How Silicone Rubber Harnesses Smart Device Innovations?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Smart Devices: Evolution and Objectives

Silicone rubber has played a pivotal role in the evolution of smart devices, revolutionizing their design, functionality, and user experience. The journey of silicone rubber in smart device innovations can be traced back to the mid-20th century when it first emerged as a versatile material in various industries. Its unique properties, including flexibility, durability, and resistance to extreme temperatures, made it an ideal candidate for electronic applications.

As smart devices began to proliferate in the late 20th and early 21st centuries, silicone rubber found new applications in this rapidly evolving field. Initially, it was primarily used for protective casings and simple button interfaces. However, as technology advanced, so did the utilization of silicone rubber in smart devices.

The evolution of silicone rubber in smart devices has been marked by several key milestones. The introduction of touch-sensitive silicone keypads in mobile phones was a significant breakthrough, enhancing user interaction and device durability. This was followed by the development of silicone-based flexible displays, which opened up new possibilities for device form factors and user interfaces.

In recent years, the integration of silicone rubber with advanced electronics has led to the creation of smart textiles and wearable devices. These innovations have enabled the development of health monitoring systems, interactive clothing, and other cutting-edge applications that seamlessly blend technology with everyday life.

The objectives of silicone rubber in smart device innovations are multifaceted. Primarily, it aims to enhance device functionality, durability, and user experience. By leveraging the material's unique properties, manufacturers seek to create devices that are more resilient, comfortable to use, and capable of withstanding various environmental conditions.

Another key objective is to enable new form factors and design possibilities. The flexibility and moldability of silicone rubber allow for the creation of devices with unconventional shapes and sizes, pushing the boundaries of traditional device design. This has led to the development of foldable smartphones, rollable displays, and other innovative form factors that were previously impossible with rigid materials.

Furthermore, silicone rubber plays a crucial role in improving the energy efficiency and sustainability of smart devices. Its excellent insulating properties contribute to better battery life, while its durability helps extend device lifespan, reducing electronic waste. As the tech industry moves towards more sustainable practices, the role of silicone rubber in achieving these goals becomes increasingly important.

Looking ahead, the objectives for silicone rubber in smart device innovations include further integration with advanced technologies such as artificial intelligence and the Internet of Things. The material's adaptability and compatibility with various sensors and electronic components make it an ideal platform for developing more intelligent and responsive devices that can seamlessly interact with their environment and users.

As smart devices began to proliferate in the late 20th and early 21st centuries, silicone rubber found new applications in this rapidly evolving field. Initially, it was primarily used for protective casings and simple button interfaces. However, as technology advanced, so did the utilization of silicone rubber in smart devices.

The evolution of silicone rubber in smart devices has been marked by several key milestones. The introduction of touch-sensitive silicone keypads in mobile phones was a significant breakthrough, enhancing user interaction and device durability. This was followed by the development of silicone-based flexible displays, which opened up new possibilities for device form factors and user interfaces.

In recent years, the integration of silicone rubber with advanced electronics has led to the creation of smart textiles and wearable devices. These innovations have enabled the development of health monitoring systems, interactive clothing, and other cutting-edge applications that seamlessly blend technology with everyday life.

The objectives of silicone rubber in smart device innovations are multifaceted. Primarily, it aims to enhance device functionality, durability, and user experience. By leveraging the material's unique properties, manufacturers seek to create devices that are more resilient, comfortable to use, and capable of withstanding various environmental conditions.

Another key objective is to enable new form factors and design possibilities. The flexibility and moldability of silicone rubber allow for the creation of devices with unconventional shapes and sizes, pushing the boundaries of traditional device design. This has led to the development of foldable smartphones, rollable displays, and other innovative form factors that were previously impossible with rigid materials.

Furthermore, silicone rubber plays a crucial role in improving the energy efficiency and sustainability of smart devices. Its excellent insulating properties contribute to better battery life, while its durability helps extend device lifespan, reducing electronic waste. As the tech industry moves towards more sustainable practices, the role of silicone rubber in achieving these goals becomes increasingly important.

Looking ahead, the objectives for silicone rubber in smart device innovations include further integration with advanced technologies such as artificial intelligence and the Internet of Things. The material's adaptability and compatibility with various sensors and electronic components make it an ideal platform for developing more intelligent and responsive devices that can seamlessly interact with their environment and users.

Market Demand Analysis for Smart Silicone Applications

The market demand for smart silicone applications has been experiencing significant growth, driven by the increasing adoption of smart devices across various industries. Silicone rubber, with its unique properties such as flexibility, durability, and heat resistance, has become a crucial material in the development of innovative smart devices.

In the consumer electronics sector, there is a growing demand for wearable technology, including smartwatches, fitness trackers, and health monitoring devices. These products require materials that can withstand constant wear and exposure to various environmental conditions. Silicone rubber meets these requirements while providing a comfortable user experience, leading to increased market demand for smart silicone applications in this segment.

The healthcare industry has also shown a substantial interest in smart silicone applications. Medical devices such as smart implants, drug delivery systems, and biosensors benefit from the biocompatibility and flexibility of silicone rubber. As the aging population grows and the focus on personalized healthcare intensifies, the demand for smart medical devices incorporating silicone rubber is expected to rise significantly.

In the automotive sector, the trend towards connected and autonomous vehicles has created new opportunities for smart silicone applications. From touch-sensitive controls to advanced sensor systems, silicone rubber plays a crucial role in enhancing the functionality and durability of smart automotive components. The increasing integration of IoT technologies in vehicles further drives the demand for silicone-based solutions.

The smart home market represents another area of growth for smart silicone applications. As consumers seek more intuitive and responsive home automation systems, there is a rising demand for touch-sensitive interfaces, flexible displays, and durable, weather-resistant outdoor smart devices. Silicone rubber's versatility makes it an ideal material for these applications, contributing to the expanding market demand.

Industrial IoT and smart manufacturing sectors are also driving the demand for smart silicone applications. The need for robust, flexible materials in harsh industrial environments has led to increased adoption of silicone-based sensors, actuators, and protective coatings for smart industrial equipment.

As sustainability becomes a key focus across industries, the recyclability and long lifespan of silicone rubber align well with eco-friendly initiatives. This factor is likely to further boost the demand for smart silicone applications in the coming years, as companies seek to develop more sustainable and durable smart devices.

In the consumer electronics sector, there is a growing demand for wearable technology, including smartwatches, fitness trackers, and health monitoring devices. These products require materials that can withstand constant wear and exposure to various environmental conditions. Silicone rubber meets these requirements while providing a comfortable user experience, leading to increased market demand for smart silicone applications in this segment.

The healthcare industry has also shown a substantial interest in smart silicone applications. Medical devices such as smart implants, drug delivery systems, and biosensors benefit from the biocompatibility and flexibility of silicone rubber. As the aging population grows and the focus on personalized healthcare intensifies, the demand for smart medical devices incorporating silicone rubber is expected to rise significantly.

In the automotive sector, the trend towards connected and autonomous vehicles has created new opportunities for smart silicone applications. From touch-sensitive controls to advanced sensor systems, silicone rubber plays a crucial role in enhancing the functionality and durability of smart automotive components. The increasing integration of IoT technologies in vehicles further drives the demand for silicone-based solutions.

The smart home market represents another area of growth for smart silicone applications. As consumers seek more intuitive and responsive home automation systems, there is a rising demand for touch-sensitive interfaces, flexible displays, and durable, weather-resistant outdoor smart devices. Silicone rubber's versatility makes it an ideal material for these applications, contributing to the expanding market demand.

Industrial IoT and smart manufacturing sectors are also driving the demand for smart silicone applications. The need for robust, flexible materials in harsh industrial environments has led to increased adoption of silicone-based sensors, actuators, and protective coatings for smart industrial equipment.

As sustainability becomes a key focus across industries, the recyclability and long lifespan of silicone rubber align well with eco-friendly initiatives. This factor is likely to further boost the demand for smart silicone applications in the coming years, as companies seek to develop more sustainable and durable smart devices.

Current Challenges in Silicone-Based Smart Technologies

The integration of silicone rubber in smart device innovations has led to significant advancements, but it also presents several challenges that researchers and manufacturers must address. One of the primary obstacles is achieving optimal electrical conductivity while maintaining the inherent flexibility and durability of silicone rubber. Traditional conductive materials often compromise the elastomeric properties of silicone, limiting its effectiveness in wearable and stretchable electronics.

Another challenge lies in the development of reliable and long-lasting sensor technologies within silicone-based smart devices. The dynamic nature of silicone rubber can lead to inconsistencies in sensor readings over time, particularly when subjected to repeated stretching and deformation. This issue is especially critical in applications such as health monitoring devices and smart textiles, where accuracy and reliability are paramount.

The integration of power sources and energy harvesting systems into silicone-based smart technologies presents yet another hurdle. Conventional battery technologies are often rigid and incompatible with the flexible nature of silicone rubber. Developing thin, flexible, and high-capacity power solutions that can withstand the mechanical stresses associated with silicone-based devices remains a significant challenge.

Thermal management is also a concern in silicone-based smart technologies. As electronic components generate heat during operation, efficient heat dissipation becomes crucial to maintain device performance and longevity. The inherent thermal insulation properties of silicone rubber can exacerbate this issue, necessitating innovative cooling solutions that do not compromise the material's flexibility or form factor.

Furthermore, the manufacturing processes for silicone-based smart devices present their own set of challenges. Achieving consistent and scalable production of complex, multi-layered silicone structures with embedded electronics requires advanced fabrication techniques. Issues such as air bubble formation, layer adhesion, and precise component placement must be addressed to ensure product quality and reliability.

Lastly, the environmental impact and recyclability of silicone-based smart technologies pose significant challenges. As the demand for these devices grows, developing sustainable manufacturing processes and end-of-life recycling solutions becomes increasingly important. Balancing the durability and longevity of silicone rubber with environmental considerations remains a complex issue that requires innovative approaches to material design and product lifecycle management.

Another challenge lies in the development of reliable and long-lasting sensor technologies within silicone-based smart devices. The dynamic nature of silicone rubber can lead to inconsistencies in sensor readings over time, particularly when subjected to repeated stretching and deformation. This issue is especially critical in applications such as health monitoring devices and smart textiles, where accuracy and reliability are paramount.

The integration of power sources and energy harvesting systems into silicone-based smart technologies presents yet another hurdle. Conventional battery technologies are often rigid and incompatible with the flexible nature of silicone rubber. Developing thin, flexible, and high-capacity power solutions that can withstand the mechanical stresses associated with silicone-based devices remains a significant challenge.

Thermal management is also a concern in silicone-based smart technologies. As electronic components generate heat during operation, efficient heat dissipation becomes crucial to maintain device performance and longevity. The inherent thermal insulation properties of silicone rubber can exacerbate this issue, necessitating innovative cooling solutions that do not compromise the material's flexibility or form factor.

Furthermore, the manufacturing processes for silicone-based smart devices present their own set of challenges. Achieving consistent and scalable production of complex, multi-layered silicone structures with embedded electronics requires advanced fabrication techniques. Issues such as air bubble formation, layer adhesion, and precise component placement must be addressed to ensure product quality and reliability.

Lastly, the environmental impact and recyclability of silicone-based smart technologies pose significant challenges. As the demand for these devices grows, developing sustainable manufacturing processes and end-of-life recycling solutions becomes increasingly important. Balancing the durability and longevity of silicone rubber with environmental considerations remains a complex issue that requires innovative approaches to material design and product lifecycle management.

Existing Silicone Solutions for Smart Device Integration

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the polymer structure. This can include improving thermal stability, increasing mechanical strength, enhancing electrical properties, or adjusting the rubber's hardness or elasticity to suit specific applications.

- Silicone rubber in medical and healthcare applications: Silicone rubber is widely used in medical and healthcare applications due to its biocompatibility, flexibility, and durability. It can be formulated for use in medical devices, implants, prosthetics, and drug delivery systems. Special grades of silicone rubber can be developed to meet specific medical requirements such as sterilization resistance or long-term implantation.

- Silicone rubber composites and blends: Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This can include the incorporation of nanoparticles, fibers, or other polymers to improve mechanical strength, thermal conductivity, or other specific characteristics. These composites find applications in various industries including automotive, aerospace, and electronics.

- Processing and manufacturing techniques for silicone rubber products: Various processing and manufacturing techniques are employed to produce silicone rubber products. These can include injection molding, extrusion, compression molding, and 3D printing. Advanced manufacturing methods may be developed to improve production efficiency, reduce waste, or create complex shapes and structures that were previously difficult to achieve with traditional methods.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the molecular structure. This can include improving mechanical strength, increasing thermal stability, enhancing electrical properties, or adjusting the rubber's hardness or elasticity to suit specific applications.Expand Specific Solutions03 Silicone rubber in medical and healthcare applications

Silicone rubber is widely used in medical and healthcare products due to its biocompatibility, flexibility, and durability. Applications include medical implants, prosthetics, drug delivery systems, and various medical devices. Special formulations may be developed to meet specific medical requirements such as antimicrobial properties or controlled drug release.Expand Specific Solutions04 Silicone rubber in industrial and consumer products

Silicone rubber finds extensive use in industrial and consumer products due to its versatility and unique properties. It is used in automotive parts, electrical insulation, cookware, sealants, and various household items. The material can be formulated to withstand extreme temperatures, resist chemicals, and maintain its properties over long periods.Expand Specific Solutions05 Advanced processing techniques for silicone rubber

Advanced processing techniques are being developed to enhance the manufacturing and performance of silicone rubber products. These may include novel curing methods, precision molding techniques, or the integration of silicone rubber with other materials to create composite structures. Such advancements aim to improve product quality, reduce production costs, and expand the range of possible applications.Expand Specific Solutions

Key Players in Silicone Smart Device Industry

The market for silicone rubber in smart device innovations is in a growth phase, driven by increasing demand for flexible and durable materials in consumer electronics. The global silicone rubber market size is projected to expand significantly, with key players like Shin-Etsu Chemical, Wacker Chemie, and Dow Silicones leading the way. These companies have demonstrated advanced technological capabilities in developing high-performance silicone materials for smart devices. The technology is relatively mature but continues to evolve, with ongoing research focused on enhancing properties such as thermal stability, electrical conductivity, and biocompatibility. Emerging players like Dongguan Langsheng Material Technology are also contributing to market innovation, particularly in specialized applications.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has developed advanced silicone rubber compounds specifically for smart device applications. Their KE series of silicone elastomers offers excellent electrical properties and heat resistance, making them suitable for various electronic components in smart devices[1]. Shin-Etsu has introduced optically clear silicone rubbers with high refractive indices, enhancing the performance of LED displays and optical sensors in wearable technology[2]. The company's liquid silicone rubber (LSR) products provide precision molding capabilities for intricate smart device components, such as buttons, seals, and gaskets[3]. Shin-Etsu has also developed silicone thermal interface materials that efficiently manage heat dissipation in compact smart devices, improving overall performance and reliability[4].

Strengths: Comprehensive range of silicone products, strong presence in Asian markets, expertise in high-performance silicone formulations. Weaknesses: Potential challenges in global market expansion, competition from well-established Western silicone manufacturers.

Apple, Inc.

Technical Solution: Apple has leveraged silicone rubber technology in various smart device innovations. They have developed custom silicone rubber compounds for their device casings and accessories, providing enhanced grip, shock absorption, and water resistance[1]. Apple's AirPods Pro utilize silicone ear tips that offer improved sound isolation and comfort[2]. The company has also incorporated silicone rubber in their smartwatch bands, offering durability and flexibility for all-day wear[3]. In their latest iPhone models, Apple has implemented advanced silicone rubber seals to achieve IP68 water and dust resistance ratings[4]. Additionally, they have explored the use of silicone-based materials in flexible display technologies for potential future devices[5].

Strengths: Integration of silicone rubber across multiple product lines, focus on user comfort and device protection. Weaknesses: Reliance on third-party suppliers for silicone materials, potential for material degradation over time in certain use cases.

Innovative Silicone Formulations for Smart Applications

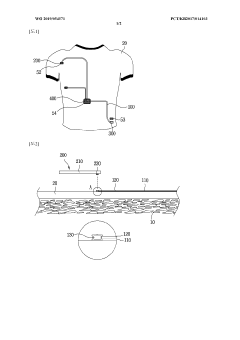

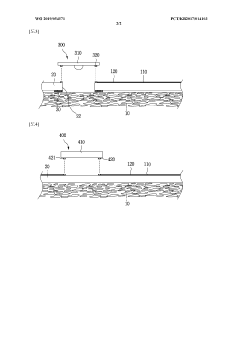

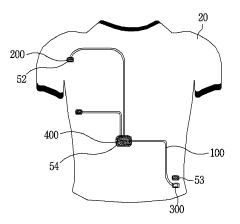

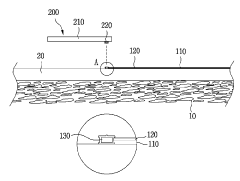

Smart garment integrated with wire coated with conductive silicone rubber

PatentWO2019054571A1

Innovation

- The integration of wires coated with elastic conductive silicone rubber allows for easy attachment and detachment of sensors and devices, with electrically conductive Velcro or metal snap buttons, and a breathable cover for durability and flexibility, enabling real-time biometric data collection during activities.

Non-staining silicone rubber composition for wearable and smart devices

PatentInactiveKR1020200129218A

Innovation

- A non-staining silicone rubber composition comprising a silicone polymer, ionic antistatic agent, organic peroxide crosslinking agent, slip agent, and conductive filler, optimized for crosslinking to enhance conductivity and minimize foreign substance adhesion.

Environmental Impact of Silicone in Smart Devices

The environmental impact of silicone in smart devices is a crucial consideration as the technology industry continues to evolve. Silicone rubber, a key component in many smart devices, offers both advantages and challenges from an ecological perspective.

One of the primary environmental benefits of silicone rubber is its durability and longevity. Smart devices incorporating silicone components tend to have extended lifespans, reducing the frequency of replacements and, consequently, electronic waste. This durability contributes to a decrease in the overall environmental footprint of consumer electronics.

However, the production of silicone rubber does raise some environmental concerns. The manufacturing process involves energy-intensive steps and the use of potentially harmful chemicals. While efforts are being made to improve production efficiency and reduce emissions, there is still room for improvement in making the manufacturing process more environmentally friendly.

Recycling silicone rubber presents both opportunities and challenges. On the positive side, silicone can be recycled and repurposed, potentially reducing waste. However, the recycling process for silicone-containing electronics is complex and not yet widely implemented. This complexity stems from the need to separate silicone components from other materials in smart devices.

The use of silicone in smart devices also contributes to improved energy efficiency. Silicone's excellent insulating properties help in creating more energy-efficient devices, potentially reducing power consumption and extending battery life. This efficiency can lead to lower energy demands and, by extension, reduced carbon emissions associated with device usage.

Water resistance is another environmental advantage of silicone in smart devices. By providing effective protection against water and moisture, silicone helps prevent damage and extends the lifespan of devices, further reducing electronic waste.

As the industry moves towards more sustainable practices, there is growing interest in developing bio-based silicones. These alternatives, derived from renewable resources, could potentially offer a more environmentally friendly option for smart device manufacturing in the future.

In conclusion, while silicone rubber in smart devices presents some environmental challenges, particularly in production and end-of-life recycling, its contributions to device longevity, energy efficiency, and durability offer significant environmental benefits. The ongoing research into more sustainable silicone alternatives and improved recycling methods suggests a promising future for reducing the environmental impact of silicone in smart devices.

One of the primary environmental benefits of silicone rubber is its durability and longevity. Smart devices incorporating silicone components tend to have extended lifespans, reducing the frequency of replacements and, consequently, electronic waste. This durability contributes to a decrease in the overall environmental footprint of consumer electronics.

However, the production of silicone rubber does raise some environmental concerns. The manufacturing process involves energy-intensive steps and the use of potentially harmful chemicals. While efforts are being made to improve production efficiency and reduce emissions, there is still room for improvement in making the manufacturing process more environmentally friendly.

Recycling silicone rubber presents both opportunities and challenges. On the positive side, silicone can be recycled and repurposed, potentially reducing waste. However, the recycling process for silicone-containing electronics is complex and not yet widely implemented. This complexity stems from the need to separate silicone components from other materials in smart devices.

The use of silicone in smart devices also contributes to improved energy efficiency. Silicone's excellent insulating properties help in creating more energy-efficient devices, potentially reducing power consumption and extending battery life. This efficiency can lead to lower energy demands and, by extension, reduced carbon emissions associated with device usage.

Water resistance is another environmental advantage of silicone in smart devices. By providing effective protection against water and moisture, silicone helps prevent damage and extends the lifespan of devices, further reducing electronic waste.

As the industry moves towards more sustainable practices, there is growing interest in developing bio-based silicones. These alternatives, derived from renewable resources, could potentially offer a more environmentally friendly option for smart device manufacturing in the future.

In conclusion, while silicone rubber in smart devices presents some environmental challenges, particularly in production and end-of-life recycling, its contributions to device longevity, energy efficiency, and durability offer significant environmental benefits. The ongoing research into more sustainable silicone alternatives and improved recycling methods suggests a promising future for reducing the environmental impact of silicone in smart devices.

Intellectual Property Landscape in Smart Silicone Innovation

The intellectual property landscape in smart silicone innovation is rapidly evolving, reflecting the growing importance of this technology in the development of smart devices. Patents related to smart silicone applications have seen a significant increase in recent years, with major tech companies and specialized materials firms leading the way in innovation.

Key areas of patent activity include conductive silicone composites, stretchable electronics, and sensor integration. Companies are focusing on developing silicone formulations that can maintain flexibility while incorporating conductive elements, enabling the creation of soft, pliable electronic components. Patents in this area often cover specific material compositions, manufacturing processes, and novel device structures.

Another prominent trend in the IP landscape is the development of self-healing silicone materials. These innovations aim to enhance the durability and longevity of smart devices by allowing them to recover from minor damage automatically. Patents in this field typically involve unique chemical formulations and mechanisms for triggering the self-healing process.

Wearable technology represents a significant portion of smart silicone-related patents. Innovations in this space include improved methods for integrating sensors into silicone-based wearables, enhancing comfort and durability while maintaining accurate data collection. Patents also cover novel designs for stretchable displays and touch-sensitive interfaces using silicone substrates.

The medical and healthcare sectors are also driving patent activity in smart silicone innovation. Patents in this area focus on biocompatible silicone formulations for implantable devices, drug delivery systems, and advanced prosthetics. These innovations often combine silicone's flexibility and biocompatibility with smart functionalities such as controlled release mechanisms or integrated biosensors.

Geographically, the United States, China, and Japan are leading in terms of patent filings related to smart silicone technologies. However, European countries, particularly Germany and the United Kingdom, are also making significant contributions to the field.

As the smart device market continues to expand, we can expect to see an increase in patent litigation and licensing activities surrounding smart silicone technologies. Companies are likely to form strategic partnerships and cross-licensing agreements to navigate the complex IP landscape and bring innovative products to market more efficiently.

Key areas of patent activity include conductive silicone composites, stretchable electronics, and sensor integration. Companies are focusing on developing silicone formulations that can maintain flexibility while incorporating conductive elements, enabling the creation of soft, pliable electronic components. Patents in this area often cover specific material compositions, manufacturing processes, and novel device structures.

Another prominent trend in the IP landscape is the development of self-healing silicone materials. These innovations aim to enhance the durability and longevity of smart devices by allowing them to recover from minor damage automatically. Patents in this field typically involve unique chemical formulations and mechanisms for triggering the self-healing process.

Wearable technology represents a significant portion of smart silicone-related patents. Innovations in this space include improved methods for integrating sensors into silicone-based wearables, enhancing comfort and durability while maintaining accurate data collection. Patents also cover novel designs for stretchable displays and touch-sensitive interfaces using silicone substrates.

The medical and healthcare sectors are also driving patent activity in smart silicone innovation. Patents in this area focus on biocompatible silicone formulations for implantable devices, drug delivery systems, and advanced prosthetics. These innovations often combine silicone's flexibility and biocompatibility with smart functionalities such as controlled release mechanisms or integrated biosensors.

Geographically, the United States, China, and Japan are leading in terms of patent filings related to smart silicone technologies. However, European countries, particularly Germany and the United Kingdom, are also making significant contributions to the field.

As the smart device market continues to expand, we can expect to see an increase in patent litigation and licensing activities surrounding smart silicone technologies. Companies are likely to form strategic partnerships and cross-licensing agreements to navigate the complex IP landscape and bring innovative products to market more efficiently.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!