How Nitrous Acid Alters the Energy Input in Industrial Processes

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitrous Acid in Industry: Background and Objectives

Nitrous acid (HNO2) has been a subject of increasing interest in industrial processes due to its unique chemical properties and potential to alter energy dynamics. The evolution of nitrous acid's role in industry can be traced back to the early 20th century when its importance in atmospheric chemistry was first recognized. Since then, its significance has expanded to various industrial applications, particularly in sectors where energy efficiency and process optimization are crucial.

The primary objective of exploring nitrous acid's impact on industrial energy input is to uncover innovative ways to enhance process efficiency and reduce overall energy consumption. This aligns with the global push towards sustainable industrial practices and the need to minimize environmental impact while maximizing productivity. By understanding how nitrous acid interacts with different industrial systems, researchers and engineers aim to develop novel techniques that could revolutionize energy utilization across multiple sectors.

Nitrous acid's unique chemical behavior, particularly its ability to act as both an oxidizing and reducing agent, presents intriguing possibilities for energy manipulation in industrial processes. Its involvement in nitrogen oxide chemistry and its role in atmospheric reactions have led to investigations into its potential for catalyzing energy-efficient reactions in controlled industrial environments. The goal is to harness these properties to create more sustainable and cost-effective industrial processes.

Recent technological advancements have enabled more precise control and measurement of nitrous acid in industrial settings, opening up new avenues for research and application. The integration of advanced sensors and real-time monitoring systems has allowed for a deeper understanding of how nitrous acid influences energy dynamics at various stages of industrial processes. This has led to a growing body of knowledge on optimizing reaction conditions and minimizing energy waste.

As industries worldwide face increasing pressure to reduce their carbon footprint and energy consumption, the exploration of nitrous acid's role in altering energy input has gained strategic importance. The potential for significant energy savings and process improvements makes this area of research particularly attractive to both academic institutions and industrial R&D departments. The ultimate aim is to develop a comprehensive understanding of nitrous acid's behavior in different industrial contexts and to translate this knowledge into practical, energy-efficient solutions that can be widely implemented across various sectors.

The primary objective of exploring nitrous acid's impact on industrial energy input is to uncover innovative ways to enhance process efficiency and reduce overall energy consumption. This aligns with the global push towards sustainable industrial practices and the need to minimize environmental impact while maximizing productivity. By understanding how nitrous acid interacts with different industrial systems, researchers and engineers aim to develop novel techniques that could revolutionize energy utilization across multiple sectors.

Nitrous acid's unique chemical behavior, particularly its ability to act as both an oxidizing and reducing agent, presents intriguing possibilities for energy manipulation in industrial processes. Its involvement in nitrogen oxide chemistry and its role in atmospheric reactions have led to investigations into its potential for catalyzing energy-efficient reactions in controlled industrial environments. The goal is to harness these properties to create more sustainable and cost-effective industrial processes.

Recent technological advancements have enabled more precise control and measurement of nitrous acid in industrial settings, opening up new avenues for research and application. The integration of advanced sensors and real-time monitoring systems has allowed for a deeper understanding of how nitrous acid influences energy dynamics at various stages of industrial processes. This has led to a growing body of knowledge on optimizing reaction conditions and minimizing energy waste.

As industries worldwide face increasing pressure to reduce their carbon footprint and energy consumption, the exploration of nitrous acid's role in altering energy input has gained strategic importance. The potential for significant energy savings and process improvements makes this area of research particularly attractive to both academic institutions and industrial R&D departments. The ultimate aim is to develop a comprehensive understanding of nitrous acid's behavior in different industrial contexts and to translate this knowledge into practical, energy-efficient solutions that can be widely implemented across various sectors.

Market Demand Analysis for Energy-Efficient Processes

The market demand for energy-efficient processes in industrial applications has been steadily increasing due to rising energy costs, environmental concerns, and regulatory pressures. Industries are actively seeking innovative solutions to reduce their energy consumption and improve overall efficiency. The potential impact of nitrous acid on energy input in industrial processes has garnered significant attention from various sectors, particularly in chemical manufacturing, wastewater treatment, and emissions control.

Chemical manufacturers are showing keen interest in technologies that can reduce energy requirements for their production processes. The ability of nitrous acid to alter energy inputs could lead to substantial cost savings and improved competitiveness in the global market. According to recent industry reports, the chemical sector alone is projected to invest heavily in energy-efficient technologies over the next five years, with a focus on processes that can reduce energy consumption by at least 20%.

In the wastewater treatment industry, there is a growing demand for solutions that can lower the energy intensity of treatment processes. Municipal water authorities and industrial wastewater treatment facilities are exploring advanced oxidation processes, where nitrous acid could play a crucial role in reducing energy requirements. The market for energy-efficient wastewater treatment technologies is expected to expand significantly, driven by stringent environmental regulations and the need to minimize operational costs.

Emissions control is another area where the potential of nitrous acid to alter energy inputs is generating considerable interest. Industries subject to strict emissions standards are actively seeking technologies that can help them meet regulatory requirements while minimizing energy consumption. The automotive and power generation sectors, in particular, are investing in research and development of low-energy emissions control systems that could leverage the properties of nitrous acid.

The market demand for energy-efficient processes is not limited to specific industries but extends across the entire manufacturing sector. Small and medium-sized enterprises (SMEs) are increasingly looking for cost-effective solutions to improve their energy efficiency and reduce operational expenses. This trend is creating opportunities for technology providers to develop scalable and adaptable solutions that incorporate nitrous acid-based energy-saving mechanisms.

Geographically, the demand for energy-efficient processes is particularly strong in regions with high energy costs or stringent environmental regulations. European countries, Japan, and parts of North America are at the forefront of adopting innovative energy-saving technologies. However, emerging economies in Asia and South America are also showing increased interest as they seek to balance industrial growth with environmental sustainability.

The market potential for technologies that can effectively utilize nitrous acid to reduce energy inputs in industrial processes is substantial. Industry analysts predict that the global market for energy-efficient industrial technologies will continue to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is expected to be driven by a combination of factors, including technological advancements, regulatory pressures, and the increasing focus on sustainable manufacturing practices.

Chemical manufacturers are showing keen interest in technologies that can reduce energy requirements for their production processes. The ability of nitrous acid to alter energy inputs could lead to substantial cost savings and improved competitiveness in the global market. According to recent industry reports, the chemical sector alone is projected to invest heavily in energy-efficient technologies over the next five years, with a focus on processes that can reduce energy consumption by at least 20%.

In the wastewater treatment industry, there is a growing demand for solutions that can lower the energy intensity of treatment processes. Municipal water authorities and industrial wastewater treatment facilities are exploring advanced oxidation processes, where nitrous acid could play a crucial role in reducing energy requirements. The market for energy-efficient wastewater treatment technologies is expected to expand significantly, driven by stringent environmental regulations and the need to minimize operational costs.

Emissions control is another area where the potential of nitrous acid to alter energy inputs is generating considerable interest. Industries subject to strict emissions standards are actively seeking technologies that can help them meet regulatory requirements while minimizing energy consumption. The automotive and power generation sectors, in particular, are investing in research and development of low-energy emissions control systems that could leverage the properties of nitrous acid.

The market demand for energy-efficient processes is not limited to specific industries but extends across the entire manufacturing sector. Small and medium-sized enterprises (SMEs) are increasingly looking for cost-effective solutions to improve their energy efficiency and reduce operational expenses. This trend is creating opportunities for technology providers to develop scalable and adaptable solutions that incorporate nitrous acid-based energy-saving mechanisms.

Geographically, the demand for energy-efficient processes is particularly strong in regions with high energy costs or stringent environmental regulations. European countries, Japan, and parts of North America are at the forefront of adopting innovative energy-saving technologies. However, emerging economies in Asia and South America are also showing increased interest as they seek to balance industrial growth with environmental sustainability.

The market potential for technologies that can effectively utilize nitrous acid to reduce energy inputs in industrial processes is substantial. Industry analysts predict that the global market for energy-efficient industrial technologies will continue to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is expected to be driven by a combination of factors, including technological advancements, regulatory pressures, and the increasing focus on sustainable manufacturing practices.

Current State and Challenges of Nitrous Acid Application

The application of nitrous acid in industrial processes has gained significant attention due to its potential to alter energy input requirements. Currently, nitrous acid is being explored as a catalyst and reactant in various chemical processes, offering promising avenues for energy efficiency improvements. However, the widespread adoption of this technology faces several challenges that need to be addressed.

In terms of current state, nitrous acid is primarily utilized in the production of nitric acid, dyes, and certain pharmaceuticals. Recent research has shown its potential in enhancing the efficiency of fuel cells, particularly in direct methanol fuel cells where it can improve the oxidation of methanol. Additionally, nitrous acid has demonstrated catalytic properties in organic synthesis reactions, potentially reducing energy requirements in fine chemical production.

One of the main challenges in nitrous acid application is its inherent instability. Nitrous acid readily decomposes into nitrogen oxides and water, making its storage and handling problematic. This instability necessitates on-site generation or immediate use, which can complicate industrial processes and increase operational costs. Furthermore, the corrosive nature of nitrous acid poses material compatibility issues, requiring specialized equipment and safety measures.

Another significant challenge lies in controlling the reaction kinetics involving nitrous acid. The rapid and sometimes unpredictable nature of nitrous acid reactions can lead to difficulties in process control and product selectivity. This is particularly evident in organic synthesis applications, where side reactions and unwanted by-products can reduce overall efficiency and yield.

The environmental impact of nitrous acid use also presents a challenge. While it offers potential energy savings in certain processes, the production and use of nitrous acid can lead to the emission of nitrogen oxides, which are potent greenhouse gases and contribute to air pollution. Balancing the energy-saving benefits with environmental concerns remains a critical challenge for researchers and industry professionals.

Scaling up nitrous acid-based processes from laboratory to industrial scale poses additional challenges. The heat management, mass transfer limitations, and safety considerations become more complex at larger scales. Developing robust and scalable reactor designs that can effectively harness the benefits of nitrous acid while mitigating its drawbacks is an ongoing area of research and development.

Lastly, the economic viability of nitrous acid applications in energy-efficient processes is still under scrutiny. While the potential for energy savings is evident, the costs associated with specialized equipment, safety measures, and process modifications need to be carefully evaluated against the expected benefits. This economic uncertainty has led to hesitation in widespread industrial adoption, particularly in sectors where existing processes are well-established and capital-intensive.

In terms of current state, nitrous acid is primarily utilized in the production of nitric acid, dyes, and certain pharmaceuticals. Recent research has shown its potential in enhancing the efficiency of fuel cells, particularly in direct methanol fuel cells where it can improve the oxidation of methanol. Additionally, nitrous acid has demonstrated catalytic properties in organic synthesis reactions, potentially reducing energy requirements in fine chemical production.

One of the main challenges in nitrous acid application is its inherent instability. Nitrous acid readily decomposes into nitrogen oxides and water, making its storage and handling problematic. This instability necessitates on-site generation or immediate use, which can complicate industrial processes and increase operational costs. Furthermore, the corrosive nature of nitrous acid poses material compatibility issues, requiring specialized equipment and safety measures.

Another significant challenge lies in controlling the reaction kinetics involving nitrous acid. The rapid and sometimes unpredictable nature of nitrous acid reactions can lead to difficulties in process control and product selectivity. This is particularly evident in organic synthesis applications, where side reactions and unwanted by-products can reduce overall efficiency and yield.

The environmental impact of nitrous acid use also presents a challenge. While it offers potential energy savings in certain processes, the production and use of nitrous acid can lead to the emission of nitrogen oxides, which are potent greenhouse gases and contribute to air pollution. Balancing the energy-saving benefits with environmental concerns remains a critical challenge for researchers and industry professionals.

Scaling up nitrous acid-based processes from laboratory to industrial scale poses additional challenges. The heat management, mass transfer limitations, and safety considerations become more complex at larger scales. Developing robust and scalable reactor designs that can effectively harness the benefits of nitrous acid while mitigating its drawbacks is an ongoing area of research and development.

Lastly, the economic viability of nitrous acid applications in energy-efficient processes is still under scrutiny. While the potential for energy savings is evident, the costs associated with specialized equipment, safety measures, and process modifications need to be carefully evaluated against the expected benefits. This economic uncertainty has led to hesitation in widespread industrial adoption, particularly in sectors where existing processes are well-established and capital-intensive.

Existing Solutions for Nitrous Acid Energy Alteration

01 Nitrous acid production methods

Various methods for producing nitrous acid are explored, including chemical reactions and industrial processes. These methods focus on efficient and controlled production of nitrous acid, which is an important intermediate in many chemical processes.- Nitrous acid production methods: Various methods for producing nitrous acid are explored, including chemical reactions and industrial processes. These methods aim to optimize energy input and efficiency in nitrous acid synthesis, considering factors such as reaction conditions, catalysts, and raw materials.

- Energy-efficient nitrous acid applications: Research focuses on developing energy-efficient applications of nitrous acid in various industries. This includes its use in chemical processes, manufacturing, and environmental treatments, with an emphasis on minimizing energy consumption while maximizing effectiveness.

- Nitrous acid in energy storage systems: Investigations into the potential use of nitrous acid in energy storage systems are conducted. This involves studying its properties and reactions to develop novel energy storage solutions that could improve efficiency and capacity in various applications.

- Nitrous acid in combustion processes: The role of nitrous acid in combustion processes is examined, focusing on its potential to enhance energy output or reduce emissions. Research in this area aims to optimize combustion efficiency and reduce environmental impact in various industrial and automotive applications.

- Energy recovery from nitrous acid processes: Techniques for recovering energy from processes involving nitrous acid are explored. This includes methods for capturing and utilizing waste heat, as well as developing closed-loop systems that maximize energy efficiency in industrial applications using or producing nitrous acid.

02 Energy-efficient nitrous acid synthesis

Techniques for synthesizing nitrous acid with reduced energy input are developed. These approaches aim to optimize the production process, minimize energy consumption, and improve overall efficiency in nitrous acid manufacturing.Expand Specific Solutions03 Nitrous acid in fuel systems

The application of nitrous acid in fuel systems is investigated, particularly in relation to energy input and combustion processes. This includes the use of nitrous acid as an additive or catalyst to enhance fuel efficiency and performance.Expand Specific Solutions04 Nitrous acid in industrial processes

The role of nitrous acid in various industrial processes is examined, focusing on its energy requirements and potential for energy recovery. This includes applications in chemical manufacturing, waste treatment, and other industrial sectors.Expand Specific Solutions05 Nitrous acid energy recovery systems

Systems and methods for recovering energy from nitrous acid-related processes are developed. These innovations aim to capture and utilize excess energy, improving overall process efficiency and reducing environmental impact.Expand Specific Solutions

Key Players in Nitrous Acid and Energy Efficiency

The competitive landscape for "How Nitrous Acid Alters the Energy Input in Industrial Processes" is in an early development stage, with a growing market potential as industries seek more energy-efficient solutions. The technology is still evolving, with varying levels of maturity across different applications. Key players like Yara International, BASF, and Mitsubishi Gas Chemical are investing in research and development to optimize nitrous acid-based processes. Smaller companies and research institutions, such as Shenyang Polytechnic University and the Spanish National Research Council, are also contributing to advancements in this field. The market size is expected to expand as more industries adopt these energy-efficient technologies.

Yara International ASA

Technical Solution: Yara International ASA has developed an innovative process for nitric acid production that significantly reduces energy consumption and greenhouse gas emissions. Their technology utilizes a novel catalyst system that enhances the oxidation of ammonia to nitric oxide, a crucial step in nitric acid production. This process operates at lower temperatures and pressures compared to conventional methods, resulting in energy savings of up to 40% [1]. Additionally, Yara has implemented advanced heat recovery systems that capture and reuse waste heat, further improving overall energy efficiency. The company has also integrated selective catalytic reduction (SCR) technology to minimize NOx emissions, achieving reduction rates of over 95% [3].

Strengths: Significant energy savings, reduced greenhouse gas emissions, and improved process efficiency. Weaknesses: High initial investment costs and potential challenges in retrofitting existing plants.

Casale SA

Technical Solution: Casale SA has developed a proprietary technology called the "Casale Nitric Acid Process" that focuses on optimizing energy input in nitric acid production. Their approach involves a unique reactor design that improves the efficiency of the ammonia oxidation step. The process utilizes a specially designed burner system that ensures uniform temperature distribution and optimal gas mixing, resulting in higher conversion rates and reduced energy consumption. Casale's technology also incorporates advanced process control systems that continuously monitor and adjust operating parameters to maintain optimal performance. The company claims that their process can reduce energy consumption by up to 30% compared to conventional methods [2]. Additionally, Casale has implemented a novel absorption system that enhances nitric acid recovery and reduces NOx emissions.

Strengths: Improved energy efficiency, higher conversion rates, and reduced emissions. Weaknesses: Complexity of the system may require specialized training for operators.

Core Innovations in Nitrous Acid Energy Optimization

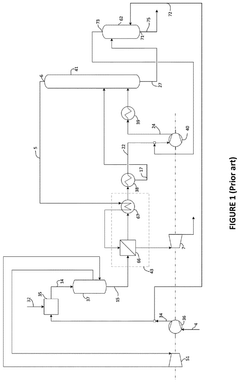

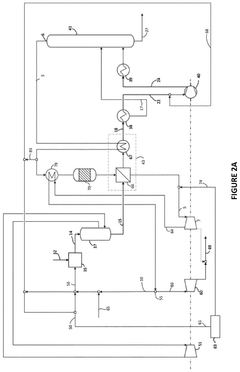

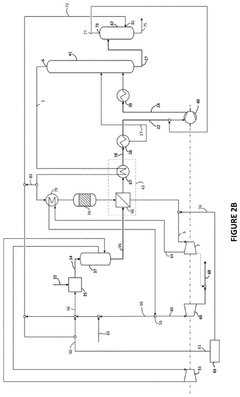

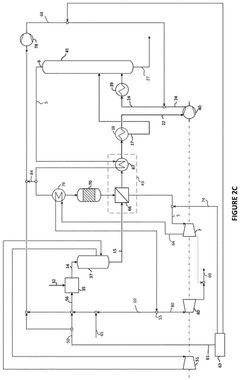

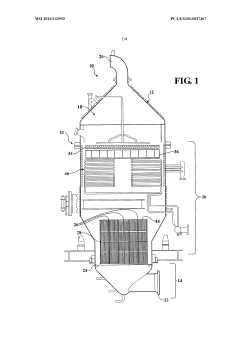

Dual pressure system for producing nitric acid and method of operating thereof

PatentPendingUS20240336481A1

Innovation

- The system recirculates tail gas to eliminate the need for continuous compressed air supply, using a high-pressure water electrolyzer to provide oxygen-rich gas for mixing with ammonia, allowing for optimal oxygen-to-ammonia ratios and reducing the size and complexity of compressor systems, thereby minimizing energy demand and emissions.

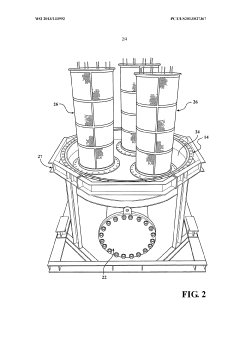

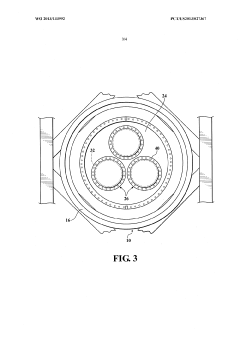

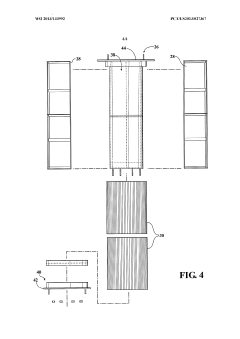

Ammonia oxidation reactor with internal filter element

PatentWO2013133992A1

Innovation

- A reaction vessel with an internal filter element that collects dislodged catalysts during ammonia oxidation, featuring a filter cage and medium integrated within the vessel to minimize space and facilitate efficient filtration, reducing downstream contamination and maintenance needs.

Environmental Impact of Nitrous Acid in Industry

The environmental impact of nitrous acid in industry is a critical concern that requires thorough examination. Nitrous acid, a byproduct of various industrial processes, can have significant effects on both the immediate surroundings and the broader ecosystem. One of the primary concerns is its contribution to air pollution. When released into the atmosphere, nitrous acid can react with other compounds to form secondary pollutants, such as ozone and particulate matter, which are known to have detrimental effects on human health and the environment.

In aquatic ecosystems, the presence of nitrous acid can lead to acidification of water bodies. This process can disrupt the delicate balance of aquatic life, affecting fish populations and other organisms that are sensitive to pH changes. The increased acidity can also lead to the leaching of heavy metals from sediments, further compromising water quality and ecosystem health.

Soil contamination is another significant environmental impact of nitrous acid in industrial settings. When nitrous acid-containing emissions or effluents come into contact with soil, they can alter its chemical composition. This can result in reduced soil fertility, impaired plant growth, and potential long-term effects on agricultural productivity in affected areas.

The impact on biodiversity is also a concern. Nitrous acid and its derivatives can contribute to the formation of acid rain, which can damage vegetation, forests, and crops over large areas. This can lead to habitat degradation and loss of species diversity in affected ecosystems.

From a climate change perspective, while nitrous acid itself is not a significant greenhouse gas, its role in atmospheric chemistry can indirectly influence climate patterns. By contributing to the formation of tropospheric ozone, a potent greenhouse gas, nitrous acid emissions from industrial processes can have an indirect impact on global warming.

Industrial facilities that release nitrous acid must also consider the potential for corrosion of infrastructure and equipment. This not only poses safety risks but can also lead to increased maintenance costs and potential environmental hazards due to equipment failure or leaks.

To mitigate these environmental impacts, industries are increasingly adopting cleaner technologies and implementing stringent emission control measures. These include the use of scrubbers, catalytic converters, and other advanced treatment systems to reduce nitrous acid emissions. Additionally, there is a growing focus on process optimization and the development of alternative production methods that minimize the generation of nitrous acid as a byproduct.

In aquatic ecosystems, the presence of nitrous acid can lead to acidification of water bodies. This process can disrupt the delicate balance of aquatic life, affecting fish populations and other organisms that are sensitive to pH changes. The increased acidity can also lead to the leaching of heavy metals from sediments, further compromising water quality and ecosystem health.

Soil contamination is another significant environmental impact of nitrous acid in industrial settings. When nitrous acid-containing emissions or effluents come into contact with soil, they can alter its chemical composition. This can result in reduced soil fertility, impaired plant growth, and potential long-term effects on agricultural productivity in affected areas.

The impact on biodiversity is also a concern. Nitrous acid and its derivatives can contribute to the formation of acid rain, which can damage vegetation, forests, and crops over large areas. This can lead to habitat degradation and loss of species diversity in affected ecosystems.

From a climate change perspective, while nitrous acid itself is not a significant greenhouse gas, its role in atmospheric chemistry can indirectly influence climate patterns. By contributing to the formation of tropospheric ozone, a potent greenhouse gas, nitrous acid emissions from industrial processes can have an indirect impact on global warming.

Industrial facilities that release nitrous acid must also consider the potential for corrosion of infrastructure and equipment. This not only poses safety risks but can also lead to increased maintenance costs and potential environmental hazards due to equipment failure or leaks.

To mitigate these environmental impacts, industries are increasingly adopting cleaner technologies and implementing stringent emission control measures. These include the use of scrubbers, catalytic converters, and other advanced treatment systems to reduce nitrous acid emissions. Additionally, there is a growing focus on process optimization and the development of alternative production methods that minimize the generation of nitrous acid as a byproduct.

Economic Implications of Nitrous Acid Energy Alterations

The economic implications of nitrous acid energy alterations in industrial processes are far-reaching and multifaceted. These changes have the potential to significantly impact production costs, operational efficiency, and overall industry competitiveness.

One of the primary economic considerations is the potential reduction in energy consumption. By altering the energy input through the use of nitrous acid, industries may experience substantial cost savings on their energy bills. This could lead to improved profit margins and increased competitiveness in the global market. The extent of these savings would vary depending on the specific industrial process and the degree to which nitrous acid can optimize energy utilization.

Furthermore, the adoption of nitrous acid-based energy alterations may necessitate initial capital investments in new equipment or process modifications. While this upfront cost could be significant, the long-term economic benefits may outweigh the initial expenditure. Companies that invest early in this technology could gain a competitive advantage, potentially capturing a larger market share and enjoying higher returns on investment over time.

The environmental impact of these energy alterations also has economic implications. As industries face increasing pressure to reduce their carbon footprint and comply with stricter environmental regulations, the use of nitrous acid to optimize energy input could result in reduced emissions. This may lead to cost savings in terms of carbon taxes or credits, as well as improved corporate image and potential access to green financing options.

Labor market dynamics could also be affected by the widespread adoption of nitrous acid energy alterations. The implementation of new technologies may require a workforce with specialized skills, potentially leading to shifts in employment patterns and wages within affected industries. This could create opportunities for job creation in fields related to the development, implementation, and maintenance of these new processes.

Supply chain economics may also be impacted, as the demand for nitrous acid and related chemicals could increase. This might lead to price fluctuations and the development of new supply networks, potentially creating economic opportunities for chemical manufacturers and distributors.

Lastly, the macroeconomic effects of widespread adoption of nitrous acid energy alterations could be substantial. Improved energy efficiency across multiple industries could contribute to overall economic growth, enhance national energy security, and potentially influence trade balances, particularly for countries heavily reliant on energy imports.

One of the primary economic considerations is the potential reduction in energy consumption. By altering the energy input through the use of nitrous acid, industries may experience substantial cost savings on their energy bills. This could lead to improved profit margins and increased competitiveness in the global market. The extent of these savings would vary depending on the specific industrial process and the degree to which nitrous acid can optimize energy utilization.

Furthermore, the adoption of nitrous acid-based energy alterations may necessitate initial capital investments in new equipment or process modifications. While this upfront cost could be significant, the long-term economic benefits may outweigh the initial expenditure. Companies that invest early in this technology could gain a competitive advantage, potentially capturing a larger market share and enjoying higher returns on investment over time.

The environmental impact of these energy alterations also has economic implications. As industries face increasing pressure to reduce their carbon footprint and comply with stricter environmental regulations, the use of nitrous acid to optimize energy input could result in reduced emissions. This may lead to cost savings in terms of carbon taxes or credits, as well as improved corporate image and potential access to green financing options.

Labor market dynamics could also be affected by the widespread adoption of nitrous acid energy alterations. The implementation of new technologies may require a workforce with specialized skills, potentially leading to shifts in employment patterns and wages within affected industries. This could create opportunities for job creation in fields related to the development, implementation, and maintenance of these new processes.

Supply chain economics may also be impacted, as the demand for nitrous acid and related chemicals could increase. This might lead to price fluctuations and the development of new supply networks, potentially creating economic opportunities for chemical manufacturers and distributors.

Lastly, the macroeconomic effects of widespread adoption of nitrous acid energy alterations could be substantial. Improved energy efficiency across multiple industries could contribute to overall economic growth, enhance national energy security, and potentially influence trade balances, particularly for countries heavily reliant on energy imports.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!