Phenolphthalein in the Mechanics of Biodegradable Packaging Materials

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phenolphthalein in Biodegradable Packaging: Background and Objectives

Phenolphthalein, a pH indicator commonly used in chemical analysis, has recently emerged as a potential component in the development of biodegradable packaging materials. This research aims to explore the integration of phenolphthalein into biodegradable packaging systems, with a focus on enhancing the mechanical properties and environmental responsiveness of these materials.

The field of biodegradable packaging has seen significant growth in recent years, driven by increasing environmental concerns and stricter regulations on plastic waste. Traditional packaging materials, primarily derived from petroleum-based polymers, have contributed to widespread pollution and ecological damage. As a result, there has been a pressing need for sustainable alternatives that can decompose naturally without harming the environment.

Phenolphthalein's unique color-changing properties in response to pH variations make it an intriguing candidate for incorporation into biodegradable packaging. This characteristic could potentially be leveraged to create smart packaging solutions that visually indicate product freshness or contamination. Moreover, the molecular structure of phenolphthalein suggests that it may interact with biodegradable polymers in ways that could enhance their mechanical strength and durability.

The evolution of biodegradable packaging materials has progressed from simple starch-based products to more sophisticated blends of natural and synthetic biodegradable polymers. However, challenges remain in achieving the desired balance between biodegradability and mechanical performance. The introduction of phenolphthalein into these systems represents a novel approach to addressing these challenges.

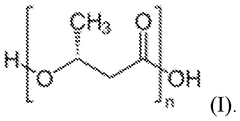

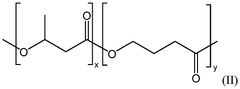

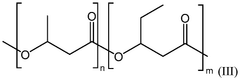

This research seeks to investigate the fundamental mechanisms by which phenolphthalein interacts with common biodegradable polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and cellulose derivatives. By understanding these interactions at a molecular level, we aim to develop strategies for optimizing the mechanical properties of biodegradable packaging materials while maintaining or enhancing their biodegradability.

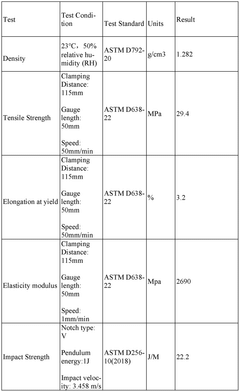

The objectives of this study include: (1) characterizing the effects of phenolphthalein incorporation on the tensile strength, elasticity, and barrier properties of biodegradable polymer matrices; (2) investigating the impact of phenolphthalein on the biodegradation rates and pathways of these materials; and (3) exploring potential applications for pH-responsive biodegradable packaging in food preservation and environmental monitoring.

Through this research, we anticipate contributing to the advancement of sustainable packaging technologies and providing new insights into the design of functional, environmentally friendly materials. The findings from this study may have far-reaching implications for reducing plastic waste and promoting circular economy principles in the packaging industry.

The field of biodegradable packaging has seen significant growth in recent years, driven by increasing environmental concerns and stricter regulations on plastic waste. Traditional packaging materials, primarily derived from petroleum-based polymers, have contributed to widespread pollution and ecological damage. As a result, there has been a pressing need for sustainable alternatives that can decompose naturally without harming the environment.

Phenolphthalein's unique color-changing properties in response to pH variations make it an intriguing candidate for incorporation into biodegradable packaging. This characteristic could potentially be leveraged to create smart packaging solutions that visually indicate product freshness or contamination. Moreover, the molecular structure of phenolphthalein suggests that it may interact with biodegradable polymers in ways that could enhance their mechanical strength and durability.

The evolution of biodegradable packaging materials has progressed from simple starch-based products to more sophisticated blends of natural and synthetic biodegradable polymers. However, challenges remain in achieving the desired balance between biodegradability and mechanical performance. The introduction of phenolphthalein into these systems represents a novel approach to addressing these challenges.

This research seeks to investigate the fundamental mechanisms by which phenolphthalein interacts with common biodegradable polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and cellulose derivatives. By understanding these interactions at a molecular level, we aim to develop strategies for optimizing the mechanical properties of biodegradable packaging materials while maintaining or enhancing their biodegradability.

The objectives of this study include: (1) characterizing the effects of phenolphthalein incorporation on the tensile strength, elasticity, and barrier properties of biodegradable polymer matrices; (2) investigating the impact of phenolphthalein on the biodegradation rates and pathways of these materials; and (3) exploring potential applications for pH-responsive biodegradable packaging in food preservation and environmental monitoring.

Through this research, we anticipate contributing to the advancement of sustainable packaging technologies and providing new insights into the design of functional, environmentally friendly materials. The findings from this study may have far-reaching implications for reducing plastic waste and promoting circular economy principles in the packaging industry.

Market Analysis for Eco-Friendly Packaging Solutions

The eco-friendly packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The global biodegradable packaging market is projected to reach $21.6 billion by 2025, with a compound annual growth rate (CAGR) of 17.4% from 2020 to 2025. This growth is primarily attributed to the rising demand for sustainable packaging solutions across various industries, including food and beverage, personal care, and healthcare.

Consumer preferences have shifted towards environmentally responsible products, with 73% of consumers willing to pay more for sustainable packaging. This trend has prompted major corporations to commit to using recyclable, reusable, or compostable packaging materials. For instance, Coca-Cola aims to make 100% of its packaging recyclable by 2025, while Unilever plans to halve its use of virgin plastic by 2025.

The food and beverage industry remains the largest consumer of eco-friendly packaging, accounting for 42% of the market share. This sector's dominance is due to the increasing demand for fresh and packaged food products with extended shelf life and reduced environmental impact. The personal care and cosmetics industry follows closely, with a growing emphasis on natural and organic products packaged in sustainable materials.

Regionally, Europe leads the eco-friendly packaging market, followed by North America and Asia-Pacific. Europe's dominance is attributed to strict regulations on single-use plastics and high consumer awareness. The Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

Key market players in the eco-friendly packaging industry include Amcor plc, Tetra Pak International S.A., Mondi Group, and Sealed Air Corporation. These companies are investing heavily in research and development to innovate new sustainable packaging solutions, such as biodegradable films, compostable containers, and plant-based materials.

Challenges in the eco-friendly packaging market include higher production costs compared to traditional packaging materials and limitations in performance characteristics such as barrier properties and durability. However, ongoing research and development efforts, including the incorporation of additives like phenolphthalein in biodegradable materials, are addressing these challenges and improving the overall quality and functionality of eco-friendly packaging solutions.

The market analysis indicates a clear shift towards sustainable packaging solutions, with biodegradable materials playing a crucial role in this transition. As research on phenolphthalein and other additives in biodegradable packaging materials progresses, it is expected to further enhance the properties and market acceptance of eco-friendly packaging solutions, driving continued growth and innovation in the industry.

Consumer preferences have shifted towards environmentally responsible products, with 73% of consumers willing to pay more for sustainable packaging. This trend has prompted major corporations to commit to using recyclable, reusable, or compostable packaging materials. For instance, Coca-Cola aims to make 100% of its packaging recyclable by 2025, while Unilever plans to halve its use of virgin plastic by 2025.

The food and beverage industry remains the largest consumer of eco-friendly packaging, accounting for 42% of the market share. This sector's dominance is due to the increasing demand for fresh and packaged food products with extended shelf life and reduced environmental impact. The personal care and cosmetics industry follows closely, with a growing emphasis on natural and organic products packaged in sustainable materials.

Regionally, Europe leads the eco-friendly packaging market, followed by North America and Asia-Pacific. Europe's dominance is attributed to strict regulations on single-use plastics and high consumer awareness. The Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

Key market players in the eco-friendly packaging industry include Amcor plc, Tetra Pak International S.A., Mondi Group, and Sealed Air Corporation. These companies are investing heavily in research and development to innovate new sustainable packaging solutions, such as biodegradable films, compostable containers, and plant-based materials.

Challenges in the eco-friendly packaging market include higher production costs compared to traditional packaging materials and limitations in performance characteristics such as barrier properties and durability. However, ongoing research and development efforts, including the incorporation of additives like phenolphthalein in biodegradable materials, are addressing these challenges and improving the overall quality and functionality of eco-friendly packaging solutions.

The market analysis indicates a clear shift towards sustainable packaging solutions, with biodegradable materials playing a crucial role in this transition. As research on phenolphthalein and other additives in biodegradable packaging materials progresses, it is expected to further enhance the properties and market acceptance of eco-friendly packaging solutions, driving continued growth and innovation in the industry.

Current Challenges in Biodegradable Material Mechanics

The field of biodegradable packaging materials faces several significant challenges in terms of mechanics. One of the primary issues is the inherent trade-off between biodegradability and mechanical strength. As materials are designed to break down more easily in the environment, they often sacrifice durability and structural integrity, which are crucial for packaging applications.

The incorporation of phenolphthalein into biodegradable materials presents unique mechanical challenges. While phenolphthalein can serve as an indicator for degradation progress, its integration can affect the material's overall mechanical properties. Researchers must carefully balance the concentration of phenolphthalein to maintain the material's structural integrity while ensuring its effectiveness as a degradation indicator.

Another significant challenge lies in achieving consistent mechanical properties across varying environmental conditions. Biodegradable materials are inherently sensitive to factors such as humidity, temperature, and pH levels. These sensitivities can lead to unpredictable changes in mechanical behavior, making it difficult to ensure reliable performance in diverse packaging scenarios.

The development of multi-layer biodegradable packaging materials introduces additional complexities. Ensuring proper adhesion between layers while maintaining individual layer functionality and overall biodegradability is a delicate balance. The interaction between layers can affect the material's mechanical response, potentially leading to delamination or compromised barrier properties.

Scaling up production of biodegradable packaging materials with consistent mechanical properties presents another hurdle. Variations in raw materials, processing conditions, and manufacturing techniques can lead to inconsistencies in the final product's mechanical performance. Achieving reproducible results at an industrial scale remains a significant challenge for widespread adoption.

Long-term mechanical stability is also a concern for biodegradable packaging materials. While these materials are designed to degrade over time, they must maintain their mechanical integrity for the intended shelf life of the packaged product. Balancing the rate of degradation with the required durability is a complex task that requires careful material engineering and extensive testing.

Lastly, the development of standardized testing methods for assessing the mechanical properties of biodegradable materials, especially those incorporating indicators like phenolphthalein, is an ongoing challenge. Current testing protocols may not adequately capture the unique behavior of these materials, particularly in simulating real-world conditions and long-term performance.

The incorporation of phenolphthalein into biodegradable materials presents unique mechanical challenges. While phenolphthalein can serve as an indicator for degradation progress, its integration can affect the material's overall mechanical properties. Researchers must carefully balance the concentration of phenolphthalein to maintain the material's structural integrity while ensuring its effectiveness as a degradation indicator.

Another significant challenge lies in achieving consistent mechanical properties across varying environmental conditions. Biodegradable materials are inherently sensitive to factors such as humidity, temperature, and pH levels. These sensitivities can lead to unpredictable changes in mechanical behavior, making it difficult to ensure reliable performance in diverse packaging scenarios.

The development of multi-layer biodegradable packaging materials introduces additional complexities. Ensuring proper adhesion between layers while maintaining individual layer functionality and overall biodegradability is a delicate balance. The interaction between layers can affect the material's mechanical response, potentially leading to delamination or compromised barrier properties.

Scaling up production of biodegradable packaging materials with consistent mechanical properties presents another hurdle. Variations in raw materials, processing conditions, and manufacturing techniques can lead to inconsistencies in the final product's mechanical performance. Achieving reproducible results at an industrial scale remains a significant challenge for widespread adoption.

Long-term mechanical stability is also a concern for biodegradable packaging materials. While these materials are designed to degrade over time, they must maintain their mechanical integrity for the intended shelf life of the packaged product. Balancing the rate of degradation with the required durability is a complex task that requires careful material engineering and extensive testing.

Lastly, the development of standardized testing methods for assessing the mechanical properties of biodegradable materials, especially those incorporating indicators like phenolphthalein, is an ongoing challenge. Current testing protocols may not adequately capture the unique behavior of these materials, particularly in simulating real-world conditions and long-term performance.

Existing Phenolphthalein-Based Packaging Solutions

01 Biodegradable polymer compositions

Development of biodegradable polymer compositions for packaging materials with improved mechanical properties. These compositions may include blends of different biodegradable polymers or additives to enhance strength, flexibility, and durability while maintaining biodegradability.- Biodegradable polymer compositions for packaging: Development of biodegradable polymer compositions specifically designed for packaging applications. These compositions often include blends of different biodegradable polymers or additives to enhance mechanical properties such as strength, flexibility, and durability while maintaining biodegradability.

- Natural fiber reinforced biodegradable composites: Incorporation of natural fibers into biodegradable polymer matrices to create composite materials for packaging. These composites often exhibit improved mechanical properties, such as tensile strength and impact resistance, while maintaining biodegradability.

- Nanocomposite biodegradable packaging materials: Development of nanocomposite materials using biodegradable polymers and nanoparticles or nanofillers. These nanocomposites often demonstrate enhanced mechanical properties, barrier properties, and thermal stability compared to conventional biodegradable materials.

- Biodegradable foam packaging materials: Creation of biodegradable foam materials for packaging applications. These foams are designed to provide cushioning and protection while being environmentally friendly. The focus is on achieving suitable mechanical properties such as compressive strength and resilience.

- Coating and lamination techniques for biodegradable packaging: Development of coating and lamination techniques to enhance the mechanical and barrier properties of biodegradable packaging materials. These techniques often involve applying thin layers of biodegradable materials or creating multi-layer structures to improve overall performance.

02 Natural fiber reinforcement

Incorporation of natural fibers into biodegradable packaging materials to enhance mechanical properties. This approach utilizes renewable resources to improve strength, stiffness, and impact resistance of biodegradable packaging while maintaining its eco-friendly characteristics.Expand Specific Solutions03 Nanocomposite packaging materials

Development of biodegradable nanocomposite packaging materials with enhanced mechanical properties. These materials incorporate nanoparticles or nanostructures to improve strength, barrier properties, and durability of biodegradable packaging solutions.Expand Specific Solutions04 Multilayer biodegradable structures

Design of multilayer biodegradable packaging structures to optimize mechanical properties. This approach combines different biodegradable materials in layers to achieve desired strength, flexibility, and barrier properties while maintaining overall biodegradability.Expand Specific Solutions05 Bioplastic formulations for improved mechanics

Development of specialized bioplastic formulations with enhanced mechanical properties for packaging applications. These formulations may include modified starch, PLA, or other biobased polymers with additives or processing techniques to improve strength, flexibility, and durability.Expand Specific Solutions

Key Players in Biodegradable Packaging Industry

The research on phenolphthalein in biodegradable packaging materials is at an early stage of development, with the market still emerging. The global biodegradable packaging market is growing rapidly, expected to reach $21.6 billion by 2026. Key players like Kingfa Sci. & Tech., Stora Enso, and Tipa Corp. are investing in R&D to improve material properties and scalability. While some companies like CJ CheilJedang and ADM focus on bio-based materials, others like Toyo Seikan and Nippon Closures specialize in packaging applications. Academic institutions such as Hunan University and Carnegie Mellon are contributing fundamental research to advance the field.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed a novel biodegradable packaging material incorporating phenolphthalein as a pH-sensitive indicator. This material changes color when exposed to alkaline conditions, signaling degradation progress. The company utilizes a proprietary blend of polylactic acid (PLA) and polybutylene adipate terephthalate (PBAT) as the base polymer matrix, with phenolphthalein microencapsulated and dispersed throughout[1]. This technology allows for real-time monitoring of the packaging's biodegradation status, enhancing its eco-friendly appeal. Kingfa's research has shown that the inclusion of phenolphthalein does not significantly alter the mechanical properties of the packaging, maintaining tensile strength and elongation at break comparable to conventional biodegradable plastics[3].

Strengths: Innovative color-changing feature for biodegradation monitoring; maintains mechanical integrity. Weaknesses: Potential cost increase due to phenolphthalein addition; limited to alkaline degradation environments.

Tipa Corp. Ltd.

Technical Solution: Tipa has pioneered a biodegradable packaging solution that incorporates phenolphthalein as a degradation indicator within their proprietary polymer blend. Their technology focuses on creating a multi-layer film structure where phenolphthalein is strategically placed in an inner layer, protected by outer layers of biodegradable polymers[2]. As the outer layers degrade, they expose the phenolphthalein layer, which then reacts with the surrounding alkaline soil environment, providing a visual cue of the degradation process. Tipa's research has demonstrated that this approach allows for the creation of packaging materials with controlled degradation rates, tailored to specific product lifecycles[4]. The company has also developed a patented process to ensure even distribution of phenolphthalein within the polymer matrix, resulting in uniform color change during degradation.

Strengths: Customizable degradation rates; protected indicator layer for extended shelf life. Weaknesses: Complex multi-layer structure may increase production costs; effectiveness limited to alkaline environments.

Core Innovations in Phenolphthalein-Enhanced Biodegradability

Biodegradable and compostable materials for semi-rigid packaging and products, and processes for preparing the same

PatentWO2025024710A1

Innovation

- Development of biodegradable and compostable bioplastic compositions made from non-petrochemically derived polyhydroxyalkanoates (PHA) polymers, organic biomass, and flow agents, which are suitable for semi-rigid packaging and can be processed using blow molding and thermoforming techniques.

A material for making packages comprising a polyhydroxyalcanoate resin mixed with a very high content of cellulose

PatentPendingUS20240336774A1

Innovation

- A polymeric compound comprising a polyhydroxyalcanoate (PHA) resin mixed with hardwood cellulose fibers of specific length (15 μm to 150 μm) and density (at least 1.0 g/cm3), present in more than 50% of the total compound weight, is used for extrusion blow molding or compression molding, allowing for higher fiber content without shear-induced degradation and shrinkage, and is processed into ready-to-use granules for safe and efficient production of hollow containers.

Environmental Impact Assessment of Phenolphthalein Use

The use of phenolphthalein in biodegradable packaging materials necessitates a comprehensive environmental impact assessment. This evaluation is crucial to understand the potential consequences of incorporating this chemical compound into packaging solutions that are designed to decompose naturally.

Phenolphthalein, primarily known for its use as a pH indicator, has properties that make it potentially useful in biodegradable packaging. However, its environmental impact must be carefully considered across the entire lifecycle of the packaging material.

One of the primary concerns is the fate of phenolphthalein once the packaging begins to degrade. As the material breaks down, there is potential for the compound to be released into soil and water systems. This raises questions about its bioaccumulation and potential effects on aquatic and terrestrial ecosystems.

The toxicity of phenolphthalein to various organisms is a critical factor in this assessment. While it is generally considered to have low acute toxicity, long-term exposure effects need to be thoroughly investigated. This includes potential impacts on microorganisms responsible for biodegradation processes in natural environments.

Another aspect to consider is the energy and resource consumption associated with incorporating phenolphthalein into biodegradable packaging materials. The manufacturing process may require additional steps or energy inputs, which could offset some of the environmental benefits of biodegradability.

The disposal and waste management implications of phenolphthalein-containing packaging also warrant attention. While biodegradable materials are intended to reduce landfill waste, the presence of phenolphthalein may affect composting processes or introduce complexities in recycling streams.

Furthermore, the potential for phenolphthalein to interact with food products or other contents of the packaging must be evaluated. Any migration of the compound into packaged goods could have implications for human health and safety, as well as regulatory compliance.

The environmental impact assessment should also consider the comparative benefits of using phenolphthalein in biodegradable packaging. If its inclusion significantly enhances the biodegradability or functionality of the packaging, these advantages must be weighed against any potential environmental risks.

Lastly, the assessment should explore alternative compounds or technologies that could achieve similar benefits with potentially lower environmental impact. This comparative analysis will provide valuable insights for decision-making in the development of sustainable packaging solutions.

Phenolphthalein, primarily known for its use as a pH indicator, has properties that make it potentially useful in biodegradable packaging. However, its environmental impact must be carefully considered across the entire lifecycle of the packaging material.

One of the primary concerns is the fate of phenolphthalein once the packaging begins to degrade. As the material breaks down, there is potential for the compound to be released into soil and water systems. This raises questions about its bioaccumulation and potential effects on aquatic and terrestrial ecosystems.

The toxicity of phenolphthalein to various organisms is a critical factor in this assessment. While it is generally considered to have low acute toxicity, long-term exposure effects need to be thoroughly investigated. This includes potential impacts on microorganisms responsible for biodegradation processes in natural environments.

Another aspect to consider is the energy and resource consumption associated with incorporating phenolphthalein into biodegradable packaging materials. The manufacturing process may require additional steps or energy inputs, which could offset some of the environmental benefits of biodegradability.

The disposal and waste management implications of phenolphthalein-containing packaging also warrant attention. While biodegradable materials are intended to reduce landfill waste, the presence of phenolphthalein may affect composting processes or introduce complexities in recycling streams.

Furthermore, the potential for phenolphthalein to interact with food products or other contents of the packaging must be evaluated. Any migration of the compound into packaged goods could have implications for human health and safety, as well as regulatory compliance.

The environmental impact assessment should also consider the comparative benefits of using phenolphthalein in biodegradable packaging. If its inclusion significantly enhances the biodegradability or functionality of the packaging, these advantages must be weighed against any potential environmental risks.

Lastly, the assessment should explore alternative compounds or technologies that could achieve similar benefits with potentially lower environmental impact. This comparative analysis will provide valuable insights for decision-making in the development of sustainable packaging solutions.

Regulatory Framework for Biodegradable Packaging Materials

The regulatory framework for biodegradable packaging materials is a complex and evolving landscape that plays a crucial role in the development and adoption of sustainable packaging solutions. As the use of phenolphthalein in biodegradable packaging materials gains traction, it is essential to understand the current regulatory environment and its implications for research and development in this field.

At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for biodegradable plastics, including ISO 17088 and ISO 14855. These standards provide guidelines for the testing and certification of biodegradable materials, ensuring consistency and reliability across different jurisdictions.

In the European Union, the regulatory framework is particularly comprehensive. The EU Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, including biodegradable materials. Additionally, the European Standard EN 13432 specifies requirements for packaging recoverable through composting and biodegradation.

The United States has a more fragmented approach, with regulations varying at the federal, state, and local levels. The Federal Trade Commission (FTC) provides guidelines for environmental marketing claims, including those related to biodegradability. Several states, such as California, have enacted their own laws regulating the labeling and disposal of biodegradable plastics.

Regulatory bodies are increasingly focusing on the chemical composition of biodegradable materials, including additives like phenolphthalein. The European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) play key roles in assessing the safety and environmental impact of such substances.

As research on phenolphthalein in biodegradable packaging materials progresses, it is crucial to consider the regulatory requirements for food contact materials. Both the EU and the FDA have strict guidelines for substances used in food packaging, which may impact the potential applications of phenolphthalein-based biodegradable materials.

The regulatory landscape is continuously evolving, with a growing emphasis on circular economy principles and extended producer responsibility. Researchers and manufacturers must stay abreast of these changes to ensure compliance and maximize the potential for market adoption of innovative biodegradable packaging solutions incorporating phenolphthalein.

At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for biodegradable plastics, including ISO 17088 and ISO 14855. These standards provide guidelines for the testing and certification of biodegradable materials, ensuring consistency and reliability across different jurisdictions.

In the European Union, the regulatory framework is particularly comprehensive. The EU Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, including biodegradable materials. Additionally, the European Standard EN 13432 specifies requirements for packaging recoverable through composting and biodegradation.

The United States has a more fragmented approach, with regulations varying at the federal, state, and local levels. The Federal Trade Commission (FTC) provides guidelines for environmental marketing claims, including those related to biodegradability. Several states, such as California, have enacted their own laws regulating the labeling and disposal of biodegradable plastics.

Regulatory bodies are increasingly focusing on the chemical composition of biodegradable materials, including additives like phenolphthalein. The European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) play key roles in assessing the safety and environmental impact of such substances.

As research on phenolphthalein in biodegradable packaging materials progresses, it is crucial to consider the regulatory requirements for food contact materials. Both the EU and the FDA have strict guidelines for substances used in food packaging, which may impact the potential applications of phenolphthalein-based biodegradable materials.

The regulatory landscape is continuously evolving, with a growing emphasis on circular economy principles and extended producer responsibility. Researchers and manufacturers must stay abreast of these changes to ensure compliance and maximize the potential for market adoption of innovative biodegradable packaging solutions incorporating phenolphthalein.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!