with existing Industry 4.0 systems, real-time adaptive control, and predictive maintenance capabilities. Weaknesses: High initial implementation cost and potential complexity for smaller manufacturing operations.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has implemented cutting-edge laminar flow technologies in their semiconductor fabrication facilities. Their approach focuses on ultra-clean environments crucial for nanoscale chip production. TSMC's laminar flow systems incorporate advanced HEPA filtration and precise airflow control to maintain Class 1 cleanroom conditions[2]. They have developed proprietary software that monitors and adjusts airflow patterns in real-time, optimizing particle control and thermal management. TSMC's laminar flow enhancement also includes innovative cleanroom design with optimized layout and personnel flow to minimize disruptions to laminar airflow[4].

Strengths: Unparalleled cleanliness control for nanoscale manufacturing, energy-efficient designs, and seamless integration with automated manufacturing processes. Weaknesses: Extremely high implementation and maintenance costs, limited applicability outside of high-precision industries.

Core Innovations in Laminar Flow Control Systems

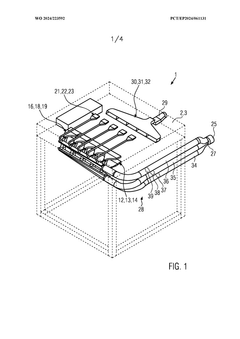

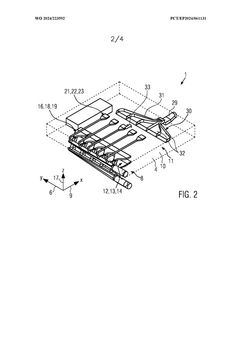

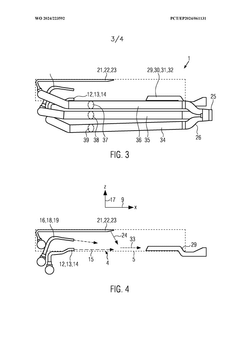

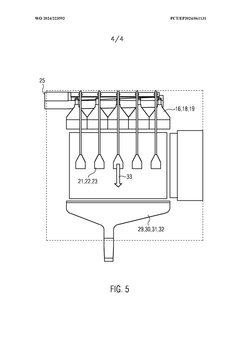

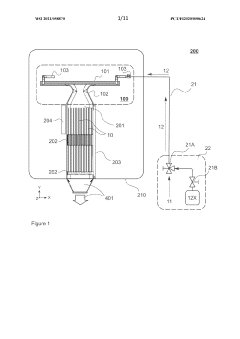

Device and method for the directed application of gas to a build space for additive manufacturing

PatentWO2024223592A1

Innovation

- A device with a unique nozzle configuration that generates a laminar gas flow by combining horizontal and vertical gas streams, ensuring a uniform and efficient gas distribution over the construction platform, reducing turbulence and enhancing energy input during the manufacturing process.

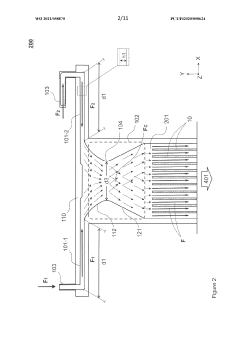

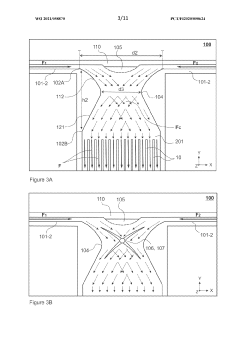

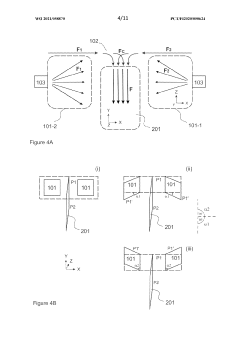

Fluid distributing device for a thin-film deposition apparatus, related apparatus and methods

PatentWO2021058870A1

Innovation

- A fluid distributing device with an expansion region and transition region is designed to establish laminar flow by directing fluid streams towards each other, combining them in a way that maintains laminar flow through the reaction chamber, preventing premature mixing of precursors and optimizing purging efficiency.

Energy Efficiency and Sustainability Impacts

Laminar flow technology in smart manufacturing operations significantly contributes to energy efficiency and sustainability. By optimizing fluid dynamics, laminar flow systems reduce energy consumption in various processes. These systems minimize turbulence and friction, leading to lower power requirements for pumps and fans. In precision manufacturing, laminar flow enables more accurate control of temperature and humidity, reducing the energy needed for environmental control.

The implementation of laminar flow in clean rooms and controlled environments results in substantial energy savings. Traditional turbulent air systems require higher air change rates to maintain cleanliness, whereas laminar flow systems can achieve the same level of cleanliness with lower air velocities and fewer air changes. This reduction in air movement translates directly to decreased energy consumption in HVAC systems, often resulting in 20-30% energy savings compared to conventional methods.

Laminar flow also enhances the efficiency of heat transfer processes in manufacturing. By promoting uniform fluid distribution and reducing mixing, these systems improve the effectiveness of heat exchangers and cooling systems. This optimization leads to reduced energy requirements for heating and cooling processes, contributing to overall energy efficiency in production facilities.

In terms of sustainability, laminar flow technology supports the reduction of waste and resource consumption. The precise control offered by laminar flow systems in coating and spraying applications minimizes overspray and material waste. This not only conserves raw materials but also reduces the energy required for material production and waste treatment. Additionally, the improved process control enabled by laminar flow can lead to fewer defects and rework, further conserving energy and resources.

The integration of laminar flow principles in smart manufacturing aligns with circular economy concepts. By enhancing process efficiency and reducing waste, these systems support the development of more sustainable production cycles. The technology's ability to optimize fluid and air management also contributes to water conservation efforts in manufacturing processes, addressing another critical aspect of sustainability.

As industries strive to meet increasingly stringent environmental regulations and sustainability goals, the adoption of laminar flow technology in smart manufacturing becomes increasingly relevant. Its potential to significantly reduce energy consumption, minimize waste, and improve resource utilization positions it as a key enabler of sustainable manufacturing practices in the future.

The implementation of laminar flow in clean rooms and controlled environments results in substantial energy savings. Traditional turbulent air systems require higher air change rates to maintain cleanliness, whereas laminar flow systems can achieve the same level of cleanliness with lower air velocities and fewer air changes. This reduction in air movement translates directly to decreased energy consumption in HVAC systems, often resulting in 20-30% energy savings compared to conventional methods.

Laminar flow also enhances the efficiency of heat transfer processes in manufacturing. By promoting uniform fluid distribution and reducing mixing, these systems improve the effectiveness of heat exchangers and cooling systems. This optimization leads to reduced energy requirements for heating and cooling processes, contributing to overall energy efficiency in production facilities.

In terms of sustainability, laminar flow technology supports the reduction of waste and resource consumption. The precise control offered by laminar flow systems in coating and spraying applications minimizes overspray and material waste. This not only conserves raw materials but also reduces the energy required for material production and waste treatment. Additionally, the improved process control enabled by laminar flow can lead to fewer defects and rework, further conserving energy and resources.

The integration of laminar flow principles in smart manufacturing aligns with circular economy concepts. By enhancing process efficiency and reducing waste, these systems support the development of more sustainable production cycles. The technology's ability to optimize fluid and air management also contributes to water conservation efforts in manufacturing processes, addressing another critical aspect of sustainability.

As industries strive to meet increasingly stringent environmental regulations and sustainability goals, the adoption of laminar flow technology in smart manufacturing becomes increasingly relevant. Its potential to significantly reduce energy consumption, minimize waste, and improve resource utilization positions it as a key enabler of sustainable manufacturing practices in the future.

Integration with Industry 4.0 Technologies

The integration of laminar flow technology with Industry 4.0 technologies represents a significant advancement in smart manufacturing operations. This synergy enhances production efficiency, quality control, and overall operational performance. Laminar flow, characterized by smooth and predictable fluid movement, aligns seamlessly with the principles of Industry 4.0, which emphasizes data-driven decision-making and interconnected systems.

One key area of integration is in the realm of Internet of Things (IoT) sensors. By incorporating IoT devices into laminar flow systems, manufacturers can continuously monitor and adjust flow parameters in real-time. This enables precise control over production environments, ensuring optimal conditions for sensitive processes such as semiconductor manufacturing or pharmaceutical production. The data collected from these sensors can be analyzed using advanced analytics and machine learning algorithms to predict maintenance needs and optimize flow patterns.

Artificial Intelligence (AI) and Machine Learning (ML) play crucial roles in leveraging laminar flow technology within Industry 4.0 frameworks. These technologies can analyze vast amounts of data from laminar flow systems to identify patterns, predict potential issues, and optimize flow characteristics. For instance, AI algorithms can adjust flow rates and compositions based on real-time production data, ensuring consistent product quality and reducing waste.

Digital Twin technology, another cornerstone of Industry 4.0, can be applied to laminar flow systems to create virtual replicas of physical production environments. These digital twins allow manufacturers to simulate and test various flow scenarios without disrupting actual production. This capability is particularly valuable for optimizing cleanroom designs, where laminar flow is critical for maintaining sterile conditions.

Augmented Reality (AR) and Virtual Reality (VR) technologies can enhance the visualization and management of laminar flow systems. Technicians can use AR overlays to view real-time flow data and system performance metrics, facilitating quicker troubleshooting and maintenance. VR simulations can be used for training purposes, allowing operators to practice managing laminar flow systems in a risk-free virtual environment.

The integration of laminar flow with Industry 4.0 technologies also extends to supply chain management. Advanced tracking systems can monitor the movement of materials and products through laminar flow-controlled environments, ensuring that quality standards are maintained throughout the production and distribution process. This level of traceability is particularly crucial in industries with stringent regulatory requirements, such as pharmaceuticals and food production.

One key area of integration is in the realm of Internet of Things (IoT) sensors. By incorporating IoT devices into laminar flow systems, manufacturers can continuously monitor and adjust flow parameters in real-time. This enables precise control over production environments, ensuring optimal conditions for sensitive processes such as semiconductor manufacturing or pharmaceutical production. The data collected from these sensors can be analyzed using advanced analytics and machine learning algorithms to predict maintenance needs and optimize flow patterns.

Artificial Intelligence (AI) and Machine Learning (ML) play crucial roles in leveraging laminar flow technology within Industry 4.0 frameworks. These technologies can analyze vast amounts of data from laminar flow systems to identify patterns, predict potential issues, and optimize flow characteristics. For instance, AI algorithms can adjust flow rates and compositions based on real-time production data, ensuring consistent product quality and reducing waste.

Digital Twin technology, another cornerstone of Industry 4.0, can be applied to laminar flow systems to create virtual replicas of physical production environments. These digital twins allow manufacturers to simulate and test various flow scenarios without disrupting actual production. This capability is particularly valuable for optimizing cleanroom designs, where laminar flow is critical for maintaining sterile conditions.

Augmented Reality (AR) and Virtual Reality (VR) technologies can enhance the visualization and management of laminar flow systems. Technicians can use AR overlays to view real-time flow data and system performance metrics, facilitating quicker troubleshooting and maintenance. VR simulations can be used for training purposes, allowing operators to practice managing laminar flow systems in a risk-free virtual environment.

The integration of laminar flow with Industry 4.0 technologies also extends to supply chain management. Advanced tracking systems can monitor the movement of materials and products through laminar flow-controlled environments, ensuring that quality standards are maintained throughout the production and distribution process. This level of traceability is particularly crucial in industries with stringent regulatory requirements, such as pharmaceuticals and food production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!