How Silicone Rubber Supports Advanced Microelectronics?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Microelectronics: Background and Objectives

Silicone rubber has emerged as a critical material in the field of advanced microelectronics, playing a pivotal role in the development and production of cutting-edge electronic devices. The journey of silicone rubber in this domain began in the mid-20th century, with its unique properties attracting the attention of electronics manufacturers seeking innovative solutions for component protection and insulation.

As the microelectronics industry evolved rapidly, the demands placed on materials used in electronic devices became increasingly complex. Silicone rubber, with its exceptional thermal stability, electrical insulation properties, and flexibility, proved to be an ideal candidate for addressing many of these challenges. Its ability to maintain performance across a wide range of temperatures and environmental conditions made it particularly valuable in the face of miniaturization trends and the need for more robust electronic components.

The technological objectives associated with silicone rubber in microelectronics have expanded significantly over time. Initially, the focus was primarily on basic insulation and protection. However, as the industry progressed, the goals shifted towards enhancing the material's properties to meet more sophisticated requirements. These include improving its thermal management capabilities, increasing its resistance to harsh chemicals and environmental factors, and developing formulations that can withstand the extreme conditions encountered in advanced manufacturing processes.

One of the key technological trends in this field has been the development of silicone rubber compounds with enhanced electrical and thermal conductivity. This seemingly paradoxical goal – creating a traditionally insulating material that can also conduct heat or electricity – has opened up new possibilities for the design of compact, efficient electronic devices. Researchers and manufacturers have been working on incorporating conductive fillers and developing novel molecular structures to achieve these properties without compromising the material's other beneficial characteristics.

Another significant trend is the pursuit of ultra-thin silicone rubber films and coatings. As electronic devices continue to shrink in size, there is a growing need for protective materials that can be applied in extremely thin layers without losing their effectiveness. This has led to innovations in silicone rubber formulations and application techniques, enabling the creation of nanoscale coatings that offer superior protection while minimizing the overall size and weight of electronic components.

Looking ahead, the technological objectives for silicone rubber in microelectronics are likely to focus on even greater precision and functionality. This may include the development of smart silicone materials that can respond to environmental changes, self-healing silicone rubbers that can repair minor damage autonomously, and biocompatible formulations for use in medical electronics and implantable devices. The ongoing evolution of silicone rubber technology continues to support and drive advancements in the field of microelectronics, promising exciting innovations in the years to come.

As the microelectronics industry evolved rapidly, the demands placed on materials used in electronic devices became increasingly complex. Silicone rubber, with its exceptional thermal stability, electrical insulation properties, and flexibility, proved to be an ideal candidate for addressing many of these challenges. Its ability to maintain performance across a wide range of temperatures and environmental conditions made it particularly valuable in the face of miniaturization trends and the need for more robust electronic components.

The technological objectives associated with silicone rubber in microelectronics have expanded significantly over time. Initially, the focus was primarily on basic insulation and protection. However, as the industry progressed, the goals shifted towards enhancing the material's properties to meet more sophisticated requirements. These include improving its thermal management capabilities, increasing its resistance to harsh chemicals and environmental factors, and developing formulations that can withstand the extreme conditions encountered in advanced manufacturing processes.

One of the key technological trends in this field has been the development of silicone rubber compounds with enhanced electrical and thermal conductivity. This seemingly paradoxical goal – creating a traditionally insulating material that can also conduct heat or electricity – has opened up new possibilities for the design of compact, efficient electronic devices. Researchers and manufacturers have been working on incorporating conductive fillers and developing novel molecular structures to achieve these properties without compromising the material's other beneficial characteristics.

Another significant trend is the pursuit of ultra-thin silicone rubber films and coatings. As electronic devices continue to shrink in size, there is a growing need for protective materials that can be applied in extremely thin layers without losing their effectiveness. This has led to innovations in silicone rubber formulations and application techniques, enabling the creation of nanoscale coatings that offer superior protection while minimizing the overall size and weight of electronic components.

Looking ahead, the technological objectives for silicone rubber in microelectronics are likely to focus on even greater precision and functionality. This may include the development of smart silicone materials that can respond to environmental changes, self-healing silicone rubbers that can repair minor damage autonomously, and biocompatible formulations for use in medical electronics and implantable devices. The ongoing evolution of silicone rubber technology continues to support and drive advancements in the field of microelectronics, promising exciting innovations in the years to come.

Market Demand Analysis for Silicone-Based Microelectronics

The market demand for silicone-based microelectronics has been experiencing significant growth, driven by the increasing complexity and miniaturization of electronic devices across various industries. Silicone rubber, with its unique properties, has become a crucial material in advanced microelectronics, supporting the development of flexible, durable, and high-performance electronic components.

In the consumer electronics sector, the demand for silicone-based microelectronics is particularly strong. Smartphones, wearable devices, and other portable gadgets require flexible and reliable components that can withstand daily wear and tear. Silicone rubber's ability to provide excellent insulation, heat resistance, and flexibility makes it an ideal material for these applications. The market for flexible displays, a key application area for silicone-based microelectronics, is expected to grow substantially in the coming years.

The automotive industry is another major driver of demand for silicone-based microelectronics. As vehicles become increasingly electrified and autonomous, the need for advanced sensors, control systems, and power electronics grows. Silicone rubber's thermal stability and resistance to harsh environments make it well-suited for automotive applications, where components must operate reliably under extreme conditions.

In the medical device sector, silicone-based microelectronics are gaining traction due to their biocompatibility and flexibility. Implantable devices, wearable health monitors, and advanced diagnostic equipment all benefit from the unique properties of silicone rubber. The aging population and increasing focus on personalized healthcare are expected to further boost demand in this sector.

The aerospace and defense industries also contribute significantly to the market demand for silicone-based microelectronics. These sectors require highly reliable and durable components that can withstand extreme temperatures, vibrations, and other harsh conditions. Silicone rubber's ability to maintain its properties under such conditions makes it an attractive material for aerospace and defense applications.

The Internet of Things (IoT) and smart home devices represent another growing market for silicone-based microelectronics. As more devices become interconnected and embedded with sensors, the need for flexible, durable, and environmentally resistant components increases. Silicone rubber's versatility makes it well-suited for a wide range of IoT applications, from smart appliances to industrial sensors.

Overall, the market demand for silicone-based microelectronics is expected to continue its upward trajectory, driven by technological advancements and the expanding applications across multiple industries. The unique properties of silicone rubber, combined with ongoing innovations in microelectronics, position this market segment for sustained growth in the coming years.

In the consumer electronics sector, the demand for silicone-based microelectronics is particularly strong. Smartphones, wearable devices, and other portable gadgets require flexible and reliable components that can withstand daily wear and tear. Silicone rubber's ability to provide excellent insulation, heat resistance, and flexibility makes it an ideal material for these applications. The market for flexible displays, a key application area for silicone-based microelectronics, is expected to grow substantially in the coming years.

The automotive industry is another major driver of demand for silicone-based microelectronics. As vehicles become increasingly electrified and autonomous, the need for advanced sensors, control systems, and power electronics grows. Silicone rubber's thermal stability and resistance to harsh environments make it well-suited for automotive applications, where components must operate reliably under extreme conditions.

In the medical device sector, silicone-based microelectronics are gaining traction due to their biocompatibility and flexibility. Implantable devices, wearable health monitors, and advanced diagnostic equipment all benefit from the unique properties of silicone rubber. The aging population and increasing focus on personalized healthcare are expected to further boost demand in this sector.

The aerospace and defense industries also contribute significantly to the market demand for silicone-based microelectronics. These sectors require highly reliable and durable components that can withstand extreme temperatures, vibrations, and other harsh conditions. Silicone rubber's ability to maintain its properties under such conditions makes it an attractive material for aerospace and defense applications.

The Internet of Things (IoT) and smart home devices represent another growing market for silicone-based microelectronics. As more devices become interconnected and embedded with sensors, the need for flexible, durable, and environmentally resistant components increases. Silicone rubber's versatility makes it well-suited for a wide range of IoT applications, from smart appliances to industrial sensors.

Overall, the market demand for silicone-based microelectronics is expected to continue its upward trajectory, driven by technological advancements and the expanding applications across multiple industries. The unique properties of silicone rubber, combined with ongoing innovations in microelectronics, position this market segment for sustained growth in the coming years.

Current Challenges in Silicone Rubber Microelectronics Integration

The integration of silicone rubber in advanced microelectronics faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is achieving consistent and reliable adhesion between silicone rubber and various substrate materials used in microelectronic devices. The inherent low surface energy of silicone rubber makes it difficult to form strong bonds with metals, ceramics, and other polymers commonly used in electronic components.

Another critical challenge lies in maintaining the electrical and thermal properties of silicone rubber when incorporated into complex microelectronic systems. As devices become smaller and more densely packed, the silicone rubber must retain its insulating capabilities and thermal management properties under increasingly demanding conditions. This includes withstanding higher operating temperatures, resisting degradation from electromagnetic interference, and maintaining stability in the presence of various chemicals and solvents used in manufacturing processes.

The precision required in microelectronics manufacturing also poses significant challenges for silicone rubber integration. Achieving the necessary dimensional accuracy and consistency in silicone rubber components, especially at the microscale, remains a formidable task. Traditional molding and casting techniques often fall short of meeting the stringent tolerances required for advanced microelectronic applications.

Furthermore, the long-term reliability and aging characteristics of silicone rubber in microelectronic environments are not fully understood. Factors such as thermal cycling, mechanical stress, and exposure to various environmental conditions can potentially lead to degradation of silicone rubber properties over time. This uncertainty raises concerns about the long-term performance and reliability of microelectronic devices incorporating silicone rubber components.

Compatibility with existing manufacturing processes and equipment presents another hurdle. Integrating silicone rubber into established microelectronics production lines often requires significant modifications to tooling, handling procedures, and quality control measures. This can result in increased production costs and potential disruptions to existing manufacturing workflows.

Lastly, the development of standardized testing and characterization methods for silicone rubber in microelectronic applications remains an ongoing challenge. The lack of universally accepted standards makes it difficult to compare different silicone rubber formulations and evaluate their suitability for specific microelectronic applications. This gap in standardization also complicates the process of quality assurance and regulatory compliance for manufacturers incorporating silicone rubber into their products.

Another critical challenge lies in maintaining the electrical and thermal properties of silicone rubber when incorporated into complex microelectronic systems. As devices become smaller and more densely packed, the silicone rubber must retain its insulating capabilities and thermal management properties under increasingly demanding conditions. This includes withstanding higher operating temperatures, resisting degradation from electromagnetic interference, and maintaining stability in the presence of various chemicals and solvents used in manufacturing processes.

The precision required in microelectronics manufacturing also poses significant challenges for silicone rubber integration. Achieving the necessary dimensional accuracy and consistency in silicone rubber components, especially at the microscale, remains a formidable task. Traditional molding and casting techniques often fall short of meeting the stringent tolerances required for advanced microelectronic applications.

Furthermore, the long-term reliability and aging characteristics of silicone rubber in microelectronic environments are not fully understood. Factors such as thermal cycling, mechanical stress, and exposure to various environmental conditions can potentially lead to degradation of silicone rubber properties over time. This uncertainty raises concerns about the long-term performance and reliability of microelectronic devices incorporating silicone rubber components.

Compatibility with existing manufacturing processes and equipment presents another hurdle. Integrating silicone rubber into established microelectronics production lines often requires significant modifications to tooling, handling procedures, and quality control measures. This can result in increased production costs and potential disruptions to existing manufacturing workflows.

Lastly, the development of standardized testing and characterization methods for silicone rubber in microelectronic applications remains an ongoing challenge. The lack of universally accepted standards makes it difficult to compare different silicone rubber formulations and evaluate their suitability for specific microelectronic applications. This gap in standardization also complicates the process of quality assurance and regulatory compliance for manufacturers incorporating silicone rubber into their products.

Existing Silicone Rubber Solutions for Microelectronics

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to modify properties such as strength, flexibility, and heat resistance.- Composition and formulation of silicone rubber: Silicone rubber compositions typically consist of silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or impart specific functionalities.

- Manufacturing processes for silicone rubber products: Different manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. These processes involve precise control of temperature, pressure, and curing conditions to achieve desired product specifications. Advanced manufacturing methods may incorporate automation and quality control systems.

- Modifications and improvements to silicone rubber properties: Researchers continually work on enhancing silicone rubber properties through various modifications. This includes the development of new polymer structures, incorporation of novel fillers, and the use of specialized additives. These improvements aim to enhance characteristics such as tear strength, chemical resistance, and thermal stability.

- Applications of silicone rubber in various industries: Silicone rubber finds widespread use across multiple industries due to its unique properties. It is utilized in medical devices, automotive components, electrical insulation, and consumer products. The material's biocompatibility, durability, and resistance to extreme temperatures make it suitable for diverse applications.

- Environmental considerations and sustainability of silicone rubber: As environmental concerns grow, there is increasing focus on the sustainability of silicone rubber. Research is being conducted on biodegradable silicone formulations, recycling methods, and eco-friendly production processes. The industry is also exploring bio-based alternatives and ways to reduce the environmental impact of silicone rubber products throughout their lifecycle.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the manufacturing process. This can include improving thermal stability, enhancing electrical properties, or increasing chemical resistance. Techniques may involve blending with other polymers or incorporating specialized fillers.Expand Specific Solutions03 Applications of silicone rubber

Silicone rubber finds wide-ranging applications due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, and consumer products. Its biocompatibility, heat resistance, and flexibility make it suitable for diverse industrial and commercial uses.Expand Specific Solutions04 Curing methods for silicone rubber

Various curing methods are employed in the production of silicone rubber, including heat curing, room temperature vulcanization (RTV), and UV curing. Each method affects the final properties of the rubber and is chosen based on the specific application requirements and manufacturing constraints.Expand Specific Solutions05 Silicone rubber composites and blends

Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This includes reinforcing with fibers, blending with other elastomers, or incorporating nanoparticles. These combinations can result in materials with improved mechanical strength, conductivity, or specific functional characteristics.Expand Specific Solutions

Key Players in Silicone Rubber and Microelectronics Industries

The market for silicone rubber in advanced microelectronics is in a growth phase, driven by increasing demand for miniaturization and high-performance electronic devices. The global market size is projected to expand significantly in the coming years. Technologically, silicone rubber applications are advancing rapidly, with key players like Shin-Etsu Chemical, Wacker Chemie, and Momentive Performance Materials leading innovation. These companies are developing specialized formulations with enhanced thermal, electrical, and mechanical properties tailored for microelectronics. While the technology is relatively mature, ongoing R&D focuses on improving performance, reliability, and manufacturing processes to meet evolving industry needs.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has developed advanced silicone rubber compounds specifically designed for microelectronics applications. Their silicone elastomers offer excellent thermal stability, electrical insulation, and resistance to environmental stresses. The company's liquid silicone rubber (LSR) technology allows for precision molding of intricate microelectronic components with high dimensional accuracy[1]. Shin-Etsu's silicone products also include thermally conductive materials that efficiently dissipate heat in densely packed electronic devices, addressing one of the key challenges in modern microelectronics[2]. Their silicone encapsulants provide protection against moisture, dust, and other contaminants, extending the lifespan of sensitive electronic components[3].

Strengths: Industry-leading expertise in silicone technology, wide range of specialized products for microelectronics, strong R&D capabilities. Weaknesses: Potential higher costs compared to some alternatives, dependency on raw material supply chains.

Dow Toray Co.,Ltd.

Technical Solution: Dow Toray Co., Ltd. has developed advanced silicone rubber solutions specifically tailored for the microelectronics industry. Their SILASTIC™ brand of silicone elastomers offers exceptional thermal stability and electrical insulation properties, crucial for high-performance electronic devices[1]. The company's liquid silicone rubber (LSR) technology enables the production of complex, miniaturized components with high precision and consistency, supporting the trend towards smaller and more intricate microelectronic designs[2]. Dow Toray's silicone adhesives and sealants provide robust protection against environmental factors such as moisture and contaminants, enhancing the reliability and longevity of sensitive electronic components[3]. Additionally, their thermally conductive silicone materials address the critical need for efficient heat dissipation in densely packed electronic assemblies, contributing to improved device performance and reliability[4].

Strengths: Strong expertise in silicone chemistry, global presence and resources, ability to provide customized solutions. Weaknesses: Potential higher costs for specialized products, challenges in adapting to rapidly evolving microelectronics requirements.

Innovative Silicone Rubber Technologies for Advanced Microelectronics

Silicone rubber composition

PatentInactiveUS20050165161A1

Innovation

- A silicone rubber composition is formulated with an organopolysiloxane having a degree of polymerization of 100 or higher and at least two silicon-bonded alkenyl groups, combined with wet silica having a specific surface area of 50 m2/g or larger and a water content of 4% or lower, along with a suitable curing agent, to inhibit foaming and enhance electrical properties.

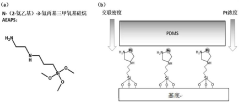

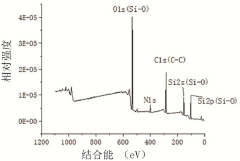

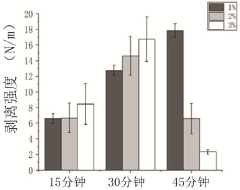

Preparation method of step curing silica gel film and application of step curing silica gel film in field of epidermal electronics

PatentActiveCN113845673A

Innovation

- A gradient cured silica gel film is prepared by loading N-(2-aminoethyl)-3-aminopropyltrimethoxysilane (AEAPS) on a glass sheet to form a gradient polysiloxane film. The catalyst concentration is used to form a gradient polysiloxane film. The gradient achieves a cross-linking density gradient, with one side having a low modulus for skin attachment and the other side having a high modulus for device integration.

Environmental Impact of Silicone Rubber in Electronics

The environmental impact of silicone rubber in electronics is a critical consideration as the microelectronics industry continues to advance. Silicone rubber, while offering numerous benefits in electronic applications, also presents certain environmental challenges that must be addressed.

One of the primary environmental concerns associated with silicone rubber in electronics is its long-term persistence in the environment. Silicone rubber is not biodegradable and can remain in landfills for extended periods. This persistence contributes to the growing issue of electronic waste (e-waste) accumulation, which is a significant global environmental problem.

However, silicone rubber does offer some environmental advantages compared to other materials used in electronics. It is generally considered non-toxic and does not release harmful chemicals into the environment during its use phase. This characteristic makes it a safer option for both human health and ecosystems compared to some alternative materials.

The production process of silicone rubber also has environmental implications. The manufacturing of silicone rubber requires significant energy input and involves the use of various chemicals. This can lead to greenhouse gas emissions and potential chemical pollution if not properly managed. However, advancements in manufacturing technologies are continually improving the efficiency and reducing the environmental footprint of silicone rubber production.

In terms of recyclability, silicone rubber presents both challenges and opportunities. While it is technically recyclable, the process is complex and not widely implemented on a large scale. The cross-linked structure of silicone rubber makes it difficult to break down and reprocess. However, research is ongoing to develop more effective recycling methods for silicone-based materials in electronics.

The use of silicone rubber in electronics can contribute to improved energy efficiency and longevity of devices. Its excellent insulating properties and durability can lead to more efficient electronic components and longer-lasting products. This indirectly reduces the environmental impact by decreasing energy consumption and slowing the rate of electronic device replacement.

As the electronics industry moves towards more sustainable practices, there is increasing focus on developing eco-friendly alternatives to traditional silicone rubber. Bio-based silicones and other sustainable elastomers are being researched as potential replacements that could offer similar performance characteristics with reduced environmental impact.

In conclusion, while silicone rubber provides crucial support for advanced microelectronics, its environmental impact is complex. The industry must continue to balance the material's performance benefits with efforts to mitigate its environmental drawbacks through improved production processes, enhanced recycling techniques, and the development of more sustainable alternatives.

One of the primary environmental concerns associated with silicone rubber in electronics is its long-term persistence in the environment. Silicone rubber is not biodegradable and can remain in landfills for extended periods. This persistence contributes to the growing issue of electronic waste (e-waste) accumulation, which is a significant global environmental problem.

However, silicone rubber does offer some environmental advantages compared to other materials used in electronics. It is generally considered non-toxic and does not release harmful chemicals into the environment during its use phase. This characteristic makes it a safer option for both human health and ecosystems compared to some alternative materials.

The production process of silicone rubber also has environmental implications. The manufacturing of silicone rubber requires significant energy input and involves the use of various chemicals. This can lead to greenhouse gas emissions and potential chemical pollution if not properly managed. However, advancements in manufacturing technologies are continually improving the efficiency and reducing the environmental footprint of silicone rubber production.

In terms of recyclability, silicone rubber presents both challenges and opportunities. While it is technically recyclable, the process is complex and not widely implemented on a large scale. The cross-linked structure of silicone rubber makes it difficult to break down and reprocess. However, research is ongoing to develop more effective recycling methods for silicone-based materials in electronics.

The use of silicone rubber in electronics can contribute to improved energy efficiency and longevity of devices. Its excellent insulating properties and durability can lead to more efficient electronic components and longer-lasting products. This indirectly reduces the environmental impact by decreasing energy consumption and slowing the rate of electronic device replacement.

As the electronics industry moves towards more sustainable practices, there is increasing focus on developing eco-friendly alternatives to traditional silicone rubber. Bio-based silicones and other sustainable elastomers are being researched as potential replacements that could offer similar performance characteristics with reduced environmental impact.

In conclusion, while silicone rubber provides crucial support for advanced microelectronics, its environmental impact is complex. The industry must continue to balance the material's performance benefits with efforts to mitigate its environmental drawbacks through improved production processes, enhanced recycling techniques, and the development of more sustainable alternatives.

Thermal Management Strategies Using Silicone Rubber

Silicone rubber has emerged as a crucial material in thermal management strategies for advanced microelectronics. Its unique properties make it particularly suitable for addressing the increasing thermal challenges in modern electronic devices. The high thermal conductivity of silicone rubber, combined with its flexibility and electrical insulation properties, allows for efficient heat dissipation while maintaining the integrity of electronic components.

One of the primary thermal management strategies utilizing silicone rubber is the development of thermally conductive gap fillers. These materials are designed to fill the gaps between heat-generating components and heat sinks, ensuring optimal thermal contact and minimizing air pockets that can impede heat transfer. Silicone-based gap fillers can conform to irregular surfaces, accommodating the complex geometries often found in advanced microelectronic assemblies.

Another significant application is in the creation of thermal interface materials (TIMs). Silicone rubber-based TIMs are used to enhance the thermal connection between heat-generating components and cooling solutions. These materials can be formulated with various fillers to achieve specific thermal conductivity levels, allowing for customization based on the requirements of different electronic systems.

Silicone rubber is also employed in the manufacturing of thermally conductive adhesives. These adhesives not only provide a strong bond between components but also facilitate heat transfer. This dual functionality is particularly valuable in compact electronic designs where space is at a premium, and every element must contribute to overall thermal management.

The development of silicone rubber-based heat spreaders represents another innovative thermal management strategy. These thin, flexible sheets can be integrated into electronic devices to distribute heat more evenly across surfaces, preventing the formation of localized hot spots that can lead to performance issues or component failure.

In the realm of encapsulation and potting compounds, silicone rubber offers excellent thermal stability and heat dissipation properties. These compounds are used to protect sensitive electronic components from environmental factors while simultaneously aiding in heat management. The ability of silicone rubber to maintain its properties over a wide temperature range makes it ideal for applications in harsh environments.

As electronic devices continue to shrink in size while increasing in power density, the role of silicone rubber in thermal management strategies is likely to expand. Research is ongoing to further enhance the thermal properties of silicone rubber through the incorporation of advanced fillers and the development of novel formulations. These efforts aim to push the boundaries of thermal management capabilities, enabling the next generation of high-performance microelectronics.

One of the primary thermal management strategies utilizing silicone rubber is the development of thermally conductive gap fillers. These materials are designed to fill the gaps between heat-generating components and heat sinks, ensuring optimal thermal contact and minimizing air pockets that can impede heat transfer. Silicone-based gap fillers can conform to irregular surfaces, accommodating the complex geometries often found in advanced microelectronic assemblies.

Another significant application is in the creation of thermal interface materials (TIMs). Silicone rubber-based TIMs are used to enhance the thermal connection between heat-generating components and cooling solutions. These materials can be formulated with various fillers to achieve specific thermal conductivity levels, allowing for customization based on the requirements of different electronic systems.

Silicone rubber is also employed in the manufacturing of thermally conductive adhesives. These adhesives not only provide a strong bond between components but also facilitate heat transfer. This dual functionality is particularly valuable in compact electronic designs where space is at a premium, and every element must contribute to overall thermal management.

The development of silicone rubber-based heat spreaders represents another innovative thermal management strategy. These thin, flexible sheets can be integrated into electronic devices to distribute heat more evenly across surfaces, preventing the formation of localized hot spots that can lead to performance issues or component failure.

In the realm of encapsulation and potting compounds, silicone rubber offers excellent thermal stability and heat dissipation properties. These compounds are used to protect sensitive electronic components from environmental factors while simultaneously aiding in heat management. The ability of silicone rubber to maintain its properties over a wide temperature range makes it ideal for applications in harsh environments.

As electronic devices continue to shrink in size while increasing in power density, the role of silicone rubber in thermal management strategies is likely to expand. Research is ongoing to further enhance the thermal properties of silicone rubber through the incorporation of advanced fillers and the development of novel formulations. These efforts aim to push the boundaries of thermal management capabilities, enabling the next generation of high-performance microelectronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!