How Silicone Rubber Innovates Surface Modifier Techniques?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Evolution

Silicone rubber has undergone a remarkable evolution since its inception in the 1940s, revolutionizing various industries with its unique properties and versatile applications. Initially developed as an insulating material for electric motors and generators, silicone rubber quickly gained prominence due to its exceptional thermal stability, electrical insulation, and resistance to environmental factors.

The 1950s and 1960s saw significant advancements in silicone rubber technology, with researchers focusing on improving its mechanical properties and expanding its potential uses. During this period, new formulations and curing methods were developed, leading to enhanced strength, durability, and flexibility. These improvements paved the way for silicone rubber's adoption in aerospace, automotive, and medical industries.

In the 1970s and 1980s, the focus shifted towards developing specialized silicone rubber compounds tailored for specific applications. This era witnessed the emergence of liquid silicone rubber (LSR) technology, which offered improved processing capabilities and enabled the production of complex, precision-molded parts. Concurrently, advancements in surface modification techniques began to emerge, laying the groundwork for future innovations in this field.

The 1990s and early 2000s marked a period of rapid expansion in silicone rubber applications, particularly in the realm of surface modifiers. Researchers began exploring ways to manipulate the surface properties of silicone rubber, aiming to enhance its adhesion, wettability, and compatibility with other materials. This led to the development of various surface treatment methods, including plasma treatment, corona discharge, and chemical etching.

In recent years, the evolution of silicone rubber has been closely tied to advancements in nanotechnology and smart materials. Researchers have been incorporating nanoparticles and functional additives into silicone rubber matrices, creating composite materials with enhanced properties and novel functionalities. These innovations have opened up new possibilities for surface modification techniques, allowing for precise control over surface characteristics at the molecular level.

The ongoing evolution of silicone rubber continues to push the boundaries of surface modifier techniques. Current research focuses on developing environmentally friendly and sustainable surface modification methods, as well as exploring the potential of bio-inspired surface structures. As we look to the future, the integration of silicone rubber with emerging technologies such as 3D printing and self-healing materials promises to further revolutionize surface modification techniques, enabling the creation of advanced, multifunctional surfaces with unprecedented properties and applications.

The 1950s and 1960s saw significant advancements in silicone rubber technology, with researchers focusing on improving its mechanical properties and expanding its potential uses. During this period, new formulations and curing methods were developed, leading to enhanced strength, durability, and flexibility. These improvements paved the way for silicone rubber's adoption in aerospace, automotive, and medical industries.

In the 1970s and 1980s, the focus shifted towards developing specialized silicone rubber compounds tailored for specific applications. This era witnessed the emergence of liquid silicone rubber (LSR) technology, which offered improved processing capabilities and enabled the production of complex, precision-molded parts. Concurrently, advancements in surface modification techniques began to emerge, laying the groundwork for future innovations in this field.

The 1990s and early 2000s marked a period of rapid expansion in silicone rubber applications, particularly in the realm of surface modifiers. Researchers began exploring ways to manipulate the surface properties of silicone rubber, aiming to enhance its adhesion, wettability, and compatibility with other materials. This led to the development of various surface treatment methods, including plasma treatment, corona discharge, and chemical etching.

In recent years, the evolution of silicone rubber has been closely tied to advancements in nanotechnology and smart materials. Researchers have been incorporating nanoparticles and functional additives into silicone rubber matrices, creating composite materials with enhanced properties and novel functionalities. These innovations have opened up new possibilities for surface modification techniques, allowing for precise control over surface characteristics at the molecular level.

The ongoing evolution of silicone rubber continues to push the boundaries of surface modifier techniques. Current research focuses on developing environmentally friendly and sustainable surface modification methods, as well as exploring the potential of bio-inspired surface structures. As we look to the future, the integration of silicone rubber with emerging technologies such as 3D printing and self-healing materials promises to further revolutionize surface modification techniques, enabling the creation of advanced, multifunctional surfaces with unprecedented properties and applications.

Market Demand Analysis

The market demand for silicone rubber as a surface modifier has been steadily increasing across various industries due to its unique properties and versatile applications. The automotive sector, in particular, has shown significant interest in silicone rubber-based surface modifiers for their ability to enhance paint adhesion, improve scratch resistance, and provide water repellency to vehicle exteriors. This demand is driven by consumer preferences for longer-lasting, more durable finishes on automobiles.

In the electronics industry, silicone rubber surface modifiers have gained traction for their ability to provide water and dust resistance to electronic devices. As consumers increasingly demand waterproof and dustproof smartphones, tablets, and wearables, manufacturers are turning to silicone-based solutions to meet these requirements. The market for such protective coatings is expected to grow as electronic devices become more integrated into daily life and exposed to various environmental conditions.

The construction sector has also recognized the potential of silicone rubber surface modifiers. These materials are being used to enhance the durability and weather resistance of building materials, particularly in exterior applications. The ability of silicone-based modifiers to provide UV protection, water repellency, and thermal stability has made them attractive for use in paints, sealants, and coatings for buildings. This trend is likely to continue as the construction industry seeks more sustainable and long-lasting solutions for building maintenance and protection.

In the medical field, silicone rubber surface modifiers are finding applications in the development of antimicrobial surfaces for medical devices and hospital equipment. The growing concern over hospital-acquired infections has led to increased demand for materials that can inhibit bacterial growth and facilitate easy cleaning. Silicone-based modifiers offer a promising solution due to their biocompatibility and ability to be functionalized with antimicrobial agents.

The textile industry is another sector showing growing interest in silicone rubber surface modifiers. These materials are being used to impart water repellency, stain resistance, and softness to fabrics. The demand for performance textiles in sportswear and outdoor gear has been a key driver for the adoption of silicone-based treatments. Additionally, the use of silicone modifiers in technical textiles for industrial applications is expected to expand as manufacturers seek to improve the durability and functionality of their products.

As environmental concerns become more prominent, there is an increasing demand for eco-friendly surface modification techniques. Silicone rubber, being non-toxic and having a long service life, aligns well with sustainability goals. This has led to research and development efforts focused on creating more environmentally friendly silicone-based surface modifiers, further driving market growth and innovation in this field.

In the electronics industry, silicone rubber surface modifiers have gained traction for their ability to provide water and dust resistance to electronic devices. As consumers increasingly demand waterproof and dustproof smartphones, tablets, and wearables, manufacturers are turning to silicone-based solutions to meet these requirements. The market for such protective coatings is expected to grow as electronic devices become more integrated into daily life and exposed to various environmental conditions.

The construction sector has also recognized the potential of silicone rubber surface modifiers. These materials are being used to enhance the durability and weather resistance of building materials, particularly in exterior applications. The ability of silicone-based modifiers to provide UV protection, water repellency, and thermal stability has made them attractive for use in paints, sealants, and coatings for buildings. This trend is likely to continue as the construction industry seeks more sustainable and long-lasting solutions for building maintenance and protection.

In the medical field, silicone rubber surface modifiers are finding applications in the development of antimicrobial surfaces for medical devices and hospital equipment. The growing concern over hospital-acquired infections has led to increased demand for materials that can inhibit bacterial growth and facilitate easy cleaning. Silicone-based modifiers offer a promising solution due to their biocompatibility and ability to be functionalized with antimicrobial agents.

The textile industry is another sector showing growing interest in silicone rubber surface modifiers. These materials are being used to impart water repellency, stain resistance, and softness to fabrics. The demand for performance textiles in sportswear and outdoor gear has been a key driver for the adoption of silicone-based treatments. Additionally, the use of silicone modifiers in technical textiles for industrial applications is expected to expand as manufacturers seek to improve the durability and functionality of their products.

As environmental concerns become more prominent, there is an increasing demand for eco-friendly surface modification techniques. Silicone rubber, being non-toxic and having a long service life, aligns well with sustainability goals. This has led to research and development efforts focused on creating more environmentally friendly silicone-based surface modifiers, further driving market growth and innovation in this field.

Technical Challenges

The development of silicone rubber as a surface modifier faces several technical challenges that researchers and industry professionals are actively addressing. One of the primary obstacles is achieving optimal adhesion between silicone rubber and various substrate materials. The inherent low surface energy of silicone rubber often results in poor bonding, limiting its effectiveness as a surface modifier in certain applications.

Another significant challenge lies in enhancing the durability and longevity of silicone rubber surface modifications. While silicone rubber exhibits excellent resistance to weathering and UV radiation, improving its resistance to mechanical wear, abrasion, and chemical degradation remains a focus area for innovation. This is particularly crucial in industries where prolonged exposure to harsh environments is common.

The control of surface properties, such as hydrophobicity and oleophobicity, presents another technical hurdle. While silicone rubber naturally possesses water-repellent characteristics, fine-tuning these properties for specific applications and maintaining them over extended periods requires advanced formulation and processing techniques. Researchers are exploring various methods to modify the surface chemistry of silicone rubber to achieve desired surface properties without compromising its inherent benefits.

Compatibility with other materials and coatings is an ongoing challenge in silicone rubber surface modification. Ensuring that silicone rubber-based modifiers can be effectively integrated with existing surface treatment processes and materials is crucial for widespread adoption across industries. This includes addressing issues related to potential contamination or interference with subsequent manufacturing steps or product performance.

The development of environmentally friendly and sustainable silicone rubber formulations for surface modification is another area of focus. As global regulations become more stringent, there is a growing need for silicone rubber modifiers that minimize environmental impact throughout their lifecycle, from production to disposal. This challenge encompasses reducing volatile organic compound (VOC) emissions, improving biodegradability, and exploring bio-based alternatives.

Scalability and cost-effectiveness in manufacturing processes pose additional technical challenges. While silicone rubber offers unique properties as a surface modifier, developing efficient, large-scale production methods that maintain consistent quality and performance is essential for its widespread industrial adoption. This includes optimizing curing processes, reducing material waste, and improving overall production efficiency.

Another significant challenge lies in enhancing the durability and longevity of silicone rubber surface modifications. While silicone rubber exhibits excellent resistance to weathering and UV radiation, improving its resistance to mechanical wear, abrasion, and chemical degradation remains a focus area for innovation. This is particularly crucial in industries where prolonged exposure to harsh environments is common.

The control of surface properties, such as hydrophobicity and oleophobicity, presents another technical hurdle. While silicone rubber naturally possesses water-repellent characteristics, fine-tuning these properties for specific applications and maintaining them over extended periods requires advanced formulation and processing techniques. Researchers are exploring various methods to modify the surface chemistry of silicone rubber to achieve desired surface properties without compromising its inherent benefits.

Compatibility with other materials and coatings is an ongoing challenge in silicone rubber surface modification. Ensuring that silicone rubber-based modifiers can be effectively integrated with existing surface treatment processes and materials is crucial for widespread adoption across industries. This includes addressing issues related to potential contamination or interference with subsequent manufacturing steps or product performance.

The development of environmentally friendly and sustainable silicone rubber formulations for surface modification is another area of focus. As global regulations become more stringent, there is a growing need for silicone rubber modifiers that minimize environmental impact throughout their lifecycle, from production to disposal. This challenge encompasses reducing volatile organic compound (VOC) emissions, improving biodegradability, and exploring bio-based alternatives.

Scalability and cost-effectiveness in manufacturing processes pose additional technical challenges. While silicone rubber offers unique properties as a surface modifier, developing efficient, large-scale production methods that maintain consistent quality and performance is essential for its widespread industrial adoption. This includes optimizing curing processes, reducing material waste, and improving overall production efficiency.

Current Modification Methods

01 Surface modification of silicone rubber

Various methods and compounds are used to modify the surface properties of silicone rubber. These modifications can improve characteristics such as adhesion, wettability, and chemical resistance. Techniques may include plasma treatment, chemical etching, or the application of specialized coatings.- Surface modification of silicone rubber: Various methods and compounds are used to modify the surface of silicone rubber, improving its properties such as adhesion, wettability, and compatibility with other materials. These modifications can involve chemical treatments, plasma treatments, or the application of specific coatings to alter the surface characteristics of the silicone rubber.

- Incorporation of functional additives: Functional additives are incorporated into silicone rubber formulations to enhance specific properties. These additives can include fillers, plasticizers, or reactive compounds that modify the surface properties of the cured silicone rubber. The selection and concentration of these additives are crucial in achieving the desired surface characteristics.

- Silane coupling agents for surface modification: Silane coupling agents are widely used to modify the surface of silicone rubber. These agents can improve adhesion between the silicone rubber and other materials, enhance compatibility with fillers, and modify surface energy. The selection of appropriate silane coupling agents depends on the specific application and desired properties.

- Plasma treatment for surface modification: Plasma treatment is an effective method for modifying the surface of silicone rubber. This process can alter the surface energy, improve wettability, and enhance adhesion properties. Various gases and treatment parameters can be used to achieve specific surface modifications without affecting the bulk properties of the silicone rubber.

- Nanoparticle-based surface modifiers: Nanoparticles are increasingly used as surface modifiers for silicone rubber. These nanoparticles can be incorporated into the silicone rubber matrix or applied as a coating to modify surface properties such as hydrophobicity, wear resistance, and electrical conductivity. The type, size, and concentration of nanoparticles are crucial factors in determining the final surface properties.

02 Incorporation of functional additives

Functional additives are incorporated into silicone rubber formulations to enhance specific properties. These additives can include reinforcing fillers, antioxidants, UV stabilizers, or other specialty chemicals that modify the surface characteristics or overall performance of the silicone rubber.Expand Specific Solutions03 Silane coupling agents for surface modification

Silane coupling agents are utilized to modify the surface of silicone rubber, improving its compatibility with other materials or enhancing specific properties. These agents can create chemical bonds between the silicone rubber and other substrates or coatings, leading to improved adhesion and durability.Expand Specific Solutions04 Nanoparticle-based surface modifiers

Nanoparticles are incorporated into silicone rubber or applied as coatings to modify surface properties. These can include metal oxides, carbon nanotubes, or other nanomaterials that impart specific characteristics such as improved wear resistance, electrical conductivity, or hydrophobicity.Expand Specific Solutions05 Polymer blending for surface modification

Blending silicone rubber with other polymers or elastomers is used to modify its surface properties. This approach can create composite materials with unique combinations of properties, such as improved chemical resistance, thermal stability, or mechanical strength at the surface.Expand Specific Solutions

Key Industry Players

The silicone rubber surface modifier technology market is in a growth phase, driven by increasing demand across industries like healthcare, electronics, and automotive. The global market size is estimated to reach several billion dollars by 2025, with a compound annual growth rate of 5-7%. Technological maturity varies, with established players like Evonik, Bayer, and Shin-Etsu Chemical leading in advanced formulations. Emerging companies such as Haichang Contact Lens and Raumedic are focusing on niche applications. Research institutions like Sichuan University and Fraunhofer-Gesellschaft are contributing to innovation through collaborative projects with industry partners, pushing the boundaries of silicone rubber surface modification techniques.

Nitto Denko Corp.

Technical Solution: Nitto Denko Corp. has made significant strides in silicone rubber surface modifier techniques, particularly in the field of adhesive technologies. Their innovative approach involves the development of silicone-based pressure-sensitive adhesives (PSAs) with modified surface properties[1]. These PSAs feature enhanced adhesion to low surface energy substrates while maintaining the inherent flexibility and durability of silicone rubber[2]. Nitto Denko has also introduced silicone rubber films with controlled surface roughness and patterning, achieved through advanced molding and etching techniques[3]. This allows for the creation of functional surfaces with specific optical, tactile, or fluidic properties. Additionally, the company has developed silicone rubber composites with embedded nanoparticles that can be activated to change surface properties on-demand, enabling smart and responsive materials[4].

Strengths: Strong focus on adhesive technologies, diverse product portfolio, and expertise in film and coating applications. Weaknesses: Potential limitations in non-adhesive applications and competition from specialized silicone manufacturers.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has developed innovative silicone rubber surface modifier techniques that enhance the material's properties for various applications. Their approach involves modifying the silicone rubber surface through chemical grafting and plasma treatment processes[1]. This results in improved adhesion, wettability, and biocompatibility of the silicone rubber surfaces[2]. The company has also introduced self-healing silicone rubber coatings that can repair minor damage autonomously, extending the lifespan of products[3]. Additionally, Shin-Etsu has developed silicone rubber composites with nanoparticles to enhance thermal conductivity and electrical properties, making them suitable for advanced electronic applications[4].

Strengths: Extensive experience in silicone chemistry, diverse product range, and strong R&D capabilities. Weaknesses: Potential high costs associated with advanced surface modification techniques and limited applicability in some industries.

Innovative Silicone Solutions

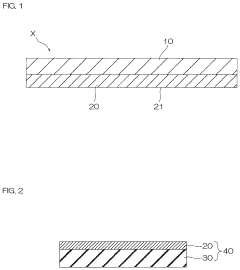

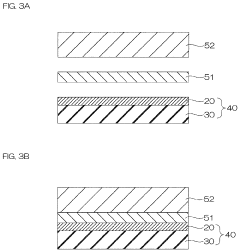

Surface modification sheet for silicone rubber

PatentInactiveUS20220314587A1

Innovation

- A surface modification sheet for silicone rubber comprising a release sheet with a surface modification layer containing a polymer with ethylenic double bonds, specifically an adduct of an isocyanate compound like 2-methacryloyloxyethyl isocyanate, which forms a strong bond with the silicone rubber surface during heat molding.

Hydrophilicity modification method and application method of silicone rubber surface

PatentInactiveKR1020200062341A

Innovation

- A method involving the preparation of a silicone rubber substrate with double bonds through mixing vinyl polysiloxane, polyhydrosiloxane, and polyvinyl monomer, followed by ultraviolet light initiation of a hydrophilic monomer solution to chemically bond the hydrophilic layer, reducing surface contact angle and enhancing biocompatibility.

Environmental Impact

The environmental impact of silicone rubber as a surface modifier is a critical consideration in its application and development. Silicone rubber, when used as a surface modifier, offers several environmental benefits compared to traditional materials. Its durability and long-lasting properties contribute to reduced waste generation and resource consumption over time. The material's resistance to weathering, UV radiation, and chemical degradation means that surfaces treated with silicone rubber require less frequent replacement or maintenance, leading to a decrease in overall environmental footprint.

Furthermore, silicone rubber surface modifiers often enhance the energy efficiency of various products and structures. For instance, when applied to building exteriors, they can improve thermal insulation, reducing heating and cooling requirements and consequently lowering energy consumption. In automotive applications, silicone rubber coatings can reduce drag, potentially improving fuel efficiency and reducing emissions.

However, the production of silicone rubber does have some environmental concerns. The manufacturing process involves the use of silica and hydrocarbons, which are energy-intensive to extract and process. Additionally, some silicone rubber formulations may contain additives or catalysts that could have potential environmental impacts if not properly managed during production or disposal.

The end-of-life management of silicone rubber surface modifiers is an area of ongoing research and development. While silicone rubber is generally inert and non-toxic, its disposal can be challenging due to its durability. Recycling options for silicone rubber are limited, and it does not biodegrade easily in natural environments. This persistence can lead to accumulation in landfills or potential marine pollution if not properly managed.

Innovations in silicone rubber technology are addressing these environmental challenges. Research is focused on developing more sustainable production methods, such as using renewable resources or implementing closed-loop manufacturing processes. Efforts are also being made to improve the recyclability of silicone rubber products, including the development of chemical recycling techniques that can break down the material into its base components for reuse.

The water-repellent properties of silicone rubber surface modifiers also contribute to environmental protection in certain applications. For example, when used on marine structures or offshore wind turbines, these coatings can reduce biofouling, decreasing the need for harmful anti-fouling chemicals and improving the efficiency and lifespan of the equipment.

As environmental regulations become more stringent, the silicone rubber industry is adapting by focusing on eco-friendly formulations. This includes the development of bio-based silicones and the reduction or elimination of volatile organic compounds (VOCs) in surface modifier products. These advancements not only improve the environmental profile of silicone rubber but also open up new applications in sensitive environments where traditional surface modifiers may not be suitable.

Furthermore, silicone rubber surface modifiers often enhance the energy efficiency of various products and structures. For instance, when applied to building exteriors, they can improve thermal insulation, reducing heating and cooling requirements and consequently lowering energy consumption. In automotive applications, silicone rubber coatings can reduce drag, potentially improving fuel efficiency and reducing emissions.

However, the production of silicone rubber does have some environmental concerns. The manufacturing process involves the use of silica and hydrocarbons, which are energy-intensive to extract and process. Additionally, some silicone rubber formulations may contain additives or catalysts that could have potential environmental impacts if not properly managed during production or disposal.

The end-of-life management of silicone rubber surface modifiers is an area of ongoing research and development. While silicone rubber is generally inert and non-toxic, its disposal can be challenging due to its durability. Recycling options for silicone rubber are limited, and it does not biodegrade easily in natural environments. This persistence can lead to accumulation in landfills or potential marine pollution if not properly managed.

Innovations in silicone rubber technology are addressing these environmental challenges. Research is focused on developing more sustainable production methods, such as using renewable resources or implementing closed-loop manufacturing processes. Efforts are also being made to improve the recyclability of silicone rubber products, including the development of chemical recycling techniques that can break down the material into its base components for reuse.

The water-repellent properties of silicone rubber surface modifiers also contribute to environmental protection in certain applications. For example, when used on marine structures or offshore wind turbines, these coatings can reduce biofouling, decreasing the need for harmful anti-fouling chemicals and improving the efficiency and lifespan of the equipment.

As environmental regulations become more stringent, the silicone rubber industry is adapting by focusing on eco-friendly formulations. This includes the development of bio-based silicones and the reduction or elimination of volatile organic compounds (VOCs) in surface modifier products. These advancements not only improve the environmental profile of silicone rubber but also open up new applications in sensitive environments where traditional surface modifiers may not be suitable.

Regulatory Compliance

The regulatory landscape for silicone rubber surface modifiers is complex and evolving, with various agencies and standards bodies overseeing their development and application. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating silicone rubber materials used in food contact applications and medical devices. The FDA's 21 CFR 177.2600 specifically addresses rubber articles intended for repeated use in food contact, including silicone elastomers.

For industrial applications, the Occupational Safety and Health Administration (OSHA) sets guidelines for workplace safety related to the handling and processing of silicone rubber materials. These regulations cover aspects such as personal protective equipment, ventilation requirements, and exposure limits for volatile organic compounds (VOCs) that may be released during the manufacturing process.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the use of silicone rubber surface modifiers. Manufacturers must register substances used in their products and provide safety data to the European Chemicals Agency (ECHA). Additionally, the EU's RoHS (Restriction of Hazardous Substances) directive limits the use of certain hazardous materials in electrical and electronic equipment, which may affect silicone rubber formulations used in these applications.

Environmental regulations also play a significant role in shaping the development of silicone rubber surface modifiers. Many countries have implemented strict controls on volatile organic compound (VOC) emissions, prompting manufacturers to develop low-VOC or VOC-free formulations. The U.S. Environmental Protection Agency (EPA) and its counterparts in other nations enforce these regulations, which vary by region and industry sector.

As nanotechnology becomes more prevalent in surface modification techniques, regulatory bodies are increasingly focusing on the potential health and environmental impacts of nanomaterials. The National Institute for Occupational Safety and Health (NIOSH) in the U.S. has issued guidelines for working with nanomaterials, which may apply to certain silicone rubber surface modifiers incorporating nanoparticles.

Compliance with these regulations requires ongoing vigilance and adaptation from manufacturers. As scientific understanding of material interactions and environmental impacts evolves, regulatory frameworks are likely to become more stringent. This dynamic regulatory environment drives innovation in silicone rubber surface modifier techniques, pushing manufacturers to develop safer, more environmentally friendly formulations that meet or exceed current standards while maintaining or improving performance characteristics.

For industrial applications, the Occupational Safety and Health Administration (OSHA) sets guidelines for workplace safety related to the handling and processing of silicone rubber materials. These regulations cover aspects such as personal protective equipment, ventilation requirements, and exposure limits for volatile organic compounds (VOCs) that may be released during the manufacturing process.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the use of silicone rubber surface modifiers. Manufacturers must register substances used in their products and provide safety data to the European Chemicals Agency (ECHA). Additionally, the EU's RoHS (Restriction of Hazardous Substances) directive limits the use of certain hazardous materials in electrical and electronic equipment, which may affect silicone rubber formulations used in these applications.

Environmental regulations also play a significant role in shaping the development of silicone rubber surface modifiers. Many countries have implemented strict controls on volatile organic compound (VOC) emissions, prompting manufacturers to develop low-VOC or VOC-free formulations. The U.S. Environmental Protection Agency (EPA) and its counterparts in other nations enforce these regulations, which vary by region and industry sector.

As nanotechnology becomes more prevalent in surface modification techniques, regulatory bodies are increasingly focusing on the potential health and environmental impacts of nanomaterials. The National Institute for Occupational Safety and Health (NIOSH) in the U.S. has issued guidelines for working with nanomaterials, which may apply to certain silicone rubber surface modifiers incorporating nanoparticles.

Compliance with these regulations requires ongoing vigilance and adaptation from manufacturers. As scientific understanding of material interactions and environmental impacts evolves, regulatory frameworks are likely to become more stringent. This dynamic regulatory environment drives innovation in silicone rubber surface modifier techniques, pushing manufacturers to develop safer, more environmentally friendly formulations that meet or exceed current standards while maintaining or improving performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!