SiC Gate Driver Fault Telemetry: SOA Logging, Lifetime Models And Diagnostics

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Gate Driver Technology Evolution and Objectives

Silicon Carbide (SiC) power devices have revolutionized power electronics since their commercial introduction in the early 2000s. The evolution of SiC technology has been marked by significant improvements in device performance, reliability, and cost reduction. Initially, SiC Schottky diodes were the first commercially viable SiC devices, followed by the introduction of SiC MOSFETs in the late 2000s, which offered superior switching characteristics compared to silicon counterparts.

The development trajectory of SiC gate drivers has closely followed the evolution of SiC power devices. Early gate drivers were adapted from silicon IGBT drivers but quickly proved inadequate for the unique characteristics of SiC devices. The higher switching speeds, increased dv/dt and di/dt rates, and different gate voltage requirements of SiC MOSFETs necessitated specialized gate driver solutions.

From 2010 to 2015, the industry witnessed the emergence of dedicated SiC gate drivers designed to handle the higher switching frequencies while maintaining robust protection features. These drivers incorporated faster short-circuit protection mechanisms and more precise voltage control to accommodate the narrower safe operating area (SOA) of SiC devices.

The period from 2016 to 2020 saw significant advancements in integration, with gate drivers incorporating sophisticated monitoring and protection features. This era marked the beginning of telemetry capabilities in gate drivers, allowing for basic fault detection and reporting.

Current state-of-the-art SiC gate drivers (2021-present) feature advanced telemetry systems capable of real-time monitoring of critical parameters such as gate voltage, drain current, temperature, and switching characteristics. These systems enable comprehensive SOA logging, which is crucial for understanding device behavior under various operating conditions.

The primary objective of SiC gate driver fault telemetry is to enhance system reliability while maximizing the performance potential of SiC devices. This involves developing sophisticated monitoring systems that can detect anomalies before they lead to catastrophic failures, thereby extending the operational lifetime of power modules.

Another key goal is the development of accurate lifetime models based on telemetry data. By continuously monitoring and logging operational parameters, engineers can create predictive models that estimate remaining useful life and optimize maintenance schedules. These models aim to correlate specific operational patterns with degradation mechanisms, enabling more precise lifetime predictions.

Advanced diagnostics represent the third major objective, focusing on the ability to not only detect faults but also identify their root causes. This includes distinguishing between different failure modes such as gate oxide degradation, bond wire fatigue, or die attach degradation, which require different mitigation strategies.

The technology trajectory is moving toward increasingly intelligent gate drivers with embedded AI capabilities for real-time decision-making and adaptive control strategies based on operational history and current conditions.

The development trajectory of SiC gate drivers has closely followed the evolution of SiC power devices. Early gate drivers were adapted from silicon IGBT drivers but quickly proved inadequate for the unique characteristics of SiC devices. The higher switching speeds, increased dv/dt and di/dt rates, and different gate voltage requirements of SiC MOSFETs necessitated specialized gate driver solutions.

From 2010 to 2015, the industry witnessed the emergence of dedicated SiC gate drivers designed to handle the higher switching frequencies while maintaining robust protection features. These drivers incorporated faster short-circuit protection mechanisms and more precise voltage control to accommodate the narrower safe operating area (SOA) of SiC devices.

The period from 2016 to 2020 saw significant advancements in integration, with gate drivers incorporating sophisticated monitoring and protection features. This era marked the beginning of telemetry capabilities in gate drivers, allowing for basic fault detection and reporting.

Current state-of-the-art SiC gate drivers (2021-present) feature advanced telemetry systems capable of real-time monitoring of critical parameters such as gate voltage, drain current, temperature, and switching characteristics. These systems enable comprehensive SOA logging, which is crucial for understanding device behavior under various operating conditions.

The primary objective of SiC gate driver fault telemetry is to enhance system reliability while maximizing the performance potential of SiC devices. This involves developing sophisticated monitoring systems that can detect anomalies before they lead to catastrophic failures, thereby extending the operational lifetime of power modules.

Another key goal is the development of accurate lifetime models based on telemetry data. By continuously monitoring and logging operational parameters, engineers can create predictive models that estimate remaining useful life and optimize maintenance schedules. These models aim to correlate specific operational patterns with degradation mechanisms, enabling more precise lifetime predictions.

Advanced diagnostics represent the third major objective, focusing on the ability to not only detect faults but also identify their root causes. This includes distinguishing between different failure modes such as gate oxide degradation, bond wire fatigue, or die attach degradation, which require different mitigation strategies.

The technology trajectory is moving toward increasingly intelligent gate drivers with embedded AI capabilities for real-time decision-making and adaptive control strategies based on operational history and current conditions.

Market Demand Analysis for SiC Power Electronics

The Silicon Carbide (SiC) power electronics market is experiencing unprecedented growth driven by increasing demand for high-efficiency power conversion systems across multiple industries. The global SiC power device market, valued at approximately $1.1 billion in 2022, is projected to reach $6.3 billion by 2028, representing a compound annual growth rate (CAGR) of over 33%. This remarkable growth trajectory underscores the critical importance of advanced gate driver technologies with fault telemetry capabilities.

Electric vehicle (EV) manufacturers constitute the primary demand driver, as they seek to extend vehicle range, reduce charging times, and minimize thermal management requirements. The EV market's transition toward 800V and even 1200V architectures has accelerated SiC adoption, with major automakers including Tesla, Volkswagen Group, and BYD committing to SiC-based power systems in their newest models. Industry analysts estimate that SiC content per vehicle will increase from approximately $70 in 2022 to over $220 by 2026.

Industrial power conversion represents another significant market segment, particularly in renewable energy applications. Solar inverters and wind power converters benefit substantially from SiC's higher switching frequencies and reduced losses. The solar inverter market alone is expected to incorporate over $800 million worth of SiC devices by 2025, with fault telemetry systems becoming standard requirements for utility-scale installations.

Data center power infrastructure presents a rapidly expanding opportunity, driven by escalating computational demands and energy efficiency imperatives. SiC-based power supplies can reduce conversion losses by up to 30% compared to silicon alternatives, translating to millions in operational cost savings for hyperscale facilities. Market research indicates that data center operators are willing to pay a 15-20% premium for power systems with advanced diagnostics and predictive maintenance capabilities.

The aerospace and defense sectors, though smaller in volume, offer premium pricing opportunities for SiC solutions with sophisticated fault telemetry. These applications demand the highest reliability standards and are willing to pay 3-5 times the commercial price for systems with comprehensive health monitoring and prognostics.

Geographically, Asia-Pacific represents the largest market for SiC power electronics (42% share), followed by North America (28%) and Europe (24%). China has emerged as both the largest consumer and producer, with substantial government investments supporting domestic SiC supply chain development through its "Made in China 2025" initiative.

Customer requirements increasingly emphasize lifetime prediction models and real-time diagnostics as essential features rather than optional add-ons. A recent industry survey revealed that 78% of power system engineers consider advanced fault telemetry capabilities "very important" or "critical" when selecting SiC power modules for new designs.

Electric vehicle (EV) manufacturers constitute the primary demand driver, as they seek to extend vehicle range, reduce charging times, and minimize thermal management requirements. The EV market's transition toward 800V and even 1200V architectures has accelerated SiC adoption, with major automakers including Tesla, Volkswagen Group, and BYD committing to SiC-based power systems in their newest models. Industry analysts estimate that SiC content per vehicle will increase from approximately $70 in 2022 to over $220 by 2026.

Industrial power conversion represents another significant market segment, particularly in renewable energy applications. Solar inverters and wind power converters benefit substantially from SiC's higher switching frequencies and reduced losses. The solar inverter market alone is expected to incorporate over $800 million worth of SiC devices by 2025, with fault telemetry systems becoming standard requirements for utility-scale installations.

Data center power infrastructure presents a rapidly expanding opportunity, driven by escalating computational demands and energy efficiency imperatives. SiC-based power supplies can reduce conversion losses by up to 30% compared to silicon alternatives, translating to millions in operational cost savings for hyperscale facilities. Market research indicates that data center operators are willing to pay a 15-20% premium for power systems with advanced diagnostics and predictive maintenance capabilities.

The aerospace and defense sectors, though smaller in volume, offer premium pricing opportunities for SiC solutions with sophisticated fault telemetry. These applications demand the highest reliability standards and are willing to pay 3-5 times the commercial price for systems with comprehensive health monitoring and prognostics.

Geographically, Asia-Pacific represents the largest market for SiC power electronics (42% share), followed by North America (28%) and Europe (24%). China has emerged as both the largest consumer and producer, with substantial government investments supporting domestic SiC supply chain development through its "Made in China 2025" initiative.

Customer requirements increasingly emphasize lifetime prediction models and real-time diagnostics as essential features rather than optional add-ons. A recent industry survey revealed that 78% of power system engineers consider advanced fault telemetry capabilities "very important" or "critical" when selecting SiC power modules for new designs.

Current Challenges in SiC Gate Driver Fault Detection

Despite significant advancements in Silicon Carbide (SiC) power semiconductor technology, fault detection in SiC gate drivers remains a complex challenge that impedes wider adoption in high-reliability applications. The primary difficulty stems from SiC devices' faster switching speeds and higher operating temperatures compared to traditional silicon counterparts, which create more stringent requirements for fault detection systems.

One major challenge is the detection speed requirement. SiC MOSFETs can transition from normal operation to catastrophic failure in nanoseconds, necessitating ultra-fast fault detection mechanisms that can operate in the sub-microsecond range. Conventional fault detection methods developed for silicon devices often prove inadequate due to their relatively slower response times.

Temperature sensitivity presents another significant hurdle. SiC devices operate at junction temperatures up to 200°C, requiring fault detection circuits that remain accurate and reliable across extreme temperature ranges. Current temperature compensation techniques often struggle to maintain consistent performance across such wide operating conditions.

The integration of sensing elements without compromising the gate driver's performance constitutes a substantial technical barrier. Adding current and voltage sensors can introduce parasitic inductances and capacitances that degrade switching performance—a particularly critical issue given SiC's sensitivity to layout parasitics. This creates a fundamental design trade-off between comprehensive fault monitoring and optimal switching performance.

Noise immunity represents a persistent challenge in SiC applications. The high dv/dt and di/dt rates during switching (often exceeding 50V/ns and 1A/ns respectively) generate substantial electromagnetic interference that can trigger false fault detections. Developing robust filtering algorithms that distinguish between normal switching transients and actual fault conditions remains problematic.

Data processing limitations further complicate fault detection. The volume of high-speed telemetry data generated during SiC operation can overwhelm conventional processing systems. Real-time analysis of this data stream requires specialized hardware and algorithms that balance processing speed with power consumption constraints.

Reliability validation of fault detection systems themselves presents a methodological challenge. Creating repeatable test conditions that accurately simulate real-world fault scenarios without damaging expensive SiC devices requires sophisticated test equipment and protocols that many organizations lack. This hampers the development and verification of new detection techniques.

Standardization gaps across the industry further impede progress. The absence of unified testing protocols and performance metrics for SiC gate driver fault detection makes it difficult to compare different solutions and establish best practices, slowing the overall advancement of the technology.

One major challenge is the detection speed requirement. SiC MOSFETs can transition from normal operation to catastrophic failure in nanoseconds, necessitating ultra-fast fault detection mechanisms that can operate in the sub-microsecond range. Conventional fault detection methods developed for silicon devices often prove inadequate due to their relatively slower response times.

Temperature sensitivity presents another significant hurdle. SiC devices operate at junction temperatures up to 200°C, requiring fault detection circuits that remain accurate and reliable across extreme temperature ranges. Current temperature compensation techniques often struggle to maintain consistent performance across such wide operating conditions.

The integration of sensing elements without compromising the gate driver's performance constitutes a substantial technical barrier. Adding current and voltage sensors can introduce parasitic inductances and capacitances that degrade switching performance—a particularly critical issue given SiC's sensitivity to layout parasitics. This creates a fundamental design trade-off between comprehensive fault monitoring and optimal switching performance.

Noise immunity represents a persistent challenge in SiC applications. The high dv/dt and di/dt rates during switching (often exceeding 50V/ns and 1A/ns respectively) generate substantial electromagnetic interference that can trigger false fault detections. Developing robust filtering algorithms that distinguish between normal switching transients and actual fault conditions remains problematic.

Data processing limitations further complicate fault detection. The volume of high-speed telemetry data generated during SiC operation can overwhelm conventional processing systems. Real-time analysis of this data stream requires specialized hardware and algorithms that balance processing speed with power consumption constraints.

Reliability validation of fault detection systems themselves presents a methodological challenge. Creating repeatable test conditions that accurately simulate real-world fault scenarios without damaging expensive SiC devices requires sophisticated test equipment and protocols that many organizations lack. This hampers the development and verification of new detection techniques.

Standardization gaps across the industry further impede progress. The absence of unified testing protocols and performance metrics for SiC gate driver fault detection makes it difficult to compare different solutions and establish best practices, slowing the overall advancement of the technology.

Existing Fault Telemetry Solutions for SiC Gate Drivers

01 SiC Gate Driver Fault Detection and Telemetry Systems

Silicon Carbide (SiC) gate driver circuits incorporate advanced fault detection and telemetry systems that monitor operational parameters in real-time. These systems collect data on voltage spikes, current surges, and thermal conditions to identify potential failures before they occur. The telemetry components transmit this diagnostic information to control systems, enabling immediate response to abnormal conditions and preventing catastrophic failures in power electronics applications.- SiC Gate Driver Fault Detection and Telemetry Systems: Silicon Carbide (SiC) gate driver circuits incorporate advanced fault detection mechanisms that monitor critical parameters during operation. These systems collect real-time telemetry data on gate voltage, current, temperature, and switching characteristics to identify potential failures before they occur. The telemetry systems transmit this data to control units for analysis, enabling predictive maintenance and improved system reliability in power electronics applications.

- Safe Operating Area (SOA) Monitoring and Logging for SiC Devices: SOA monitoring systems continuously track the operating conditions of SiC power devices to ensure they remain within safe parameters. These systems log voltage, current, temperature, and switching transients to prevent device operation outside manufacturer-specified limits. The logged data provides valuable insights into device stress patterns and can be used to optimize system design and operation. Advanced SOA monitoring includes dynamic adjustment of operating parameters based on real-time conditions.

- SiC Device Lifetime Models and Degradation Analysis: Lifetime modeling techniques for SiC power devices analyze accumulated stress factors to predict remaining useful life. These models incorporate thermal cycling, power cycling, voltage stress, and switching event data to estimate degradation rates. Machine learning algorithms process historical operating data to refine lifetime predictions and identify early indicators of potential failure. This approach enables condition-based maintenance strategies and extends the operational life of SiC-based power systems.

- Diagnostic Systems for SiC Gate Driver Circuits: Diagnostic systems for SiC gate drivers employ specialized algorithms to identify abnormal operating conditions and component degradation. These systems analyze switching waveforms, gate resistance changes, and thermal patterns to detect early signs of failure. Self-test routines can be executed during system startup or during operation to verify proper functionality of gate driver components. Advanced diagnostics include isolation monitoring, power supply verification, and short-circuit protection validation.

- Data Management and Analysis for SiC Power Electronics: Comprehensive data management systems collect, store, and analyze operational data from SiC power devices across their lifecycle. These systems integrate telemetry data with maintenance records and environmental conditions to provide holistic health monitoring. Cloud-based platforms enable remote monitoring and fleet-wide analysis to identify common failure patterns. Advanced analytics apply statistical methods and artificial intelligence to extract actionable insights from the collected data, supporting design improvements and operational optimizations.

02 Safe Operating Area (SOA) Monitoring and Logging

SOA monitoring systems continuously track whether SiC power devices operate within their specified electrical and thermal boundaries. These systems log critical parameters including gate voltage, drain current, and junction temperature to ensure operation remains within safe limits. Advanced SOA logging mechanisms store historical operational data that can be used for post-event analysis, system optimization, and preventive maintenance scheduling, helping to maximize device reliability while preventing operation in potentially damaging conditions.Expand Specific Solutions03 SiC Device Lifetime Models and Predictive Diagnostics

Lifetime modeling techniques for SiC power devices incorporate stress factors such as thermal cycling, voltage stress, and switching frequency to predict remaining useful life. These models analyze accumulated stress data from operational history to estimate degradation rates and project failure probabilities. Predictive diagnostic algorithms use this information to schedule maintenance before failures occur, optimizing system reliability and reducing unplanned downtime in critical applications where SiC devices are deployed.Expand Specific Solutions04 Real-time Diagnostic Systems for SiC Power Modules

Real-time diagnostic systems for SiC power modules employ embedded sensors and monitoring circuits that continuously evaluate device health. These systems analyze switching characteristics, thermal patterns, and electrical parameters to detect early signs of degradation or impending failure. Advanced diagnostic algorithms can distinguish between normal operational variations and actual fault conditions, reducing false alarms while providing actionable intelligence about module condition and performance trends.Expand Specific Solutions05 Integrated Fault Management and Protection Circuits

Integrated fault management systems for SiC gate drivers combine detection, protection, and reporting functions in a single architecture. These systems implement multi-level protection strategies including fast overcurrent shutdown, thermal protection, and under/over-voltage lockout. When faults are detected, the protection circuits can safely disable the gate driver, log fault information with timestamps, and communicate fault details to higher-level control systems, enabling comprehensive system protection while maintaining detailed records for later analysis.Expand Specific Solutions

Key Industry Players in SiC Power Semiconductor Market

The SiC Gate Driver Fault Telemetry market is currently in an early growth phase, characterized by increasing adoption of silicon carbide power devices across automotive, industrial, and energy sectors. The global market is projected to expand significantly as demand for high-efficiency power electronics grows, with estimates suggesting a CAGR of 25-30% through 2028. Technologically, the field is advancing rapidly with key players demonstrating varying levels of maturity. Companies like Infineon Technologies, Mitsubishi Electric, and Hitachi lead with comprehensive fault detection solutions, while semiconductor manufacturers such as TSMC and Global Power Technology focus on integrating telemetry capabilities directly into SiC devices. Academic institutions including Huazhong University and Xi'an Jiaotong University are contributing fundamental research on lifetime modeling, while industrial players like Bosch and Siemens are developing application-specific diagnostic systems.

Infineon Technologies AG

Technical Solution: Infineon's SiC Gate Driver solution incorporates advanced fault telemetry systems that continuously monitor critical parameters during device operation. Their technology implements real-time Safe Operating Area (SOA) logging through integrated sensors that measure junction temperature, current density, and switching transients. The system employs a proprietary algorithm that compares operational data against predefined SOA boundaries, triggering protective measures when limits are approached. Infineon's lifetime modeling approach integrates accumulated stress factors including thermal cycling, voltage stress, and switching events to predict remaining useful life. Their diagnostic capabilities include detection of abnormal switching patterns, gate oxide degradation monitoring, and threshold voltage drift analysis. The telemetry data is processed through their CoolSiC™ technology platform, which enables comprehensive health monitoring while maintaining high switching frequencies (up to 100kHz) without compromising system reliability.

Strengths: Industry-leading integration of sensing elements directly within driver ICs, providing more accurate measurements with minimal external components. Comprehensive lifetime modeling algorithms based on extensive reliability testing data. Weaknesses: Higher implementation cost compared to traditional solutions, and proprietary nature of diagnostic algorithms may limit customization for specialized applications.

Siemens AG

Technical Solution: Siemens has developed a sophisticated SiC Gate Driver Fault Telemetry system that focuses on predictive maintenance and operational reliability. Their approach combines hardware and software solutions to create a comprehensive monitoring framework. The hardware component features high-precision analog front-end circuits that capture microsecond-level switching events and voltage/current anomalies. These measurements feed into their SIMATIC industrial control platform, where advanced algorithms process the telemetry data. Siemens' SOA logging implementation records not only electrical parameters but also environmental conditions that affect device performance. Their lifetime modeling incorporates both physics-based and data-driven approaches, utilizing accumulated field data from industrial deployments to refine prediction accuracy. The diagnostic system employs machine learning techniques to identify subtle changes in switching characteristics that may indicate impending failure, allowing for scheduled maintenance before catastrophic failures occur. This system has been validated in high-power industrial drives and traction applications, demonstrating significant improvements in system availability.

Strengths: Exceptional integration with existing industrial automation systems, allowing seamless incorporation into factory environments. Robust data analytics platform that improves prediction accuracy over time through machine learning. Weaknesses: System complexity requires specialized knowledge for implementation and maintenance, and the solution is optimized primarily for high-power industrial applications rather than consumer electronics.

Core Patents in SOA Logging and Diagnostics Technology

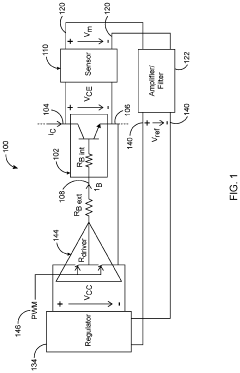

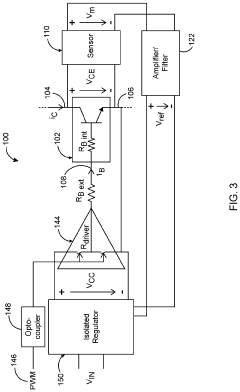

High temperature gate driver for silicon carbide metal-oxide-semiconductor field-effect transistor

PatentWO2019046033A1

Innovation

- A low-cost HT gate driver using commercial-off-the-shelf (COTS) discrete transistors and diodes, integrated with a short-circuit or overcurrent protection circuit and under voltage lock out (UVLO) protection, designed to operate up to 180°C with reduced propagation delay and flexible fault protection.

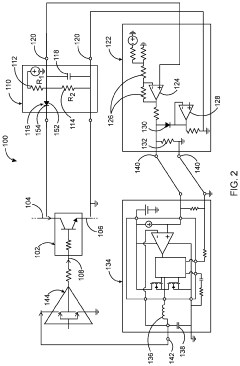

Advanced gate drivers for silicon carbide bipolar junction transistors

PatentActiveUS20200403611A1

Innovation

- A gate driver circuit comprising a sensor, amplifier, and regulator that measures collector-emitter voltage to adjust base current proportionally and continuously, eliminating the need for high bandwidth sensors and digital signal processing, and optimizing base current based on instantaneous collector current and temperature effects.

Reliability Standards and Testing Methodologies

The reliability standards and testing methodologies for SiC gate driver fault telemetry systems must adhere to rigorous international frameworks to ensure consistent performance under extreme conditions. Key standards include IEC 60747 for semiconductor devices, specifically IEC 60747-8 for power MOSFETs, and IEC 60747-9 for insulated-gate bipolar transistors. These standards establish baseline requirements for electrical characteristics, thermal performance, and switching behavior that SiC gate drivers must meet.

JEDEC standards, particularly JEDEC JEP122 for failure mechanisms and models, provide essential guidelines for reliability testing of semiconductor devices. For SiC-specific applications, AEC-Q101 qualification requirements have been adapted to address the unique characteristics of wide bandgap semiconductors, including higher operating temperatures and voltage ratings.

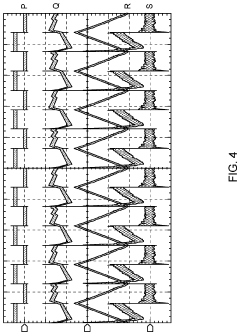

Testing methodologies for SiC gate driver fault telemetry systems typically follow a multi-tiered approach. Accelerated life testing (ALT) protocols subject devices to elevated stress conditions—including temperature cycling (−55°C to +175°C), high-temperature operating life (HTOL) tests at 175°C, and high-temperature reverse bias (HTRB) tests—to induce failure mechanisms that might occur over years of normal operation.

Power cycling tests are particularly critical for SiC applications, as they evaluate the resilience of gate drivers under repetitive thermal stress conditions. Standard methodologies include active power cycling with ΔTj variations from 40K to 100K and passive temperature cycling according to JESD22-A104. These tests help identify weaknesses in die-attach materials, wire bonds, and package interfaces.

Short-circuit robustness testing follows standards like IEC 60747-9-2, with modifications to accommodate the faster switching speeds and higher di/dt characteristics of SiC devices. Fault condition simulation protocols have been developed to verify telemetry system response times, which must be in the sub-microsecond range for effective protection.

EMI/EMC testing according to IEC 61000 series standards ensures that fault telemetry systems maintain accuracy in electrically noisy environments. This is particularly important as SiC devices generate higher frequency electromagnetic emissions due to faster switching speeds.

Humidity and corrosion resistance testing follows JESD22-A101 and JESD22-A110 standards, evaluating the long-term reliability of gate driver circuits in harsh environmental conditions. These tests are essential for applications in automotive and industrial environments where moisture and contaminants are prevalent.

Recent developments include the establishment of specific test protocols for evaluating the accuracy of SOA (Safe Operating Area) logging systems, with requirements for temporal resolution below 100ns and measurement accuracy within ±2% across temperature ranges from −40°C to +150°C.

JEDEC standards, particularly JEDEC JEP122 for failure mechanisms and models, provide essential guidelines for reliability testing of semiconductor devices. For SiC-specific applications, AEC-Q101 qualification requirements have been adapted to address the unique characteristics of wide bandgap semiconductors, including higher operating temperatures and voltage ratings.

Testing methodologies for SiC gate driver fault telemetry systems typically follow a multi-tiered approach. Accelerated life testing (ALT) protocols subject devices to elevated stress conditions—including temperature cycling (−55°C to +175°C), high-temperature operating life (HTOL) tests at 175°C, and high-temperature reverse bias (HTRB) tests—to induce failure mechanisms that might occur over years of normal operation.

Power cycling tests are particularly critical for SiC applications, as they evaluate the resilience of gate drivers under repetitive thermal stress conditions. Standard methodologies include active power cycling with ΔTj variations from 40K to 100K and passive temperature cycling according to JESD22-A104. These tests help identify weaknesses in die-attach materials, wire bonds, and package interfaces.

Short-circuit robustness testing follows standards like IEC 60747-9-2, with modifications to accommodate the faster switching speeds and higher di/dt characteristics of SiC devices. Fault condition simulation protocols have been developed to verify telemetry system response times, which must be in the sub-microsecond range for effective protection.

EMI/EMC testing according to IEC 61000 series standards ensures that fault telemetry systems maintain accuracy in electrically noisy environments. This is particularly important as SiC devices generate higher frequency electromagnetic emissions due to faster switching speeds.

Humidity and corrosion resistance testing follows JESD22-A101 and JESD22-A110 standards, evaluating the long-term reliability of gate driver circuits in harsh environmental conditions. These tests are essential for applications in automotive and industrial environments where moisture and contaminants are prevalent.

Recent developments include the establishment of specific test protocols for evaluating the accuracy of SOA (Safe Operating Area) logging systems, with requirements for temporal resolution below 100ns and measurement accuracy within ±2% across temperature ranges from −40°C to +150°C.

Thermal Management Considerations for SiC Devices

Thermal management is a critical aspect of SiC device implementation, particularly when considering fault telemetry systems. Silicon Carbide devices operate at significantly higher temperatures than traditional silicon counterparts, with junction temperatures reaching up to 200°C compared to silicon's typical 150°C limit. This thermal advantage, while beneficial for power density, creates unique challenges for monitoring and management systems.

The thermal characteristics of SiC devices directly impact the design requirements for gate driver fault telemetry systems. As SiC MOSFETs and diodes operate at elevated temperatures, the surrounding components, including gate drivers and sensing circuits, must maintain reliability under these conditions. Conventional temperature sensing methods often prove inadequate due to the extreme thermal gradients present in SiC power modules.

Advanced thermal management solutions for SiC-based systems typically incorporate multiple cooling strategies. Direct liquid cooling has emerged as a preferred method for high-power applications, offering junction-to-ambient thermal resistances as low as 0.1°C/W. This approach enables more accurate temperature monitoring by reducing thermal transients that can mask fault conditions during telemetry data collection.

The relationship between thermal cycling and device lifetime represents a key consideration for fault telemetry systems. Research indicates that SiC devices experience different failure mechanisms compared to silicon under thermal stress. While silicon typically fails due to bond wire lift-off after 100,000-300,000 cycles, SiC modules often show die-attach degradation as the primary failure mode, occurring at different thermal cycle counts depending on the packaging technology.

Temperature measurement accuracy becomes particularly challenging in SiC applications. Traditional methods using thermocouples or infrared cameras often fail to capture the rapid thermal transients during fault conditions. Advanced telemetry systems now incorporate embedded temperature sensors with response times under 1μs, enabling real-time correlation between electrical faults and thermal events.

The thermal interface materials (TIMs) used in SiC modules significantly impact both thermal performance and telemetry accuracy. Recent developments in phase-change materials and sintered silver interfaces have reduced thermal resistance by up to 70% compared to conventional thermal greases, improving temperature uniformity and measurement reliability during fault logging operations.

Thermal modeling techniques have evolved specifically for SiC applications, with 3D finite element models now incorporating electro-thermal coupling effects. These models enable more accurate prediction of temperature distribution during fault conditions, supporting the development of more precise safe operating area (SOA) boundaries for telemetry systems to monitor.

The thermal characteristics of SiC devices directly impact the design requirements for gate driver fault telemetry systems. As SiC MOSFETs and diodes operate at elevated temperatures, the surrounding components, including gate drivers and sensing circuits, must maintain reliability under these conditions. Conventional temperature sensing methods often prove inadequate due to the extreme thermal gradients present in SiC power modules.

Advanced thermal management solutions for SiC-based systems typically incorporate multiple cooling strategies. Direct liquid cooling has emerged as a preferred method for high-power applications, offering junction-to-ambient thermal resistances as low as 0.1°C/W. This approach enables more accurate temperature monitoring by reducing thermal transients that can mask fault conditions during telemetry data collection.

The relationship between thermal cycling and device lifetime represents a key consideration for fault telemetry systems. Research indicates that SiC devices experience different failure mechanisms compared to silicon under thermal stress. While silicon typically fails due to bond wire lift-off after 100,000-300,000 cycles, SiC modules often show die-attach degradation as the primary failure mode, occurring at different thermal cycle counts depending on the packaging technology.

Temperature measurement accuracy becomes particularly challenging in SiC applications. Traditional methods using thermocouples or infrared cameras often fail to capture the rapid thermal transients during fault conditions. Advanced telemetry systems now incorporate embedded temperature sensors with response times under 1μs, enabling real-time correlation between electrical faults and thermal events.

The thermal interface materials (TIMs) used in SiC modules significantly impact both thermal performance and telemetry accuracy. Recent developments in phase-change materials and sintered silver interfaces have reduced thermal resistance by up to 70% compared to conventional thermal greases, improving temperature uniformity and measurement reliability during fault logging operations.

Thermal modeling techniques have evolved specifically for SiC applications, with 3D finite element models now incorporating electro-thermal coupling effects. These models enable more accurate prediction of temperature distribution during fault conditions, supporting the development of more precise safe operating area (SOA) boundaries for telemetry systems to monitor.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!