How Phenolphthalein-Modified Surfaces Influence Bacterial Adhesion

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phenolphthalein-Bacterial Adhesion Background

Phenolphthalein, a widely recognized pH indicator, has recently garnered attention in the field of bacterial adhesion research. This compound, traditionally used in acid-base titrations, exhibits a unique color-changing property when exposed to different pH levels. The exploration of phenolphthalein-modified surfaces and their influence on bacterial adhesion represents a novel approach in combating microbial colonization and biofilm formation.

The study of bacterial adhesion to surfaces is crucial in various sectors, including healthcare, food processing, and industrial applications. Bacterial attachment to surfaces is often the first step in biofilm formation, which can lead to persistent infections, contamination, and equipment degradation. Understanding and controlling this process is essential for developing effective strategies to prevent bacterial colonization.

Phenolphthalein's potential in this context stems from its ability to change its molecular structure and surface properties in response to environmental pH changes. This dynamic behavior could potentially disrupt the mechanisms by which bacteria adhere to surfaces. The concept of using phenolphthalein-modified surfaces to influence bacterial adhesion builds upon the broader field of smart materials and responsive surfaces in antimicrobial applications.

Recent advancements in surface modification techniques have enabled the integration of phenolphthalein into various materials, including polymers, metals, and ceramics. These modified surfaces can potentially exhibit switchable properties, altering their interaction with bacterial cells based on the surrounding pH conditions. This approach offers a promising alternative to traditional antimicrobial coatings, which often rely on the release of biocidal agents and may contribute to the development of antimicrobial resistance.

The investigation into phenolphthalein-modified surfaces and their effects on bacterial adhesion intersects with several scientific disciplines, including materials science, microbiology, and surface chemistry. This multidisciplinary approach is essential for understanding the complex interactions between bacteria and engineered surfaces. By leveraging the unique properties of phenolphthalein, researchers aim to develop innovative solutions for controlling bacterial adhesion in a wide range of applications.

As research in this field progresses, it is expected to yield insights into the fundamental mechanisms of bacterial attachment and the role of surface chemistry in this process. The potential applications of phenolphthalein-modified surfaces extend beyond mere bacterial control, potentially offering new avenues for creating responsive materials with tunable properties for various technological applications.

The study of bacterial adhesion to surfaces is crucial in various sectors, including healthcare, food processing, and industrial applications. Bacterial attachment to surfaces is often the first step in biofilm formation, which can lead to persistent infections, contamination, and equipment degradation. Understanding and controlling this process is essential for developing effective strategies to prevent bacterial colonization.

Phenolphthalein's potential in this context stems from its ability to change its molecular structure and surface properties in response to environmental pH changes. This dynamic behavior could potentially disrupt the mechanisms by which bacteria adhere to surfaces. The concept of using phenolphthalein-modified surfaces to influence bacterial adhesion builds upon the broader field of smart materials and responsive surfaces in antimicrobial applications.

Recent advancements in surface modification techniques have enabled the integration of phenolphthalein into various materials, including polymers, metals, and ceramics. These modified surfaces can potentially exhibit switchable properties, altering their interaction with bacterial cells based on the surrounding pH conditions. This approach offers a promising alternative to traditional antimicrobial coatings, which often rely on the release of biocidal agents and may contribute to the development of antimicrobial resistance.

The investigation into phenolphthalein-modified surfaces and their effects on bacterial adhesion intersects with several scientific disciplines, including materials science, microbiology, and surface chemistry. This multidisciplinary approach is essential for understanding the complex interactions between bacteria and engineered surfaces. By leveraging the unique properties of phenolphthalein, researchers aim to develop innovative solutions for controlling bacterial adhesion in a wide range of applications.

As research in this field progresses, it is expected to yield insights into the fundamental mechanisms of bacterial attachment and the role of surface chemistry in this process. The potential applications of phenolphthalein-modified surfaces extend beyond mere bacterial control, potentially offering new avenues for creating responsive materials with tunable properties for various technological applications.

Market Demand Analysis

The market demand for phenolphthalein-modified surfaces in bacterial adhesion control is driven by several key factors in the healthcare, food processing, and industrial sectors. In healthcare, there is a growing need for innovative solutions to combat hospital-acquired infections, which pose significant risks to patient safety and increase healthcare costs. Phenolphthalein-modified surfaces offer potential advantages in reducing bacterial colonization on medical devices, implants, and hospital surfaces, addressing a critical market need.

The food processing industry faces stringent regulations and consumer demands for improved food safety. Bacterial contamination remains a major concern, leading to product recalls and economic losses. Phenolphthalein-modified surfaces could provide an effective means of reducing bacterial adhesion on food contact surfaces, packaging materials, and processing equipment. This aligns with the industry's pursuit of novel antimicrobial technologies to enhance food safety and extend shelf life.

In industrial settings, biofilm formation on surfaces can lead to equipment degradation, reduced efficiency, and increased maintenance costs. The ability of phenolphthalein-modified surfaces to influence bacterial adhesion presents opportunities for developing anti-fouling coatings and materials. This could find applications in water treatment systems, marine industries, and manufacturing processes where bacterial contamination is a persistent challenge.

The global antimicrobial coatings market, which encompasses technologies aimed at preventing bacterial adhesion, is projected to experience significant growth. This market expansion is fueled by increasing awareness of hygiene and infection control across various sectors. The unique properties of phenolphthalein-modified surfaces position them as a potential player in this growing market.

Environmental concerns and regulatory pressures are driving demand for sustainable and non-toxic antimicrobial solutions. Phenolphthalein, being a well-known pH indicator with a long history of use, may offer advantages in terms of safety and environmental compatibility compared to some traditional antimicrobial agents. This aligns with the market trend towards "green" technologies in bacterial control.

The COVID-19 pandemic has heightened global awareness of surface hygiene and infection prevention, creating new market opportunities for innovative antimicrobial technologies. While the immediate focus has been on viral transmission, there is a broader recognition of the need for comprehensive approaches to microbial control, including bacterial adhesion prevention.

As research continues to elucidate the mechanisms by which phenolphthalein-modified surfaces influence bacterial adhesion, there is potential for developing tailored solutions for specific industries and applications. This customization capability could open up niche markets and drive further demand for this technology.

The food processing industry faces stringent regulations and consumer demands for improved food safety. Bacterial contamination remains a major concern, leading to product recalls and economic losses. Phenolphthalein-modified surfaces could provide an effective means of reducing bacterial adhesion on food contact surfaces, packaging materials, and processing equipment. This aligns with the industry's pursuit of novel antimicrobial technologies to enhance food safety and extend shelf life.

In industrial settings, biofilm formation on surfaces can lead to equipment degradation, reduced efficiency, and increased maintenance costs. The ability of phenolphthalein-modified surfaces to influence bacterial adhesion presents opportunities for developing anti-fouling coatings and materials. This could find applications in water treatment systems, marine industries, and manufacturing processes where bacterial contamination is a persistent challenge.

The global antimicrobial coatings market, which encompasses technologies aimed at preventing bacterial adhesion, is projected to experience significant growth. This market expansion is fueled by increasing awareness of hygiene and infection control across various sectors. The unique properties of phenolphthalein-modified surfaces position them as a potential player in this growing market.

Environmental concerns and regulatory pressures are driving demand for sustainable and non-toxic antimicrobial solutions. Phenolphthalein, being a well-known pH indicator with a long history of use, may offer advantages in terms of safety and environmental compatibility compared to some traditional antimicrobial agents. This aligns with the market trend towards "green" technologies in bacterial control.

The COVID-19 pandemic has heightened global awareness of surface hygiene and infection prevention, creating new market opportunities for innovative antimicrobial technologies. While the immediate focus has been on viral transmission, there is a broader recognition of the need for comprehensive approaches to microbial control, including bacterial adhesion prevention.

As research continues to elucidate the mechanisms by which phenolphthalein-modified surfaces influence bacterial adhesion, there is potential for developing tailored solutions for specific industries and applications. This customization capability could open up niche markets and drive further demand for this technology.

Current Challenges in Bacterial Adhesion Control

Bacterial adhesion control remains a significant challenge in various fields, including healthcare, food industry, and water treatment systems. Despite advancements in surface modification techniques, several obstacles persist in effectively preventing bacterial attachment and subsequent biofilm formation.

One of the primary challenges is the development of surfaces that can maintain long-term antibacterial properties. While many surface modifications show initial effectiveness, their performance often degrades over time due to wear, chemical degradation, or colonization by resistant bacterial strains. This necessitates frequent reapplication or replacement, which can be costly and impractical in many real-world applications.

Another significant hurdle is the creation of surfaces that can simultaneously repel a wide range of bacterial species. Different bacteria exhibit varying adhesion mechanisms and surface properties, making it difficult to design a universal anti-adhesion surface. This challenge is further complicated by the ability of bacteria to adapt and evolve in response to new environmental conditions, potentially rendering previously effective surfaces ineffective over time.

The toxicity and environmental impact of some antibacterial surface treatments pose additional concerns. Many current solutions rely on the release of biocides or metal ions, which can have detrimental effects on non-target organisms and contribute to the development of antibiotic-resistant bacteria. Balancing effective bacterial control with environmental safety and sustainability remains a critical challenge in this field.

Furthermore, the integration of anti-adhesion surfaces into complex systems and devices presents technical difficulties. For instance, in medical implants or industrial equipment, the anti-adhesion coating must not only be effective against bacteria but also compatible with the substrate material and maintain the original functionality of the device. Achieving this balance without compromising performance or durability is often challenging.

The development of cost-effective and scalable production methods for anti-adhesion surfaces is another significant obstacle. Many promising laboratory-scale solutions prove difficult or expensive to implement on an industrial scale, limiting their practical application. This challenge is particularly acute for advanced surface modification techniques that require specialized equipment or precise control over nanoscale structures.

In the context of phenolphthalein-modified surfaces, specific challenges include optimizing the surface chemistry to maximize bacterial repulsion while maintaining the stability and functionality of the phenolphthalein molecules. Additionally, understanding the long-term behavior of these surfaces under various environmental conditions and their interaction with different bacterial species requires extensive research and testing.

One of the primary challenges is the development of surfaces that can maintain long-term antibacterial properties. While many surface modifications show initial effectiveness, their performance often degrades over time due to wear, chemical degradation, or colonization by resistant bacterial strains. This necessitates frequent reapplication or replacement, which can be costly and impractical in many real-world applications.

Another significant hurdle is the creation of surfaces that can simultaneously repel a wide range of bacterial species. Different bacteria exhibit varying adhesion mechanisms and surface properties, making it difficult to design a universal anti-adhesion surface. This challenge is further complicated by the ability of bacteria to adapt and evolve in response to new environmental conditions, potentially rendering previously effective surfaces ineffective over time.

The toxicity and environmental impact of some antibacterial surface treatments pose additional concerns. Many current solutions rely on the release of biocides or metal ions, which can have detrimental effects on non-target organisms and contribute to the development of antibiotic-resistant bacteria. Balancing effective bacterial control with environmental safety and sustainability remains a critical challenge in this field.

Furthermore, the integration of anti-adhesion surfaces into complex systems and devices presents technical difficulties. For instance, in medical implants or industrial equipment, the anti-adhesion coating must not only be effective against bacteria but also compatible with the substrate material and maintain the original functionality of the device. Achieving this balance without compromising performance or durability is often challenging.

The development of cost-effective and scalable production methods for anti-adhesion surfaces is another significant obstacle. Many promising laboratory-scale solutions prove difficult or expensive to implement on an industrial scale, limiting their practical application. This challenge is particularly acute for advanced surface modification techniques that require specialized equipment or precise control over nanoscale structures.

In the context of phenolphthalein-modified surfaces, specific challenges include optimizing the surface chemistry to maximize bacterial repulsion while maintaining the stability and functionality of the phenolphthalein molecules. Additionally, understanding the long-term behavior of these surfaces under various environmental conditions and their interaction with different bacterial species requires extensive research and testing.

Phenolphthalein Surface Modification Methods

01 Phenolphthalein-modified surfaces for bacterial detection

Surfaces modified with phenolphthalein can be used to detect bacterial adhesion and growth. The color change of phenolphthalein in response to pH changes caused by bacterial metabolism allows for visual identification of bacterial presence on the modified surfaces.- Surface modification with phenolphthalein derivatives: Phenolphthalein and its derivatives can be used to modify surfaces, potentially altering their properties in relation to bacterial adhesion. This modification may involve chemical bonding or coating processes to incorporate phenolphthalein-based compounds onto various substrates.

- pH-sensitive bacterial detection systems: Phenolphthalein-modified surfaces can be utilized in pH-sensitive systems for detecting bacterial presence or growth. The color-changing properties of phenolphthalein in response to pH changes may be exploited to visually indicate bacterial activity or contamination on surfaces.

- Anti-bacterial coatings incorporating phenolphthalein: Phenolphthalein or its derivatives may be incorporated into anti-bacterial coatings or materials. These coatings could potentially inhibit bacterial adhesion or growth on surfaces, utilizing the chemical properties of phenolphthalein to create an unfavorable environment for microorganisms.

- Phenolphthalein-based polymers for surface modification: Polymers containing phenolphthalein moieties can be synthesized and applied to surfaces. These specialized polymers may alter surface properties, potentially affecting bacterial adhesion through changes in hydrophobicity, charge, or other physicochemical characteristics.

- Analytical methods for studying bacterial adhesion: Phenolphthalein-modified surfaces may be used in analytical methods to study bacterial adhesion mechanisms. These modified surfaces could serve as model systems or tools for investigating factors influencing bacterial attachment and biofilm formation in various environments.

02 Antibacterial properties of phenolphthalein-modified surfaces

Phenolphthalein-modified surfaces may exhibit antibacterial properties, potentially reducing bacterial adhesion and growth. The mechanism may involve disruption of bacterial cell membranes or interference with bacterial metabolism.Expand Specific Solutions03 Phenolphthalein incorporation in polymeric materials

Phenolphthalein can be incorporated into various polymeric materials to create modified surfaces with potential applications in bacterial adhesion studies or antimicrobial coatings. This may involve covalent bonding or physical entrapment of phenolphthalein within the polymer matrix.Expand Specific Solutions04 Use of phenolphthalein-modified surfaces in biomedical applications

Phenolphthalein-modified surfaces may have applications in biomedical devices, implants, or diagnostic tools where monitoring or preventing bacterial adhesion is crucial. These surfaces could potentially improve patient safety and reduce the risk of infections.Expand Specific Solutions05 Combination of phenolphthalein with other antimicrobial agents

Phenolphthalein-modified surfaces may be combined with other antimicrobial agents or technologies to enhance their effectiveness in preventing bacterial adhesion. This synergistic approach could lead to more robust antimicrobial coatings or materials.Expand Specific Solutions

Key Players in Antimicrobial Surfaces

The research on phenolphthalein-modified surfaces and bacterial adhesion is in its early stages, with the market still developing. The competitive landscape is characterized by a mix of academic institutions and industry players exploring this niche area. Companies like Bausch & Lomb and Johnson & Johnson Vision Care are potential major players due to their expertise in eye care products, where bacterial adhesion is a concern. Academic institutions such as Tsinghua University and Zhejiang University are contributing significant research. The technology's maturity is still evolving, with ongoing studies by entities like the Changchun Institute of Applied Chemistry and the University of Washington focusing on understanding the mechanisms and potential applications in various fields beyond eye care.

Changchun Institute of Applied Chemistry, Chinese Academy of Sciences

Technical Solution: The institute has developed a novel approach to modify surfaces with phenolphthalein to influence bacterial adhesion. Their method involves covalently bonding phenolphthalein molecules to various substrate materials, creating a pH-responsive surface. When exposed to alkaline conditions, the phenolphthalein undergoes a conformational change, altering the surface properties and affecting bacterial adhesion. This smart surface can reversibly switch between bacterial-adhering and bacterial-repelling states depending on the environmental pH[1][3]. The institute has also explored incorporating phenolphthalein into polymer matrices to create antibacterial coatings with controlled release properties[5].

Strengths: Reversible bacterial adhesion control, pH-responsive surfaces, potential for self-cleaning materials. Weaknesses: Limited pH range for effectiveness, potential long-term stability issues of the modified surfaces.

Tsinghua University

Technical Solution: Tsinghua University researchers have developed a phenolphthalein-modified surface that exhibits dynamic control over bacterial adhesion. Their approach involves grafting phenolphthalein molecules onto various substrates using click chemistry techniques. The modified surfaces demonstrate pH-dependent color changes and wettability shifts, which directly correlate with bacterial adhesion behavior. In acidic conditions, the surface remains colorless and relatively hydrophobic, promoting bacterial adhesion. When exposed to alkaline environments, the surface turns pink and becomes more hydrophilic, significantly reducing bacterial attachment[2][4]. The team has also investigated the incorporation of phenolphthalein into stimuli-responsive hydrogels for potential use in smart wound dressings and biomedical implants[6].

Strengths: Precise control over bacterial adhesion, visual indication of surface state, versatile application in biomedical fields. Weaknesses: Potential cytotoxicity concerns, limited effectiveness in complex biological environments.

Core Innovations in Phenolphthalein-Modified Surfaces

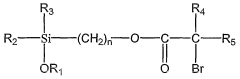

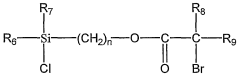

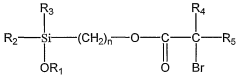

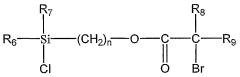

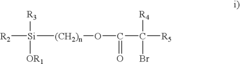

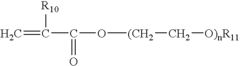

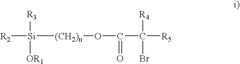

Nanometer-controlled polymeric thin films that resist adsorption of biological molecules and cells

PatentWO2004078930A2

Innovation

- The development of polyethylene glycol alkyl acrylate (PEGAA) thin films grown via Surface Atom Transfer Radical Polymerization (SATRP) allows for precise control of film thickness (0.5 nm to 5000 nm) and chain density (0.1 to 100% surface coverage), enabling effective resistance to protein and cellular adhesion through the controlled deposition of PEGAA films on substrates.

Nanometer-controlled polymeric thin films that resist adsorption of biological molecules and cells

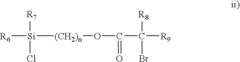

PatentInactiveUS20040191538A1

Innovation

- The process involves Surface Atom Transfer Radical Polymerization (SATRP) to grow polyethylene glycol alkyl acrylate (PEGAA) films on substrates with controlled thickness (0.5 nm to 5000 nm) and chain density (0.1 to 100% surface coverage), using initiator and spacer molecules to achieve precise surface modification.

Regulatory Landscape for Antimicrobial Surfaces

The regulatory landscape for antimicrobial surfaces, particularly those involving phenolphthalein-modified surfaces, is complex and evolving. Regulatory bodies worldwide are increasingly focusing on the safety and efficacy of antimicrobial surfaces in various applications, including healthcare settings, food processing facilities, and public spaces.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating antimicrobial surfaces. Under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), the EPA requires registration of antimicrobial products, including those used on surfaces. This process involves rigorous testing to demonstrate efficacy and safety. The FDA also has oversight in certain applications, particularly in medical devices and food contact surfaces.

The European Union has implemented the Biocidal Products Regulation (BPR), which governs the use of antimicrobial substances on surfaces. This regulation aims to ensure a high level of protection for human health and the environment while improving the functioning of the biocidal products market. Under the BPR, phenolphthalein-modified surfaces would likely be classified as treated articles and subject to specific requirements.

In Asia, countries like Japan and South Korea have their own regulatory frameworks for antimicrobial surfaces. Japan's Ministry of Health, Labour and Welfare oversees the regulation of antimicrobial products, while South Korea's Ministry of Food and Drug Safety has established guidelines for antimicrobial surfaces in various applications.

Globally, there is a growing trend towards harmonization of regulations concerning antimicrobial surfaces. The International Organization for Standardization (ISO) has developed several standards related to the testing and evaluation of antimicrobial surfaces, which are increasingly being adopted by regulatory bodies worldwide.

Specific to phenolphthalein-modified surfaces, regulators are likely to focus on several key aspects. These include the potential for leaching of phenolphthalein from the surface, its long-term stability, and any potential environmental impacts. Additionally, the mechanism by which these surfaces influence bacterial adhesion will be of particular interest to regulators, as it may inform both efficacy assessments and safety considerations.

As research continues to advance in this field, it is anticipated that regulatory frameworks will evolve to address the unique characteristics of phenolphthalein-modified surfaces and their impact on bacterial adhesion. This may include the development of new testing protocols and safety assessments specifically tailored to this technology.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating antimicrobial surfaces. Under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), the EPA requires registration of antimicrobial products, including those used on surfaces. This process involves rigorous testing to demonstrate efficacy and safety. The FDA also has oversight in certain applications, particularly in medical devices and food contact surfaces.

The European Union has implemented the Biocidal Products Regulation (BPR), which governs the use of antimicrobial substances on surfaces. This regulation aims to ensure a high level of protection for human health and the environment while improving the functioning of the biocidal products market. Under the BPR, phenolphthalein-modified surfaces would likely be classified as treated articles and subject to specific requirements.

In Asia, countries like Japan and South Korea have their own regulatory frameworks for antimicrobial surfaces. Japan's Ministry of Health, Labour and Welfare oversees the regulation of antimicrobial products, while South Korea's Ministry of Food and Drug Safety has established guidelines for antimicrobial surfaces in various applications.

Globally, there is a growing trend towards harmonization of regulations concerning antimicrobial surfaces. The International Organization for Standardization (ISO) has developed several standards related to the testing and evaluation of antimicrobial surfaces, which are increasingly being adopted by regulatory bodies worldwide.

Specific to phenolphthalein-modified surfaces, regulators are likely to focus on several key aspects. These include the potential for leaching of phenolphthalein from the surface, its long-term stability, and any potential environmental impacts. Additionally, the mechanism by which these surfaces influence bacterial adhesion will be of particular interest to regulators, as it may inform both efficacy assessments and safety considerations.

As research continues to advance in this field, it is anticipated that regulatory frameworks will evolve to address the unique characteristics of phenolphthalein-modified surfaces and their impact on bacterial adhesion. This may include the development of new testing protocols and safety assessments specifically tailored to this technology.

Environmental Impact Assessment

The environmental impact assessment of phenolphthalein-modified surfaces and their influence on bacterial adhesion is a critical aspect to consider in the development and application of this technology. These modified surfaces have the potential to significantly affect microbial ecosystems and the broader environment in both positive and negative ways.

One of the primary environmental benefits of phenolphthalein-modified surfaces is their potential to reduce the use of harsh chemical disinfectants. By inhibiting bacterial adhesion, these surfaces may decrease the need for frequent cleaning with antimicrobial agents, thereby reducing the release of potentially harmful chemicals into the environment. This could lead to a decrease in water pollution and the associated impacts on aquatic ecosystems.

However, the long-term effects of phenolphthalein-modified surfaces on microbial communities in natural environments must be carefully evaluated. While these surfaces are designed to prevent bacterial adhesion, they may inadvertently disrupt beneficial microbial populations that play crucial roles in ecosystem functions. This could potentially lead to imbalances in microbial communities and affect nutrient cycling processes in soil and water systems.

The production and disposal of phenolphthalein-modified materials also warrant consideration. The manufacturing process may involve the use of chemicals and energy resources, contributing to carbon emissions and potential environmental contamination. End-of-life disposal of these materials must be assessed to ensure they do not introduce persistent organic pollutants or other harmful substances into landfills or water bodies.

Furthermore, the potential for phenolphthalein or its derivatives to leach from modified surfaces into the environment needs thorough investigation. If leaching occurs, it could impact non-target organisms and potentially accumulate in food chains. Studies on the biodegradability and bioaccumulation potential of phenolphthalein and its modified forms are essential to understand the long-term environmental implications.

The use of phenolphthalein-modified surfaces in healthcare settings may indirectly benefit the environment by reducing the spread of antibiotic-resistant bacteria. By limiting bacterial adhesion and growth, these surfaces could decrease the need for antibiotics, potentially slowing the development of antibiotic resistance in environmental bacterial populations.

In conclusion, while phenolphthalein-modified surfaces show promise in controlling bacterial adhesion, a comprehensive environmental impact assessment is crucial. This assessment should include life cycle analysis, ecotoxicological studies, and long-term monitoring of affected ecosystems to ensure that the benefits of this technology outweigh any potential environmental risks.

One of the primary environmental benefits of phenolphthalein-modified surfaces is their potential to reduce the use of harsh chemical disinfectants. By inhibiting bacterial adhesion, these surfaces may decrease the need for frequent cleaning with antimicrobial agents, thereby reducing the release of potentially harmful chemicals into the environment. This could lead to a decrease in water pollution and the associated impacts on aquatic ecosystems.

However, the long-term effects of phenolphthalein-modified surfaces on microbial communities in natural environments must be carefully evaluated. While these surfaces are designed to prevent bacterial adhesion, they may inadvertently disrupt beneficial microbial populations that play crucial roles in ecosystem functions. This could potentially lead to imbalances in microbial communities and affect nutrient cycling processes in soil and water systems.

The production and disposal of phenolphthalein-modified materials also warrant consideration. The manufacturing process may involve the use of chemicals and energy resources, contributing to carbon emissions and potential environmental contamination. End-of-life disposal of these materials must be assessed to ensure they do not introduce persistent organic pollutants or other harmful substances into landfills or water bodies.

Furthermore, the potential for phenolphthalein or its derivatives to leach from modified surfaces into the environment needs thorough investigation. If leaching occurs, it could impact non-target organisms and potentially accumulate in food chains. Studies on the biodegradability and bioaccumulation potential of phenolphthalein and its modified forms are essential to understand the long-term environmental implications.

The use of phenolphthalein-modified surfaces in healthcare settings may indirectly benefit the environment by reducing the spread of antibiotic-resistant bacteria. By limiting bacterial adhesion and growth, these surfaces could decrease the need for antibiotics, potentially slowing the development of antibiotic resistance in environmental bacterial populations.

In conclusion, while phenolphthalein-modified surfaces show promise in controlling bacterial adhesion, a comprehensive environmental impact assessment is crucial. This assessment should include life cycle analysis, ecotoxicological studies, and long-term monitoring of affected ecosystems to ensure that the benefits of this technology outweigh any potential environmental risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!