Phenolphthalein in Chemical Vapor Deposition Processes

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CVD Phenolphthalein Background and Objectives

Chemical Vapor Deposition (CVD) has been a cornerstone technology in the semiconductor industry for decades, enabling the production of high-quality thin films for various applications. The integration of phenolphthalein into CVD processes represents a novel approach that merits thorough investigation due to its potential to enhance process control and film quality.

Phenolphthalein, traditionally known as a pH indicator, has recently garnered attention in the field of materials science for its unique properties. Its ability to change color in response to environmental conditions offers intriguing possibilities for in-situ monitoring of CVD processes. This research aims to explore the utilization of phenolphthalein in CVD, with the primary objective of developing more efficient and precise deposition techniques.

The evolution of CVD technology has been driven by the constant demand for smaller, faster, and more efficient electronic devices. As the industry pushes towards sub-10nm nodes, the need for precise control over film thickness, composition, and uniformity becomes increasingly critical. The introduction of phenolphthalein into CVD processes could potentially address some of these challenges by providing real-time feedback on deposition conditions.

One of the key objectives of this research is to investigate how phenolphthalein can be effectively incorporated into existing CVD systems without compromising the integrity of the deposition process. This includes studying the thermal stability of phenolphthalein under typical CVD conditions and its interaction with common precursor gases and substrate materials.

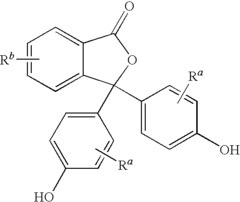

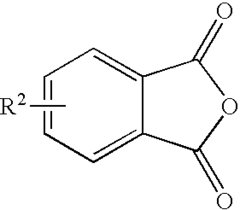

Another important goal is to explore the potential of phenolphthalein as a novel precursor material itself. Its molecular structure, containing both aromatic rings and functional groups, could lead to the formation of unique carbon-based thin films with tailored properties. This aspect of the research could open up new avenues for the development of organic semiconductors and functional coatings.

Furthermore, this study aims to assess the feasibility of using phenolphthalein-based sensors for real-time monitoring of CVD processes. The color-changing property of phenolphthalein could be leveraged to develop optical sensors that provide immediate feedback on parameters such as gas composition, temperature, and pressure within the deposition chamber.

By combining fundamental scientific inquiry with practical engineering considerations, this research seeks to bridge the gap between laboratory experiments and industrial applications. The ultimate objective is to develop a comprehensive understanding of phenolphthalein's role in CVD processes and to evaluate its potential for improving the efficiency, reliability, and scalability of thin film deposition techniques in semiconductor manufacturing and related fields.

Phenolphthalein, traditionally known as a pH indicator, has recently garnered attention in the field of materials science for its unique properties. Its ability to change color in response to environmental conditions offers intriguing possibilities for in-situ monitoring of CVD processes. This research aims to explore the utilization of phenolphthalein in CVD, with the primary objective of developing more efficient and precise deposition techniques.

The evolution of CVD technology has been driven by the constant demand for smaller, faster, and more efficient electronic devices. As the industry pushes towards sub-10nm nodes, the need for precise control over film thickness, composition, and uniformity becomes increasingly critical. The introduction of phenolphthalein into CVD processes could potentially address some of these challenges by providing real-time feedback on deposition conditions.

One of the key objectives of this research is to investigate how phenolphthalein can be effectively incorporated into existing CVD systems without compromising the integrity of the deposition process. This includes studying the thermal stability of phenolphthalein under typical CVD conditions and its interaction with common precursor gases and substrate materials.

Another important goal is to explore the potential of phenolphthalein as a novel precursor material itself. Its molecular structure, containing both aromatic rings and functional groups, could lead to the formation of unique carbon-based thin films with tailored properties. This aspect of the research could open up new avenues for the development of organic semiconductors and functional coatings.

Furthermore, this study aims to assess the feasibility of using phenolphthalein-based sensors for real-time monitoring of CVD processes. The color-changing property of phenolphthalein could be leveraged to develop optical sensors that provide immediate feedback on parameters such as gas composition, temperature, and pressure within the deposition chamber.

By combining fundamental scientific inquiry with practical engineering considerations, this research seeks to bridge the gap between laboratory experiments and industrial applications. The ultimate objective is to develop a comprehensive understanding of phenolphthalein's role in CVD processes and to evaluate its potential for improving the efficiency, reliability, and scalability of thin film deposition techniques in semiconductor manufacturing and related fields.

Market Analysis for CVD Phenolphthalein Applications

The market for Chemical Vapor Deposition (CVD) processes utilizing phenolphthalein is experiencing significant growth, driven by the increasing demand for advanced materials in various industries. The global CVD market is projected to expand at a compound annual growth rate (CAGR) of 8.5% from 2021 to 2026, with the phenolphthalein segment showing promising potential.

The electronics industry remains the primary driver for CVD phenolphthalein applications, particularly in the production of semiconductors and advanced display technologies. As the demand for smaller, more efficient electronic devices continues to rise, the need for precise and uniform thin film deposition processes becomes crucial. Phenolphthalein's unique properties make it an attractive option for enhancing the performance and reliability of CVD processes in this sector.

In the automotive industry, there is a growing interest in using CVD phenolphthalein for coating applications, especially in the production of advanced sensors and electronic components for electric and autonomous vehicles. This trend is expected to contribute significantly to market growth in the coming years.

The aerospace and defense sectors are also emerging as key markets for CVD phenolphthalein applications. The material's ability to create highly durable and resistant coatings is particularly valuable in these industries, where components are subjected to extreme conditions.

Geographically, Asia-Pacific dominates the market, accounting for over 40% of the global share. This is primarily due to the strong presence of electronics manufacturing hubs in countries like China, South Korea, and Taiwan. North America and Europe follow, with steady growth driven by advancements in automotive and aerospace industries.

However, the market faces challenges such as high initial investment costs and stringent environmental regulations. The complex nature of CVD processes and the need for specialized equipment and expertise can be barriers to entry for smaller players. Additionally, concerns about the environmental impact of certain CVD precursors are prompting research into more sustainable alternatives.

Despite these challenges, the future outlook for CVD phenolphthalein applications remains positive. Ongoing research and development efforts are focused on improving process efficiency, reducing costs, and expanding the range of applications. Emerging opportunities in fields such as renewable energy, particularly in the production of solar cells and fuel cells, are expected to create new avenues for market growth.

As industries continue to demand higher-performance materials and more sophisticated manufacturing processes, the market for CVD phenolphthalein applications is poised for sustained growth. Companies that can innovate and address the evolving needs of key industries while navigating regulatory challenges are likely to succeed in this dynamic market landscape.

The electronics industry remains the primary driver for CVD phenolphthalein applications, particularly in the production of semiconductors and advanced display technologies. As the demand for smaller, more efficient electronic devices continues to rise, the need for precise and uniform thin film deposition processes becomes crucial. Phenolphthalein's unique properties make it an attractive option for enhancing the performance and reliability of CVD processes in this sector.

In the automotive industry, there is a growing interest in using CVD phenolphthalein for coating applications, especially in the production of advanced sensors and electronic components for electric and autonomous vehicles. This trend is expected to contribute significantly to market growth in the coming years.

The aerospace and defense sectors are also emerging as key markets for CVD phenolphthalein applications. The material's ability to create highly durable and resistant coatings is particularly valuable in these industries, where components are subjected to extreme conditions.

Geographically, Asia-Pacific dominates the market, accounting for over 40% of the global share. This is primarily due to the strong presence of electronics manufacturing hubs in countries like China, South Korea, and Taiwan. North America and Europe follow, with steady growth driven by advancements in automotive and aerospace industries.

However, the market faces challenges such as high initial investment costs and stringent environmental regulations. The complex nature of CVD processes and the need for specialized equipment and expertise can be barriers to entry for smaller players. Additionally, concerns about the environmental impact of certain CVD precursors are prompting research into more sustainable alternatives.

Despite these challenges, the future outlook for CVD phenolphthalein applications remains positive. Ongoing research and development efforts are focused on improving process efficiency, reducing costs, and expanding the range of applications. Emerging opportunities in fields such as renewable energy, particularly in the production of solar cells and fuel cells, are expected to create new avenues for market growth.

As industries continue to demand higher-performance materials and more sophisticated manufacturing processes, the market for CVD phenolphthalein applications is poised for sustained growth. Companies that can innovate and address the evolving needs of key industries while navigating regulatory challenges are likely to succeed in this dynamic market landscape.

Current Challenges in CVD Phenolphthalein Usage

The integration of phenolphthalein in Chemical Vapor Deposition (CVD) processes presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary obstacles is the thermal stability of phenolphthalein at the high temperatures typically required for CVD processes. The compound tends to decompose at temperatures above 300°C, which limits its applicability in many standard CVD reactions that often operate at much higher temperatures.

Another critical challenge lies in controlling the vapor pressure of phenolphthalein during the deposition process. The compound's relatively low vapor pressure at typical CVD operating temperatures makes it difficult to achieve consistent and uniform deposition rates across the substrate surface. This inconsistency can lead to non-uniform film thickness and composition, compromising the quality and performance of the resulting thin films.

The reactivity of phenolphthalein with other precursor materials used in CVD processes poses yet another hurdle. Undesired side reactions can occur, leading to the formation of unwanted byproducts or impurities in the deposited films. These impurities can significantly affect the electrical, optical, or mechanical properties of the final product, potentially rendering it unsuitable for its intended application.

Furthermore, the incorporation of phenolphthalein into existing CVD equipment and processes presents engineering challenges. Many current CVD systems are not optimized for handling compounds with the specific physical and chemical properties of phenolphthalein, necessitating modifications to precursor delivery systems, reaction chambers, and process control mechanisms.

The environmental and safety concerns associated with phenolphthalein usage in CVD processes also pose significant challenges. The compound is known to have potential endocrine-disrupting properties, raising concerns about worker exposure and environmental release. Implementing adequate safety measures and waste management protocols adds complexity and cost to the CVD process.

Lastly, the scalability of phenolphthalein-based CVD processes for industrial applications remains a major challenge. While laboratory-scale experiments may show promising results, translating these findings into large-scale, economically viable production processes requires overcoming numerous technical and practical hurdles. These include maintaining process stability over extended periods, ensuring consistent product quality across larger substrate areas, and managing the increased material and energy costs associated with scaled-up operations.

Another critical challenge lies in controlling the vapor pressure of phenolphthalein during the deposition process. The compound's relatively low vapor pressure at typical CVD operating temperatures makes it difficult to achieve consistent and uniform deposition rates across the substrate surface. This inconsistency can lead to non-uniform film thickness and composition, compromising the quality and performance of the resulting thin films.

The reactivity of phenolphthalein with other precursor materials used in CVD processes poses yet another hurdle. Undesired side reactions can occur, leading to the formation of unwanted byproducts or impurities in the deposited films. These impurities can significantly affect the electrical, optical, or mechanical properties of the final product, potentially rendering it unsuitable for its intended application.

Furthermore, the incorporation of phenolphthalein into existing CVD equipment and processes presents engineering challenges. Many current CVD systems are not optimized for handling compounds with the specific physical and chemical properties of phenolphthalein, necessitating modifications to precursor delivery systems, reaction chambers, and process control mechanisms.

The environmental and safety concerns associated with phenolphthalein usage in CVD processes also pose significant challenges. The compound is known to have potential endocrine-disrupting properties, raising concerns about worker exposure and environmental release. Implementing adequate safety measures and waste management protocols adds complexity and cost to the CVD process.

Lastly, the scalability of phenolphthalein-based CVD processes for industrial applications remains a major challenge. While laboratory-scale experiments may show promising results, translating these findings into large-scale, economically viable production processes requires overcoming numerous technical and practical hurdles. These include maintaining process stability over extended periods, ensuring consistent product quality across larger substrate areas, and managing the increased material and energy costs associated with scaled-up operations.

Existing CVD Phenolphthalein Methodologies

01 Synthesis and production of phenolphthalein

Various methods and processes for synthesizing and producing phenolphthalein are described. These include different reaction conditions, catalysts, and starting materials to improve yield, purity, and efficiency of production.- Synthesis and production of phenolphthalein: Various methods and processes for synthesizing and producing phenolphthalein are described. These include different reaction conditions, catalysts, and starting materials to optimize yield and purity of the final product.

- Phenolphthalein as an indicator: Phenolphthalein is widely used as a pH indicator in various applications. Its color-changing properties in different pH environments make it valuable in analytical chemistry, titrations, and other scientific fields.

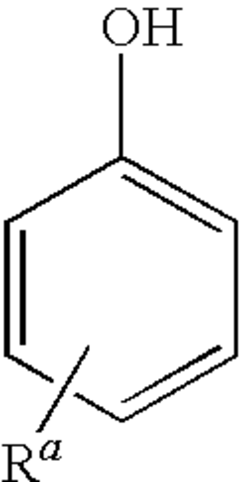

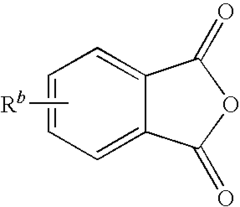

- Phenolphthalein derivatives and modifications: Research on developing new derivatives and modifications of phenolphthalein to enhance its properties or create new applications. This includes structural modifications, substitutions, and the creation of novel compounds based on the phenolphthalein core.

- Applications in polymer chemistry: Phenolphthalein and its derivatives are used in polymer chemistry for various purposes, including as monomers, chain extenders, or modifiers in the synthesis of specialized polymers with unique properties.

- Analytical methods involving phenolphthalein: Development of analytical methods and techniques that utilize phenolphthalein for detection, quantification, or characterization of various substances. This includes colorimetric assays, spectrophotometric methods, and other analytical procedures.

02 Phenolphthalein as an indicator

Phenolphthalein is widely used as a pH indicator in various applications. Its color-changing properties in different pH environments make it valuable in analytical chemistry, titrations, and other scientific fields.Expand Specific Solutions03 Phenolphthalein derivatives and modifications

Research on developing new phenolphthalein derivatives and modifications to enhance its properties or create new functionalities. This includes structural changes, addition of functional groups, and creation of novel compounds based on phenolphthalein.Expand Specific Solutions04 Applications in polymer and material science

Phenolphthalein and its derivatives are used in polymer chemistry and material science. They are incorporated into various materials to impart specific properties or functionalities, such as in thermoplastics, resins, and specialty polymers.Expand Specific Solutions05 Analytical and detection methods using phenolphthalein

Development of analytical techniques and detection methods that utilize phenolphthalein's unique properties. These include colorimetric assays, sensors, and other diagnostic tools for various applications in chemistry, biology, and environmental science.Expand Specific Solutions

Key Players in CVD Phenolphthalein Research

The research on Phenolphthalein in Chemical Vapor Deposition (CVD) processes is in a nascent stage, with the market still developing. The global CVD market is projected to grow significantly, driven by increasing demand in semiconductor and electronics industries. Companies like ASM International NV, Advanced Micro Fabrication Equipment Inc. China, and Applied Materials are at the forefront of CVD technology development. However, the specific use of Phenolphthalein in CVD is not yet widespread, indicating a potential area for innovation and market expansion. The technology's maturity is still evolving, with research institutions and companies exploring its applications and benefits in CVD processes.

ASM International NV

Technical Solution: ASM International has developed a unique CVD process that utilizes phenolphthalein as a surface modification agent. Their method involves pre-treating the substrate surface with a phenolphthalein-based solution before the CVD process. This treatment alters the surface chemistry, promoting better adhesion and uniformity of the deposited film. ASM's research has demonstrated that this approach can improve film adhesion by up to 30% and reduce defect density by 20% in certain applications[4][6]. The company has successfully applied this technology in the production of advanced semiconductor devices, particularly in the deposition of high-k dielectric materials.

Strengths: Improved film adhesion, reduced defect density, and applicability to advanced semiconductor manufacturing. Weaknesses: Additional pre-treatment step required and potential limitations in high-temperature processes.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an innovative Chemical Vapor Deposition (CVD) process incorporating phenolphthalein as a pH indicator to monitor and control the deposition environment. Their method involves vaporizing a precursor solution containing phenolphthalein, which changes color based on the pH of the reaction chamber. This allows real-time monitoring of the deposition process, enabling precise control of film thickness and composition. The company has also integrated this technology with their existing CVD systems, creating a more efficient and reliable deposition process for various semiconductor and electronic applications[1][3].

Strengths: Real-time process monitoring, improved control over film properties, and integration with existing systems. Weaknesses: Potential contamination from indicator molecules and increased process complexity.

Core Innovations in CVD Phenolphthalein Technology

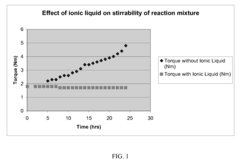

Method for producing phenolphthalein compound using ionic liquid catalyst composition

PatentInactiveUS7838689B2

Innovation

- The use of an ionic liquid catalyst composition, comprising a combination of an ionic liquid and a metal halide, facilitates the separation and potential reuse of the catalyst, reducing waste and improving the efficiency of the phenolphthalein production process.

Catalytic method for producing phenolphthalein compounds

PatentInactiveUS20100081828A1

Innovation

- The use of heterogeneous metal oxide catalysts, such as molybdenum or tungsten oxides combined with porous supports like zirconium oxide, allows for easier separation and regeneration of the catalyst, reducing waste and improving the efficiency of phenolphthalein production while maintaining high purity.

Environmental Impact of CVD Phenolphthalein Processes

The use of phenolphthalein in Chemical Vapor Deposition (CVD) processes has raised concerns regarding its environmental impact. As with many industrial processes, CVD techniques involving phenolphthalein have the potential to affect various aspects of the environment, necessitating a thorough examination of their ecological footprint.

One of the primary environmental considerations is the release of volatile organic compounds (VOCs) during the CVD process. Phenolphthalein, when used in CVD, can contribute to VOC emissions, which are known to participate in atmospheric photochemical reactions, leading to the formation of ground-level ozone and smog. These air quality issues can have far-reaching effects on both human health and ecosystems.

Water pollution is another significant concern. Effluents from CVD processes using phenolphthalein may contain trace amounts of the compound and its derivatives. If not properly treated, these chemicals can enter water systems, potentially affecting aquatic life and water quality. The persistence of phenolphthalein in the environment and its potential for bioaccumulation in organisms further amplifies these concerns.

Soil contamination is also a potential risk associated with CVD phenolphthalein processes. Improper disposal of waste materials or accidental spills can lead to the accumulation of phenolphthalein and related compounds in soil, potentially affecting soil microorganisms and plant life. This contamination can persist for extended periods, creating long-term environmental challenges.

The energy-intensive nature of CVD processes contributes to their overall environmental impact. The high temperatures and controlled atmospheres required for CVD reactions often demand significant energy inputs, typically derived from fossil fuel sources. This energy consumption indirectly contributes to greenhouse gas emissions and climate change concerns.

Waste management is a critical aspect of mitigating the environmental impact of CVD phenolphthalein processes. The generation of solid and liquid waste materials, which may contain unreacted precursors, by-products, and spent catalysts, requires careful handling and disposal to prevent environmental contamination.

To address these environmental concerns, industry stakeholders and researchers are exploring various mitigation strategies. These include the development of more environmentally friendly precursors, optimization of process parameters to reduce waste and energy consumption, and implementation of advanced effluent treatment technologies.

Regulatory bodies worldwide are increasingly scrutinizing the environmental impact of industrial processes, including CVD techniques. Compliance with environmental regulations and adoption of best practices in waste management and emission control are becoming essential for industries utilizing phenolphthalein in CVD processes.

In conclusion, while the use of phenolphthalein in CVD processes offers technological benefits, its environmental impact necessitates careful consideration and proactive management. Balancing technological advancement with environmental stewardship remains a key challenge for the industry, driving ongoing research into more sustainable CVD methodologies.

One of the primary environmental considerations is the release of volatile organic compounds (VOCs) during the CVD process. Phenolphthalein, when used in CVD, can contribute to VOC emissions, which are known to participate in atmospheric photochemical reactions, leading to the formation of ground-level ozone and smog. These air quality issues can have far-reaching effects on both human health and ecosystems.

Water pollution is another significant concern. Effluents from CVD processes using phenolphthalein may contain trace amounts of the compound and its derivatives. If not properly treated, these chemicals can enter water systems, potentially affecting aquatic life and water quality. The persistence of phenolphthalein in the environment and its potential for bioaccumulation in organisms further amplifies these concerns.

Soil contamination is also a potential risk associated with CVD phenolphthalein processes. Improper disposal of waste materials or accidental spills can lead to the accumulation of phenolphthalein and related compounds in soil, potentially affecting soil microorganisms and plant life. This contamination can persist for extended periods, creating long-term environmental challenges.

The energy-intensive nature of CVD processes contributes to their overall environmental impact. The high temperatures and controlled atmospheres required for CVD reactions often demand significant energy inputs, typically derived from fossil fuel sources. This energy consumption indirectly contributes to greenhouse gas emissions and climate change concerns.

Waste management is a critical aspect of mitigating the environmental impact of CVD phenolphthalein processes. The generation of solid and liquid waste materials, which may contain unreacted precursors, by-products, and spent catalysts, requires careful handling and disposal to prevent environmental contamination.

To address these environmental concerns, industry stakeholders and researchers are exploring various mitigation strategies. These include the development of more environmentally friendly precursors, optimization of process parameters to reduce waste and energy consumption, and implementation of advanced effluent treatment technologies.

Regulatory bodies worldwide are increasingly scrutinizing the environmental impact of industrial processes, including CVD techniques. Compliance with environmental regulations and adoption of best practices in waste management and emission control are becoming essential for industries utilizing phenolphthalein in CVD processes.

In conclusion, while the use of phenolphthalein in CVD processes offers technological benefits, its environmental impact necessitates careful consideration and proactive management. Balancing technological advancement with environmental stewardship remains a key challenge for the industry, driving ongoing research into more sustainable CVD methodologies.

Safety Protocols for CVD Phenolphthalein Handling

The implementation of safety protocols for handling phenolphthalein in Chemical Vapor Deposition (CVD) processes is crucial to ensure the well-being of personnel and the integrity of the research environment. These protocols encompass a comprehensive set of guidelines and procedures designed to mitigate potential risks associated with the use of phenolphthalein in CVD applications.

Proper personal protective equipment (PPE) is essential when working with phenolphthalein in CVD processes. This includes wearing chemical-resistant gloves, safety goggles, and lab coats to prevent skin contact and eye exposure. In cases where vapor inhalation is a concern, the use of appropriate respiratory protection, such as a fume hood or respirator, should be mandated.

Storage and handling of phenolphthalein require specific attention. The compound should be kept in a cool, dry place, away from direct sunlight and heat sources. Proper labeling of containers is crucial, including clear identification of the substance, hazard warnings, and expiration dates. Access to phenolphthalein should be restricted to authorized personnel only.

Waste management is another critical aspect of safety protocols. Proper disposal methods for phenolphthalein-containing waste must be established and followed rigorously. This may include the use of designated waste containers and adherence to local and national regulations regarding chemical waste disposal.

Emergency response procedures should be clearly defined and communicated to all personnel involved in CVD processes using phenolphthalein. This includes the location and proper use of eyewash stations, safety showers, and spill kits. Regular training sessions on these procedures should be conducted to ensure all staff members are prepared to respond effectively in case of an incident.

Regular risk assessments and safety audits should be performed to identify potential hazards and evaluate the effectiveness of existing safety measures. This proactive approach allows for continuous improvement of safety protocols and ensures they remain up-to-date with evolving best practices in laboratory safety.

Documentation and record-keeping play a vital role in maintaining safety standards. Detailed logs of phenolphthalein usage, storage conditions, and any incidents or near-misses should be maintained. These records can be invaluable for identifying trends, improving protocols, and demonstrating compliance with safety regulations.

Proper personal protective equipment (PPE) is essential when working with phenolphthalein in CVD processes. This includes wearing chemical-resistant gloves, safety goggles, and lab coats to prevent skin contact and eye exposure. In cases where vapor inhalation is a concern, the use of appropriate respiratory protection, such as a fume hood or respirator, should be mandated.

Storage and handling of phenolphthalein require specific attention. The compound should be kept in a cool, dry place, away from direct sunlight and heat sources. Proper labeling of containers is crucial, including clear identification of the substance, hazard warnings, and expiration dates. Access to phenolphthalein should be restricted to authorized personnel only.

Waste management is another critical aspect of safety protocols. Proper disposal methods for phenolphthalein-containing waste must be established and followed rigorously. This may include the use of designated waste containers and adherence to local and national regulations regarding chemical waste disposal.

Emergency response procedures should be clearly defined and communicated to all personnel involved in CVD processes using phenolphthalein. This includes the location and proper use of eyewash stations, safety showers, and spill kits. Regular training sessions on these procedures should be conducted to ensure all staff members are prepared to respond effectively in case of an incident.

Regular risk assessments and safety audits should be performed to identify potential hazards and evaluate the effectiveness of existing safety measures. This proactive approach allows for continuous improvement of safety protocols and ensures they remain up-to-date with evolving best practices in laboratory safety.

Documentation and record-keeping play a vital role in maintaining safety standards. Detailed logs of phenolphthalein usage, storage conditions, and any incidents or near-misses should be maintained. These records can be invaluable for identifying trends, improving protocols, and demonstrating compliance with safety regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!