How Silicone Rubber Supports Long-Lasting Thermal Control Systems?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Thermal Control: Background and Objectives

Silicone rubber has emerged as a crucial material in the development of long-lasting thermal control systems. Its unique properties and versatility have positioned it at the forefront of technological advancements in this field. The evolution of silicone rubber in thermal management can be traced back to the mid-20th century when its potential for heat resistance and stability was first recognized.

Over the decades, silicone rubber has undergone significant improvements in its formulation and manufacturing processes. These advancements have led to enhanced thermal conductivity, improved durability, and increased resistance to extreme temperatures. The material's ability to maintain its properties over extended periods has made it an ideal choice for applications requiring long-term thermal stability.

The primary objective in utilizing silicone rubber for thermal control systems is to achieve efficient and reliable heat management in various industries. This includes aerospace, automotive, electronics, and energy sectors, where maintaining optimal operating temperatures is critical for system performance and longevity. Silicone rubber's low thermal conductivity, coupled with its ability to be engineered for specific thermal properties, allows for precise temperature regulation in complex environments.

Another key goal is to develop sustainable and environmentally friendly thermal management solutions. Silicone rubber's long lifespan and recyclability contribute to reducing waste and environmental impact. Additionally, its non-toxic nature aligns with growing demands for safer materials in consumer and industrial applications.

The technological trajectory of silicone rubber in thermal control systems is focused on enhancing its thermal conductivity while maintaining its inherent flexibility and durability. Research efforts are directed towards developing composite materials that incorporate silicone rubber with other thermally conductive substances, such as ceramics or metal particles. These innovations aim to create materials that can efficiently dissipate heat while retaining the beneficial properties of silicone rubber.

Furthermore, the integration of smart technologies with silicone rubber-based thermal control systems is an emerging trend. This includes the development of self-regulating materials that can adapt to changing thermal conditions, as well as the incorporation of sensors for real-time temperature monitoring and control. These advancements are expected to revolutionize thermal management strategies across various industries, leading to more efficient and responsive systems.

As we look towards the future, the role of silicone rubber in thermal control systems is poised to expand further. The ongoing research and development in this field are likely to yield new applications and improved performance characteristics, cementing silicone rubber's position as a cornerstone material in long-lasting thermal management solutions.

Over the decades, silicone rubber has undergone significant improvements in its formulation and manufacturing processes. These advancements have led to enhanced thermal conductivity, improved durability, and increased resistance to extreme temperatures. The material's ability to maintain its properties over extended periods has made it an ideal choice for applications requiring long-term thermal stability.

The primary objective in utilizing silicone rubber for thermal control systems is to achieve efficient and reliable heat management in various industries. This includes aerospace, automotive, electronics, and energy sectors, where maintaining optimal operating temperatures is critical for system performance and longevity. Silicone rubber's low thermal conductivity, coupled with its ability to be engineered for specific thermal properties, allows for precise temperature regulation in complex environments.

Another key goal is to develop sustainable and environmentally friendly thermal management solutions. Silicone rubber's long lifespan and recyclability contribute to reducing waste and environmental impact. Additionally, its non-toxic nature aligns with growing demands for safer materials in consumer and industrial applications.

The technological trajectory of silicone rubber in thermal control systems is focused on enhancing its thermal conductivity while maintaining its inherent flexibility and durability. Research efforts are directed towards developing composite materials that incorporate silicone rubber with other thermally conductive substances, such as ceramics or metal particles. These innovations aim to create materials that can efficiently dissipate heat while retaining the beneficial properties of silicone rubber.

Furthermore, the integration of smart technologies with silicone rubber-based thermal control systems is an emerging trend. This includes the development of self-regulating materials that can adapt to changing thermal conditions, as well as the incorporation of sensors for real-time temperature monitoring and control. These advancements are expected to revolutionize thermal management strategies across various industries, leading to more efficient and responsive systems.

As we look towards the future, the role of silicone rubber in thermal control systems is poised to expand further. The ongoing research and development in this field are likely to yield new applications and improved performance characteristics, cementing silicone rubber's position as a cornerstone material in long-lasting thermal management solutions.

Market Analysis for Silicone-Based Thermal Management Solutions

The market for silicone-based thermal management solutions is experiencing significant growth, driven by the increasing demand for efficient heat dissipation in various industries. The global thermal management market is projected to reach $20.7 billion by 2026, with silicone-based solutions playing a crucial role in this expansion. The automotive sector, in particular, is a major contributor to this growth, as electric vehicles require advanced thermal management systems to maintain optimal battery performance and longevity.

In the electronics industry, the miniaturization of devices and the rise of high-performance computing have created a pressing need for effective thermal management. Silicone-based solutions are gaining traction due to their superior thermal conductivity, flexibility, and durability. The aerospace and defense sectors are also adopting silicone-based thermal management systems to address the challenges of extreme temperature fluctuations in aircraft and military equipment.

The healthcare industry is another key market for silicone-based thermal management solutions. Medical devices, such as imaging equipment and surgical instruments, require precise temperature control to ensure optimal performance and patient safety. Silicone's biocompatibility and thermal stability make it an ideal choice for these applications.

Geographically, Asia-Pacific is expected to dominate the market, with China and India leading the growth. The region's rapid industrialization, coupled with the increasing adoption of electric vehicles and consumer electronics, is driving the demand for advanced thermal management solutions. North America and Europe are also significant markets, particularly in the aerospace and automotive sectors.

The market is characterized by intense competition among key players such as Dow Corning, Henkel, and 3M. These companies are investing heavily in research and development to create innovative silicone-based thermal management products. The trend towards customized solutions tailored to specific industry needs is becoming increasingly prevalent.

Emerging technologies, such as 5G networks and Internet of Things (IoT) devices, are expected to create new opportunities for silicone-based thermal management solutions. The growing focus on energy efficiency and sustainability is also driving the adoption of these materials, as they can help reduce overall energy consumption in various applications.

However, the market faces challenges such as the high initial cost of silicone-based solutions compared to traditional materials. Additionally, the volatility of raw material prices and the need for specialized manufacturing processes can impact market growth. Despite these challenges, the long-term benefits of silicone-based thermal management solutions, including their durability and performance in extreme conditions, continue to drive market expansion across multiple industries.

In the electronics industry, the miniaturization of devices and the rise of high-performance computing have created a pressing need for effective thermal management. Silicone-based solutions are gaining traction due to their superior thermal conductivity, flexibility, and durability. The aerospace and defense sectors are also adopting silicone-based thermal management systems to address the challenges of extreme temperature fluctuations in aircraft and military equipment.

The healthcare industry is another key market for silicone-based thermal management solutions. Medical devices, such as imaging equipment and surgical instruments, require precise temperature control to ensure optimal performance and patient safety. Silicone's biocompatibility and thermal stability make it an ideal choice for these applications.

Geographically, Asia-Pacific is expected to dominate the market, with China and India leading the growth. The region's rapid industrialization, coupled with the increasing adoption of electric vehicles and consumer electronics, is driving the demand for advanced thermal management solutions. North America and Europe are also significant markets, particularly in the aerospace and automotive sectors.

The market is characterized by intense competition among key players such as Dow Corning, Henkel, and 3M. These companies are investing heavily in research and development to create innovative silicone-based thermal management products. The trend towards customized solutions tailored to specific industry needs is becoming increasingly prevalent.

Emerging technologies, such as 5G networks and Internet of Things (IoT) devices, are expected to create new opportunities for silicone-based thermal management solutions. The growing focus on energy efficiency and sustainability is also driving the adoption of these materials, as they can help reduce overall energy consumption in various applications.

However, the market faces challenges such as the high initial cost of silicone-based solutions compared to traditional materials. Additionally, the volatility of raw material prices and the need for specialized manufacturing processes can impact market growth. Despite these challenges, the long-term benefits of silicone-based thermal management solutions, including their durability and performance in extreme conditions, continue to drive market expansion across multiple industries.

Current Challenges in Long-Lasting Thermal Control Systems

Long-lasting thermal control systems face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the degradation of materials over time, particularly in extreme temperature environments. Silicone rubber, while offering excellent thermal properties, can experience changes in its physical and chemical structure when exposed to prolonged heat or cold cycles.

The maintenance of consistent thermal conductivity poses another major challenge. As systems age, their ability to efficiently transfer heat can diminish, leading to reduced overall performance. This is especially problematic in applications requiring precise temperature control, such as in aerospace or industrial processes.

Thermal expansion and contraction cycles present a significant strain on the integrity of thermal control systems. The repeated stress can lead to micro-cracks, delamination, or other structural defects that compromise the system's effectiveness. Silicone rubber's flexibility helps mitigate some of these issues, but long-term solutions are still needed to address fatigue and wear.

Environmental factors such as UV radiation, moisture, and chemical exposure can accelerate the degradation of thermal control materials. While silicone rubber exhibits good resistance to many of these factors, prolonged exposure can still lead to material breakdown and reduced efficiency.

The challenge of achieving uniform heat distribution across large surfaces or complex geometries remains a significant hurdle. Hotspots or cold zones can develop over time, leading to localized failures or reduced overall system performance. Advanced design techniques and material innovations are required to address this issue effectively.

Cost-effectiveness and scalability present ongoing challenges for long-lasting thermal control systems. While silicone rubber offers many advantages, balancing performance with economic viability for large-scale applications remains a key consideration for manufacturers and end-users alike.

Integration with other systems and materials can also be problematic. Ensuring compatibility and maintaining thermal performance at interface points between different materials or subsystems is crucial for overall system longevity and efficiency.

Finally, the development of reliable predictive models and accelerated aging tests for long-term performance remains an ongoing challenge. Accurately forecasting the behavior of thermal control systems over extended periods is essential for design optimization and lifecycle management, but current methods often fall short in capturing the full complexity of real-world conditions.

The maintenance of consistent thermal conductivity poses another major challenge. As systems age, their ability to efficiently transfer heat can diminish, leading to reduced overall performance. This is especially problematic in applications requiring precise temperature control, such as in aerospace or industrial processes.

Thermal expansion and contraction cycles present a significant strain on the integrity of thermal control systems. The repeated stress can lead to micro-cracks, delamination, or other structural defects that compromise the system's effectiveness. Silicone rubber's flexibility helps mitigate some of these issues, but long-term solutions are still needed to address fatigue and wear.

Environmental factors such as UV radiation, moisture, and chemical exposure can accelerate the degradation of thermal control materials. While silicone rubber exhibits good resistance to many of these factors, prolonged exposure can still lead to material breakdown and reduced efficiency.

The challenge of achieving uniform heat distribution across large surfaces or complex geometries remains a significant hurdle. Hotspots or cold zones can develop over time, leading to localized failures or reduced overall system performance. Advanced design techniques and material innovations are required to address this issue effectively.

Cost-effectiveness and scalability present ongoing challenges for long-lasting thermal control systems. While silicone rubber offers many advantages, balancing performance with economic viability for large-scale applications remains a key consideration for manufacturers and end-users alike.

Integration with other systems and materials can also be problematic. Ensuring compatibility and maintaining thermal performance at interface points between different materials or subsystems is crucial for overall system longevity and efficiency.

Finally, the development of reliable predictive models and accelerated aging tests for long-term performance remains an ongoing challenge. Accurately forecasting the behavior of thermal control systems over extended periods is essential for design optimization and lifecycle management, but current methods often fall short in capturing the full complexity of real-world conditions.

Existing Silicone-Based Thermal Control Solutions

01 Thermal management in electronic devices

Silicone rubber is used for thermal control in electronic devices, particularly in image forming apparatuses. It helps in efficient heat dissipation and temperature regulation, ensuring optimal performance and longevity of the components.- Composition of silicone rubber for thermal control: Silicone rubber compositions are developed with specific additives to enhance thermal control properties. These compositions may include fillers, cross-linking agents, and other modifiers to improve heat dissipation, thermal stability, and overall performance in temperature regulation applications.

- Manufacturing processes for thermally conductive silicone rubber: Various manufacturing techniques are employed to produce silicone rubber with enhanced thermal control capabilities. These processes may involve specialized mixing methods, curing procedures, and surface treatments to optimize the material's thermal conductivity and heat transfer properties.

- Application of silicone rubber in electronic thermal management: Silicone rubber is utilized in electronic devices for effective thermal management. It is applied as thermal interface materials, heat spreaders, or encapsulants to dissipate heat from electronic components, ensuring optimal performance and longevity of the devices.

- Integration of phase change materials in silicone rubber: Phase change materials are incorporated into silicone rubber matrices to enhance thermal control capabilities. This integration allows for improved temperature regulation through the absorption and release of latent heat during phase transitions, providing more efficient thermal management in various applications.

- Surface modification of silicone rubber for thermal control: Surface modification techniques are applied to silicone rubber to enhance its thermal control properties. These modifications may include the application of coatings, chemical treatments, or physical texturing to improve heat transfer, emissivity, or reflectivity of the silicone rubber surface.

02 Composition of thermally conductive silicone rubber

Thermally conductive silicone rubber compositions are developed by incorporating specific fillers and additives. These formulations enhance the material's heat transfer properties while maintaining its flexibility and electrical insulation characteristics.Expand Specific Solutions03 Application in aerospace and automotive industries

Silicone rubber with thermal control properties finds applications in aerospace and automotive industries. It is used for insulation, sealing, and thermal management in extreme temperature conditions, improving overall system efficiency and reliability.Expand Specific Solutions04 Integration with phase change materials

Silicone rubber is combined with phase change materials to create advanced thermal management solutions. This integration allows for better temperature regulation and energy storage capabilities in various applications.Expand Specific Solutions05 Manufacturing processes for thermal control silicone rubber

Specialized manufacturing processes are developed to produce silicone rubber with enhanced thermal control properties. These processes focus on achieving uniform dispersion of fillers, optimizing curing conditions, and ensuring consistent thermal performance across the material.Expand Specific Solutions

Key Players in Silicone Rubber and Thermal Control Industries

The market for silicone rubber in thermal control systems is in a growth phase, driven by increasing demand across industries like electronics, automotive, and aerospace. The global silicone rubber market size is projected to reach over $10 billion by 2027, with thermal management applications as a key growth driver. Technologically, silicone rubber for thermal control is relatively mature, with ongoing innovations focused on enhancing performance and durability. Key players like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie are leading development efforts, while companies such as Apple and Aptiv are driving demand through applications in consumer electronics and automotive thermal management systems.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds specifically designed for thermal management in long-lasting control systems. Their proprietary formulations incorporate high thermal conductivity fillers and optimized cross-linking structures to enhance heat dissipation capabilities[1]. The company's silicone rubber products feature excellent thermal stability, maintaining their properties over a wide temperature range (-50°C to 200°C) for extended periods[2]. Shin-Etsu's silicone elastomers also exhibit low compression set and minimal outgassing, ensuring consistent performance in sealed thermal control applications[3]. Their materials are engineered to provide effective heat transfer while maintaining electrical insulation properties, making them ideal for use in power electronics and automotive thermal management systems[4].

Strengths: Superior thermal conductivity, excellent long-term stability, and versatility in various thermal control applications. Weaknesses: Higher cost compared to conventional rubbers, potential for lower mechanical strength in some formulations.

Dow Silicones Corp.

Technical Solution: Dow Silicones has developed a range of silicone rubber solutions tailored for long-lasting thermal control systems. Their SILASTIC™ brand of silicone elastomers incorporates advanced thermal management technologies, including thermally conductive fillers and optimized polymer structures[1]. These materials offer excellent heat dissipation properties, with thermal conductivities ranging from 0.7 to 3.0 W/mK[2]. Dow's silicone rubbers maintain their flexibility and performance over a wide temperature range (-45°C to 200°C) and demonstrate exceptional resistance to thermal cycling and aging[3]. The company's products also feature low volatility and minimal outgassing, making them suitable for sealed thermal management applications in electronics and automotive industries[4]. Dow's silicone rubbers can be customized to meet specific thermal and mechanical requirements, allowing for optimized performance in various thermal control system designs[5].

Strengths: High thermal conductivity, excellent long-term stability, and customizable properties. Weaknesses: Potentially higher cost than traditional materials, may require specialized processing techniques.

Innovative Silicone Rubber Formulations for Thermal Stability

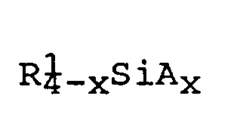

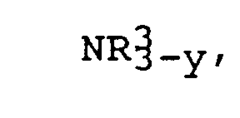

Addition-curable compositions for the provision of heat-stable silicone rubber

PatentInactiveEP0668325A1

Innovation

- Incorporation of palladium-containing heat stabilizers into addition-crosslinking silicone rubber compositions, which provide enhanced thermal stability by maintaining mechanical properties such as Shore A hardness, tear strength, and dynamic modulus under compression deformation, even at elevated temperatures.

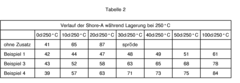

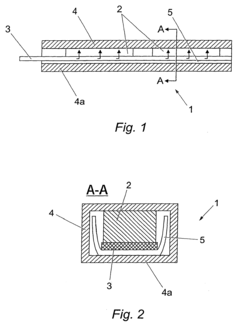

Heating device

PatentInactiveEP1666286A1

Innovation

- A heating device employing a flexible and heat-conductive silicone rubber insulating sheet between the contact sheet and the housing to ensure electrical insulation while enhancing thermal energy transfer and durability.

Environmental Impact of Silicone Rubber in Thermal Systems

The environmental impact of silicone rubber in thermal control systems is a crucial consideration for long-term sustainability. Silicone rubber, while offering excellent thermal properties, presents both advantages and challenges in terms of its ecological footprint.

One of the primary environmental benefits of silicone rubber in thermal systems is its durability and longevity. The material's resistance to degradation under extreme temperatures and harsh conditions means that thermal control systems using silicone rubber require less frequent replacement. This longevity reduces the overall consumption of resources and energy associated with manufacturing and replacing components.

However, the production of silicone rubber does have environmental implications. The process involves the use of fossil fuels and energy-intensive manufacturing techniques. The extraction of silica, a primary raw material for silicone production, can lead to habitat disruption and soil erosion if not managed responsibly.

On the positive side, silicone rubber is inert and non-toxic, which minimizes its impact on ecosystems during its use phase. Unlike some other materials used in thermal systems, silicone rubber does not leach harmful chemicals into the environment, making it a safer choice for applications in sensitive areas.

End-of-life considerations for silicone rubber in thermal systems present both challenges and opportunities. While silicone rubber is not biodegradable, it can be recycled through specialized processes. Advanced recycling technologies are being developed to recover and reuse silicone materials, potentially reducing the environmental impact of disposal.

The thermal efficiency of silicone rubber also contributes to its environmental profile. Its excellent insulating properties can lead to improved energy efficiency in thermal control systems, potentially reducing overall energy consumption and associated carbon emissions throughout the system's lifecycle.

In terms of carbon footprint, the production of silicone rubber does generate greenhouse gas emissions. However, when considering the entire lifecycle of thermal control systems, the extended lifespan and energy efficiency benefits of silicone rubber may offset initial production emissions.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing more sustainable production methods for silicone rubber. This includes exploring bio-based alternatives and improving energy efficiency in manufacturing processes to reduce the overall environmental impact.

In conclusion, while silicone rubber in thermal control systems does have some environmental drawbacks, particularly in its production phase, its long-term durability, efficiency, and potential for recycling offer significant environmental benefits. Ongoing research and development in sustainable manufacturing and recycling technologies are likely to further improve its environmental profile in the future.

One of the primary environmental benefits of silicone rubber in thermal systems is its durability and longevity. The material's resistance to degradation under extreme temperatures and harsh conditions means that thermal control systems using silicone rubber require less frequent replacement. This longevity reduces the overall consumption of resources and energy associated with manufacturing and replacing components.

However, the production of silicone rubber does have environmental implications. The process involves the use of fossil fuels and energy-intensive manufacturing techniques. The extraction of silica, a primary raw material for silicone production, can lead to habitat disruption and soil erosion if not managed responsibly.

On the positive side, silicone rubber is inert and non-toxic, which minimizes its impact on ecosystems during its use phase. Unlike some other materials used in thermal systems, silicone rubber does not leach harmful chemicals into the environment, making it a safer choice for applications in sensitive areas.

End-of-life considerations for silicone rubber in thermal systems present both challenges and opportunities. While silicone rubber is not biodegradable, it can be recycled through specialized processes. Advanced recycling technologies are being developed to recover and reuse silicone materials, potentially reducing the environmental impact of disposal.

The thermal efficiency of silicone rubber also contributes to its environmental profile. Its excellent insulating properties can lead to improved energy efficiency in thermal control systems, potentially reducing overall energy consumption and associated carbon emissions throughout the system's lifecycle.

In terms of carbon footprint, the production of silicone rubber does generate greenhouse gas emissions. However, when considering the entire lifecycle of thermal control systems, the extended lifespan and energy efficiency benefits of silicone rubber may offset initial production emissions.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing more sustainable production methods for silicone rubber. This includes exploring bio-based alternatives and improving energy efficiency in manufacturing processes to reduce the overall environmental impact.

In conclusion, while silicone rubber in thermal control systems does have some environmental drawbacks, particularly in its production phase, its long-term durability, efficiency, and potential for recycling offer significant environmental benefits. Ongoing research and development in sustainable manufacturing and recycling technologies are likely to further improve its environmental profile in the future.

Cost-Benefit Analysis of Silicone-Based Thermal Solutions

The cost-benefit analysis of silicone-based thermal solutions reveals a compelling case for their adoption in long-lasting thermal control systems. Initially, the upfront costs of silicone rubber components may appear higher compared to traditional materials. However, when considering the total cost of ownership over the system's lifecycle, silicone-based solutions often prove more economical.

Silicone rubber's exceptional durability significantly extends the lifespan of thermal control systems, reducing the frequency and costs associated with replacements and maintenance. This longevity translates to lower long-term expenses and minimized system downtime, which is particularly valuable in critical applications where continuous operation is essential.

The material's resistance to extreme temperatures, UV radiation, and chemical exposure further contributes to its cost-effectiveness. These properties ensure consistent performance in harsh environments, reducing the need for premature replacements due to material degradation. Additionally, silicone rubber's flexibility and ease of installation can lead to reduced labor costs during system assembly and maintenance.

Energy efficiency is another crucial factor in the cost-benefit equation. Silicone-based thermal solutions often exhibit superior thermal management properties, potentially leading to improved overall system efficiency. This can result in reduced energy consumption and associated costs over the system's operational life.

While the initial investment may be higher, the long-term benefits of silicone-based thermal solutions often outweigh the costs. Improved reliability, reduced maintenance requirements, and enhanced system performance contribute to a lower total cost of ownership. Furthermore, the extended lifespan of silicone-based systems aligns with sustainability goals, potentially offering additional value through reduced environmental impact and improved corporate social responsibility.

It's important to note that the exact cost-benefit ratio can vary depending on the specific application, operating conditions, and system requirements. A thorough analysis considering factors such as expected lifespan, maintenance schedules, energy costs, and potential downtime should be conducted for each unique scenario to determine the most cost-effective solution.

Silicone rubber's exceptional durability significantly extends the lifespan of thermal control systems, reducing the frequency and costs associated with replacements and maintenance. This longevity translates to lower long-term expenses and minimized system downtime, which is particularly valuable in critical applications where continuous operation is essential.

The material's resistance to extreme temperatures, UV radiation, and chemical exposure further contributes to its cost-effectiveness. These properties ensure consistent performance in harsh environments, reducing the need for premature replacements due to material degradation. Additionally, silicone rubber's flexibility and ease of installation can lead to reduced labor costs during system assembly and maintenance.

Energy efficiency is another crucial factor in the cost-benefit equation. Silicone-based thermal solutions often exhibit superior thermal management properties, potentially leading to improved overall system efficiency. This can result in reduced energy consumption and associated costs over the system's operational life.

While the initial investment may be higher, the long-term benefits of silicone-based thermal solutions often outweigh the costs. Improved reliability, reduced maintenance requirements, and enhanced system performance contribute to a lower total cost of ownership. Furthermore, the extended lifespan of silicone-based systems aligns with sustainability goals, potentially offering additional value through reduced environmental impact and improved corporate social responsibility.

It's important to note that the exact cost-benefit ratio can vary depending on the specific application, operating conditions, and system requirements. A thorough analysis considering factors such as expected lifespan, maintenance schedules, energy costs, and potential downtime should be conducted for each unique scenario to determine the most cost-effective solution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!