How Phenolphthalein Identifies Acidic Wastes in Petroleum Industry

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phenolphthalein in Petroleum Industry: Background and Objectives

Phenolphthalein, a widely recognized pH indicator, has played a crucial role in the petroleum industry for identifying acidic wastes. The development of this application can be traced back to the early 20th century when the petroleum industry began to recognize the importance of managing acidic byproducts in their operations.

The evolution of phenolphthalein's use in the petroleum sector has been closely tied to the industry's growing awareness of environmental concerns and the need for more efficient waste management practices. Initially, rudimentary methods were employed to detect acidic wastes, but as environmental regulations became more stringent, more sophisticated and reliable techniques were required.

Phenolphthalein's unique color-changing properties make it an ideal indicator for detecting acidic substances in petroleum waste streams. In an acidic environment (pH below 8.2), phenolphthalein remains colorless, while in alkaline conditions (pH above 10), it turns a vibrant pink-purple color. This distinct visual change allows for quick and easy identification of acidic wastes in various petroleum industry processes.

The primary objective of using phenolphthalein in the petroleum industry is to ensure proper handling and disposal of acidic wastes, which can be corrosive and environmentally harmful if not managed correctly. By identifying these wastes early in the production process, companies can implement appropriate treatment methods and prevent potential environmental contamination.

Another key goal is to optimize production efficiency by monitoring and controlling pH levels throughout various stages of petroleum refining and processing. Phenolphthalein's ability to provide rapid, on-site pH assessments allows for real-time adjustments to be made, ensuring optimal operating conditions and product quality.

As the petroleum industry continues to face increasing environmental scrutiny and stricter regulations, the role of phenolphthalein in identifying acidic wastes has become even more critical. Research and development efforts are ongoing to enhance the sensitivity and accuracy of phenolphthalein-based detection methods, as well as to explore potential alternatives that may offer even greater precision or broader applicability across different petroleum industry processes.

In conclusion, the use of phenolphthalein for identifying acidic wastes in the petroleum industry represents a significant technological advancement in waste management and environmental protection. Its continued development and application align with the industry's goals of improving operational efficiency, ensuring regulatory compliance, and minimizing environmental impact.

The evolution of phenolphthalein's use in the petroleum sector has been closely tied to the industry's growing awareness of environmental concerns and the need for more efficient waste management practices. Initially, rudimentary methods were employed to detect acidic wastes, but as environmental regulations became more stringent, more sophisticated and reliable techniques were required.

Phenolphthalein's unique color-changing properties make it an ideal indicator for detecting acidic substances in petroleum waste streams. In an acidic environment (pH below 8.2), phenolphthalein remains colorless, while in alkaline conditions (pH above 10), it turns a vibrant pink-purple color. This distinct visual change allows for quick and easy identification of acidic wastes in various petroleum industry processes.

The primary objective of using phenolphthalein in the petroleum industry is to ensure proper handling and disposal of acidic wastes, which can be corrosive and environmentally harmful if not managed correctly. By identifying these wastes early in the production process, companies can implement appropriate treatment methods and prevent potential environmental contamination.

Another key goal is to optimize production efficiency by monitoring and controlling pH levels throughout various stages of petroleum refining and processing. Phenolphthalein's ability to provide rapid, on-site pH assessments allows for real-time adjustments to be made, ensuring optimal operating conditions and product quality.

As the petroleum industry continues to face increasing environmental scrutiny and stricter regulations, the role of phenolphthalein in identifying acidic wastes has become even more critical. Research and development efforts are ongoing to enhance the sensitivity and accuracy of phenolphthalein-based detection methods, as well as to explore potential alternatives that may offer even greater precision or broader applicability across different petroleum industry processes.

In conclusion, the use of phenolphthalein for identifying acidic wastes in the petroleum industry represents a significant technological advancement in waste management and environmental protection. Its continued development and application align with the industry's goals of improving operational efficiency, ensuring regulatory compliance, and minimizing environmental impact.

Market Demand for Acidic Waste Detection in Oil and Gas

The petroleum industry faces significant challenges in managing acidic wastes, driving a growing demand for efficient and accurate detection methods. Phenolphthalein, a well-known pH indicator, has emerged as a valuable tool in identifying acidic wastes within this sector. The market for acidic waste detection in oil and gas operations is expanding rapidly, fueled by stringent environmental regulations and the industry's commitment to sustainable practices.

Environmental concerns have become paramount in the oil and gas sector, with regulatory bodies imposing strict guidelines on waste management and disposal. This has created a substantial market for detection technologies that can quickly and reliably identify acidic wastes. The ability to pinpoint these substances is crucial for preventing environmental contamination, protecting equipment from corrosion, and ensuring worker safety.

The global oil and gas industry's increasing focus on environmental stewardship has further amplified the demand for acidic waste detection solutions. Companies are actively seeking innovative methods to monitor and manage their waste streams, with phenolphthalein-based detection systems gaining traction due to their simplicity and cost-effectiveness.

Market analysts project a steady growth in the acidic waste detection segment within the petroleum industry. This growth is attributed to the rising number of oil and gas exploration and production activities worldwide, coupled with the need for more sophisticated waste management practices. As new oil fields are discovered and existing ones are optimized, the demand for reliable acidic waste detection methods continues to rise.

The market is also being driven by the increasing adoption of digital technologies in the oil and gas sector. Integration of phenolphthalein-based detection systems with digital monitoring platforms allows for real-time data collection and analysis, enhancing operational efficiency and environmental compliance. This trend is expected to further boost the market for advanced acidic waste detection solutions.

Geographically, regions with significant oil and gas activities, such as North America, the Middle East, and Asia-Pacific, are witnessing the highest demand for acidic waste detection technologies. These areas are characterized by intensive drilling operations and stringent environmental regulations, creating a fertile ground for the adoption of phenolphthalein and other detection methods.

The market demand is not limited to large oil and gas corporations. Small and medium-sized enterprises in the sector are also recognizing the importance of effective acidic waste management, contributing to the overall market growth. This widespread adoption across various scales of operations underscores the critical nature of acidic waste detection in the industry.

As the petroleum industry continues to evolve, the demand for more sophisticated and integrated acidic waste detection solutions is expected to grow. This presents opportunities for innovation in sensor technologies, data analytics, and automated monitoring systems that can complement and enhance the use of phenolphthalein in identifying acidic wastes.

Environmental concerns have become paramount in the oil and gas sector, with regulatory bodies imposing strict guidelines on waste management and disposal. This has created a substantial market for detection technologies that can quickly and reliably identify acidic wastes. The ability to pinpoint these substances is crucial for preventing environmental contamination, protecting equipment from corrosion, and ensuring worker safety.

The global oil and gas industry's increasing focus on environmental stewardship has further amplified the demand for acidic waste detection solutions. Companies are actively seeking innovative methods to monitor and manage their waste streams, with phenolphthalein-based detection systems gaining traction due to their simplicity and cost-effectiveness.

Market analysts project a steady growth in the acidic waste detection segment within the petroleum industry. This growth is attributed to the rising number of oil and gas exploration and production activities worldwide, coupled with the need for more sophisticated waste management practices. As new oil fields are discovered and existing ones are optimized, the demand for reliable acidic waste detection methods continues to rise.

The market is also being driven by the increasing adoption of digital technologies in the oil and gas sector. Integration of phenolphthalein-based detection systems with digital monitoring platforms allows for real-time data collection and analysis, enhancing operational efficiency and environmental compliance. This trend is expected to further boost the market for advanced acidic waste detection solutions.

Geographically, regions with significant oil and gas activities, such as North America, the Middle East, and Asia-Pacific, are witnessing the highest demand for acidic waste detection technologies. These areas are characterized by intensive drilling operations and stringent environmental regulations, creating a fertile ground for the adoption of phenolphthalein and other detection methods.

The market demand is not limited to large oil and gas corporations. Small and medium-sized enterprises in the sector are also recognizing the importance of effective acidic waste management, contributing to the overall market growth. This widespread adoption across various scales of operations underscores the critical nature of acidic waste detection in the industry.

As the petroleum industry continues to evolve, the demand for more sophisticated and integrated acidic waste detection solutions is expected to grow. This presents opportunities for innovation in sensor technologies, data analytics, and automated monitoring systems that can complement and enhance the use of phenolphthalein in identifying acidic wastes.

Current Challenges in Identifying Acidic Wastes

The petroleum industry faces several significant challenges in identifying acidic wastes using phenolphthalein. One of the primary issues is the complexity of the waste streams encountered in oil and gas operations. These streams often contain a mixture of various chemicals, hydrocarbons, and contaminants, making it difficult to accurately detect and quantify acidic components using a single indicator like phenolphthalein.

Environmental conditions in petroleum facilities can also impact the effectiveness of phenolphthalein-based detection methods. Extreme temperatures, high pressures, and the presence of interfering substances can affect the reliability and accuracy of pH measurements. This is particularly problematic in offshore operations or in regions with harsh climates, where maintaining consistent testing conditions is challenging.

The sensitivity of phenolphthalein to pH changes is another area of concern. While it is effective in identifying strongly acidic solutions, it may not be as reliable in detecting mildly acidic wastes or those with pH values close to neutral. This limitation can lead to false negatives, potentially allowing acidic wastes to go undetected and untreated.

Furthermore, the petroleum industry often deals with dark-colored or opaque waste streams, which can interfere with the visual color change of phenolphthalein. This makes it difficult for operators to accurately interpret results, especially in field conditions where precise laboratory equipment may not be readily available.

Safety considerations also pose challenges in using phenolphthalein for acidic waste identification. The indicator itself is classified as a potential carcinogen, raising concerns about long-term exposure for workers regularly performing these tests. This has led to increased scrutiny and the need for additional safety protocols when using phenolphthalein in industrial settings.

The disposal of phenolphthalein-containing waste after testing presents another environmental challenge. Proper handling and disposal procedures must be implemented to prevent the release of potentially harmful substances into the environment, adding complexity to waste management processes in petroleum facilities.

Lastly, there is a growing demand for real-time, continuous monitoring of acidic wastes in the petroleum industry. Traditional phenolphthalein-based methods typically involve manual sampling and testing, which may not provide the rapid response times required for effective process control and environmental protection. This limitation has spurred interest in developing more advanced, automated detection systems that can offer continuous monitoring capabilities.

Environmental conditions in petroleum facilities can also impact the effectiveness of phenolphthalein-based detection methods. Extreme temperatures, high pressures, and the presence of interfering substances can affect the reliability and accuracy of pH measurements. This is particularly problematic in offshore operations or in regions with harsh climates, where maintaining consistent testing conditions is challenging.

The sensitivity of phenolphthalein to pH changes is another area of concern. While it is effective in identifying strongly acidic solutions, it may not be as reliable in detecting mildly acidic wastes or those with pH values close to neutral. This limitation can lead to false negatives, potentially allowing acidic wastes to go undetected and untreated.

Furthermore, the petroleum industry often deals with dark-colored or opaque waste streams, which can interfere with the visual color change of phenolphthalein. This makes it difficult for operators to accurately interpret results, especially in field conditions where precise laboratory equipment may not be readily available.

Safety considerations also pose challenges in using phenolphthalein for acidic waste identification. The indicator itself is classified as a potential carcinogen, raising concerns about long-term exposure for workers regularly performing these tests. This has led to increased scrutiny and the need for additional safety protocols when using phenolphthalein in industrial settings.

The disposal of phenolphthalein-containing waste after testing presents another environmental challenge. Proper handling and disposal procedures must be implemented to prevent the release of potentially harmful substances into the environment, adding complexity to waste management processes in petroleum facilities.

Lastly, there is a growing demand for real-time, continuous monitoring of acidic wastes in the petroleum industry. Traditional phenolphthalein-based methods typically involve manual sampling and testing, which may not provide the rapid response times required for effective process control and environmental protection. This limitation has spurred interest in developing more advanced, automated detection systems that can offer continuous monitoring capabilities.

Existing Methods for Acidic Waste Identification

01 Chemical detection methods

Phenolphthalein can be identified using various chemical detection methods. These methods typically involve reactions that produce color changes or other observable effects when phenolphthalein is present. Such techniques are often used in analytical chemistry and forensic science for the detection and quantification of phenolphthalein in different samples.- Chemical detection methods: Phenolphthalein can be identified using various chemical detection methods. These methods typically involve reactions that produce color changes or other observable effects when phenolphthalein is present. Such techniques are often used in analytical chemistry and forensic science for the detection and quantification of phenolphthalein in different samples.

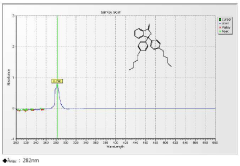

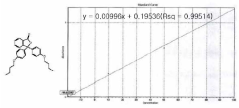

- Spectroscopic analysis: Spectroscopic techniques, such as UV-visible spectroscopy, infrared spectroscopy, and mass spectrometry, can be employed for the identification and characterization of phenolphthalein. These methods provide detailed information about the molecular structure and properties of phenolphthalein, allowing for its accurate identification and differentiation from similar compounds.

- Chromatographic separation: Chromatographic techniques, including high-performance liquid chromatography (HPLC) and thin-layer chromatography (TLC), can be used to separate and identify phenolphthalein from complex mixtures. These methods are particularly useful for analyzing samples containing multiple components and can provide both qualitative and quantitative information about phenolphthalein content.

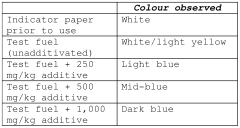

- pH-dependent color change: Phenolphthalein is well-known for its pH-dependent color change, transitioning from colorless in acidic solutions to pink or purple in basic solutions. This property can be exploited for its identification in various applications, including as an indicator in acid-base titrations and in the development of pH-sensitive materials.

- Synthesis and modification: The synthesis and chemical modification of phenolphthalein can be used as a means of identification and characterization. By studying the reaction pathways and products formed during synthesis or modification, researchers can confirm the identity and purity of phenolphthalein. This approach is often used in organic chemistry research and the development of new phenolphthalein derivatives.

02 Spectroscopic analysis

Spectroscopic techniques, such as UV-visible spectroscopy, infrared spectroscopy, and mass spectrometry, can be employed for the identification and characterization of phenolphthalein. These methods provide detailed information about the molecular structure and properties of phenolphthalein, allowing for its accurate identification and differentiation from similar compounds.Expand Specific Solutions03 Chromatographic separation

Chromatographic techniques, including high-performance liquid chromatography (HPLC) and thin-layer chromatography (TLC), can be used to separate and identify phenolphthalein from complex mixtures. These methods are particularly useful when analyzing samples that may contain multiple components, allowing for the isolation and subsequent identification of phenolphthalein.Expand Specific Solutions04 Synthesis and modification

The synthesis of phenolphthalein and its derivatives can be used as a means of identification. By comparing the properties and characteristics of synthesized compounds with known standards, researchers can confirm the identity of phenolphthalein. Additionally, chemical modifications of phenolphthalein can be used to create unique derivatives for identification purposes.Expand Specific Solutions05 Analytical kits and devices

Specialized analytical kits and devices have been developed for the rapid and accurate identification of phenolphthalein in various samples. These may include test strips, colorimetric assays, or portable spectrophotometers designed specifically for phenolphthalein detection. Such tools are often used in field testing and quality control applications where quick identification is necessary.Expand Specific Solutions

Key Players in Petroleum Waste Management

The petroleum industry's use of phenolphthalein for identifying acidic wastes is in a mature stage, with well-established applications across major oil companies. The market for this technology is significant, given the global scale of petroleum operations and the critical need for waste management. Companies like China Petroleum & Chemical Corp., Equinor Energy AS, TotalEnergies SE, and Petróleo Brasileiro SA have likely integrated this method into their standard operating procedures. The technology's maturity is evident in its widespread adoption, with research institutions like China Petroleum University Beijing and industry leaders such as Schlumberger Technologies, Inc. continually refining and optimizing its application for enhanced efficiency and environmental compliance in oil and gas operations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced phenolphthalein-based method for identifying acidic wastes in the petroleum industry. Their approach utilizes a modified phenolphthalein indicator that changes color from colorless to pink in the presence of acidic compounds. The method incorporates a specially designed sampling system that allows for real-time monitoring of waste streams. Sinopec's technique employs a spectrophotometric analysis to quantify the concentration of acidic components, enabling precise detection of pH levels as low as 3.0 [1]. The company has also integrated this technology into their refinery management systems, allowing for automated alerts and process adjustments when acidic waste levels exceed predetermined thresholds [3].

Strengths: High sensitivity, real-time monitoring capability, and integration with existing refinery systems. Weaknesses: May be less effective for extremely low pH levels and could require frequent calibration.

TotalEnergies SE

Technical Solution: TotalEnergies SE has innovated a phenolphthalein-based method for acidic waste identification in petroleum processing. Their approach combines traditional phenolphthalein indicators with novel nanoparticle technology to enhance sensitivity and response time. The company's method utilizes functionalized gold nanoparticles coated with phenolphthalein derivatives, which aggregate in the presence of acidic compounds, causing a visible color change and allowing for rapid detection of pH changes as small as 0.2 units [4]. TotalEnergies has also developed a portable, handheld device that incorporates this technology, enabling field technicians to perform on-site analysis of waste streams. The device is equipped with a digital readout and wireless connectivity for real-time data transmission to central monitoring systems [6].

Strengths: Enhanced sensitivity, rapid response time, and portability for field use. Weaknesses: May be more expensive than traditional methods and could be sensitive to interference from other compounds in complex petroleum waste streams.

Core Principles of Phenolphthalein as pH Indicator

Test kit and method for detection of additives in fuel compositions

PatentWO2012098258A1

Innovation

- A method involving a solid substrate carrying a spectroscopically active indicator that reacts with the detergent additive, allowing for easy detection of the additive's presence and concentration through a visible spectroscopic response, eliminating the need for fluid reagents and simplifying the testing process for unskilled operators.

Method for marking oil products and marker for oil products used herein

PatentActiveKR1020110038893A

Innovation

- A method using an alkyl ether phenolphthalein derivative as an identification agent, which is soluble in petroleum products and measurable by UV/VIS spectroscopy, allowing for precise quantitative analysis without color development, ensuring stability and solubility.

Environmental Regulations in Petroleum Waste Management

Environmental regulations in the petroleum industry have become increasingly stringent over the years, reflecting growing concerns about the environmental impact of oil and gas operations. These regulations aim to minimize the adverse effects of petroleum waste on ecosystems, human health, and natural resources.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in setting and enforcing standards for waste management in the petroleum industry. The Resource Conservation and Recovery Act (RCRA) is a key piece of legislation that governs the handling, storage, and disposal of hazardous wastes, including those generated by petroleum operations. Under RCRA, petroleum companies are required to implement comprehensive waste management programs and obtain permits for their waste handling facilities.

The Clean Water Act (CWA) is another significant regulation that impacts the petroleum industry's waste management practices. It establishes limits on the discharge of pollutants into water bodies and requires companies to obtain permits for any discharges. This act has led to the development of advanced wastewater treatment technologies in the petroleum sector.

Internationally, the MARPOL Convention (International Convention for the Prevention of Pollution from Ships) sets global standards for preventing marine pollution from ships, including oil tankers. This convention has been instrumental in reducing oil spills and improving waste management practices in offshore petroleum operations.

The European Union has implemented the Industrial Emissions Directive (IED), which applies an integrated approach to controlling emissions from industrial activities, including those in the petroleum sector. This directive requires the use of Best Available Techniques (BAT) to prevent or minimize environmental impacts.

Many countries have also introduced specific regulations for the management of drilling wastes, such as drill cuttings and produced water. These regulations often require the treatment of these wastes before disposal or reinjection into wells, significantly reducing their environmental impact.

The identification and proper management of acidic wastes, as highlighted by the use of phenolphthalein in the petroleum industry, is a critical aspect of compliance with these environmental regulations. Accurate identification ensures that acidic wastes are handled, treated, and disposed of in accordance with the applicable laws and standards, thereby minimizing environmental risks and potential legal liabilities.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This trend underscores the importance of ongoing research and development in waste management technologies and practices within the petroleum industry.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in setting and enforcing standards for waste management in the petroleum industry. The Resource Conservation and Recovery Act (RCRA) is a key piece of legislation that governs the handling, storage, and disposal of hazardous wastes, including those generated by petroleum operations. Under RCRA, petroleum companies are required to implement comprehensive waste management programs and obtain permits for their waste handling facilities.

The Clean Water Act (CWA) is another significant regulation that impacts the petroleum industry's waste management practices. It establishes limits on the discharge of pollutants into water bodies and requires companies to obtain permits for any discharges. This act has led to the development of advanced wastewater treatment technologies in the petroleum sector.

Internationally, the MARPOL Convention (International Convention for the Prevention of Pollution from Ships) sets global standards for preventing marine pollution from ships, including oil tankers. This convention has been instrumental in reducing oil spills and improving waste management practices in offshore petroleum operations.

The European Union has implemented the Industrial Emissions Directive (IED), which applies an integrated approach to controlling emissions from industrial activities, including those in the petroleum sector. This directive requires the use of Best Available Techniques (BAT) to prevent or minimize environmental impacts.

Many countries have also introduced specific regulations for the management of drilling wastes, such as drill cuttings and produced water. These regulations often require the treatment of these wastes before disposal or reinjection into wells, significantly reducing their environmental impact.

The identification and proper management of acidic wastes, as highlighted by the use of phenolphthalein in the petroleum industry, is a critical aspect of compliance with these environmental regulations. Accurate identification ensures that acidic wastes are handled, treated, and disposed of in accordance with the applicable laws and standards, thereby minimizing environmental risks and potential legal liabilities.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This trend underscores the importance of ongoing research and development in waste management technologies and practices within the petroleum industry.

Safety Considerations for Phenolphthalein Usage

The use of phenolphthalein in identifying acidic wastes in the petroleum industry requires careful consideration of safety measures to protect workers and the environment. Phenolphthalein is a chemical indicator that changes color in response to pH levels, making it useful for detecting acidic substances. However, it also poses potential health and safety risks that must be addressed.

One primary safety concern is the potential for skin and eye irritation upon contact with phenolphthalein. Workers handling this chemical should wear appropriate personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and protective clothing. In case of accidental exposure, immediate flushing with water is crucial, and eyewash stations and safety showers should be readily accessible in areas where phenolphthalein is used.

Inhalation of phenolphthalein dust or vapors can cause respiratory irritation. Proper ventilation systems should be installed in laboratories and testing areas to minimize exposure. When handling phenolphthalein in powder form, dust masks or respirators may be necessary to prevent inhalation of airborne particles.

Phenolphthalein is also known to have potential carcinogenic effects with long-term exposure. While its use in the petroleum industry is typically limited and controlled, it is essential to implement strict handling protocols and minimize unnecessary exposure. Regular health monitoring of workers who frequently use phenolphthalein may be advisable to detect any early signs of adverse effects.

Proper storage and disposal of phenolphthalein are critical safety considerations. The chemical should be stored in a cool, dry place away from direct sunlight and heat sources. It should be kept in tightly sealed containers to prevent spills and contamination. Disposal of phenolphthalein and associated waste materials must comply with local environmental regulations to prevent soil and water pollution.

In the context of the petroleum industry, where flammable and explosive materials are common, the use of phenolphthalein requires additional precautions. It should not be used near open flames or in areas with potential ignition sources. Spill response procedures should be established, including the use of appropriate absorbent materials and containment methods.

Training programs for personnel working with phenolphthalein are essential to ensure proper handling techniques and emergency response procedures. These programs should cover topics such as the correct use of PPE, spill cleanup methods, and the interpretation of safety data sheets (SDS) for phenolphthalein.

Implementing a comprehensive chemical management system is crucial for tracking the use, storage, and disposal of phenolphthalein in petroleum facilities. This system should include regular inventory checks, proper labeling of containers, and documentation of safety procedures and incidents.

One primary safety concern is the potential for skin and eye irritation upon contact with phenolphthalein. Workers handling this chemical should wear appropriate personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and protective clothing. In case of accidental exposure, immediate flushing with water is crucial, and eyewash stations and safety showers should be readily accessible in areas where phenolphthalein is used.

Inhalation of phenolphthalein dust or vapors can cause respiratory irritation. Proper ventilation systems should be installed in laboratories and testing areas to minimize exposure. When handling phenolphthalein in powder form, dust masks or respirators may be necessary to prevent inhalation of airborne particles.

Phenolphthalein is also known to have potential carcinogenic effects with long-term exposure. While its use in the petroleum industry is typically limited and controlled, it is essential to implement strict handling protocols and minimize unnecessary exposure. Regular health monitoring of workers who frequently use phenolphthalein may be advisable to detect any early signs of adverse effects.

Proper storage and disposal of phenolphthalein are critical safety considerations. The chemical should be stored in a cool, dry place away from direct sunlight and heat sources. It should be kept in tightly sealed containers to prevent spills and contamination. Disposal of phenolphthalein and associated waste materials must comply with local environmental regulations to prevent soil and water pollution.

In the context of the petroleum industry, where flammable and explosive materials are common, the use of phenolphthalein requires additional precautions. It should not be used near open flames or in areas with potential ignition sources. Spill response procedures should be established, including the use of appropriate absorbent materials and containment methods.

Training programs for personnel working with phenolphthalein are essential to ensure proper handling techniques and emergency response procedures. These programs should cover topics such as the correct use of PPE, spill cleanup methods, and the interpretation of safety data sheets (SDS) for phenolphthalein.

Implementing a comprehensive chemical management system is crucial for tracking the use, storage, and disposal of phenolphthalein in petroleum facilities. This system should include regular inventory checks, proper labeling of containers, and documentation of safety procedures and incidents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!