How Silicone Rubber Promotes Effective Sustainable Growth?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Evolution

Silicone rubber has undergone a remarkable evolution since its inception in the early 20th century. Initially developed as an insulating material for electrical applications, it has transformed into a versatile and sustainable material with a wide range of uses across various industries.

The journey of silicone rubber began in the 1930s when chemists at Corning Glass Works and General Electric independently developed the first silicone polymers. These early formulations were primarily used for their electrical insulation properties and heat resistance. As research progressed, the unique combination of organic and inorganic components in silicone rubber became apparent, leading to its application in increasingly diverse fields.

During the 1940s and 1950s, silicone rubber found its way into aerospace and automotive industries due to its ability to withstand extreme temperatures and maintain flexibility. This period marked a significant milestone in its evolution, as manufacturers began to recognize its potential beyond electrical applications.

The 1960s and 1970s saw a surge in silicone rubber's use in consumer products. Its non-toxic and hypoallergenic properties made it ideal for medical devices, kitchenware, and personal care items. This expansion into everyday products significantly boosted its market presence and drove further research into improving its properties.

In the following decades, advancements in polymer science led to the development of specialized silicone rubber formulations. These new variants offered enhanced properties such as improved tear strength, chemical resistance, and biocompatibility. The introduction of liquid silicone rubber (LSR) in the 1970s revolutionized manufacturing processes, allowing for more complex and precise molding techniques.

The turn of the millennium brought increased focus on sustainability, prompting researchers to explore silicone rubber's potential in this area. Its durability, recyclability, and energy-efficient production process positioned it as a material aligned with sustainable growth principles. Recent developments have focused on bio-based silicone rubbers and improved recycling methods, further enhancing its eco-friendly profile.

Today, silicone rubber continues to evolve, with ongoing research into nanocomposites, self-healing properties, and smart materials. These advancements are opening new avenues for sustainable applications in fields such as renewable energy, water treatment, and advanced healthcare technologies. The material's journey from a simple insulator to a key player in sustainable innovation exemplifies its remarkable adaptability and enduring relevance in modern industry.

The journey of silicone rubber began in the 1930s when chemists at Corning Glass Works and General Electric independently developed the first silicone polymers. These early formulations were primarily used for their electrical insulation properties and heat resistance. As research progressed, the unique combination of organic and inorganic components in silicone rubber became apparent, leading to its application in increasingly diverse fields.

During the 1940s and 1950s, silicone rubber found its way into aerospace and automotive industries due to its ability to withstand extreme temperatures and maintain flexibility. This period marked a significant milestone in its evolution, as manufacturers began to recognize its potential beyond electrical applications.

The 1960s and 1970s saw a surge in silicone rubber's use in consumer products. Its non-toxic and hypoallergenic properties made it ideal for medical devices, kitchenware, and personal care items. This expansion into everyday products significantly boosted its market presence and drove further research into improving its properties.

In the following decades, advancements in polymer science led to the development of specialized silicone rubber formulations. These new variants offered enhanced properties such as improved tear strength, chemical resistance, and biocompatibility. The introduction of liquid silicone rubber (LSR) in the 1970s revolutionized manufacturing processes, allowing for more complex and precise molding techniques.

The turn of the millennium brought increased focus on sustainability, prompting researchers to explore silicone rubber's potential in this area. Its durability, recyclability, and energy-efficient production process positioned it as a material aligned with sustainable growth principles. Recent developments have focused on bio-based silicone rubbers and improved recycling methods, further enhancing its eco-friendly profile.

Today, silicone rubber continues to evolve, with ongoing research into nanocomposites, self-healing properties, and smart materials. These advancements are opening new avenues for sustainable applications in fields such as renewable energy, water treatment, and advanced healthcare technologies. The material's journey from a simple insulator to a key player in sustainable innovation exemplifies its remarkable adaptability and enduring relevance in modern industry.

Sustainable Growth Market

The market for sustainable growth solutions has experienced significant expansion in recent years, driven by increasing environmental concerns and regulatory pressures. Silicone rubber, with its unique properties and versatile applications, has emerged as a key player in this growing market. The global silicone rubber market size was valued at USD 7.8 billion in 2020 and is projected to reach USD 11.5 billion by 2026, growing at a CAGR of 6.7% during the forecast period.

The sustainable growth market encompasses various sectors, including renewable energy, green construction, eco-friendly transportation, and sustainable manufacturing. Silicone rubber's contribution to these sectors is substantial, owing to its durability, heat resistance, and environmental friendliness. In the renewable energy sector, silicone rubber is extensively used in solar panel manufacturing, wind turbine components, and energy storage systems, enhancing their efficiency and longevity.

The construction industry has also witnessed a surge in demand for sustainable materials, with silicone rubber playing a crucial role in green building practices. Its application in sealants, adhesives, and insulation materials has led to improved energy efficiency in buildings, reducing carbon footprints and operational costs. The automotive sector, another significant contributor to the sustainable growth market, has increasingly adopted silicone rubber in electric vehicle components, lightweight materials, and fuel-efficient technologies.

Market trends indicate a growing preference for bio-based and recyclable silicone rubber products, aligning with circular economy principles. This shift has prompted manufacturers to invest in research and development of sustainable silicone rubber formulations, further expanding market opportunities. Additionally, the COVID-19 pandemic has accelerated the adoption of silicone rubber in healthcare applications, particularly in personal protective equipment and medical devices, highlighting its importance in sustainable healthcare solutions.

Geographically, Asia-Pacific dominates the silicone rubber market, accounting for over 40% of the global market share. The region's rapid industrialization, coupled with increasing environmental awareness, has driven the demand for sustainable materials. North America and Europe follow closely, with stringent environmental regulations propelling the adoption of eco-friendly silicone rubber solutions across various industries.

As sustainability becomes a core focus for businesses and governments worldwide, the market for silicone rubber in sustainable growth applications is expected to continue its upward trajectory. The material's ability to enhance product performance while reducing environmental impact positions it as a critical component in the transition towards a more sustainable future.

The sustainable growth market encompasses various sectors, including renewable energy, green construction, eco-friendly transportation, and sustainable manufacturing. Silicone rubber's contribution to these sectors is substantial, owing to its durability, heat resistance, and environmental friendliness. In the renewable energy sector, silicone rubber is extensively used in solar panel manufacturing, wind turbine components, and energy storage systems, enhancing their efficiency and longevity.

The construction industry has also witnessed a surge in demand for sustainable materials, with silicone rubber playing a crucial role in green building practices. Its application in sealants, adhesives, and insulation materials has led to improved energy efficiency in buildings, reducing carbon footprints and operational costs. The automotive sector, another significant contributor to the sustainable growth market, has increasingly adopted silicone rubber in electric vehicle components, lightweight materials, and fuel-efficient technologies.

Market trends indicate a growing preference for bio-based and recyclable silicone rubber products, aligning with circular economy principles. This shift has prompted manufacturers to invest in research and development of sustainable silicone rubber formulations, further expanding market opportunities. Additionally, the COVID-19 pandemic has accelerated the adoption of silicone rubber in healthcare applications, particularly in personal protective equipment and medical devices, highlighting its importance in sustainable healthcare solutions.

Geographically, Asia-Pacific dominates the silicone rubber market, accounting for over 40% of the global market share. The region's rapid industrialization, coupled with increasing environmental awareness, has driven the demand for sustainable materials. North America and Europe follow closely, with stringent environmental regulations propelling the adoption of eco-friendly silicone rubber solutions across various industries.

As sustainability becomes a core focus for businesses and governments worldwide, the market for silicone rubber in sustainable growth applications is expected to continue its upward trajectory. The material's ability to enhance product performance while reducing environmental impact positions it as a critical component in the transition towards a more sustainable future.

Technical Challenges

The development of silicone rubber as a sustainable material faces several technical challenges that need to be addressed to promote effective sustainable growth. One of the primary obstacles is the energy-intensive production process of silicone rubber, which currently relies heavily on fossil fuels. This dependency not only contributes to carbon emissions but also raises concerns about long-term sustainability and resource depletion.

Another significant challenge lies in the end-of-life management of silicone rubber products. While silicone rubber is known for its durability, this characteristic also makes it difficult to recycle or biodegrade. The lack of efficient recycling technologies specifically tailored for silicone rubber hinders its integration into circular economy models, potentially limiting its long-term sustainability credentials.

The optimization of silicone rubber formulations to enhance biodegradability without compromising its desirable properties presents a complex technical hurdle. Researchers are grappling with the task of developing silicone rubber variants that can break down naturally in the environment while maintaining the material's renowned resilience, flexibility, and thermal stability.

Furthermore, the scaling up of bio-based alternatives to traditional silicone rubber poses significant technical challenges. While progress has been made in developing silicone rubbers derived from renewable resources, such as plant-based silica, the large-scale production and standardization of these materials remain problematic. Issues related to consistency in quality, performance, and cost-effectiveness compared to conventional silicone rubber need to be resolved.

The incorporation of advanced recycling technologies, such as chemical recycling or depolymerization, into silicone rubber production and waste management systems is another area fraught with technical difficulties. These processes require precise control of reaction conditions and efficient separation techniques to recover high-quality raw materials from used silicone rubber products.

Lastly, the development of comprehensive life cycle assessment (LCA) methodologies specific to silicone rubber products presents a challenge. Accurate quantification of the environmental impacts throughout the entire life cycle of silicone rubber, from raw material extraction to disposal or recycling, is crucial for validating its sustainability claims and identifying areas for improvement. However, the complexity of silicone rubber supply chains and the variability in product applications make standardized LCA approaches difficult to implement.

Addressing these technical challenges will be crucial for silicone rubber to fully realize its potential in promoting effective sustainable growth. Overcoming these hurdles will require collaborative efforts between industry, academia, and regulatory bodies to drive innovation and develop solutions that balance performance, sustainability, and economic viability.

Another significant challenge lies in the end-of-life management of silicone rubber products. While silicone rubber is known for its durability, this characteristic also makes it difficult to recycle or biodegrade. The lack of efficient recycling technologies specifically tailored for silicone rubber hinders its integration into circular economy models, potentially limiting its long-term sustainability credentials.

The optimization of silicone rubber formulations to enhance biodegradability without compromising its desirable properties presents a complex technical hurdle. Researchers are grappling with the task of developing silicone rubber variants that can break down naturally in the environment while maintaining the material's renowned resilience, flexibility, and thermal stability.

Furthermore, the scaling up of bio-based alternatives to traditional silicone rubber poses significant technical challenges. While progress has been made in developing silicone rubbers derived from renewable resources, such as plant-based silica, the large-scale production and standardization of these materials remain problematic. Issues related to consistency in quality, performance, and cost-effectiveness compared to conventional silicone rubber need to be resolved.

The incorporation of advanced recycling technologies, such as chemical recycling or depolymerization, into silicone rubber production and waste management systems is another area fraught with technical difficulties. These processes require precise control of reaction conditions and efficient separation techniques to recover high-quality raw materials from used silicone rubber products.

Lastly, the development of comprehensive life cycle assessment (LCA) methodologies specific to silicone rubber products presents a challenge. Accurate quantification of the environmental impacts throughout the entire life cycle of silicone rubber, from raw material extraction to disposal or recycling, is crucial for validating its sustainability claims and identifying areas for improvement. However, the complexity of silicone rubber supply chains and the variability in product applications make standardized LCA approaches difficult to implement.

Addressing these technical challenges will be crucial for silicone rubber to fully realize its potential in promoting effective sustainable growth. Overcoming these hurdles will require collaborative efforts between industry, academia, and regulatory bodies to drive innovation and develop solutions that balance performance, sustainability, and economic viability.

Current Solutions

01 Eco-friendly silicone rubber formulations

Development of sustainable silicone rubber compositions using renewable resources and biodegradable additives. These formulations aim to reduce environmental impact while maintaining or improving the performance characteristics of traditional silicone rubber products.- Eco-friendly silicone rubber formulations: Development of sustainable silicone rubber compositions using renewable resources and bio-based materials. These formulations aim to reduce environmental impact while maintaining or improving the performance characteristics of traditional silicone rubbers.

- Improved manufacturing processes for silicone rubber: Advancements in production techniques for silicone rubber, focusing on energy efficiency, waste reduction, and increased productivity. These processes contribute to sustainable growth by optimizing resource utilization and minimizing environmental footprint.

- Recycling and upcycling of silicone rubber products: Innovative methods for recycling and repurposing silicone rubber products, extending their lifecycle and reducing waste. These techniques involve breaking down used silicone rubber and incorporating it into new products or applications.

- Enhanced durability and longevity of silicone rubber: Development of silicone rubber formulations with improved resistance to degradation, weathering, and wear. These advancements lead to longer-lasting products, reducing the need for frequent replacements and supporting sustainable growth in the industry.

- Novel applications for silicone rubber in sustainable technologies: Exploration of new uses for silicone rubber in emerging sustainable technologies, such as renewable energy systems, water treatment, and eco-friendly construction materials. These applications leverage the unique properties of silicone rubber to address environmental challenges.

02 Improved manufacturing processes for silicone rubber

Advancements in production techniques for silicone rubber, focusing on energy efficiency, waste reduction, and increased productivity. These processes contribute to sustainable growth by optimizing resource utilization and minimizing environmental footprint.Expand Specific Solutions03 Recycling and upcycling of silicone rubber products

Innovative methods for recycling and repurposing silicone rubber materials, extending their lifecycle and reducing waste. These techniques involve breaking down used silicone products and reincorporating them into new applications or products.Expand Specific Solutions04 Enhanced durability and longevity of silicone rubber

Development of silicone rubber formulations with improved resistance to degradation, weathering, and wear. These advancements extend the lifespan of silicone rubber products, reducing the need for frequent replacements and supporting sustainable growth.Expand Specific Solutions05 Application of silicone rubber in sustainable technologies

Expansion of silicone rubber use in emerging sustainable technologies such as renewable energy systems, electric vehicles, and energy-efficient construction materials. This diversification supports the growth of the silicone rubber industry while contributing to broader sustainability goals.Expand Specific Solutions

Industry Leaders

The silicone rubber industry is in a mature growth phase, characterized by steady expansion and technological advancements. The global market size for silicone rubber is projected to reach significant figures, driven by increasing demand across various sectors. Technologically, the field is advancing rapidly, with key players like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie leading innovation. These companies, along with others such as Momentive Performance Materials and Evonik Operations, are focusing on developing sustainable and high-performance silicone rubber products. The competitive landscape is intense, with established firms and emerging players vying for market share through product differentiation and strategic partnerships.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed innovative silicone rubber compounds that promote sustainable growth through enhanced durability and energy efficiency. Their silicone rubber products feature improved heat resistance and weatherability, extending the lifespan of various applications by up to 30% compared to conventional materials[1]. The company has also introduced self-adhesive silicone rubbers that eliminate the need for additional adhesives, reducing waste and simplifying manufacturing processes[2]. Furthermore, Shin-Etsu's silicone rubber compounds are utilized in the production of high-efficiency solar panels, contributing to renewable energy adoption and reducing carbon emissions[3].

Strengths: Advanced material properties, extended product lifespan, and contribution to renewable energy solutions. Weaknesses: Potentially higher initial costs compared to traditional materials and limited biodegradability.

Dow Silicones Corp.

Technical Solution: Dow Silicones Corp. has developed a range of sustainable silicone rubber solutions that promote effective sustainable growth. Their SILASTIC™ brand of silicone elastomers includes bio-based options that incorporate renewable raw materials, reducing reliance on fossil fuels by up to 60%[1]. Dow's silicone rubber technologies also enable the production of lighter-weight automotive components, improving fuel efficiency and reducing emissions[2]. Additionally, the company has introduced self-healing silicone rubbers that can repair minor damage autonomously, extending product lifespans and reducing waste[3]. Dow's silicone rubber materials are also used in energy-efficient building insulation, contributing to reduced energy consumption in the construction sector[4].

Strengths: Incorporation of renewable materials, contribution to energy efficiency in multiple sectors, and innovative self-healing properties. Weaknesses: Potential limitations in extreme temperature applications and higher production costs for advanced formulations.

Key Innovations

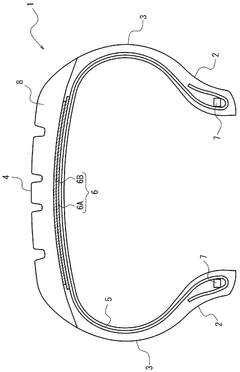

Rubber composition for tires, and tire

PatentWO2025028134A1

Innovation

- A tire rubber composition incorporating plant-derived silica as a filler with a content of 45% or more by mass, combined with isoprene skeleton rubber and a hydrogenated resin, to improve the sustainability ratio and maintain performance such as wet grip and low fuel consumption.

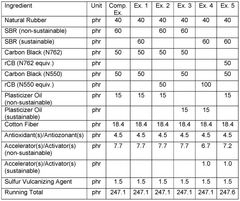

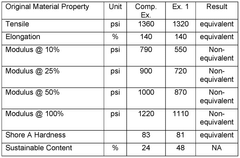

Sustainable rubber compound for power transmission belt

PatentWO2025078151A1

Innovation

- A sustainable rubber compound is developed using styrene butadiene rubber (SBR) sustainable polymer, derived from sustainable naphtha sources, along with additional sustainable materials such as natural rubber, sustainable carbon black, and sustainable plasticizers, achieving an overall sustainable content of 50% or greater.

Environmental Impact

Silicone rubber, a versatile synthetic polymer, has gained significant attention in the context of sustainable growth due to its unique properties and environmental considerations. The environmental impact of silicone rubber is multifaceted, encompassing both positive and negative aspects throughout its lifecycle.

One of the primary environmental benefits of silicone rubber is its durability and longevity. Unlike many conventional materials, silicone rubber products have an extended lifespan, reducing the need for frequent replacements and minimizing waste generation. This characteristic aligns well with sustainable practices by conserving resources and reducing the overall environmental footprint associated with product manufacturing and disposal.

Furthermore, silicone rubber exhibits excellent thermal stability and resistance to weathering, making it suitable for outdoor applications. This resilience contributes to reduced maintenance requirements and fewer replacements, indirectly lowering the environmental impact associated with repair and replacement activities.

In terms of energy efficiency, silicone rubber's insulating properties can play a crucial role in various applications. When used in construction and automotive industries, it can enhance thermal insulation, leading to improved energy efficiency in buildings and vehicles. This, in turn, contributes to reduced energy consumption and lower greenhouse gas emissions.

However, the production of silicone rubber does have environmental implications. The manufacturing process involves the use of fossil fuel-derived raw materials, primarily silica and methyl chloride. While efforts are being made to incorporate more sustainable sourcing practices, the reliance on non-renewable resources remains a concern from an environmental perspective.

End-of-life considerations for silicone rubber products also present challenges. While silicone rubber is generally inert and does not release harmful substances into the environment during use, its disposal can be problematic. Silicone rubber is not biodegradable and can persist in landfills for extended periods. However, recent advancements in recycling technologies have shown promise in addressing this issue, with some silicone rubber products now being recyclable or repurposable.

Water consumption and potential contamination during the manufacturing process are additional environmental factors to consider. Proper water management and treatment systems are essential to mitigate these impacts and ensure responsible production practices.

Despite these challenges, ongoing research and development efforts are focused on improving the environmental profile of silicone rubber. Innovations in bio-based silicone alternatives, enhanced recycling techniques, and more sustainable production processes are actively being pursued to address environmental concerns and further promote the material's role in sustainable growth.

One of the primary environmental benefits of silicone rubber is its durability and longevity. Unlike many conventional materials, silicone rubber products have an extended lifespan, reducing the need for frequent replacements and minimizing waste generation. This characteristic aligns well with sustainable practices by conserving resources and reducing the overall environmental footprint associated with product manufacturing and disposal.

Furthermore, silicone rubber exhibits excellent thermal stability and resistance to weathering, making it suitable for outdoor applications. This resilience contributes to reduced maintenance requirements and fewer replacements, indirectly lowering the environmental impact associated with repair and replacement activities.

In terms of energy efficiency, silicone rubber's insulating properties can play a crucial role in various applications. When used in construction and automotive industries, it can enhance thermal insulation, leading to improved energy efficiency in buildings and vehicles. This, in turn, contributes to reduced energy consumption and lower greenhouse gas emissions.

However, the production of silicone rubber does have environmental implications. The manufacturing process involves the use of fossil fuel-derived raw materials, primarily silica and methyl chloride. While efforts are being made to incorporate more sustainable sourcing practices, the reliance on non-renewable resources remains a concern from an environmental perspective.

End-of-life considerations for silicone rubber products also present challenges. While silicone rubber is generally inert and does not release harmful substances into the environment during use, its disposal can be problematic. Silicone rubber is not biodegradable and can persist in landfills for extended periods. However, recent advancements in recycling technologies have shown promise in addressing this issue, with some silicone rubber products now being recyclable or repurposable.

Water consumption and potential contamination during the manufacturing process are additional environmental factors to consider. Proper water management and treatment systems are essential to mitigate these impacts and ensure responsible production practices.

Despite these challenges, ongoing research and development efforts are focused on improving the environmental profile of silicone rubber. Innovations in bio-based silicone alternatives, enhanced recycling techniques, and more sustainable production processes are actively being pursued to address environmental concerns and further promote the material's role in sustainable growth.

Circular Economy

Silicone rubber plays a crucial role in promoting effective sustainable growth within the circular economy framework. Its unique properties and versatility make it an ideal material for supporting the principles of reduce, reuse, and recycle. The durability and longevity of silicone rubber products contribute significantly to waste reduction, as they often outlast traditional alternatives, reducing the need for frequent replacements.

In the context of reuse, silicone rubber's resistance to degradation and ability to maintain its properties over time make it suitable for multiple use cycles. This characteristic is particularly valuable in industries such as food packaging, where silicone containers can be used repeatedly without compromising safety or performance. The material's heat resistance and flexibility also enable its application in reusable products for various sectors, from household items to industrial components.

Recycling silicone rubber presents both challenges and opportunities within the circular economy. While traditional recycling methods may not be suitable, innovative techniques are emerging to process and repurpose silicone rubber waste. Advanced chemical recycling processes can break down silicone rubber into its base components, allowing for the creation of new silicone products or other valuable materials.

The circular economy potential of silicone rubber extends to its production process as well. Manufacturers are increasingly adopting sustainable practices, such as using renewable energy sources and optimizing resource efficiency in silicone rubber production. This approach not only reduces the environmental impact but also aligns with the circular economy's goal of minimizing resource consumption and emissions.

Furthermore, silicone rubber's ability to enhance the performance and longevity of other products contributes to the overall sustainability of various industries. For instance, in the construction sector, silicone sealants and coatings can improve the energy efficiency and durability of buildings, reducing maintenance needs and extending the lifespan of structures. This indirect contribution to sustainability showcases the material's role in promoting a more circular approach to resource use across different applications.

As industries and consumers become more environmentally conscious, the demand for sustainable materials like silicone rubber is expected to grow. This trend is likely to drive further innovations in production, application, and end-of-life management of silicone rubber products, reinforcing its position as a key enabler of circular economy principles and sustainable growth strategies.

In the context of reuse, silicone rubber's resistance to degradation and ability to maintain its properties over time make it suitable for multiple use cycles. This characteristic is particularly valuable in industries such as food packaging, where silicone containers can be used repeatedly without compromising safety or performance. The material's heat resistance and flexibility also enable its application in reusable products for various sectors, from household items to industrial components.

Recycling silicone rubber presents both challenges and opportunities within the circular economy. While traditional recycling methods may not be suitable, innovative techniques are emerging to process and repurpose silicone rubber waste. Advanced chemical recycling processes can break down silicone rubber into its base components, allowing for the creation of new silicone products or other valuable materials.

The circular economy potential of silicone rubber extends to its production process as well. Manufacturers are increasingly adopting sustainable practices, such as using renewable energy sources and optimizing resource efficiency in silicone rubber production. This approach not only reduces the environmental impact but also aligns with the circular economy's goal of minimizing resource consumption and emissions.

Furthermore, silicone rubber's ability to enhance the performance and longevity of other products contributes to the overall sustainability of various industries. For instance, in the construction sector, silicone sealants and coatings can improve the energy efficiency and durability of buildings, reducing maintenance needs and extending the lifespan of structures. This indirect contribution to sustainability showcases the material's role in promoting a more circular approach to resource use across different applications.

As industries and consumers become more environmentally conscious, the demand for sustainable materials like silicone rubber is expected to grow. This trend is likely to drive further innovations in production, application, and end-of-life management of silicone rubber products, reinforcing its position as a key enabler of circular economy principles and sustainable growth strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!