SiC Gate Driver High-Temperature Operation: Junction, Package And Aging

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Gate Driver Technology Evolution and Objectives

Silicon Carbide (SiC) gate driver technology has evolved significantly over the past three decades, transitioning from experimental concepts to commercial applications. The evolution began in the early 1990s with fundamental research on wide bandgap semiconductors, where SiC emerged as a promising material for power electronics due to its superior thermal conductivity, higher breakdown field strength, and ability to operate at elevated temperatures compared to traditional silicon.

The mid-2000s marked a critical turning point with the introduction of the first commercial SiC diodes, followed by SiC MOSFETs in the early 2010s. This advancement necessitated parallel development of specialized gate drivers capable of handling the unique switching characteristics and operating conditions of SiC power devices. Early gate drivers faced significant challenges in managing the higher switching speeds and voltage requirements of SiC devices.

From 2015 onwards, gate driver technology has rapidly advanced to address high-temperature operation requirements, with innovations in semiconductor materials, packaging technologies, and circuit topologies. The development of specialized isolation barriers, robust power supply architectures, and temperature-compensated driving circuits has enabled operation in increasingly harsh environments.

Current state-of-the-art SiC gate drivers incorporate advanced features such as desaturation protection, Miller clamping, soft turn-off capabilities, and active gate driving techniques to optimize switching performance while maintaining reliability. These developments have been driven by demands from automotive, aerospace, and industrial sectors seeking to leverage SiC benefits in high-temperature applications.

The primary objectives for next-generation SiC gate drivers focus on several critical areas. First, extending reliable operation at junction temperatures exceeding 200°C while maintaining signal integrity and isolation properties. Second, developing packaging solutions that can withstand thermal cycling and mechanical stress in extreme environments without degradation. Third, implementing advanced aging compensation techniques to maintain consistent performance throughout the device lifecycle.

Additional objectives include reducing parasitic inductances to enable faster switching speeds, improving electromagnetic interference (EMI) immunity, and developing integrated protection features specifically tailored for high-temperature operation. The integration of advanced monitoring capabilities for real-time health assessment and predictive maintenance represents another key development goal.

The ultimate aim is to create gate driver solutions that can fully exploit SiC's theoretical temperature capabilities (potentially up to 300°C for short durations) while ensuring long-term reliability, maintaining optimal switching performance, and providing comprehensive protection features across diverse application environments.

The mid-2000s marked a critical turning point with the introduction of the first commercial SiC diodes, followed by SiC MOSFETs in the early 2010s. This advancement necessitated parallel development of specialized gate drivers capable of handling the unique switching characteristics and operating conditions of SiC power devices. Early gate drivers faced significant challenges in managing the higher switching speeds and voltage requirements of SiC devices.

From 2015 onwards, gate driver technology has rapidly advanced to address high-temperature operation requirements, with innovations in semiconductor materials, packaging technologies, and circuit topologies. The development of specialized isolation barriers, robust power supply architectures, and temperature-compensated driving circuits has enabled operation in increasingly harsh environments.

Current state-of-the-art SiC gate drivers incorporate advanced features such as desaturation protection, Miller clamping, soft turn-off capabilities, and active gate driving techniques to optimize switching performance while maintaining reliability. These developments have been driven by demands from automotive, aerospace, and industrial sectors seeking to leverage SiC benefits in high-temperature applications.

The primary objectives for next-generation SiC gate drivers focus on several critical areas. First, extending reliable operation at junction temperatures exceeding 200°C while maintaining signal integrity and isolation properties. Second, developing packaging solutions that can withstand thermal cycling and mechanical stress in extreme environments without degradation. Third, implementing advanced aging compensation techniques to maintain consistent performance throughout the device lifecycle.

Additional objectives include reducing parasitic inductances to enable faster switching speeds, improving electromagnetic interference (EMI) immunity, and developing integrated protection features specifically tailored for high-temperature operation. The integration of advanced monitoring capabilities for real-time health assessment and predictive maintenance represents another key development goal.

The ultimate aim is to create gate driver solutions that can fully exploit SiC's theoretical temperature capabilities (potentially up to 300°C for short durations) while ensuring long-term reliability, maintaining optimal switching performance, and providing comprehensive protection features across diverse application environments.

Market Demand Analysis for High-Temperature SiC Applications

The market for high-temperature Silicon Carbide (SiC) applications has been experiencing robust growth, driven primarily by the automotive, aerospace, and industrial sectors. The demand for SiC-based power electronics capable of operating reliably at elevated temperatures (typically above 175°C) continues to expand as industries push toward greater efficiency, reduced cooling requirements, and higher power density solutions.

In the automotive sector, the transition to electric vehicles (EVs) represents a significant market driver. High-temperature SiC gate drivers enable more efficient power conversion in onboard chargers, DC-DC converters, and traction inverters. Market research indicates that the automotive power electronics segment utilizing wide bandgap semiconductors is growing at a compound annual rate exceeding 25%, with SiC components representing an increasingly dominant share.

Aerospace applications constitute another critical market segment, where high-temperature electronics must function reliably in extreme environments. Aircraft engine control systems, power distribution units, and actuation systems benefit substantially from SiC technology's ability to operate at elevated temperatures without extensive cooling infrastructure. This sector values the reduced weight and increased reliability that high-temperature capable SiC solutions provide.

Industrial applications, particularly in oil and gas exploration, geothermal energy harvesting, and high-temperature manufacturing processes, represent a growing market for temperature-resistant SiC gate drivers. These environments often expose electronics to temperatures exceeding 200°C, where conventional silicon-based solutions cannot operate reliably without complex cooling systems.

The market is also being shaped by regulatory pressures and efficiency standards. Energy efficiency regulations in major markets are indirectly driving adoption of SiC technology, as manufacturers seek solutions that can deliver higher performance while meeting increasingly stringent requirements. The ability of SiC gate drivers to operate efficiently at high temperatures translates directly to system-level benefits in terms of size, weight, and energy consumption.

Supply chain considerations are influencing market dynamics as well. As manufacturers seek to secure reliable sources of SiC components, there has been increased investment in production capacity and material refinement. This has gradually addressed previous concerns about supply constraints, though specialized high-temperature packaging solutions remain a potential bottleneck.

From a regional perspective, Asia-Pacific represents the fastest-growing market for high-temperature SiC applications, driven by rapid industrialization and automotive manufacturing growth. North America and Europe maintain significant market shares, particularly in aerospace and premium automotive segments where performance requirements justify the higher component costs.

In the automotive sector, the transition to electric vehicles (EVs) represents a significant market driver. High-temperature SiC gate drivers enable more efficient power conversion in onboard chargers, DC-DC converters, and traction inverters. Market research indicates that the automotive power electronics segment utilizing wide bandgap semiconductors is growing at a compound annual rate exceeding 25%, with SiC components representing an increasingly dominant share.

Aerospace applications constitute another critical market segment, where high-temperature electronics must function reliably in extreme environments. Aircraft engine control systems, power distribution units, and actuation systems benefit substantially from SiC technology's ability to operate at elevated temperatures without extensive cooling infrastructure. This sector values the reduced weight and increased reliability that high-temperature capable SiC solutions provide.

Industrial applications, particularly in oil and gas exploration, geothermal energy harvesting, and high-temperature manufacturing processes, represent a growing market for temperature-resistant SiC gate drivers. These environments often expose electronics to temperatures exceeding 200°C, where conventional silicon-based solutions cannot operate reliably without complex cooling systems.

The market is also being shaped by regulatory pressures and efficiency standards. Energy efficiency regulations in major markets are indirectly driving adoption of SiC technology, as manufacturers seek solutions that can deliver higher performance while meeting increasingly stringent requirements. The ability of SiC gate drivers to operate efficiently at high temperatures translates directly to system-level benefits in terms of size, weight, and energy consumption.

Supply chain considerations are influencing market dynamics as well. As manufacturers seek to secure reliable sources of SiC components, there has been increased investment in production capacity and material refinement. This has gradually addressed previous concerns about supply constraints, though specialized high-temperature packaging solutions remain a potential bottleneck.

From a regional perspective, Asia-Pacific represents the fastest-growing market for high-temperature SiC applications, driven by rapid industrialization and automotive manufacturing growth. North America and Europe maintain significant market shares, particularly in aerospace and premium automotive segments where performance requirements justify the higher component costs.

Current Challenges in SiC Gate Driver High-Temperature Operation

Silicon Carbide (SiC) gate drivers face significant challenges when operating in high-temperature environments, which limit their widespread adoption in critical applications such as electric vehicles, aerospace systems, and industrial power electronics. The primary challenge stems from the junction temperature limitations of semiconductor devices used in gate driver circuits. While SiC power devices can operate efficiently at temperatures exceeding 200°C, conventional silicon-based gate driver ICs typically have maximum junction temperature ratings of only 125-150°C, creating a fundamental mismatch in thermal capabilities.

Package-related challenges further complicate high-temperature operation. Traditional packaging materials, including standard epoxy molding compounds and lead frames, often exhibit degradation at elevated temperatures. Coefficient of thermal expansion (CTE) mismatches between different package materials create mechanical stress during thermal cycling, leading to delamination, wire bond failures, and solder joint cracking. These issues are particularly pronounced in applications requiring wide temperature ranges and frequent thermal cycling.

Interconnection reliability presents another significant hurdle. Bond wires, die attach materials, and solder joints all become susceptible to fatigue and failure mechanisms at elevated temperatures. The degradation of these interconnections can lead to increased resistance, intermittent connections, or complete circuit failure. High-temperature capable alternatives such as silver sintering and transient liquid phase bonding show promise but add complexity and cost to manufacturing processes.

Aging effects and reliability concerns become increasingly critical at elevated temperatures. Electromigration accelerates exponentially with temperature, causing gradual degradation of metal interconnects. Gate oxide integrity deteriorates more rapidly, leading to threshold voltage shifts and increased leakage currents. These aging mechanisms significantly reduce the operational lifetime of gate driver circuits in high-temperature environments, necessitating conservative derating or frequent replacement.

Thermal management strategies face diminishing returns at high temperatures due to reduced temperature differentials for heat dissipation. Conventional cooling approaches become less effective, requiring innovative solutions such as phase-change materials, advanced ceramics, or active cooling systems that add complexity, weight, and cost to the overall system design.

Protection and sensing circuits within gate drivers also exhibit compromised performance at elevated temperatures. Temperature-dependent parameters in current sensing elements, voltage references, and protection thresholds can drift significantly, potentially leading to false triggering or failure to detect fault conditions. This necessitates sophisticated compensation techniques or inherently temperature-stable circuit designs that can maintain consistent protection functionality across the entire operating temperature range.

Package-related challenges further complicate high-temperature operation. Traditional packaging materials, including standard epoxy molding compounds and lead frames, often exhibit degradation at elevated temperatures. Coefficient of thermal expansion (CTE) mismatches between different package materials create mechanical stress during thermal cycling, leading to delamination, wire bond failures, and solder joint cracking. These issues are particularly pronounced in applications requiring wide temperature ranges and frequent thermal cycling.

Interconnection reliability presents another significant hurdle. Bond wires, die attach materials, and solder joints all become susceptible to fatigue and failure mechanisms at elevated temperatures. The degradation of these interconnections can lead to increased resistance, intermittent connections, or complete circuit failure. High-temperature capable alternatives such as silver sintering and transient liquid phase bonding show promise but add complexity and cost to manufacturing processes.

Aging effects and reliability concerns become increasingly critical at elevated temperatures. Electromigration accelerates exponentially with temperature, causing gradual degradation of metal interconnects. Gate oxide integrity deteriorates more rapidly, leading to threshold voltage shifts and increased leakage currents. These aging mechanisms significantly reduce the operational lifetime of gate driver circuits in high-temperature environments, necessitating conservative derating or frequent replacement.

Thermal management strategies face diminishing returns at high temperatures due to reduced temperature differentials for heat dissipation. Conventional cooling approaches become less effective, requiring innovative solutions such as phase-change materials, advanced ceramics, or active cooling systems that add complexity, weight, and cost to the overall system design.

Protection and sensing circuits within gate drivers also exhibit compromised performance at elevated temperatures. Temperature-dependent parameters in current sensing elements, voltage references, and protection thresholds can drift significantly, potentially leading to false triggering or failure to detect fault conditions. This necessitates sophisticated compensation techniques or inherently temperature-stable circuit designs that can maintain consistent protection functionality across the entire operating temperature range.

Existing High-Temperature SiC Gate Driver Solutions

01 High-temperature resistant SiC gate driver designs

Silicon Carbide (SiC) gate drivers designed specifically for high-temperature environments incorporate specialized components and circuit topologies that can withstand elevated operating temperatures. These designs often feature temperature-compensated circuits, specialized packaging materials, and thermal management solutions to ensure reliable operation at temperatures exceeding conventional silicon limitations. The high-temperature capability enables these drivers to function effectively in harsh environments such as automotive, aerospace, and industrial applications where ambient temperatures can be extreme.- High-temperature resistant SiC gate driver designs: Silicon Carbide (SiC) gate drivers designed specifically for high-temperature environments incorporate specialized components and circuit topologies that can withstand elevated operating temperatures. These designs often feature temperature-compensated circuits, specialized packaging materials, and thermal management solutions to ensure reliable operation at temperatures exceeding conventional silicon limitations. The high-temperature capability enables SiC power devices to be deployed in harsh environments such as automotive, aerospace, and industrial applications where ambient temperatures can be extreme.

- Thermal management techniques for SiC gate drivers: Effective thermal management is critical for SiC gate drivers operating at high temperatures. Various techniques are employed including advanced heat sink designs, thermal interface materials, active cooling systems, and strategic component placement to optimize heat dissipation. Some designs incorporate temperature sensors and adaptive control algorithms that adjust gate driver parameters based on temperature feedback. These thermal management approaches help maintain the gate driver's performance and reliability while operating in high-temperature environments, extending the operational lifetime of the system.

- Isolation technologies for high-temperature SiC applications: Isolation technologies are essential in high-temperature SiC gate driver designs to maintain signal integrity while providing electrical isolation between control and power circuits. Advanced isolation methods include high-temperature resistant optocouplers, magnetic isolators, and capacitive coupling techniques specifically engineered to function reliably at elevated temperatures. These isolation technologies prevent ground loops, protect control circuitry from high voltages, and maintain isolation barriers even under thermal stress, ensuring safe and reliable operation of SiC power devices in high-temperature environments.

- Protection circuits for high-temperature SiC gate drivers: Protection circuits are integrated into SiC gate drivers to safeguard against overcurrent, overvoltage, and thermal runaway conditions that are particularly challenging in high-temperature operations. These circuits include temperature-compensated current limiting, desaturation detection, soft shutdown mechanisms, and active clamping networks. Advanced protection schemes may incorporate predictive algorithms that anticipate potential failure modes based on operating conditions. These protection features ensure the reliability and longevity of SiC power devices when operating near their thermal limits, preventing catastrophic failures in critical applications.

- Wide bandgap semiconductor integration in gate driver circuits: Integration of wide bandgap semiconductors within the gate driver circuits themselves enhances high-temperature performance. By utilizing SiC or GaN components in the driver circuitry alongside the power devices, these systems achieve superior thermal stability and switching performance. The wide bandgap materials in the driver stage maintain their electrical characteristics at elevated temperatures, providing consistent gate signals with minimal degradation. This integration approach results in more compact, efficient, and thermally robust power conversion systems capable of operating reliably in extreme temperature environments.

02 Thermal management techniques for SiC gate drivers

Effective thermal management is crucial for SiC gate drivers operating at high temperatures. Various techniques are employed including advanced heat sink designs, thermal interface materials, active cooling systems, and strategic component placement to optimize heat dissipation. Some designs incorporate temperature sensors and adaptive control algorithms that adjust operating parameters based on temperature feedback. These thermal management approaches help maintain the gate driver's performance and reliability while preventing thermal runaway in extreme temperature conditions.Expand Specific Solutions03 Isolation technologies for high-temperature SiC applications

Isolation technologies are essential in SiC gate driver designs for high-temperature operation to prevent signal degradation and ensure reliable power switching. These technologies include advanced optocouplers, magnetic isolators, and capacitive coupling methods specifically engineered to maintain isolation integrity at elevated temperatures. High-temperature resistant isolation materials and specialized packaging techniques are employed to prevent breakdown of the isolation barrier. These isolation solutions help maintain signal integrity while protecting control circuitry from high voltages in extreme temperature environments.Expand Specific Solutions04 Protection circuits for SiC gate drivers in extreme conditions

Protection circuits are integrated into SiC gate drivers to safeguard against various failure modes exacerbated by high-temperature operation. These include over-current protection, over-voltage protection, short-circuit protection, and under-voltage lockout circuits designed to function reliably at elevated temperatures. Some designs incorporate temperature-dependent threshold adjustments and fault detection mechanisms that respond appropriately to thermal stress conditions. These protection features ensure the longevity and reliability of both the gate driver and the SiC power devices they control in harsh operating environments.Expand Specific Solutions05 Advanced materials and packaging for high-temperature SiC drivers

Advanced materials and packaging technologies are crucial for enabling SiC gate drivers to operate reliably at high temperatures. These include high-temperature resistant substrates, specialized die-attach materials, temperature-stable encapsulants, and ceramic or metal packaging solutions. Some designs utilize novel interconnect technologies and thermally matched materials to minimize stress from thermal cycling. These material and packaging innovations help extend the temperature range of SiC gate drivers while maintaining electrical performance and mechanical integrity under extreme thermal conditions.Expand Specific Solutions

Key Industry Players in SiC Gate Driver Market

The SiC Gate Driver High-Temperature Operation market is currently in a growth phase, with increasing adoption across automotive, industrial, and renewable energy sectors. The global market size is projected to expand significantly due to the rising demand for high-efficiency power electronics in electric vehicles and industrial applications. Technologically, the field is advancing rapidly but still faces challenges in thermal management, packaging reliability, and long-term aging effects. Leading players like Wolfspeed, ROHM, and Mitsubishi Electric are driving innovation in high-temperature SiC solutions, while companies such as BASiC Semiconductor and PN Junction are emerging as significant competitors in the Asian market. Research institutions including the University of Maryland and Institute of Microelectronics of Chinese Academy of Sciences are contributing fundamental advancements in junction design and packaging technologies to address operational stability at elevated temperatures.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has developed advanced SiC gate driver solutions specifically designed for high-temperature operations up to 200°C. Their technology incorporates specialized packaging materials with high thermal conductivity and low thermal expansion coefficients to maintain mechanical integrity at elevated temperatures. The gate drivers feature integrated temperature compensation circuits that automatically adjust driving parameters as junction temperatures fluctuate, ensuring optimal switching performance across the entire operating temperature range. Wolfspeed's solutions also implement advanced isolation barriers using high-temperature capable materials that maintain dielectric strength at elevated temperatures, critical for preventing breakdown in high-voltage SiC applications. Their gate drivers incorporate specialized aging compensation algorithms that monitor device parameters over time and adjust driving signals to compensate for threshold voltage shifts and other aging-related degradations, extending the operational lifetime of SiC power devices in harsh environments.

Strengths: Industry-leading temperature capability (up to 200°C continuous operation), proprietary packaging technology with superior thermal cycling resistance, and comprehensive aging compensation algorithms. Weaknesses: Higher cost compared to conventional solutions, requires specialized design considerations for system integration, and limited compatibility with some third-party SiC devices.

Power Integrations, Inc.

Technical Solution: Power Integrations has developed the SCALE-iDriver family specifically optimized for SiC MOSFET high-temperature applications. Their solution features an Advanced Active Clamping (AAC) technology that protects SiC devices from voltage spikes during high-temperature switching, where parasitic inductances become more problematic. The gate drivers incorporate temperature-compensated current sources that maintain optimal gate drive strength across temperature variations from -40°C to 125°C, with extended capability models reaching 150°C. Their FluxLink™ technology provides reinforced galvanic isolation that maintains integrity at elevated temperatures, unlike optocouplers that degrade rapidly in hot environments. Power Integrations has implemented sophisticated on-chip monitoring systems that track junction temperature and adjust timing parameters to prevent thermal runaway conditions. Their packaging technology utilizes specialized high-temperature die attach materials and wire bonding techniques that resist thermomechanical stress during temperature cycling, significantly reducing package-related failures in demanding applications.

Strengths: Proprietary FluxLink™ isolation technology maintains performance at high temperatures where optocouplers degrade, integrated protection features specifically designed for SiC switching characteristics, and compact form factor with reduced external component requirements. Weaknesses: Limited to 150°C maximum junction temperature (below some competitors), higher power consumption compared to discrete solutions, and more restricted configurability for specialized applications.

Junction and Package Technology Innovations

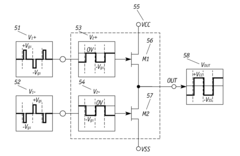

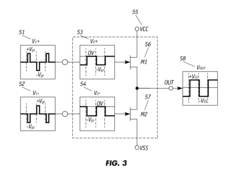

High temperature gate driver for silicon carbide metal-oxide-semiconductor field-effect transistor

PatentWO2019046033A1

Innovation

- A low-cost HT gate driver using commercial-off-the-shelf (COTS) discrete transistors and diodes, integrated with a short-circuit or overcurrent protection circuit and under voltage lock out (UVLO) protection, designed to operate up to 180°C with reduced propagation delay and flexible fault protection.

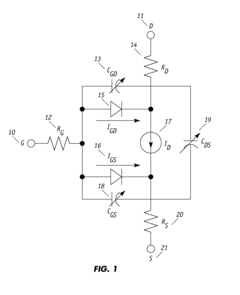

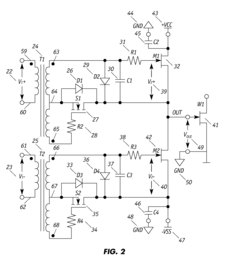

High temperature operation silicon carbide gate driver

PatentInactiveUS20130063184A1

Innovation

- A gate driver circuit utilizing silicon on insulator (SOI) and SiC devices with high-temperature passive components, including transformers, diodes, and capacitors, operating from -70°C to 250°C and 100 kHz to 500 kHz, capable of sinking/source currents up to 25 Amperes, and providing electrical isolation and dv/dt noise minimization.

Reliability and Aging Mechanisms Assessment

The reliability assessment of SiC gate drivers in high-temperature environments reveals multiple critical aging mechanisms that significantly impact long-term performance. Thermal cycling represents one of the most severe stressors, causing coefficient of thermal expansion (CTE) mismatches between different materials in the driver assembly. These mismatches generate mechanical stress at interfaces, leading to delamination, bond wire lifting, and solder joint fatigue. Repeated thermal excursions accelerate these failure modes, with data showing that reliability decreases exponentially with each 10°C increase above 150°C.

Time-dependent dielectric breakdown (TDDB) emerges as another dominant failure mechanism, particularly affecting gate oxide integrity in high-temperature operations. Accelerated testing demonstrates that TDDB lifetime decreases by approximately 50% for every 15°C temperature increase in SiC gate driver applications. This degradation is exacerbated by the higher electric fields typically employed in SiC devices compared to traditional silicon counterparts.

Hot carrier injection (HCI) phenomena intensify at elevated temperatures, causing threshold voltage shifts and transconductance degradation. Recent reliability studies indicate that after 1000 hours at 175°C, SiC gate drivers can experience threshold voltage shifts of 0.3-0.5V, potentially compromising switching performance and protection functions.

Package-related reliability concerns include die-attach degradation, encapsulant breakdown, and interconnect failures. Particularly concerning is the observation that conventional epoxy molding compounds begin to decompose at temperatures above 200°C, releasing corrosive byproducts that attack metallization layers. Advanced high-temperature packaging solutions utilizing ceramic or silicon nitride materials demonstrate superior reliability but introduce cost and manufacturing complexity.

Electromigration rates accelerate exponentially with temperature, following Black's equation, causing progressive degradation of metal interconnects. This becomes particularly problematic in the fine-pitch interconnects of modern gate driver ICs, where current densities can exceed 105 A/cm² during switching transients.

Statistical lifetime modeling based on accelerated testing suggests that while conventional gate drivers typically exhibit a mean time to failure (MTTF) of approximately 100,000 hours at 125°C, this drops to less than 10,000 hours at 200°C without specialized design and material considerations. The implementation of redundancy, derating strategies, and active cooling can significantly improve these reliability metrics, though often at the expense of system complexity and cost.

Time-dependent dielectric breakdown (TDDB) emerges as another dominant failure mechanism, particularly affecting gate oxide integrity in high-temperature operations. Accelerated testing demonstrates that TDDB lifetime decreases by approximately 50% for every 15°C temperature increase in SiC gate driver applications. This degradation is exacerbated by the higher electric fields typically employed in SiC devices compared to traditional silicon counterparts.

Hot carrier injection (HCI) phenomena intensify at elevated temperatures, causing threshold voltage shifts and transconductance degradation. Recent reliability studies indicate that after 1000 hours at 175°C, SiC gate drivers can experience threshold voltage shifts of 0.3-0.5V, potentially compromising switching performance and protection functions.

Package-related reliability concerns include die-attach degradation, encapsulant breakdown, and interconnect failures. Particularly concerning is the observation that conventional epoxy molding compounds begin to decompose at temperatures above 200°C, releasing corrosive byproducts that attack metallization layers. Advanced high-temperature packaging solutions utilizing ceramic or silicon nitride materials demonstrate superior reliability but introduce cost and manufacturing complexity.

Electromigration rates accelerate exponentially with temperature, following Black's equation, causing progressive degradation of metal interconnects. This becomes particularly problematic in the fine-pitch interconnects of modern gate driver ICs, where current densities can exceed 105 A/cm² during switching transients.

Statistical lifetime modeling based on accelerated testing suggests that while conventional gate drivers typically exhibit a mean time to failure (MTTF) of approximately 100,000 hours at 125°C, this drops to less than 10,000 hours at 200°C without specialized design and material considerations. The implementation of redundancy, derating strategies, and active cooling can significantly improve these reliability metrics, though often at the expense of system complexity and cost.

Thermal Management Strategies for SiC Gate Drivers

Effective thermal management is critical for SiC gate drivers operating in high-temperature environments. As SiC power devices can function at junction temperatures exceeding 200°C, their gate drivers must maintain reliability under these extreme conditions. Traditional cooling methods often prove inadequate for these specialized applications, necessitating innovative thermal management approaches.

Heat dissipation techniques for SiC gate drivers can be categorized into passive and active solutions. Passive cooling strategies include advanced thermal interface materials (TIMs) with enhanced thermal conductivity, specialized heat spreaders, and optimized PCB designs featuring thermal vias and copper planes. These solutions provide foundational thermal management without requiring additional power or control systems.

Active cooling methods complement passive approaches when dealing with extreme temperature conditions. Forced-air cooling using high-temperature-rated fans, liquid cooling systems with specialized coolants, and thermoelectric coolers offer dynamic thermal regulation capabilities. For aerospace and automotive applications, integrated cooling solutions that leverage existing vehicle thermal management systems have shown promising results.

Material selection plays a crucial role in thermal management strategy effectiveness. High-temperature ceramics, advanced polymer composites, and specialized metal alloys with superior thermal conductivity are increasingly being incorporated into gate driver packages. Silicon nitride and aluminum nitride substrates have demonstrated excellent thermal performance while maintaining electrical isolation properties essential for gate driver functionality.

Thermal simulation and modeling have become indispensable tools in developing effective cooling strategies. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable engineers to predict thermal behavior under various operating conditions, optimizing designs before physical prototyping. These simulation approaches have significantly reduced development cycles while improving thermal performance.

Recent innovations include phase-change materials integrated into gate driver packages, providing temperature stabilization during transient operations. Additionally, microfluidic cooling channels embedded directly in substrates offer localized cooling at the component level. These advanced solutions address the unique challenges of high-switching-frequency SiC applications where thermal loads can fluctuate rapidly.

Reliability testing protocols for thermal management systems have evolved to match the demanding requirements of SiC applications. Accelerated thermal cycling, power cycling under load, and combined environmental stress testing help validate long-term performance. Industry standards are gradually adapting to incorporate specific requirements for high-temperature SiC gate driver operation.

Heat dissipation techniques for SiC gate drivers can be categorized into passive and active solutions. Passive cooling strategies include advanced thermal interface materials (TIMs) with enhanced thermal conductivity, specialized heat spreaders, and optimized PCB designs featuring thermal vias and copper planes. These solutions provide foundational thermal management without requiring additional power or control systems.

Active cooling methods complement passive approaches when dealing with extreme temperature conditions. Forced-air cooling using high-temperature-rated fans, liquid cooling systems with specialized coolants, and thermoelectric coolers offer dynamic thermal regulation capabilities. For aerospace and automotive applications, integrated cooling solutions that leverage existing vehicle thermal management systems have shown promising results.

Material selection plays a crucial role in thermal management strategy effectiveness. High-temperature ceramics, advanced polymer composites, and specialized metal alloys with superior thermal conductivity are increasingly being incorporated into gate driver packages. Silicon nitride and aluminum nitride substrates have demonstrated excellent thermal performance while maintaining electrical isolation properties essential for gate driver functionality.

Thermal simulation and modeling have become indispensable tools in developing effective cooling strategies. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable engineers to predict thermal behavior under various operating conditions, optimizing designs before physical prototyping. These simulation approaches have significantly reduced development cycles while improving thermal performance.

Recent innovations include phase-change materials integrated into gate driver packages, providing temperature stabilization during transient operations. Additionally, microfluidic cooling channels embedded directly in substrates offer localized cooling at the component level. These advanced solutions address the unique challenges of high-switching-frequency SiC applications where thermal loads can fluctuate rapidly.

Reliability testing protocols for thermal management systems have evolved to match the demanding requirements of SiC applications. Accelerated thermal cycling, power cycling under load, and combined environmental stress testing help validate long-term performance. Industry standards are gradually adapting to incorporate specific requirements for high-temperature SiC gate driver operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!