How SiC Gate Drivers Meet Automotive/Industrial Functional Safety Requirements?

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Gate Driver Technology Background and Objectives

Silicon Carbide (SiC) power semiconductors have emerged as revolutionary components in power electronics, offering significant advantages over traditional silicon-based devices. The evolution of SiC technology began in the early 2000s but has accelerated dramatically over the past decade, driven by demands for higher efficiency, temperature tolerance, and switching speeds in power conversion applications.

The automotive and industrial sectors have become primary drivers for SiC adoption, with electric vehicles (EVs) and renewable energy systems requiring increasingly efficient power management solutions. As these applications involve critical safety functions, the gate drivers controlling SiC devices must meet stringent functional safety requirements outlined in standards such as ISO 26262 for automotive and IEC 61508 for industrial applications.

SiC MOSFETs operate at significantly higher switching frequencies and voltages compared to silicon counterparts, creating unique challenges for gate driver design. The technical trajectory has moved from basic driving capabilities to sophisticated protection features, diagnostics, and redundancy mechanisms that ensure safe operation even under fault conditions.

The primary technical objective for SiC gate drivers is to maximize the performance benefits of SiC power devices while implementing robust safety mechanisms that prevent catastrophic failures. This includes precise control of gate voltage levels, management of faster switching transients, and mitigation of parasitic effects that become more pronounced at higher frequencies.

Recent advancements have focused on integrating functional safety features directly into gate driver ICs, including undervoltage lockout, desaturation detection, short-circuit protection, and temperature monitoring. The trend is moving toward "intelligent" gate drivers with built-in microcontrollers that can perform real-time diagnostics and communicate with system controllers.

Another key objective is achieving safety certification for these components, requiring extensive documentation, failure mode analysis, and validation testing. Gate driver manufacturers must demonstrate compliance with Automotive Safety Integrity Levels (ASIL) or Safety Integrity Levels (SIL) depending on the application domain.

Looking forward, the technology roadmap aims to further enhance integration, reducing component count while improving reliability. Advanced isolation technologies, such as reinforced galvanic isolation, are being developed to maintain signal integrity while protecting low-voltage control circuits from high-voltage power stages.

The convergence of SiC power devices and functional safety requirements represents a critical technological frontier, with significant implications for the electrification of transportation and industrial processes. Success in this domain will enable more efficient, reliable, and safe power conversion systems that can accelerate the transition to sustainable energy technologies.

The automotive and industrial sectors have become primary drivers for SiC adoption, with electric vehicles (EVs) and renewable energy systems requiring increasingly efficient power management solutions. As these applications involve critical safety functions, the gate drivers controlling SiC devices must meet stringent functional safety requirements outlined in standards such as ISO 26262 for automotive and IEC 61508 for industrial applications.

SiC MOSFETs operate at significantly higher switching frequencies and voltages compared to silicon counterparts, creating unique challenges for gate driver design. The technical trajectory has moved from basic driving capabilities to sophisticated protection features, diagnostics, and redundancy mechanisms that ensure safe operation even under fault conditions.

The primary technical objective for SiC gate drivers is to maximize the performance benefits of SiC power devices while implementing robust safety mechanisms that prevent catastrophic failures. This includes precise control of gate voltage levels, management of faster switching transients, and mitigation of parasitic effects that become more pronounced at higher frequencies.

Recent advancements have focused on integrating functional safety features directly into gate driver ICs, including undervoltage lockout, desaturation detection, short-circuit protection, and temperature monitoring. The trend is moving toward "intelligent" gate drivers with built-in microcontrollers that can perform real-time diagnostics and communicate with system controllers.

Another key objective is achieving safety certification for these components, requiring extensive documentation, failure mode analysis, and validation testing. Gate driver manufacturers must demonstrate compliance with Automotive Safety Integrity Levels (ASIL) or Safety Integrity Levels (SIL) depending on the application domain.

Looking forward, the technology roadmap aims to further enhance integration, reducing component count while improving reliability. Advanced isolation technologies, such as reinforced galvanic isolation, are being developed to maintain signal integrity while protecting low-voltage control circuits from high-voltage power stages.

The convergence of SiC power devices and functional safety requirements represents a critical technological frontier, with significant implications for the electrification of transportation and industrial processes. Success in this domain will enable more efficient, reliable, and safe power conversion systems that can accelerate the transition to sustainable energy technologies.

Market Demand Analysis for Automotive/Industrial SiC Applications

The Silicon Carbide (SiC) power semiconductor market is experiencing unprecedented growth, driven primarily by automotive and industrial applications requiring higher efficiency, temperature tolerance, and reliability. The global SiC power device market is projected to reach $4.5 billion by 2026, growing at a CAGR of 34.9% from 2021, with automotive applications representing the largest segment at approximately 60% of the total market.

In the automotive sector, electric vehicles (EVs) constitute the primary demand driver for SiC technology. As EV adoption accelerates globally, manufacturers are seeking power electronics solutions that maximize range, reduce charging times, and enhance overall system efficiency. SiC-based power modules in EV inverters can reduce power losses by up to 80% compared to traditional silicon alternatives, translating to 5-10% improvement in vehicle range.

The industrial sector represents the second-largest market for SiC applications, with particular demand in renewable energy systems, industrial motor drives, and power supplies. Solar inverters utilizing SiC technology demonstrate efficiency improvements of 1-2% over silicon-based systems, which translates to significant energy savings at utility scale. Industrial motor drives with SiC components can achieve power density improvements of 30-40%, enabling more compact designs and reduced cooling requirements.

Functional safety requirements are becoming increasingly stringent in both automotive and industrial applications. The automotive industry's transition to ISO 26262 ASIL standards has created specific demand for SiC gate drivers that can meet ASIL-D requirements, the highest safety integrity level. Similarly, industrial applications following IEC 61508 standards require SIL 2 or SIL 3 compliance for many critical systems.

Regional analysis indicates that Europe leads in automotive SiC adoption, with approximately 35% market share, followed closely by Asia-Pacific at 32% and North America at 25%. For industrial applications, Asia-Pacific dominates with 45% market share, driven by China's aggressive investments in renewable energy infrastructure and industrial automation.

Market research indicates that customers are willing to pay a premium of 15-20% for SiC solutions over silicon alternatives when the total system cost benefits are clearly demonstrated. However, this premium tolerance is expected to decrease as manufacturing scales up and competition intensifies, with price sensitivity particularly high in consumer-oriented EV segments and cost-competitive industrial applications.

The market demand for functionally safe SiC gate drivers is expected to grow at 40% CAGR through 2027, outpacing the overall SiC market, as safety-critical applications in both automotive and industrial sectors continue to expand and regulatory requirements become more stringent.

In the automotive sector, electric vehicles (EVs) constitute the primary demand driver for SiC technology. As EV adoption accelerates globally, manufacturers are seeking power electronics solutions that maximize range, reduce charging times, and enhance overall system efficiency. SiC-based power modules in EV inverters can reduce power losses by up to 80% compared to traditional silicon alternatives, translating to 5-10% improvement in vehicle range.

The industrial sector represents the second-largest market for SiC applications, with particular demand in renewable energy systems, industrial motor drives, and power supplies. Solar inverters utilizing SiC technology demonstrate efficiency improvements of 1-2% over silicon-based systems, which translates to significant energy savings at utility scale. Industrial motor drives with SiC components can achieve power density improvements of 30-40%, enabling more compact designs and reduced cooling requirements.

Functional safety requirements are becoming increasingly stringent in both automotive and industrial applications. The automotive industry's transition to ISO 26262 ASIL standards has created specific demand for SiC gate drivers that can meet ASIL-D requirements, the highest safety integrity level. Similarly, industrial applications following IEC 61508 standards require SIL 2 or SIL 3 compliance for many critical systems.

Regional analysis indicates that Europe leads in automotive SiC adoption, with approximately 35% market share, followed closely by Asia-Pacific at 32% and North America at 25%. For industrial applications, Asia-Pacific dominates with 45% market share, driven by China's aggressive investments in renewable energy infrastructure and industrial automation.

Market research indicates that customers are willing to pay a premium of 15-20% for SiC solutions over silicon alternatives when the total system cost benefits are clearly demonstrated. However, this premium tolerance is expected to decrease as manufacturing scales up and competition intensifies, with price sensitivity particularly high in consumer-oriented EV segments and cost-competitive industrial applications.

The market demand for functionally safe SiC gate drivers is expected to grow at 40% CAGR through 2027, outpacing the overall SiC market, as safety-critical applications in both automotive and industrial sectors continue to expand and regulatory requirements become more stringent.

Current State and Challenges in SiC Gate Driver Safety

Silicon Carbide (SiC) gate drivers have emerged as critical components in power electronics systems for automotive and industrial applications, yet their functional safety implementation faces significant challenges. Currently, SiC gate drivers operate in environments requiring compliance with stringent safety standards such as ISO 26262 for automotive and IEC 61508 for industrial applications, which demand comprehensive fault detection and mitigation strategies.

The present state of SiC gate driver safety reveals a complex landscape where traditional silicon-based safety mechanisms prove insufficient for the unique characteristics of SiC MOSFETs. These devices operate at higher switching frequencies, voltages, and temperatures compared to their silicon counterparts, creating new failure modes that conventional protection schemes cannot adequately address. Short-circuit protection, for instance, must react within nanoseconds rather than microseconds to prevent catastrophic device failure.

A major technical challenge lies in the gate voltage monitoring and control. SiC MOSFETs require precise gate voltage regulation within narrow margins—typically between +15V to +20V for turn-on and -2V to -5V for turn-off—where even minor deviations can lead to device degradation or failure. Current gate driver solutions struggle to maintain this precision while simultaneously implementing robust fault detection mechanisms.

Thermal management represents another significant hurdle. SiC devices can operate at junction temperatures exceeding 200°C, requiring gate drivers with enhanced temperature sensing capabilities and thermal shutdown features that maintain accuracy across wide temperature ranges. Existing temperature sensing technologies often lack the precision and response time needed for SiC applications.

Isolation barriers present additional complications, as they must withstand higher common-mode transients (dv/dt) characteristic of SiC switching while maintaining signal integrity for safety-critical communications. Current optocoupler or transformer-based isolation solutions frequently exhibit aging effects that compromise long-term reliability.

Diagnostic coverage requirements for automotive functional safety (ASIL C/D) and industrial safety (SIL 2/3) demand comprehensive fault detection capabilities that can identify subtle failure modes specific to SiC technology. Present diagnostic methods often cannot detect partial gate oxide degradation or threshold voltage shifts that precede catastrophic failures.

The integration of safety mechanisms with high-speed switching capability creates a fundamental design conflict. Safety monitoring circuits introduce parasitic elements that can degrade switching performance, while attempts to optimize switching speed may compromise fault detection capabilities. This technical trade-off remains inadequately resolved in current gate driver designs.

Standardization efforts for SiC-specific safety requirements are still evolving, creating uncertainty for manufacturers developing next-generation gate drivers. The lack of industry consensus on testing methodologies and qualification procedures specifically tailored to SiC technology further complicates safety validation efforts.

The present state of SiC gate driver safety reveals a complex landscape where traditional silicon-based safety mechanisms prove insufficient for the unique characteristics of SiC MOSFETs. These devices operate at higher switching frequencies, voltages, and temperatures compared to their silicon counterparts, creating new failure modes that conventional protection schemes cannot adequately address. Short-circuit protection, for instance, must react within nanoseconds rather than microseconds to prevent catastrophic device failure.

A major technical challenge lies in the gate voltage monitoring and control. SiC MOSFETs require precise gate voltage regulation within narrow margins—typically between +15V to +20V for turn-on and -2V to -5V for turn-off—where even minor deviations can lead to device degradation or failure. Current gate driver solutions struggle to maintain this precision while simultaneously implementing robust fault detection mechanisms.

Thermal management represents another significant hurdle. SiC devices can operate at junction temperatures exceeding 200°C, requiring gate drivers with enhanced temperature sensing capabilities and thermal shutdown features that maintain accuracy across wide temperature ranges. Existing temperature sensing technologies often lack the precision and response time needed for SiC applications.

Isolation barriers present additional complications, as they must withstand higher common-mode transients (dv/dt) characteristic of SiC switching while maintaining signal integrity for safety-critical communications. Current optocoupler or transformer-based isolation solutions frequently exhibit aging effects that compromise long-term reliability.

Diagnostic coverage requirements for automotive functional safety (ASIL C/D) and industrial safety (SIL 2/3) demand comprehensive fault detection capabilities that can identify subtle failure modes specific to SiC technology. Present diagnostic methods often cannot detect partial gate oxide degradation or threshold voltage shifts that precede catastrophic failures.

The integration of safety mechanisms with high-speed switching capability creates a fundamental design conflict. Safety monitoring circuits introduce parasitic elements that can degrade switching performance, while attempts to optimize switching speed may compromise fault detection capabilities. This technical trade-off remains inadequately resolved in current gate driver designs.

Standardization efforts for SiC-specific safety requirements are still evolving, creating uncertainty for manufacturers developing next-generation gate drivers. The lack of industry consensus on testing methodologies and qualification procedures specifically tailored to SiC technology further complicates safety validation efforts.

Current Functional Safety Solutions for SiC Gate Drivers

01 SiC Gate Driver Safety Monitoring and Fault Detection

Silicon Carbide (SiC) gate drivers can be designed with integrated safety monitoring circuits that continuously check for abnormal operating conditions. These systems detect faults such as overcurrent, overvoltage, and short circuits, enabling rapid shutdown to prevent device failure. Advanced implementations include redundant monitoring paths, self-diagnostic capabilities, and isolation mechanisms that maintain functional safety integrity levels required in critical applications.- SiC Gate Driver Safety Monitoring and Fault Detection: Silicon Carbide (SiC) gate drivers can be designed with integrated safety monitoring circuits that continuously check for abnormal operating conditions. These systems detect faults such as overcurrent, overvoltage, and short circuits, enabling rapid shutdown to prevent device failure. Advanced implementations include redundant monitoring paths, self-diagnostic capabilities, and isolation mechanisms that maintain functional safety integrity levels required in critical applications.

- Redundancy and Fail-Safe Mechanisms in SiC Gate Drivers: Implementing redundancy in SiC gate driver designs enhances functional safety through duplicate control paths and comparison circuits. These systems feature fail-safe mechanisms that default to a safe state when discrepancies are detected. Designs may incorporate watchdog timers, dual-channel architectures, and cross-checking logic to ensure reliable operation even when components fail. This approach is particularly important in high-power applications where gate driver failure could lead to catastrophic system damage.

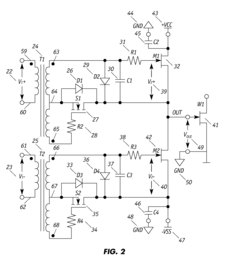

- Isolation Technologies for SiC Gate Driver Safety: Galvanic isolation between control circuits and power stages is critical for SiC gate driver functional safety. Advanced isolation technologies including optical, magnetic, and capacitive coupling methods protect low-voltage control systems from high-voltage transients while maintaining signal integrity. These isolation barriers are designed with sufficient creepage and clearance distances to meet safety standards, and often include reinforced insulation characteristics to withstand the high dv/dt rates typical in SiC switching applications.

- Thermal Management and Protection for SiC Gate Drivers: Effective thermal management is essential for maintaining functional safety in SiC gate driver systems. Designs incorporate temperature sensing, monitoring circuits, and automatic shutdown mechanisms to prevent thermal runaway. Advanced cooling techniques, thermally optimized layouts, and materials with superior thermal conductivity help dissipate heat efficiently. Protection systems may include graduated responses based on temperature thresholds, allowing for reduced performance operation before complete shutdown becomes necessary.

- Compliance with Functional Safety Standards for SiC Applications: SiC gate driver designs for safety-critical applications must comply with relevant functional safety standards such as IEC 61508, ISO 26262, and industry-specific requirements. This involves systematic development processes, hazard analysis, fault tree analysis, and failure mode effects analysis. Designs incorporate diagnostic coverage, safe failure fraction calculations, and hardware fault tolerance appropriate to the required safety integrity level. Verification and validation procedures ensure that safety mechanisms perform as intended throughout the product lifecycle.

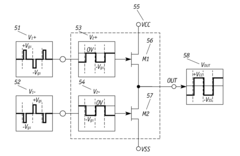

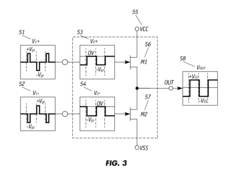

02 Redundancy and Fail-Safe Architectures for SiC Drivers

Implementing redundancy in SiC gate driver designs enhances functional safety through dual-channel architectures and backup systems. These fail-safe designs incorporate watchdog timers, cross-checking mechanisms between parallel circuits, and graceful degradation capabilities. When a fault is detected, the system can either switch to backup components or safely shut down, preventing catastrophic failures in high-power applications where SiC devices are commonly used.Expand Specific Solutions03 Isolation Technologies for SiC Gate Driver Safety

Electrical isolation is critical for SiC gate driver safety, protecting control circuits from high voltage and transients. Advanced isolation technologies include galvanic isolation through transformers, optical isolation using fiber optics, and capacitive isolation methods. These approaches maintain signal integrity while providing the voltage isolation needed to meet safety standards, with some designs achieving isolation ratings exceeding 5kV to ensure reliable operation in harsh electrical environments.Expand Specific Solutions04 Thermal Management and Protection for SiC Gate Drivers

Effective thermal management is essential for SiC gate driver functional safety due to the high switching frequencies and power densities involved. Advanced thermal protection schemes include temperature sensors with automatic derating capabilities, thermal shutdown circuits, and intelligent cooling systems. These features prevent overheating damage by monitoring junction temperatures and adjusting operation parameters or initiating protective shutdowns when thermal limits are approached.Expand Specific Solutions05 Compliance with Functional Safety Standards for SiC Applications

SiC gate driver designs increasingly incorporate features to meet international functional safety standards such as IEC 61508 and ISO 26262. These implementations include systematic documentation of safety cases, failure mode and effects analysis (FMEA), diagnostic coverage assessments, and hardware-software co-design approaches. Certification-ready gate drivers include built-in test capabilities, error logging, and configurable safety responses that can be tailored to specific application safety integrity requirements.Expand Specific Solutions

Key Industry Players in SiC Gate Driver Market

The SiC gate driver market is in a growth phase, characterized by increasing adoption in automotive and industrial applications requiring high reliability and functional safety. The market is expanding rapidly, driven by the transition to electric vehicles and industrial automation, with projections indicating significant growth over the next decade. Technologically, SiC gate drivers have reached moderate maturity, with companies like STMicroelectronics, Microchip Technology, and Power Integrations leading innovation in safety-compliant designs. Major automotive players including DENSO, Bosch, and Hyundai are integrating these solutions, while semiconductor manufacturers such as BASiC Semiconductor and Hitachi are developing specialized offerings meeting ISO 26262 and IEC 61508 standards. Research collaboration between industry and institutions like University of Electronic Science & Technology of China is accelerating technological advancement.

Power Integrations, Inc.

Technical Solution: Power Integrations has developed the SCALE-iDriver family specifically for SiC MOSFET applications with functional safety requirements. Their SiC gate drivers incorporate FluxLink™ technology, a proprietary magnetically-coupled isolation method that eliminates optocouplers while providing reinforced isolation (5kV) and superior common-mode transient immunity (200kV/μs). The drivers feature Advanced Active Clamping (AAC) that protects SiC MOSFETs during voltage spikes and short-circuit events by dynamically adjusting gate voltage. Their functional safety architecture includes comprehensive fault detection (overcurrent, short-circuit, overtemperature, and supply voltage monitoring) with <2μs response time, and implements a dual-channel design with independent watchdog timers and cross-checking mechanisms. The SiC drivers are certified to AEC-Q100 automotive standards and designed to meet ISO 26262 ASIL D requirements, with documented failure mode analysis and safety manuals to support customer safety case development.

Strengths: FluxLink™ technology provides superior isolation performance and reliability compared to optocoupler solutions, with exceptional common-mode noise immunity critical for SiC applications. Their Advanced Active Clamping offers superior protection during transient events. Weaknesses: Limited configurability compared to some competing solutions, and relatively higher power consumption in some operating modes.

Microchip Technology, Inc.

Technical Solution: Microchip Technology has developed the AgileSwitch® family of programmable SiC gate drivers specifically engineered to meet automotive and industrial functional safety requirements. Their solution features Augmented Switching™ technology that enables precise control of turn-on and turn-off profiles through digital configuration, reducing switching losses by up to 30% while minimizing EMI/RFI emissions. The drivers incorporate dual-channel isolated architecture with 5kV isolation barrier and implement redundant monitoring systems for gate voltage, temperature, and current sensing. Microchip's SiC drivers feature integrated diagnostics with fault logging capabilities and configurable fault response modes that can be tailored to specific application requirements. The company's safety architecture includes continuous Built-In Self-Test (BIST) functionality that monitors critical safety paths during operation without interrupting normal function. Their solutions are designed to comply with ISO 26262 ASIL C/D and IEC 61508 SIL3 requirements, with comprehensive safety documentation and failure rate data to support customer safety case development.

Strengths: Highly configurable switching profiles allow optimization for specific applications, balancing efficiency and EMI requirements. The programmable nature enables adaptation to different SiC MOSFET types without hardware changes. Weaknesses: More complex implementation requiring software configuration tools and potentially longer development cycles compared to fixed-function alternatives.

Critical Safety Standards and Compliance Mechanisms

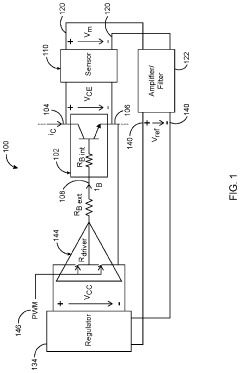

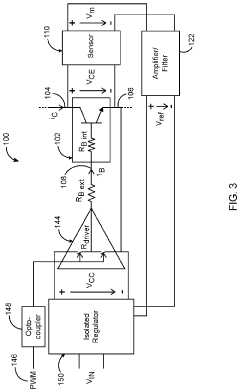

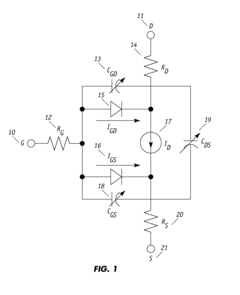

Advanced gate drivers for silicon carbide bipolar junction transistors

PatentInactiveUS20220085804A1

Innovation

- An advanced gate driver circuit that includes a sensor to measure collector-emitter voltage, an amplifier to process this voltage, and a regulator to generate a proportional base current, eliminating the need for high bandwidth current sensors and digital signal processors, and accounting for temperature effects on DC current gain.

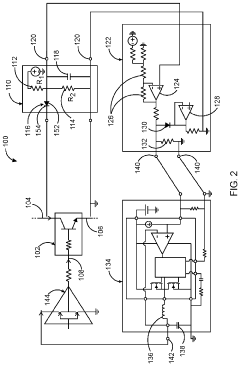

High temperature operation silicon carbide gate driver

PatentInactiveUS20130063184A1

Innovation

- A gate driver circuit utilizing silicon on insulator (SOI) and SiC devices with high-temperature passive components, including transformers, diodes, and capacitors, operating from -70°C to 250°C and 100 kHz to 500 kHz, capable of sinking/source currents up to 25 Amperes, and providing electrical isolation and dv/dt noise minimization.

Reliability Testing and Validation Methodologies

Reliability testing and validation methodologies for SiC gate drivers in automotive and industrial applications follow rigorous protocols to ensure functional safety compliance. These methodologies typically begin with accelerated life testing (ALT), which subjects gate drivers to extreme conditions exceeding normal operational parameters. This includes high-temperature operating life (HTOL) tests at temperatures ranging from 150°C to 175°C for extended periods, often 1,000+ hours, to verify long-term reliability under thermal stress.

Temperature cycling tests represent another critical validation approach, where components undergo rapid transitions between temperature extremes (-40°C to 150°C) for hundreds or thousands of cycles. This process identifies potential failures from thermal expansion and contraction, particularly important for automotive applications where temperature fluctuations are common.

Humidity and moisture sensitivity testing evaluates gate driver performance in high-humidity environments (85% relative humidity at 85°C) for extended durations. This assessment is crucial for industrial applications where equipment may operate in varying environmental conditions. Similarly, vibration and mechanical shock testing subjects devices to G-forces mimicking automotive collision scenarios or industrial machinery vibrations.

Electrical overstress testing verifies gate driver robustness against voltage spikes, current surges, and electrostatic discharge events. For SiC applications specifically, dV/dt immunity testing becomes essential due to the faster switching speeds compared to traditional silicon devices. Gate drivers must maintain signal integrity during rapid voltage transitions without false triggering or latch-up conditions.

Statistical analysis methodologies like Weibull distribution modeling help predict failure rates and establish mean time between failures (MTBF) metrics. These analyses inform reliability calculations required for automotive safety integrity levels (ASIL) or industrial safety integrity levels (SIL) certification.

Fault injection testing represents a cornerstone of functional safety validation, deliberately introducing faults to verify proper detection and response mechanisms. This includes simulating short circuits, open circuits, and communication failures to ensure the gate driver's diagnostic coverage meets ISO 26262 or IEC 61508 requirements.

Finally, documentation and traceability form the foundation of validation methodologies, with detailed test plans, procedures, and results maintained throughout the product lifecycle. This comprehensive approach ensures SiC gate drivers can achieve the reliability standards necessary for safety-critical automotive and industrial applications.

Temperature cycling tests represent another critical validation approach, where components undergo rapid transitions between temperature extremes (-40°C to 150°C) for hundreds or thousands of cycles. This process identifies potential failures from thermal expansion and contraction, particularly important for automotive applications where temperature fluctuations are common.

Humidity and moisture sensitivity testing evaluates gate driver performance in high-humidity environments (85% relative humidity at 85°C) for extended durations. This assessment is crucial for industrial applications where equipment may operate in varying environmental conditions. Similarly, vibration and mechanical shock testing subjects devices to G-forces mimicking automotive collision scenarios or industrial machinery vibrations.

Electrical overstress testing verifies gate driver robustness against voltage spikes, current surges, and electrostatic discharge events. For SiC applications specifically, dV/dt immunity testing becomes essential due to the faster switching speeds compared to traditional silicon devices. Gate drivers must maintain signal integrity during rapid voltage transitions without false triggering or latch-up conditions.

Statistical analysis methodologies like Weibull distribution modeling help predict failure rates and establish mean time between failures (MTBF) metrics. These analyses inform reliability calculations required for automotive safety integrity levels (ASIL) or industrial safety integrity levels (SIL) certification.

Fault injection testing represents a cornerstone of functional safety validation, deliberately introducing faults to verify proper detection and response mechanisms. This includes simulating short circuits, open circuits, and communication failures to ensure the gate driver's diagnostic coverage meets ISO 26262 or IEC 61508 requirements.

Finally, documentation and traceability form the foundation of validation methodologies, with detailed test plans, procedures, and results maintained throughout the product lifecycle. This comprehensive approach ensures SiC gate drivers can achieve the reliability standards necessary for safety-critical automotive and industrial applications.

Cost-Benefit Analysis of Safety-Compliant SiC Solutions

Implementing safety-compliant SiC solutions requires significant investment, necessitating thorough cost-benefit analysis to justify adoption. Initial implementation costs for SiC gate drivers with functional safety features typically exceed traditional silicon-based alternatives by 30-45%, primarily due to specialized components, redundant circuitry, and advanced monitoring systems required to meet ISO 26262 and IEC 61508 standards.

Hardware costs represent the most visible expenditure, with safety-rated SiC MOSFETs and gate drivers commanding premium prices compared to non-safety variants. Additional costs arise from implementing diagnostic circuits, fault detection mechanisms, and redundant power supplies necessary for achieving required safety integrity levels. Furthermore, development costs increase substantially due to rigorous verification and validation processes mandated by safety standards.

Despite higher upfront investments, safety-compliant SiC solutions offer compelling long-term economic benefits. System efficiency improvements of 15-25% compared to silicon-based alternatives translate to significant energy savings over product lifetime. For automotive applications, this efficiency gain directly impacts electric vehicle range and battery sizing requirements, potentially reducing overall vehicle costs.

Reliability improvements represent another substantial benefit. Safety-compliant SiC solutions demonstrate mean time between failures (MTBF) rates 2-3 times higher than non-safety variants, reducing warranty claims and maintenance costs. For industrial applications like factory automation, this translates to decreased downtime and associated production losses, which can exceed $10,000 per hour in high-volume manufacturing environments.

Risk mitigation constitutes a critical yet often undervalued benefit. Safety-compliant solutions significantly reduce liability exposure and potential recall costs, which can reach hundreds of millions for automotive manufacturers. Additionally, regulatory compliance enables market access in regions with strict safety requirements, expanding addressable markets and revenue opportunities.

The return on investment timeline varies by application, with industrial implementations typically achieving breakeven within 2-3 years through operational savings. Automotive applications may see longer payback periods of 3-5 years but benefit from enhanced brand reputation and reduced liability exposure. As production volumes increase and technology matures, the cost premium for safety-compliant SiC solutions is projected to decrease by approximately 5-8% annually, further improving the value proposition.

Hardware costs represent the most visible expenditure, with safety-rated SiC MOSFETs and gate drivers commanding premium prices compared to non-safety variants. Additional costs arise from implementing diagnostic circuits, fault detection mechanisms, and redundant power supplies necessary for achieving required safety integrity levels. Furthermore, development costs increase substantially due to rigorous verification and validation processes mandated by safety standards.

Despite higher upfront investments, safety-compliant SiC solutions offer compelling long-term economic benefits. System efficiency improvements of 15-25% compared to silicon-based alternatives translate to significant energy savings over product lifetime. For automotive applications, this efficiency gain directly impacts electric vehicle range and battery sizing requirements, potentially reducing overall vehicle costs.

Reliability improvements represent another substantial benefit. Safety-compliant SiC solutions demonstrate mean time between failures (MTBF) rates 2-3 times higher than non-safety variants, reducing warranty claims and maintenance costs. For industrial applications like factory automation, this translates to decreased downtime and associated production losses, which can exceed $10,000 per hour in high-volume manufacturing environments.

Risk mitigation constitutes a critical yet often undervalued benefit. Safety-compliant solutions significantly reduce liability exposure and potential recall costs, which can reach hundreds of millions for automotive manufacturers. Additionally, regulatory compliance enables market access in regions with strict safety requirements, expanding addressable markets and revenue opportunities.

The return on investment timeline varies by application, with industrial implementations typically achieving breakeven within 2-3 years through operational savings. Automotive applications may see longer payback periods of 3-5 years but benefit from enhanced brand reputation and reduced liability exposure. As production volumes increase and technology matures, the cost premium for safety-compliant SiC solutions is projected to decrease by approximately 5-8% annually, further improving the value proposition.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!