How To Benchmark Photocell Performance Across Manufacturers

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocell Benchmarking Background and Objectives

Photocells, also known as photoelectric cells or photoresistors, have been integral components in various electronic applications for decades. These light-sensitive devices have evolved significantly since their inception, with advancements in materials science and manufacturing techniques leading to improved performance and reliability. The technology's progression has been driven by the increasing demand for precise light detection and measurement across diverse industries, including automotive, aerospace, consumer electronics, and environmental monitoring.

The primary objective of benchmarking photocell performance across manufacturers is to establish a standardized methodology for evaluating and comparing the capabilities of different photocell products. This process is crucial for engineers, product designers, and researchers who need to select the most suitable photocell for their specific applications. By developing a comprehensive benchmarking framework, stakeholders can make informed decisions based on objective data, ensuring optimal performance and cost-effectiveness in their designs.

The evolution of photocell technology has led to a wide array of products with varying specifications and performance characteristics. Manufacturers often employ proprietary materials and manufacturing processes, resulting in photocells with distinct properties. This diversity in the market necessitates a systematic approach to benchmarking, enabling fair and accurate comparisons between different manufacturers' offerings.

Key parameters that typically require evaluation in photocell benchmarking include spectral response, sensitivity, response time, dark resistance, and temperature coefficient. These factors collectively determine a photocell's overall performance and suitability for specific applications. Additionally, long-term stability, reliability under various environmental conditions, and consistency across production batches are critical aspects that need to be assessed to ensure the photocell's effectiveness throughout its operational lifetime.

The benchmarking process aims to address several challenges inherent in comparing photocells from different manufacturers. These challenges include variations in testing methodologies, differences in reported specifications, and the impact of environmental factors on performance. By establishing a standardized benchmarking protocol, the industry can overcome these hurdles and provide a level playing field for evaluating photocell performance.

Furthermore, benchmarking photocell performance across manufacturers contributes to the overall advancement of the technology. It encourages healthy competition among manufacturers, driving innovation and continuous improvement in photocell design and manufacturing processes. This, in turn, benefits end-users by providing access to higher-quality, more reliable photocells that meet the evolving demands of modern applications.

In conclusion, the background and objectives of photocell benchmarking underscore its importance in the rapidly advancing field of optoelectronics. By establishing a robust framework for performance evaluation, the industry can foster innovation, improve product quality, and ultimately enhance the capabilities of light-sensitive technologies across various sectors.

The primary objective of benchmarking photocell performance across manufacturers is to establish a standardized methodology for evaluating and comparing the capabilities of different photocell products. This process is crucial for engineers, product designers, and researchers who need to select the most suitable photocell for their specific applications. By developing a comprehensive benchmarking framework, stakeholders can make informed decisions based on objective data, ensuring optimal performance and cost-effectiveness in their designs.

The evolution of photocell technology has led to a wide array of products with varying specifications and performance characteristics. Manufacturers often employ proprietary materials and manufacturing processes, resulting in photocells with distinct properties. This diversity in the market necessitates a systematic approach to benchmarking, enabling fair and accurate comparisons between different manufacturers' offerings.

Key parameters that typically require evaluation in photocell benchmarking include spectral response, sensitivity, response time, dark resistance, and temperature coefficient. These factors collectively determine a photocell's overall performance and suitability for specific applications. Additionally, long-term stability, reliability under various environmental conditions, and consistency across production batches are critical aspects that need to be assessed to ensure the photocell's effectiveness throughout its operational lifetime.

The benchmarking process aims to address several challenges inherent in comparing photocells from different manufacturers. These challenges include variations in testing methodologies, differences in reported specifications, and the impact of environmental factors on performance. By establishing a standardized benchmarking protocol, the industry can overcome these hurdles and provide a level playing field for evaluating photocell performance.

Furthermore, benchmarking photocell performance across manufacturers contributes to the overall advancement of the technology. It encourages healthy competition among manufacturers, driving innovation and continuous improvement in photocell design and manufacturing processes. This, in turn, benefits end-users by providing access to higher-quality, more reliable photocells that meet the evolving demands of modern applications.

In conclusion, the background and objectives of photocell benchmarking underscore its importance in the rapidly advancing field of optoelectronics. By establishing a robust framework for performance evaluation, the industry can foster innovation, improve product quality, and ultimately enhance the capabilities of light-sensitive technologies across various sectors.

Market Demand for Standardized Photocell Testing

The market demand for standardized photocell testing has been steadily increasing in recent years, driven by the growing adoption of photocells in various industries and applications. Photocells, also known as photoelectric cells or photoresistors, are crucial components in many electronic devices and systems, including lighting controls, security systems, and industrial automation equipment.

As the global market for photocells continues to expand, manufacturers, consumers, and regulatory bodies are increasingly recognizing the need for reliable and consistent performance benchmarking across different manufacturers. This demand stems from several key factors that impact the industry and its stakeholders.

Firstly, the lack of standardized testing methods has led to inconsistencies in reported performance metrics among different manufacturers. This discrepancy makes it challenging for consumers to make informed decisions when selecting photocells for their specific applications. Standardized testing would enable fair comparisons and promote transparency in the market, ultimately benefiting end-users by ensuring they receive products that meet their performance requirements.

Secondly, the growing emphasis on energy efficiency and sustainability has heightened the importance of accurate photocell performance data. Many applications, particularly in lighting control systems, rely on photocells to optimize energy consumption. Without standardized testing, it becomes difficult to accurately predict and compare the energy-saving potential of different photocell-based solutions, hindering efforts to improve overall system efficiency.

Furthermore, the increasing complexity of photocell applications in emerging technologies, such as smart cities and Internet of Things (IoT) devices, has raised the stakes for reliable performance. These advanced applications often require precise and consistent photocell operation to ensure the proper functioning of larger integrated systems. Standardized testing would help validate the suitability of photocells for these demanding applications and support the development of more robust and reliable solutions.

The demand for standardized testing is also driven by regulatory requirements and industry standards. As governments and organizations worldwide implement stricter energy efficiency regulations and performance standards, the need for consistent and reliable photocell testing becomes more critical. Standardized benchmarking would facilitate compliance with these regulations and help manufacturers demonstrate the quality and performance of their products.

Lastly, the globalization of the photocell market has intensified competition among manufacturers. Standardized testing would level the playing field, allowing companies to compete based on genuine performance metrics rather than potentially misleading marketing claims. This would foster innovation and drive improvements in photocell technology, ultimately benefiting the entire industry and its customers.

As the global market for photocells continues to expand, manufacturers, consumers, and regulatory bodies are increasingly recognizing the need for reliable and consistent performance benchmarking across different manufacturers. This demand stems from several key factors that impact the industry and its stakeholders.

Firstly, the lack of standardized testing methods has led to inconsistencies in reported performance metrics among different manufacturers. This discrepancy makes it challenging for consumers to make informed decisions when selecting photocells for their specific applications. Standardized testing would enable fair comparisons and promote transparency in the market, ultimately benefiting end-users by ensuring they receive products that meet their performance requirements.

Secondly, the growing emphasis on energy efficiency and sustainability has heightened the importance of accurate photocell performance data. Many applications, particularly in lighting control systems, rely on photocells to optimize energy consumption. Without standardized testing, it becomes difficult to accurately predict and compare the energy-saving potential of different photocell-based solutions, hindering efforts to improve overall system efficiency.

Furthermore, the increasing complexity of photocell applications in emerging technologies, such as smart cities and Internet of Things (IoT) devices, has raised the stakes for reliable performance. These advanced applications often require precise and consistent photocell operation to ensure the proper functioning of larger integrated systems. Standardized testing would help validate the suitability of photocells for these demanding applications and support the development of more robust and reliable solutions.

The demand for standardized testing is also driven by regulatory requirements and industry standards. As governments and organizations worldwide implement stricter energy efficiency regulations and performance standards, the need for consistent and reliable photocell testing becomes more critical. Standardized benchmarking would facilitate compliance with these regulations and help manufacturers demonstrate the quality and performance of their products.

Lastly, the globalization of the photocell market has intensified competition among manufacturers. Standardized testing would level the playing field, allowing companies to compete based on genuine performance metrics rather than potentially misleading marketing claims. This would foster innovation and drive improvements in photocell technology, ultimately benefiting the entire industry and its customers.

Current Challenges in Photocell Performance Evaluation

The evaluation of photocell performance across different manufacturers presents several significant challenges in the current technological landscape. One of the primary obstacles is the lack of standardized testing protocols and metrics. Different manufacturers often employ varying methodologies to assess their photocells, making direct comparisons difficult and potentially misleading.

The diversity in photocell designs and materials further complicates the benchmarking process. Manufacturers utilize a wide range of semiconductor materials, such as silicon, germanium, and gallium arsenide, each with distinct properties and performance characteristics. This variability makes it challenging to establish a universal set of parameters for comparison.

Environmental factors play a crucial role in photocell performance, yet controlling these variables across different testing environments remains a significant hurdle. Factors such as temperature, humidity, and light intensity can significantly impact photocell efficiency and response times. Ensuring consistent testing conditions across various manufacturing facilities and geographical locations is a complex task that often leads to discrepancies in reported performance data.

The rapid pace of technological advancements in photocell design and manufacturing processes adds another layer of complexity to the benchmarking challenge. As new materials and fabrication techniques emerge, existing performance metrics may become obsolete or inadequate for evaluating cutting-edge photocells. This constant evolution necessitates regular updates to benchmarking methodologies, which can be time-consuming and resource-intensive.

Accuracy and reliability of measurement equipment pose additional challenges. High-precision instruments are required to measure subtle differences in photocell performance, but the calibration and maintenance of such equipment across different manufacturers can vary, leading to inconsistencies in data collection and analysis.

The issue of proprietary technologies and trade secrets further complicates the benchmarking process. Manufacturers may be reluctant to disclose detailed information about their photocell designs or manufacturing processes, limiting the depth and accuracy of comparative analyses. This lack of transparency can hinder efforts to establish comprehensive and fair benchmarking standards.

Lastly, the diverse range of applications for photocells, from simple light detection to complex imaging systems, makes it challenging to develop a one-size-fits-all benchmarking approach. Performance criteria that are critical for one application may be less relevant for another, necessitating the development of application-specific benchmarking methodologies. This diversity in end-use requirements adds another layer of complexity to the already challenging task of creating standardized performance evaluation metrics across manufacturers.

The diversity in photocell designs and materials further complicates the benchmarking process. Manufacturers utilize a wide range of semiconductor materials, such as silicon, germanium, and gallium arsenide, each with distinct properties and performance characteristics. This variability makes it challenging to establish a universal set of parameters for comparison.

Environmental factors play a crucial role in photocell performance, yet controlling these variables across different testing environments remains a significant hurdle. Factors such as temperature, humidity, and light intensity can significantly impact photocell efficiency and response times. Ensuring consistent testing conditions across various manufacturing facilities and geographical locations is a complex task that often leads to discrepancies in reported performance data.

The rapid pace of technological advancements in photocell design and manufacturing processes adds another layer of complexity to the benchmarking challenge. As new materials and fabrication techniques emerge, existing performance metrics may become obsolete or inadequate for evaluating cutting-edge photocells. This constant evolution necessitates regular updates to benchmarking methodologies, which can be time-consuming and resource-intensive.

Accuracy and reliability of measurement equipment pose additional challenges. High-precision instruments are required to measure subtle differences in photocell performance, but the calibration and maintenance of such equipment across different manufacturers can vary, leading to inconsistencies in data collection and analysis.

The issue of proprietary technologies and trade secrets further complicates the benchmarking process. Manufacturers may be reluctant to disclose detailed information about their photocell designs or manufacturing processes, limiting the depth and accuracy of comparative analyses. This lack of transparency can hinder efforts to establish comprehensive and fair benchmarking standards.

Lastly, the diverse range of applications for photocells, from simple light detection to complex imaging systems, makes it challenging to develop a one-size-fits-all benchmarking approach. Performance criteria that are critical for one application may be less relevant for another, necessitating the development of application-specific benchmarking methodologies. This diversity in end-use requirements adds another layer of complexity to the already challenging task of creating standardized performance evaluation metrics across manufacturers.

Existing Photocell Benchmarking Techniques

01 Improved photocell sensitivity and performance

Various techniques are employed to enhance the sensitivity and overall performance of photocells. These include optimizing the semiconductor materials, improving the light-capturing surface area, and implementing advanced manufacturing processes. Such improvements result in increased efficiency and responsiveness to light, making photocells more effective in various applications.- Improved photocell sensitivity and efficiency: Various techniques are employed to enhance the sensitivity and efficiency of photocells. These include optimizing the semiconductor materials, improving the light absorption properties, and refining the cell structure. Such advancements lead to better performance in low-light conditions and increased overall energy conversion efficiency.

- Integration of photocells with optical systems: Photocells are integrated with various optical systems to improve their performance and functionality. This includes combining photocells with lenses, mirrors, or other light-focusing elements to concentrate light and enhance signal detection. Such integrations are particularly useful in applications requiring high precision or operation in challenging environments.

- Temperature compensation in photocell circuits: Temperature fluctuations can significantly affect photocell performance. To address this, various temperature compensation techniques are implemented in photocell circuits. These may include the use of thermistors, specialized circuit designs, or software-based corrections to maintain consistent performance across a wide temperature range.

- Photocell array configurations for improved performance: Multiple photocells are arranged in array configurations to enhance overall system performance. These arrays can be designed for specific applications, such as increased sensitivity, wider spectral response, or improved spatial resolution. The arrangement and interconnection of individual cells within the array are optimized to achieve desired performance characteristics.

- Signal processing and noise reduction techniques: Advanced signal processing and noise reduction techniques are applied to improve photocell performance. These may include analog or digital filtering, signal amplification, and adaptive algorithms to enhance signal-to-noise ratios. Such techniques enable photocells to operate effectively in challenging environments or when detecting weak signals.

02 Integration of photocells in imaging systems

Photocells are integrated into imaging systems to improve image quality and light detection capabilities. This integration involves incorporating photocells into sensor arrays, developing specialized readout circuits, and implementing signal processing techniques. These advancements enhance the performance of cameras, scanners, and other imaging devices.Expand Specific Solutions03 Photocell performance in specific lighting conditions

Research focuses on optimizing photocell performance under various lighting conditions, such as low light, high intensity, or specific wavelengths. This involves developing specialized coatings, filters, and circuit designs to enhance sensitivity and accuracy in challenging environments. These improvements expand the range of applications for photocells in different industries.Expand Specific Solutions04 Energy harvesting and power management in photocells

Advancements in photocell technology focus on improving energy harvesting capabilities and power management. This includes developing more efficient charge storage mechanisms, implementing smart power distribution systems, and optimizing the overall energy conversion process. These innovations lead to improved performance and longer operational life in solar-powered devices and systems.Expand Specific Solutions05 Miniaturization and integration of photocells

Efforts are made to miniaturize photocells and integrate them into compact devices. This involves developing new manufacturing techniques, exploring novel materials, and designing efficient packaging solutions. The miniaturization and integration of photocells enable their use in smaller, portable devices and expand their applications in various fields.Expand Specific Solutions

Key Players in Photocell Manufacturing and Testing

The photocell performance benchmarking market is in a mature stage, with established players and standardized testing methods. The global market size for photovoltaic testing equipment is estimated to be in the hundreds of millions of dollars, driven by the growing solar energy industry. Technologically, the field is well-developed, with companies like Trina Solar, First Solar, and SMA Solar Technology offering advanced testing solutions. Research institutions such as the National Institute of Advanced Industrial Science and Technology (AIST) and the Korea Institute of Energy Research contribute to ongoing improvements in measurement accuracy and efficiency. Emerging players like Tau Science Corp. are introducing innovative technologies, while traditional electronics giants like Panasonic and LG Chem also maintain a presence in this specialized market.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has established a comprehensive system for benchmarking photocell performance across manufacturers. Their approach integrates standardized testing protocols with large-scale production capabilities. Trina utilizes high-throughput testing lines that can rapidly assess thousands of cells, providing statistically significant data for benchmarking[10]. Their method includes both flash testing for efficiency measurements and electroluminescence imaging for defect detection. Trina has also developed in-house software for data analysis and comparison, allowing for quick identification of performance trends across different manufacturers and technologies. Additionally, they conduct accelerated aging tests to predict long-term performance and reliability, which is crucial for comparing cells from different sources[11]. Trina's benchmarking process also incorporates regular cross-validation with third-party testing laboratories to ensure accuracy and impartiality.

Strengths: Large-scale testing capabilities, integrated production and testing processes, and focus on long-term reliability assessment. Weaknesses: Potential for bias towards silicon-based technologies, given their primary focus on this type of cell.

Tau Science Corp.

Technical Solution: Tau Science Corp. has pioneered innovative techniques for benchmarking photocell performance. Their approach centers on their proprietary FlashQE system, which combines high-speed quantum efficiency measurements with electroluminescence imaging. This technology allows for rapid, non-destructive testing of photocells, providing detailed performance data in seconds rather than hours[4]. Tau Science's method includes simultaneous measurement of multiple cell parameters, including quantum efficiency, shunt resistance, and series resistance. They have also developed advanced software algorithms for data analysis and comparison, enabling precise benchmarking across different manufacturers and technologies[5]. Their system can detect subtle variations in cell quality and performance, making it particularly valuable for R&D and quality control applications.

Strengths: Rapid, non-destructive testing capabilities, comprehensive parameter measurement, and advanced data analysis. Weaknesses: Specialized equipment may be costly, potentially limiting accessibility for smaller manufacturers or research institutions.

Core Innovations in Photocell Performance Metrics

Method and apparatus for electroluminescence inspection and/or photoluminescence inspection

PatentInactiveEP2847577A1

Innovation

- The method involves recording luminescence-excited objects in at least two different spectral ranges using a multispectral approach with filters to enhance defect detection and classification, combined with the use of highly sensitive InGaAs cameras to reduce inspection time and improve signal-to-noise ratio.

Testing method of a solar cell panel, and testing apparatus thereof

PatentActiveUS20130314118A1

Innovation

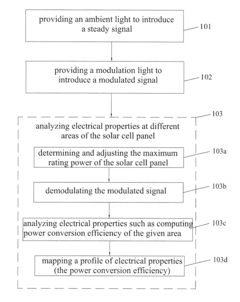

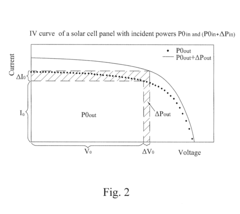

- A testing method and apparatus that uses ambient light and modulation light to analyze electrical properties of specific areas on solar cell panels, allowing for efficient detection of defects like short circuits by computing power conversion efficiency and mapping profiles, enabling accurate defect identification and correction.

Standardization Efforts in Photocell Industry

The photocell industry has recognized the need for standardized benchmarking methods to compare performance across different manufacturers. Several initiatives have been launched to address this challenge and establish uniform testing protocols and performance metrics.

The International Electrotechnical Commission (IEC) has been at the forefront of these efforts, developing standards such as IEC 60904 for photovoltaic devices. This series of standards provides guidelines for measuring photovoltaic cell characteristics, including spectral response, temperature coefficients, and current-voltage characteristics. These standards aim to create a level playing field for performance comparisons.

The National Institute of Standards and Technology (NIST) in the United States has also contributed significantly to photocell standardization. They have developed reference cells and calibration procedures that serve as benchmarks for the industry. NIST's efforts have focused on ensuring traceability and accuracy in photocell measurements, which is crucial for meaningful comparisons across manufacturers.

In Europe, the European Committee for Electrotechnical Standardization (CENELEC) has been working on harmonizing photocell standards across member countries. Their efforts have resulted in the EN 50530 standard, which specifies test procedures for evaluating the overall efficiency of photovoltaic inverters.

The International Organization for Standardization (ISO) has also played a role in photocell standardization through its technical committee ISO/TC 180 on solar energy. This committee has developed standards for solar simulators and reference solar devices, which are essential tools for consistent photocell performance evaluation.

Industry associations, such as the Solar Energy Industries Association (SEIA) and the European Photovoltaic Industry Association (EPIA), have been actively promoting the adoption of these standards among their members. They have organized workshops and training sessions to educate manufacturers on standardized testing procedures and the importance of compliance.

Despite these efforts, challenges remain in achieving full standardization across the industry. Differences in testing conditions, equipment calibration, and interpretation of results can still lead to discrepancies in reported performance metrics. Ongoing collaboration between standards organizations, manufacturers, and research institutions is necessary to refine existing standards and develop new ones as technology evolves.

The push for standardization has also extended to emerging photocell technologies, such as perovskite solar cells and multi-junction cells. As these technologies mature, new standards and testing protocols are being developed to ensure fair comparisons with traditional silicon-based photocells.

The International Electrotechnical Commission (IEC) has been at the forefront of these efforts, developing standards such as IEC 60904 for photovoltaic devices. This series of standards provides guidelines for measuring photovoltaic cell characteristics, including spectral response, temperature coefficients, and current-voltage characteristics. These standards aim to create a level playing field for performance comparisons.

The National Institute of Standards and Technology (NIST) in the United States has also contributed significantly to photocell standardization. They have developed reference cells and calibration procedures that serve as benchmarks for the industry. NIST's efforts have focused on ensuring traceability and accuracy in photocell measurements, which is crucial for meaningful comparisons across manufacturers.

In Europe, the European Committee for Electrotechnical Standardization (CENELEC) has been working on harmonizing photocell standards across member countries. Their efforts have resulted in the EN 50530 standard, which specifies test procedures for evaluating the overall efficiency of photovoltaic inverters.

The International Organization for Standardization (ISO) has also played a role in photocell standardization through its technical committee ISO/TC 180 on solar energy. This committee has developed standards for solar simulators and reference solar devices, which are essential tools for consistent photocell performance evaluation.

Industry associations, such as the Solar Energy Industries Association (SEIA) and the European Photovoltaic Industry Association (EPIA), have been actively promoting the adoption of these standards among their members. They have organized workshops and training sessions to educate manufacturers on standardized testing procedures and the importance of compliance.

Despite these efforts, challenges remain in achieving full standardization across the industry. Differences in testing conditions, equipment calibration, and interpretation of results can still lead to discrepancies in reported performance metrics. Ongoing collaboration between standards organizations, manufacturers, and research institutions is necessary to refine existing standards and develop new ones as technology evolves.

The push for standardization has also extended to emerging photocell technologies, such as perovskite solar cells and multi-junction cells. As these technologies mature, new standards and testing protocols are being developed to ensure fair comparisons with traditional silicon-based photocells.

Environmental Factors Affecting Photocell Benchmarking

Environmental factors play a crucial role in benchmarking photocell performance across manufacturers. These factors can significantly influence the accuracy and reliability of test results, making it essential to consider and control them during the benchmarking process.

Temperature is one of the most critical environmental factors affecting photocell performance. Photocells are sensitive to temperature variations, which can impact their electrical characteristics and overall efficiency. Higher temperatures typically lead to increased dark current and reduced sensitivity, while lower temperatures may improve performance but potentially cause condensation issues.

Humidity is another important factor to consider. Excessive moisture can lead to corrosion of electrical contacts and degradation of photocell materials over time. It may also affect the optical properties of the photocell surface, potentially altering its response to light. Controlling humidity levels during benchmarking ensures consistent and comparable results across different manufacturers.

Light intensity and spectral distribution are fundamental factors in photocell benchmarking. Variations in ambient light conditions can significantly impact test results, making it crucial to use standardized light sources with known spectral characteristics. This allows for accurate comparison of photocell performance across different manufacturers and ensures that the benchmarking process reflects real-world operating conditions.

Electromagnetic interference (EMI) can also affect photocell performance and benchmarking results. Nearby electrical equipment, power lines, or radio frequency sources may introduce noise or distort the photocell's output signal. Proper shielding and isolation techniques should be employed to minimize EMI effects during the benchmarking process.

Dust and particulate matter in the environment can accumulate on photocell surfaces, reducing their sensitivity and altering their spectral response. Regular cleaning and maintenance of photocells during benchmarking are essential to ensure consistent performance and accurate comparisons between different manufacturers' products.

Atmospheric pressure and altitude can impact photocell performance, particularly for applications in aerospace or high-altitude environments. Changes in pressure can affect the photocell's internal gas composition and potentially alter its electrical characteristics. Benchmarking should account for these factors when comparing photocells intended for use in diverse environmental conditions.

By carefully controlling and documenting these environmental factors during the benchmarking process, researchers and manufacturers can ensure more accurate and reliable comparisons of photocell performance across different manufacturers. This approach leads to better-informed decisions in selecting photocells for specific applications and helps drive continuous improvement in photocell technology.

Temperature is one of the most critical environmental factors affecting photocell performance. Photocells are sensitive to temperature variations, which can impact their electrical characteristics and overall efficiency. Higher temperatures typically lead to increased dark current and reduced sensitivity, while lower temperatures may improve performance but potentially cause condensation issues.

Humidity is another important factor to consider. Excessive moisture can lead to corrosion of electrical contacts and degradation of photocell materials over time. It may also affect the optical properties of the photocell surface, potentially altering its response to light. Controlling humidity levels during benchmarking ensures consistent and comparable results across different manufacturers.

Light intensity and spectral distribution are fundamental factors in photocell benchmarking. Variations in ambient light conditions can significantly impact test results, making it crucial to use standardized light sources with known spectral characteristics. This allows for accurate comparison of photocell performance across different manufacturers and ensures that the benchmarking process reflects real-world operating conditions.

Electromagnetic interference (EMI) can also affect photocell performance and benchmarking results. Nearby electrical equipment, power lines, or radio frequency sources may introduce noise or distort the photocell's output signal. Proper shielding and isolation techniques should be employed to minimize EMI effects during the benchmarking process.

Dust and particulate matter in the environment can accumulate on photocell surfaces, reducing their sensitivity and altering their spectral response. Regular cleaning and maintenance of photocells during benchmarking are essential to ensure consistent performance and accurate comparisons between different manufacturers' products.

Atmospheric pressure and altitude can impact photocell performance, particularly for applications in aerospace or high-altitude environments. Changes in pressure can affect the photocell's internal gas composition and potentially alter its electrical characteristics. Benchmarking should account for these factors when comparing photocells intended for use in diverse environmental conditions.

By carefully controlling and documenting these environmental factors during the benchmarking process, researchers and manufacturers can ensure more accurate and reliable comparisons of photocell performance across different manufacturers. This approach leads to better-informed decisions in selecting photocells for specific applications and helps drive continuous improvement in photocell technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!