How Renewable Resource-Based Hydroxyapatite Influences Polymer Durability

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydroxyapatite-Polymer Evolution and Objectives

Hydroxyapatite (HAp), a naturally occurring calcium phosphate mineral, has emerged as a promising renewable resource for enhancing polymer durability. The evolution of HAp-polymer composites can be traced back to the 1980s when researchers first began exploring the potential of incorporating this biocompatible material into polymer matrices. Initially, the focus was primarily on biomedical applications, leveraging HAp's similarity to human bone mineral.

Over the past four decades, the field has witnessed significant advancements in synthesis methods, characterization techniques, and application domains. The early 2000s marked a turning point, as scientists began to recognize the potential of HAp beyond biomedical uses. This shift led to increased research into HAp's role in improving the mechanical, thermal, and chemical properties of various polymers.

Recent years have seen a surge in interest in renewable resource-based HAp, driven by the growing emphasis on sustainability and eco-friendly materials. Researchers have explored novel sources for HAp extraction, including fish bones, eggshells, and plant-based materials, aligning with circular economy principles and reducing reliance on synthetic production methods.

The current technological landscape is characterized by a multidisciplinary approach, combining materials science, chemistry, and engineering to optimize HAp-polymer interactions. Advanced surface modification techniques and controlled synthesis processes have enabled better dispersion and interfacial bonding between HAp and polymer matrices, resulting in enhanced composite properties.

The primary objective of incorporating renewable resource-based HAp into polymers is to significantly improve their durability. This encompasses several key aspects:

1. Mechanical reinforcement: Enhancing the strength, stiffness, and impact resistance of polymers to extend their service life.

2. Thermal stability: Improving the heat resistance and dimensional stability of polymers under varying temperature conditions.

3. Chemical resistance: Increasing the polymer's resistance to degradation from environmental factors such as UV radiation, moisture, and chemical exposure.

4. Biodegradability control: Fine-tuning the degradation rate of biodegradable polymers for specific applications, particularly in environmental and biomedical fields.

5. Flame retardancy: Exploring HAp's potential to impart flame-retardant properties to polymers, reducing fire hazards in various applications.

As research progresses, the overarching goal is to develop sustainable, high-performance HAp-polymer composites that can replace conventional materials in a wide range of industries, from packaging and construction to automotive and aerospace. This evolution not only aims to enhance material properties but also to contribute to global sustainability efforts by utilizing renewable resources and potentially reducing the environmental impact of polymer production and disposal.

Over the past four decades, the field has witnessed significant advancements in synthesis methods, characterization techniques, and application domains. The early 2000s marked a turning point, as scientists began to recognize the potential of HAp beyond biomedical uses. This shift led to increased research into HAp's role in improving the mechanical, thermal, and chemical properties of various polymers.

Recent years have seen a surge in interest in renewable resource-based HAp, driven by the growing emphasis on sustainability and eco-friendly materials. Researchers have explored novel sources for HAp extraction, including fish bones, eggshells, and plant-based materials, aligning with circular economy principles and reducing reliance on synthetic production methods.

The current technological landscape is characterized by a multidisciplinary approach, combining materials science, chemistry, and engineering to optimize HAp-polymer interactions. Advanced surface modification techniques and controlled synthesis processes have enabled better dispersion and interfacial bonding between HAp and polymer matrices, resulting in enhanced composite properties.

The primary objective of incorporating renewable resource-based HAp into polymers is to significantly improve their durability. This encompasses several key aspects:

1. Mechanical reinforcement: Enhancing the strength, stiffness, and impact resistance of polymers to extend their service life.

2. Thermal stability: Improving the heat resistance and dimensional stability of polymers under varying temperature conditions.

3. Chemical resistance: Increasing the polymer's resistance to degradation from environmental factors such as UV radiation, moisture, and chemical exposure.

4. Biodegradability control: Fine-tuning the degradation rate of biodegradable polymers for specific applications, particularly in environmental and biomedical fields.

5. Flame retardancy: Exploring HAp's potential to impart flame-retardant properties to polymers, reducing fire hazards in various applications.

As research progresses, the overarching goal is to develop sustainable, high-performance HAp-polymer composites that can replace conventional materials in a wide range of industries, from packaging and construction to automotive and aerospace. This evolution not only aims to enhance material properties but also to contribute to global sustainability efforts by utilizing renewable resources and potentially reducing the environmental impact of polymer production and disposal.

Market Analysis for Sustainable Composite Materials

The market for sustainable composite materials is experiencing significant growth, driven by increasing environmental awareness and stringent regulations across various industries. The integration of renewable resource-based hydroxyapatite into polymer composites presents a promising opportunity to enhance material durability while addressing sustainability concerns.

The global sustainable composites market is projected to expand rapidly, with a particular focus on applications in automotive, construction, and consumer goods sectors. This growth is fueled by the rising demand for lightweight, high-performance materials that offer improved durability and reduced environmental impact. The automotive industry, in particular, is a key driver, as manufacturers seek to meet stringent emissions standards and improve fuel efficiency through the use of lighter, more durable materials.

Renewable resource-based hydroxyapatite, derived from sources such as fish bones or eggshells, offers a sustainable alternative to traditional synthetic reinforcements in polymer composites. This bio-based filler not only contributes to improved mechanical properties but also enhances the overall durability of the composite material. The market potential for such sustainable composites is substantial, as they address both performance and environmental concerns simultaneously.

Consumer preferences are shifting towards eco-friendly products, creating a favorable market environment for sustainable composites. Industries are increasingly recognizing the long-term cost benefits of using durable, renewable-based materials, which can lead to reduced maintenance and replacement costs over the product lifecycle. This trend is particularly evident in the construction sector, where sustainable building materials are gaining traction due to their durability and lower environmental footprint.

The Asia-Pacific region is expected to emerge as a significant market for sustainable composites, driven by rapid industrialization, infrastructure development, and growing environmental consciousness. North America and Europe continue to be major markets, with established regulations promoting the adoption of sustainable materials across various industries.

However, challenges remain in terms of cost competitiveness and scalability of production for renewable resource-based hydroxyapatite composites. Overcoming these barriers will be crucial for widespread market adoption. Collaborative efforts between material scientists, manufacturers, and end-users are essential to develop cost-effective production methods and demonstrate the long-term value proposition of these sustainable composites.

As the market for sustainable materials continues to evolve, the integration of renewable resource-based hydroxyapatite in polymer composites is poised to play a significant role in meeting the growing demand for durable, environmentally friendly materials across multiple industries.

The global sustainable composites market is projected to expand rapidly, with a particular focus on applications in automotive, construction, and consumer goods sectors. This growth is fueled by the rising demand for lightweight, high-performance materials that offer improved durability and reduced environmental impact. The automotive industry, in particular, is a key driver, as manufacturers seek to meet stringent emissions standards and improve fuel efficiency through the use of lighter, more durable materials.

Renewable resource-based hydroxyapatite, derived from sources such as fish bones or eggshells, offers a sustainable alternative to traditional synthetic reinforcements in polymer composites. This bio-based filler not only contributes to improved mechanical properties but also enhances the overall durability of the composite material. The market potential for such sustainable composites is substantial, as they address both performance and environmental concerns simultaneously.

Consumer preferences are shifting towards eco-friendly products, creating a favorable market environment for sustainable composites. Industries are increasingly recognizing the long-term cost benefits of using durable, renewable-based materials, which can lead to reduced maintenance and replacement costs over the product lifecycle. This trend is particularly evident in the construction sector, where sustainable building materials are gaining traction due to their durability and lower environmental footprint.

The Asia-Pacific region is expected to emerge as a significant market for sustainable composites, driven by rapid industrialization, infrastructure development, and growing environmental consciousness. North America and Europe continue to be major markets, with established regulations promoting the adoption of sustainable materials across various industries.

However, challenges remain in terms of cost competitiveness and scalability of production for renewable resource-based hydroxyapatite composites. Overcoming these barriers will be crucial for widespread market adoption. Collaborative efforts between material scientists, manufacturers, and end-users are essential to develop cost-effective production methods and demonstrate the long-term value proposition of these sustainable composites.

As the market for sustainable materials continues to evolve, the integration of renewable resource-based hydroxyapatite in polymer composites is poised to play a significant role in meeting the growing demand for durable, environmentally friendly materials across multiple industries.

Current Challenges in Renewable Hydroxyapatite Synthesis

The synthesis of renewable resource-based hydroxyapatite (HAp) presents several significant challenges that researchers and manufacturers must overcome. One of the primary obstacles is the variability in composition and quality of renewable resources used as precursors. Natural sources such as eggshells, fish bones, and plant materials can have inconsistent mineral content, which affects the purity and stoichiometry of the resulting HAp. This inconsistency can lead to batch-to-batch variations in the final product, making it difficult to achieve reproducible results in polymer durability applications.

Another major challenge lies in the extraction and purification processes required to obtain high-quality HAp from renewable resources. These processes often involve multiple steps, including calcination, chemical treatments, and particle size control. The complexity of these procedures can result in increased production costs and energy consumption, potentially offsetting the environmental benefits of using renewable resources. Additionally, the use of harsh chemicals or high temperatures during processing may compromise the sustainability aspect of the production method.

The control of HAp particle morphology and size distribution remains a significant hurdle in renewable resource-based synthesis. The shape and dimensions of HAp particles play a crucial role in their interaction with polymer matrices and, consequently, their influence on polymer durability. Achieving uniform and tailored particle characteristics from diverse renewable sources requires sophisticated synthesis techniques and careful process optimization, which can be challenging to implement on an industrial scale.

Furthermore, the presence of impurities and trace elements in renewable resources can affect the performance of the synthesized HAp in polymer applications. While some impurities may be beneficial, others can negatively impact the mechanical properties, biocompatibility, or long-term stability of the HAp-polymer composites. Developing efficient purification methods that selectively remove harmful impurities while retaining beneficial trace elements is an ongoing challenge in the field.

The scalability of renewable HAp synthesis processes also presents significant obstacles. Many laboratory-scale methods that produce high-quality HAp from renewable resources are difficult to scale up for industrial production. Issues such as reactor design, heat and mass transfer limitations, and maintaining consistent product quality at larger scales need to be addressed to make renewable HAp commercially viable for polymer durability applications.

Lastly, the environmental impact of renewable HAp synthesis processes requires careful consideration. While the use of renewable resources is inherently more sustainable, the overall life cycle assessment of the production process, including energy consumption, waste generation, and potential emissions, must be evaluated. Developing truly green synthesis routes that minimize environmental footprint while meeting the stringent quality requirements for polymer applications remains a complex challenge in the field of renewable HAp synthesis.

Another major challenge lies in the extraction and purification processes required to obtain high-quality HAp from renewable resources. These processes often involve multiple steps, including calcination, chemical treatments, and particle size control. The complexity of these procedures can result in increased production costs and energy consumption, potentially offsetting the environmental benefits of using renewable resources. Additionally, the use of harsh chemicals or high temperatures during processing may compromise the sustainability aspect of the production method.

The control of HAp particle morphology and size distribution remains a significant hurdle in renewable resource-based synthesis. The shape and dimensions of HAp particles play a crucial role in their interaction with polymer matrices and, consequently, their influence on polymer durability. Achieving uniform and tailored particle characteristics from diverse renewable sources requires sophisticated synthesis techniques and careful process optimization, which can be challenging to implement on an industrial scale.

Furthermore, the presence of impurities and trace elements in renewable resources can affect the performance of the synthesized HAp in polymer applications. While some impurities may be beneficial, others can negatively impact the mechanical properties, biocompatibility, or long-term stability of the HAp-polymer composites. Developing efficient purification methods that selectively remove harmful impurities while retaining beneficial trace elements is an ongoing challenge in the field.

The scalability of renewable HAp synthesis processes also presents significant obstacles. Many laboratory-scale methods that produce high-quality HAp from renewable resources are difficult to scale up for industrial production. Issues such as reactor design, heat and mass transfer limitations, and maintaining consistent product quality at larger scales need to be addressed to make renewable HAp commercially viable for polymer durability applications.

Lastly, the environmental impact of renewable HAp synthesis processes requires careful consideration. While the use of renewable resources is inherently more sustainable, the overall life cycle assessment of the production process, including energy consumption, waste generation, and potential emissions, must be evaluated. Developing truly green synthesis routes that minimize environmental footprint while meeting the stringent quality requirements for polymer applications remains a complex challenge in the field of renewable HAp synthesis.

Existing Hydroxyapatite-Polymer Composite Solutions

01 Synthesis of renewable resource-based hydroxyapatite

Methods for synthesizing hydroxyapatite from renewable resources, such as biowaste or plant-derived materials, to create a more sustainable and environmentally friendly alternative to traditional synthetic hydroxyapatite. These processes often involve the extraction and conversion of calcium and phosphate precursors from renewable sources.- Synthesis of renewable resource-based hydroxyapatite: Methods for synthesizing hydroxyapatite from renewable resources, such as biowaste or plant-derived materials, to create a more sustainable and environmentally friendly alternative to traditional synthetic hydroxyapatite. These processes often involve the extraction and conversion of calcium and phosphate precursors from renewable sources.

- Enhancing durability through composite materials: Incorporation of renewable resource-based hydroxyapatite into composite materials to improve overall durability and mechanical properties. This may involve combining the hydroxyapatite with biodegradable polymers or other natural materials to create stronger, more resilient structures for various applications.

- Surface modification for improved stability: Techniques for modifying the surface of renewable resource-based hydroxyapatite to enhance its stability and durability in various environments. This may include coating or functionalization processes that protect the hydroxyapatite from degradation or improve its integration with other materials.

- Durability testing and characterization methods: Development of specific testing protocols and characterization techniques to assess the durability of renewable resource-based hydroxyapatite. These methods may include accelerated aging tests, mechanical strength evaluations, and long-term stability studies under various conditions to ensure the material's performance over time.

- Applications leveraging durability of renewable hydroxyapatite: Exploration of various applications that take advantage of the durability properties of renewable resource-based hydroxyapatite. This may include its use in biomedical implants, environmental remediation, industrial catalysts, or advanced materials where long-term stability and performance are crucial.

02 Enhancing durability through composite materials

Incorporation of renewable resource-based hydroxyapatite into composite materials to improve overall durability and mechanical properties. This may involve combining the hydroxyapatite with biodegradable polymers or other natural materials to create stronger, more resilient structures for various applications.Expand Specific Solutions03 Surface modification for improved stability

Techniques for modifying the surface of renewable resource-based hydroxyapatite to enhance its durability and resistance to degradation. This may include coating the particles with protective layers or functionalizing the surface to improve its interaction with surrounding materials and environments.Expand Specific Solutions04 Characterization and testing of durability

Methods and systems for evaluating the durability and long-term stability of renewable resource-based hydroxyapatite. This includes accelerated aging tests, mechanical strength assessments, and chemical stability analyses to ensure the material meets performance requirements for various applications.Expand Specific Solutions05 Applications leveraging durability of renewable hydroxyapatite

Innovative uses of renewable resource-based hydroxyapatite in fields such as biomedical engineering, environmental remediation, and advanced materials, taking advantage of its enhanced durability. This may include bone tissue engineering scaffolds, water purification systems, or sustainable construction materials.Expand Specific Solutions

Key Players in Biocomposite Industry

The field of renewable resource-based hydroxyapatite and its influence on polymer durability is in an emerging stage, with growing interest due to sustainability concerns. The market size is expanding, driven by applications in biomedical, environmental, and materials science sectors. Technologically, it's progressing from basic research to early commercial applications. Key players like UCL Business Ltd., Japan Science & Technology Agency, and National Institute for Materials Science IAI are leading in research and development. Universities such as Shandong University and Central South University are contributing significantly to academic advancements. Companies like Warsaw Orthopedic, Inc. and St. Jude Medical AB are exploring practical applications in medical devices, indicating the technology's potential for commercial viability.

National Institute for Materials Science IAI

Technical Solution: The National Institute for Materials Science (NIMS) in Japan has developed a novel approach to enhance polymer durability using renewable resource-based hydroxyapatite (HAp). Their research focuses on incorporating bio-derived HAp nanoparticles into polymer matrices to improve mechanical properties and degradation resistance. The team has successfully synthesized HAp from sustainable sources such as fish bones and eggshells, ensuring a more environmentally friendly production process[1]. By optimizing the particle size distribution and surface modification of HAp, they have achieved significant improvements in polymer composite strength and toughness. Additionally, NIMS researchers have investigated the influence of HAp on polymer crystallization behavior, which plays a crucial role in determining the long-term durability of the composite materials[3]. Their findings suggest that the presence of HAp can act as nucleation sites for polymer crystallization, leading to enhanced thermal stability and chemical resistance[5].

Strengths: Utilization of renewable resources, improved mechanical properties, and enhanced thermal stability. Weaknesses: Potential challenges in achieving uniform dispersion of HAp in polymer matrices and possible increase in production costs.

Shandong University

Technical Solution: Shandong University has made significant strides in the field of renewable resource-based hydroxyapatite (HAp) and its influence on polymer durability. Their research team has developed a novel method for extracting HAp from natural sources such as animal bones and marine shells, ensuring a sustainable and cost-effective production process[2]. The university's approach focuses on the surface modification of HAp nanoparticles to enhance their compatibility with various polymer matrices. By tailoring the surface chemistry of HAp, they have successfully improved the interfacial adhesion between the filler and the polymer, resulting in enhanced mechanical properties and durability[4]. Furthermore, Shandong University researchers have investigated the impact of HAp on the biodegradation behavior of polymers, particularly in biomedical applications. Their studies have shown that the incorporation of HAp can significantly alter the degradation kinetics of biodegradable polymers, allowing for better control over the material's lifespan in physiological environments[6].

Strengths: Sustainable production methods, improved polymer-filler interface, and controlled biodegradation. Weaknesses: Limited scalability of production processes and potential variability in HAp properties due to natural source variations.

Innovations in Renewable Hydroxyapatite Technology

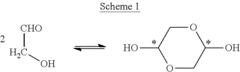

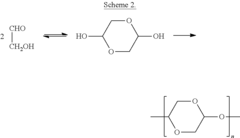

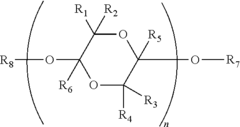

Renewable polymer and method of making

PatentActiveUS9040635B1

Innovation

- A polymer made from α-hydroxycarbonyl compounds, specifically glycolaldehyde, which spontaneously dimerizes to form 2,5-dihydroxy-1,4-dioxane, is polymerized to create a renewable thermoplastic polymer, poly(2,5-dihydroxy-1,4-dioxane) (PDHDO), using catalysts like scandium triflate and dehydration methods to achieve high molecular weights and improved properties.

Environmental Impact Assessment

The environmental impact assessment of renewable resource-based hydroxyapatite (HAp) and its influence on polymer durability is a critical aspect of sustainable materials development. This assessment encompasses various factors, including resource extraction, production processes, and end-of-life considerations.

The production of renewable resource-based HAp typically involves the use of biological sources such as eggshells, fish bones, or plant materials. Compared to synthetic HAp production, these renewable sources generally have a lower environmental footprint due to reduced energy consumption and greenhouse gas emissions. The utilization of waste materials as raw sources further contributes to waste reduction and resource efficiency.

However, the extraction and processing of these renewable resources may still have localized environmental impacts. For instance, large-scale collection of eggshells or fish bones could potentially disrupt local ecosystems or compete with other uses of these materials. It is crucial to implement sustainable harvesting practices and ensure that the sourcing does not negatively affect biodiversity or food security.

The incorporation of renewable resource-based HAp into polymers can significantly enhance their durability, potentially leading to longer-lasting products. This increased lifespan has positive environmental implications, as it reduces the need for frequent replacements and minimizes waste generation. Additionally, the improved durability may result in reduced energy and resource consumption associated with manufacturing replacement products.

From a life cycle perspective, the use of renewable resource-based HAp in polymers may contribute to reduced carbon footprints and overall environmental impacts. The enhanced durability can lead to extended product lifetimes, potentially offsetting the initial environmental costs of production. However, a comprehensive life cycle assessment is necessary to quantify these benefits accurately and compare them with traditional polymer formulations.

End-of-life considerations are also crucial in evaluating the environmental impact of HAp-enhanced polymers. The presence of HAp may affect the recyclability or biodegradability of the polymer matrix. Research is needed to determine whether these composite materials can be effectively recycled or if they require specialized disposal methods. The potential for HAp to leach into the environment during the product's use or disposal phase should also be carefully assessed.

In terms of toxicity and ecotoxicity, renewable resource-based HAp is generally considered biocompatible and environmentally friendly. However, the potential for nanoparticle release and its impact on ecosystems should be thoroughly investigated, especially for applications where the material may come into direct contact with the environment.

Overall, while renewable resource-based HAp shows promise in enhancing polymer durability with potentially reduced environmental impacts, a holistic approach to environmental assessment is necessary. This should include considerations of resource sustainability, production efficiency, product longevity, and end-of-life management to ensure that the benefits of this technology outweigh any potential environmental drawbacks.

The production of renewable resource-based HAp typically involves the use of biological sources such as eggshells, fish bones, or plant materials. Compared to synthetic HAp production, these renewable sources generally have a lower environmental footprint due to reduced energy consumption and greenhouse gas emissions. The utilization of waste materials as raw sources further contributes to waste reduction and resource efficiency.

However, the extraction and processing of these renewable resources may still have localized environmental impacts. For instance, large-scale collection of eggshells or fish bones could potentially disrupt local ecosystems or compete with other uses of these materials. It is crucial to implement sustainable harvesting practices and ensure that the sourcing does not negatively affect biodiversity or food security.

The incorporation of renewable resource-based HAp into polymers can significantly enhance their durability, potentially leading to longer-lasting products. This increased lifespan has positive environmental implications, as it reduces the need for frequent replacements and minimizes waste generation. Additionally, the improved durability may result in reduced energy and resource consumption associated with manufacturing replacement products.

From a life cycle perspective, the use of renewable resource-based HAp in polymers may contribute to reduced carbon footprints and overall environmental impacts. The enhanced durability can lead to extended product lifetimes, potentially offsetting the initial environmental costs of production. However, a comprehensive life cycle assessment is necessary to quantify these benefits accurately and compare them with traditional polymer formulations.

End-of-life considerations are also crucial in evaluating the environmental impact of HAp-enhanced polymers. The presence of HAp may affect the recyclability or biodegradability of the polymer matrix. Research is needed to determine whether these composite materials can be effectively recycled or if they require specialized disposal methods. The potential for HAp to leach into the environment during the product's use or disposal phase should also be carefully assessed.

In terms of toxicity and ecotoxicity, renewable resource-based HAp is generally considered biocompatible and environmentally friendly. However, the potential for nanoparticle release and its impact on ecosystems should be thoroughly investigated, especially for applications where the material may come into direct contact with the environment.

Overall, while renewable resource-based HAp shows promise in enhancing polymer durability with potentially reduced environmental impacts, a holistic approach to environmental assessment is necessary. This should include considerations of resource sustainability, production efficiency, product longevity, and end-of-life management to ensure that the benefits of this technology outweigh any potential environmental drawbacks.

Regulatory Framework for Biocomposite Materials

The regulatory framework for biocomposite materials incorporating renewable resource-based hydroxyapatite and polymers is a complex and evolving landscape. As these innovative materials gain traction in various industries, regulatory bodies are adapting their guidelines to ensure safety, efficacy, and environmental sustainability.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biocomposite materials, particularly those used in medical applications. The FDA's Center for Devices and Radiological Health (CDRH) oversees the approval process for medical devices incorporating these materials. Manufacturers must demonstrate the safety and effectiveness of their products through rigorous testing and clinical trials.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which came into full effect in 2021 and 2022, respectively. These regulations set stringent requirements for biocomposite materials used in medical devices, including comprehensive risk assessments and post-market surveillance.

Environmental regulations also play a significant role in shaping the development and use of biocomposite materials. The European Chemicals Agency (ECHA) enforces the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the production and use of polymers and hydroxyapatite derived from renewable resources.

In the context of waste management and circular economy principles, the EU's Waste Framework Directive and Circular Economy Action Plan influence the design, production, and end-of-life considerations for biocomposite materials. These regulations encourage the use of renewable resources and promote recyclability and biodegradability.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for biocomposite materials. These standards provide guidelines for testing methods, material characterization, and performance criteria, ensuring consistency and quality across the industry.

As the field of biocomposite materials continues to advance, regulatory frameworks are likely to evolve. Policymakers and industry stakeholders are working together to develop regulations that balance innovation with safety and environmental concerns. This collaborative approach aims to create a regulatory environment that fosters the development of sustainable, durable, and high-performance biocomposite materials while ensuring public health and environmental protection.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biocomposite materials, particularly those used in medical applications. The FDA's Center for Devices and Radiological Health (CDRH) oversees the approval process for medical devices incorporating these materials. Manufacturers must demonstrate the safety and effectiveness of their products through rigorous testing and clinical trials.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which came into full effect in 2021 and 2022, respectively. These regulations set stringent requirements for biocomposite materials used in medical devices, including comprehensive risk assessments and post-market surveillance.

Environmental regulations also play a significant role in shaping the development and use of biocomposite materials. The European Chemicals Agency (ECHA) enforces the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the production and use of polymers and hydroxyapatite derived from renewable resources.

In the context of waste management and circular economy principles, the EU's Waste Framework Directive and Circular Economy Action Plan influence the design, production, and end-of-life considerations for biocomposite materials. These regulations encourage the use of renewable resources and promote recyclability and biodegradability.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for biocomposite materials. These standards provide guidelines for testing methods, material characterization, and performance criteria, ensuring consistency and quality across the industry.

As the field of biocomposite materials continues to advance, regulatory frameworks are likely to evolve. Policymakers and industry stakeholders are working together to develop regulations that balance innovation with safety and environmental concerns. This collaborative approach aims to create a regulatory environment that fosters the development of sustainable, durable, and high-performance biocomposite materials while ensuring public health and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!