Photocell Response Time Testing: Methods And Acceptance Criteria

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocell Testing Background and Objectives

Photocell response time testing has been a critical aspect of electronic component evaluation since the advent of photoelectric devices in the early 20th century. The evolution of this technology has been closely tied to advancements in semiconductor physics and optoelectronics. Initially, photocells were primarily used in simple light detection applications, but as their sensitivity and response times improved, they found widespread use in various industries, including automation, security systems, and consumer electronics.

The primary objective of photocell response time testing is to accurately measure and characterize the speed at which a photocell can detect changes in light intensity. This parameter is crucial for applications requiring rapid light detection, such as high-speed sorting machines, laser-based communication systems, and advanced imaging devices. As technology progresses, the demand for faster and more reliable photocells continues to grow, driving the need for more sophisticated testing methods and stricter acceptance criteria.

Over the years, testing methodologies have evolved from basic manual measurements to highly automated and precise techniques. Early methods relied on simple light sources and oscilloscopes, while modern approaches utilize advanced laser systems, high-speed data acquisition equipment, and complex signal processing algorithms. This evolution has been driven by the increasing demands of industries that rely on rapid light detection and the need for more accurate and reproducible test results.

The development of testing standards has played a significant role in shaping the field. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established guidelines for photocell testing, ensuring consistency and comparability across different manufacturers and applications. These standards have been regularly updated to keep pace with technological advancements and changing industry requirements.

Current trends in photocell response time testing focus on achieving sub-nanosecond resolution, expanding the spectral range of measurements, and developing more robust testing protocols for emerging photocell technologies, such as those based on quantum dots or organic semiconductors. Additionally, there is a growing emphasis on integrating response time testing with other performance parameters, such as sensitivity, linearity, and temperature stability, to provide a more comprehensive evaluation of photocell performance.

The ultimate goal of photocell response time testing is to enable the development of faster, more reliable, and more versatile photoelectric devices. This, in turn, supports innovation in fields ranging from high-speed communications to advanced scientific instrumentation. As new applications continue to emerge, the methods and criteria for photocell response time testing will undoubtedly continue to evolve, driving further advancements in this critical area of technology.

The primary objective of photocell response time testing is to accurately measure and characterize the speed at which a photocell can detect changes in light intensity. This parameter is crucial for applications requiring rapid light detection, such as high-speed sorting machines, laser-based communication systems, and advanced imaging devices. As technology progresses, the demand for faster and more reliable photocells continues to grow, driving the need for more sophisticated testing methods and stricter acceptance criteria.

Over the years, testing methodologies have evolved from basic manual measurements to highly automated and precise techniques. Early methods relied on simple light sources and oscilloscopes, while modern approaches utilize advanced laser systems, high-speed data acquisition equipment, and complex signal processing algorithms. This evolution has been driven by the increasing demands of industries that rely on rapid light detection and the need for more accurate and reproducible test results.

The development of testing standards has played a significant role in shaping the field. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established guidelines for photocell testing, ensuring consistency and comparability across different manufacturers and applications. These standards have been regularly updated to keep pace with technological advancements and changing industry requirements.

Current trends in photocell response time testing focus on achieving sub-nanosecond resolution, expanding the spectral range of measurements, and developing more robust testing protocols for emerging photocell technologies, such as those based on quantum dots or organic semiconductors. Additionally, there is a growing emphasis on integrating response time testing with other performance parameters, such as sensitivity, linearity, and temperature stability, to provide a more comprehensive evaluation of photocell performance.

The ultimate goal of photocell response time testing is to enable the development of faster, more reliable, and more versatile photoelectric devices. This, in turn, supports innovation in fields ranging from high-speed communications to advanced scientific instrumentation. As new applications continue to emerge, the methods and criteria for photocell response time testing will undoubtedly continue to evolve, driving further advancements in this critical area of technology.

Market Demand for Rapid Response Photocells

The market demand for rapid response photocells has been steadily increasing across various industries, driven by the need for faster and more accurate light detection and measurement systems. This growing demand is particularly evident in sectors such as automotive, aerospace, consumer electronics, and industrial automation.

In the automotive industry, the push towards advanced driver assistance systems (ADAS) and autonomous vehicles has created a significant market for high-speed photocells. These components are crucial for applications like adaptive headlights, automatic emergency braking, and lane departure warning systems. The global ADAS market is projected to grow at a compound annual growth rate (CAGR) of over 10% in the coming years, indicating a strong demand for rapid response photocells in this sector.

The aerospace industry also presents a substantial market opportunity for fast-responding photocells. These devices are essential in aircraft navigation systems, missile guidance, and satellite communications. With the increasing number of satellite launches and the expansion of space exploration programs, the demand for high-performance photocells is expected to rise significantly.

In the consumer electronics sector, rapid response photocells are becoming increasingly important for applications such as ambient light sensing in smartphones, tablets, and laptops. These sensors enable automatic screen brightness adjustment, improving user experience and energy efficiency. The global smartphone market, which shipped over 1.3 billion units in 2020, represents a massive potential for rapid response photocells.

Industrial automation is another key area driving the demand for fast-responding photocells. These components are used in various applications, including object detection, sorting systems, and quality control processes. The industrial automation market is expected to grow at a CAGR of around 9% over the next five years, further fueling the demand for high-speed photocells.

The market for rapid response photocells is also being influenced by emerging technologies such as LiDAR (Light Detection and Ranging) systems for autonomous vehicles and drones. As these technologies continue to evolve and gain wider adoption, the demand for faster and more sensitive photocells is expected to increase substantially.

Furthermore, the growing emphasis on energy efficiency and smart lighting solutions in both residential and commercial buildings is creating new opportunities for rapid response photocells. These devices play a crucial role in daylight harvesting systems and occupancy sensing, contributing to significant energy savings and improved building management.

In the automotive industry, the push towards advanced driver assistance systems (ADAS) and autonomous vehicles has created a significant market for high-speed photocells. These components are crucial for applications like adaptive headlights, automatic emergency braking, and lane departure warning systems. The global ADAS market is projected to grow at a compound annual growth rate (CAGR) of over 10% in the coming years, indicating a strong demand for rapid response photocells in this sector.

The aerospace industry also presents a substantial market opportunity for fast-responding photocells. These devices are essential in aircraft navigation systems, missile guidance, and satellite communications. With the increasing number of satellite launches and the expansion of space exploration programs, the demand for high-performance photocells is expected to rise significantly.

In the consumer electronics sector, rapid response photocells are becoming increasingly important for applications such as ambient light sensing in smartphones, tablets, and laptops. These sensors enable automatic screen brightness adjustment, improving user experience and energy efficiency. The global smartphone market, which shipped over 1.3 billion units in 2020, represents a massive potential for rapid response photocells.

Industrial automation is another key area driving the demand for fast-responding photocells. These components are used in various applications, including object detection, sorting systems, and quality control processes. The industrial automation market is expected to grow at a CAGR of around 9% over the next five years, further fueling the demand for high-speed photocells.

The market for rapid response photocells is also being influenced by emerging technologies such as LiDAR (Light Detection and Ranging) systems for autonomous vehicles and drones. As these technologies continue to evolve and gain wider adoption, the demand for faster and more sensitive photocells is expected to increase substantially.

Furthermore, the growing emphasis on energy efficiency and smart lighting solutions in both residential and commercial buildings is creating new opportunities for rapid response photocells. These devices play a crucial role in daylight harvesting systems and occupancy sensing, contributing to significant energy savings and improved building management.

Current Challenges in Photocell Response Time Testing

Photocell response time testing faces several significant challenges in the current technological landscape. One of the primary issues is the lack of standardized testing methodologies across different industries and applications. This inconsistency leads to difficulties in comparing results and establishing universal acceptance criteria, hindering the development of reliable benchmarks for photocell performance.

Another major challenge lies in the increasing demand for faster response times in various applications, such as high-speed imaging and optical communication systems. As technology advances, the need for photocells with sub-nanosecond or even picosecond response times has become more prevalent. However, accurately measuring and characterizing such rapid responses poses significant technical difficulties, requiring sophisticated equipment and precise measurement techniques.

Environmental factors also present substantial obstacles in photocell response time testing. Temperature fluctuations, electromagnetic interference, and ambient light conditions can all significantly impact the accuracy and repeatability of measurements. Controlling these variables in a laboratory setting is challenging, and replicating real-world conditions for more practical assessments adds another layer of complexity to the testing process.

The miniaturization of photocells and their integration into complex systems further complicates testing procedures. As devices become smaller and more densely packed, accessing individual photocells for testing becomes increasingly difficult. This trend necessitates the development of new testing methods that can accurately assess the performance of integrated photocells without compromising the integrity of the overall system.

Additionally, the diverse range of photocell types and materials presents challenges in developing universal testing protocols. Different photocell technologies, such as photodiodes, phototransistors, and photomultiplier tubes, exhibit varying response characteristics and require tailored testing approaches. This diversity makes it difficult to establish a one-size-fits-all solution for response time testing and acceptance criteria.

The growing emphasis on reliability and long-term performance in photocell applications has also introduced new challenges in testing methodologies. Assessing how response times may degrade over extended periods or under various operational conditions requires the development of accelerated aging tests and long-term stability studies, which are both time-consuming and complex to design and implement.

Lastly, the interpretation and analysis of test results present their own set of challenges. Determining appropriate acceptance criteria that balance performance requirements with practical limitations is a complex task. It requires a deep understanding of both the technical aspects of photocell operation and the specific needs of different applications, often necessitating a collaborative approach between manufacturers, researchers, and end-users.

Another major challenge lies in the increasing demand for faster response times in various applications, such as high-speed imaging and optical communication systems. As technology advances, the need for photocells with sub-nanosecond or even picosecond response times has become more prevalent. However, accurately measuring and characterizing such rapid responses poses significant technical difficulties, requiring sophisticated equipment and precise measurement techniques.

Environmental factors also present substantial obstacles in photocell response time testing. Temperature fluctuations, electromagnetic interference, and ambient light conditions can all significantly impact the accuracy and repeatability of measurements. Controlling these variables in a laboratory setting is challenging, and replicating real-world conditions for more practical assessments adds another layer of complexity to the testing process.

The miniaturization of photocells and their integration into complex systems further complicates testing procedures. As devices become smaller and more densely packed, accessing individual photocells for testing becomes increasingly difficult. This trend necessitates the development of new testing methods that can accurately assess the performance of integrated photocells without compromising the integrity of the overall system.

Additionally, the diverse range of photocell types and materials presents challenges in developing universal testing protocols. Different photocell technologies, such as photodiodes, phototransistors, and photomultiplier tubes, exhibit varying response characteristics and require tailored testing approaches. This diversity makes it difficult to establish a one-size-fits-all solution for response time testing and acceptance criteria.

The growing emphasis on reliability and long-term performance in photocell applications has also introduced new challenges in testing methodologies. Assessing how response times may degrade over extended periods or under various operational conditions requires the development of accelerated aging tests and long-term stability studies, which are both time-consuming and complex to design and implement.

Lastly, the interpretation and analysis of test results present their own set of challenges. Determining appropriate acceptance criteria that balance performance requirements with practical limitations is a complex task. It requires a deep understanding of both the technical aspects of photocell operation and the specific needs of different applications, often necessitating a collaborative approach between manufacturers, researchers, and end-users.

Existing Photocell Response Time Testing Methods

01 Improving photocell response time through circuit design

Various circuit designs can be employed to enhance the response time of photocells. These may include the use of amplifiers, feedback loops, or specialized components to reduce signal delay and increase sensitivity. Such designs aim to minimize the time between light detection and signal output, improving overall system performance.- Improving photocell response time through circuit design: Various circuit designs can be employed to enhance the response time of photocells. These may include the use of amplifiers, feedback loops, and specialized components to reduce signal delay and increase sensitivity. Such designs can significantly improve the overall performance of photocell-based systems in applications requiring rapid light detection and response.

- Optimizing photocell materials for faster response: The choice of materials used in photocell construction plays a crucial role in determining response time. Researchers have explored various semiconductor materials and dopants to create photocells with improved electron mobility and reduced recombination rates. These advancements lead to faster response times and increased efficiency in light detection applications.

- Enhancing response time through optical design: The optical design of photocells can significantly impact their response time. Techniques such as anti-reflective coatings, light-trapping structures, and optimized geometry can improve light absorption and charge carrier collection. These enhancements result in faster and more efficient photocell responses to changes in light intensity.

- Integration of photocells with fast-response electronics: Combining photocells with high-speed electronic components and signal processing systems can greatly improve overall response time. This integration may involve the use of fast analog-to-digital converters, microcontrollers, or dedicated signal processing chips to quickly process and react to changes in photocell output.

- Temperature compensation for consistent response time: Temperature fluctuations can affect photocell response time. Implementing temperature compensation techniques, such as using thermistors or designing temperature-independent circuits, can help maintain consistent response times across a wide range of operating temperatures. This is particularly important in applications where environmental conditions may vary significantly.

02 Optimizing photocell materials for faster response

The choice of materials used in photocell construction can significantly impact response time. Researchers explore different semiconductor materials, doping techniques, and surface treatments to create photocells with faster electron-hole pair generation and recombination, leading to quicker light-to-electrical signal conversion.Expand Specific Solutions03 Enhancing photocell response time in specific applications

Tailoring photocell designs for specific applications can lead to improved response times. This may involve optimizing the photocell for particular light wavelengths, integrating it with specialized optics, or adapting it for extreme environmental conditions. Such customization can result in faster and more accurate light detection in various fields.Expand Specific Solutions04 Using advanced signal processing techniques

Implementing sophisticated signal processing algorithms and techniques can enhance the effective response time of photocell systems. This may include digital filtering, predictive algorithms, or machine learning approaches to interpret and respond to photocell signals more quickly and accurately.Expand Specific Solutions05 Miniaturization and integration for faster response

Reducing the size of photocells and integrating them with other components can lead to faster response times. This approach minimizes signal travel distances and reduces parasitic capacitances, resulting in quicker overall system response. It may involve the use of nanotechnology or advanced fabrication techniques.Expand Specific Solutions

Key Players in Photocell Manufacturing and Testing

The photocell response time testing market is in a growth phase, driven by increasing demand for high-performance sensors across various industries. The global market size for photocell technologies is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Olympus Corp., Ricoh Co., Ltd., and Hitachi High-Tech America, Inc. leading innovation in sensor development and testing methodologies. These firms are investing heavily in R&D to improve response times, accuracy, and reliability of photocells. Emerging players like Gsolar Power Co., Ltd. are also contributing to market dynamics by focusing on specialized applications in renewable energy sectors.

Olympus Corp.

Technical Solution: Olympus has developed a unique photocell response time testing method that leverages their expertise in microscopy and high-speed imaging. Their approach uses a micro-LED array to generate spatially and temporally precise light patterns for stimulating photocells[1]. This allows for testing of both global and local response characteristics. Olympus has also implemented a multi-spectral testing capability, enabling the evaluation of photocell response across different wavelengths simultaneously[2]. Their system incorporates real-time data processing and visualization, allowing for immediate feedback during the testing process[3]. Olympus has established acceptance criteria based on industry standards and customer-specific requirements, with the flexibility to adjust these criteria for different applications.

Strengths: High spatial and temporal resolution testing, multi-spectral capabilities, and real-time data processing. Weaknesses: Potentially more complex and expensive setup compared to traditional methods, may require specialized training for operators.

Ricoh Co., Ltd.

Technical Solution: Ricoh has developed an innovative photocell response time testing method that integrates their expertise in imaging and office automation. Their approach utilizes a high-speed, programmable light source array that can generate complex spatial and temporal light patterns[1]. This allows for simultaneous testing of multiple photocells or different regions of a single large-area photocell. Ricoh's system incorporates advanced signal processing techniques, including wavelet analysis, to characterize both the time-domain and frequency-domain response of photocells[2]. They have also implemented an automated testing platform that can handle high-volume production testing, with built-in statistical process control to ensure consistent quality[3]. Ricoh's acceptance criteria are based on a combination of industry standards and application-specific requirements, with the ability to customize criteria for different product lines.

Strengths: Capability for complex light pattern generation, advanced signal processing techniques, and high-volume automated testing. Weaknesses: May require significant initial investment in equipment and software development, potentially less suitable for small-scale or specialized applications.

Innovative Approaches to Response Time Measurement

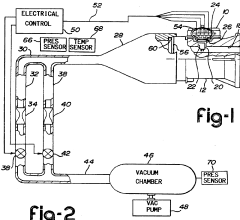

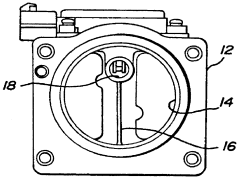

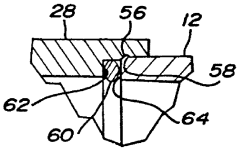

Response time test apparatus for a mass air flow sensor

PatentInactiveUS5307667A

Innovation

- An automated response time test apparatus using sonic nozzles to create controlled step changes in air flow, with electrical control to measure and compare the response time of the mass air flow sensor, ensuring it meets specification limits by accurately recording and computing the sensor's response time.

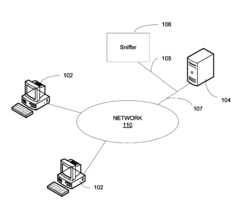

Method and system for determining response time of a server

PatentActiveUS8886795B2

Innovation

- A method that monitors communications between a client and a server to detect trigger signals, calculates response time by measuring the period between the end of a trigger signal and the beginning of the server's response, and sums these periods, excluding acknowledgement and idle times, to accurately account for processing time and network delays.

Standardization of Photocell Testing Procedures

The standardization of photocell testing procedures is crucial for ensuring consistent and reliable performance evaluation across different manufacturers and applications. This process involves establishing uniform methods for assessing photocell response times, defining acceptance criteria, and creating a framework for comparing results from various testing environments.

One of the primary challenges in standardizing photocell testing procedures is the wide range of photocell types and applications. Different industries, such as automotive, aerospace, and consumer electronics, may have varying requirements for photocell performance. To address this, a comprehensive standardization effort must consider the diverse needs of these sectors while maintaining a cohesive testing framework.

A key aspect of standardization is the development of precise testing protocols. These protocols should specify the exact conditions under which photocells are to be tested, including ambient light levels, temperature ranges, and humidity levels. By controlling these variables, testers can ensure that results are comparable across different laboratories and testing facilities.

The standardization process also involves defining specific measurement techniques for response time. This includes determining the appropriate light sources for stimulation, the methods for measuring the photocell's output, and the data analysis procedures for calculating response times. Consensus on these technical details is essential for creating a universally accepted testing standard.

Another critical component of standardization is the establishment of clear acceptance criteria. These criteria should define the minimum acceptable response times for different photocell applications, taking into account factors such as sensitivity, accuracy, and reliability. The criteria must be based on extensive research and industry consultation to ensure they are both achievable and meaningful for real-world applications.

Interlaboratory comparisons play a vital role in validating the standardized procedures. By conducting round-robin tests among multiple laboratories, the consistency and reproducibility of the testing methods can be verified. This process helps identify any discrepancies in testing equipment or procedures and allows for refinement of the standardization guidelines.

The development of reference materials and calibration standards is another crucial aspect of the standardization process. These materials provide a common baseline for comparing test results and calibrating equipment across different testing facilities. Ensuring the availability and proper use of these reference materials is essential for maintaining the integrity of the standardized testing procedures.

One of the primary challenges in standardizing photocell testing procedures is the wide range of photocell types and applications. Different industries, such as automotive, aerospace, and consumer electronics, may have varying requirements for photocell performance. To address this, a comprehensive standardization effort must consider the diverse needs of these sectors while maintaining a cohesive testing framework.

A key aspect of standardization is the development of precise testing protocols. These protocols should specify the exact conditions under which photocells are to be tested, including ambient light levels, temperature ranges, and humidity levels. By controlling these variables, testers can ensure that results are comparable across different laboratories and testing facilities.

The standardization process also involves defining specific measurement techniques for response time. This includes determining the appropriate light sources for stimulation, the methods for measuring the photocell's output, and the data analysis procedures for calculating response times. Consensus on these technical details is essential for creating a universally accepted testing standard.

Another critical component of standardization is the establishment of clear acceptance criteria. These criteria should define the minimum acceptable response times for different photocell applications, taking into account factors such as sensitivity, accuracy, and reliability. The criteria must be based on extensive research and industry consultation to ensure they are both achievable and meaningful for real-world applications.

Interlaboratory comparisons play a vital role in validating the standardized procedures. By conducting round-robin tests among multiple laboratories, the consistency and reproducibility of the testing methods can be verified. This process helps identify any discrepancies in testing equipment or procedures and allows for refinement of the standardization guidelines.

The development of reference materials and calibration standards is another crucial aspect of the standardization process. These materials provide a common baseline for comparing test results and calibrating equipment across different testing facilities. Ensuring the availability and proper use of these reference materials is essential for maintaining the integrity of the standardized testing procedures.

Environmental Factors Affecting Photocell Performance

Environmental factors play a crucial role in the performance and reliability of photocells, particularly in the context of response time testing. These factors can significantly influence the accuracy and consistency of measurements, potentially leading to misinterpretation of test results if not properly accounted for.

Temperature is one of the most critical environmental factors affecting photocell performance. Fluctuations in ambient temperature can alter the electrical properties of semiconductor materials used in photocells, impacting their sensitivity and response time. Higher temperatures generally lead to increased dark current and reduced signal-to-noise ratio, while lower temperatures may cause slower response times due to decreased charge carrier mobility.

Humidity is another important consideration, as moisture can affect the surface properties of photocells and potentially lead to degradation of performance over time. High humidity environments may cause condensation on optical surfaces, reducing light transmission and altering the photocell's response characteristics. Additionally, prolonged exposure to moisture can lead to corrosion of electrical contacts and degradation of protective coatings.

Light pollution and ambient illumination levels can significantly impact photocell response time testing. Stray light from external sources may interfere with the controlled light stimuli used in testing, potentially masking the true response characteristics of the photocell. Careful shielding and control of the testing environment are essential to minimize these effects and ensure accurate measurements.

Electromagnetic interference (EMI) from nearby electronic equipment or power sources can introduce noise into photocell measurements, affecting the accuracy of response time testing. Proper shielding and grounding techniques should be employed to mitigate EMI effects and maintain the integrity of test results.

Mechanical vibrations and shocks can also influence photocell performance, particularly in applications where precise alignment between the photocell and light source is critical. Vibrations may cause misalignment or introduce unwanted modulation of the incident light, leading to erroneous response time measurements.

Atmospheric conditions, such as air quality and particulate matter, can impact the transmission of light to the photocell surface. In environments with high levels of dust or aerosols, the incident light intensity may be attenuated, potentially affecting the photocell's response characteristics and leading to inconsistent test results.

To ensure reliable and reproducible photocell response time testing, it is essential to carefully control and monitor these environmental factors. Standardized testing procedures should include specifications for acceptable ranges of temperature, humidity, and other relevant environmental parameters. Additionally, the use of environmental chambers or controlled testing facilities may be necessary to maintain consistent conditions across multiple test runs and between different testing locations.

Temperature is one of the most critical environmental factors affecting photocell performance. Fluctuations in ambient temperature can alter the electrical properties of semiconductor materials used in photocells, impacting their sensitivity and response time. Higher temperatures generally lead to increased dark current and reduced signal-to-noise ratio, while lower temperatures may cause slower response times due to decreased charge carrier mobility.

Humidity is another important consideration, as moisture can affect the surface properties of photocells and potentially lead to degradation of performance over time. High humidity environments may cause condensation on optical surfaces, reducing light transmission and altering the photocell's response characteristics. Additionally, prolonged exposure to moisture can lead to corrosion of electrical contacts and degradation of protective coatings.

Light pollution and ambient illumination levels can significantly impact photocell response time testing. Stray light from external sources may interfere with the controlled light stimuli used in testing, potentially masking the true response characteristics of the photocell. Careful shielding and control of the testing environment are essential to minimize these effects and ensure accurate measurements.

Electromagnetic interference (EMI) from nearby electronic equipment or power sources can introduce noise into photocell measurements, affecting the accuracy of response time testing. Proper shielding and grounding techniques should be employed to mitigate EMI effects and maintain the integrity of test results.

Mechanical vibrations and shocks can also influence photocell performance, particularly in applications where precise alignment between the photocell and light source is critical. Vibrations may cause misalignment or introduce unwanted modulation of the incident light, leading to erroneous response time measurements.

Atmospheric conditions, such as air quality and particulate matter, can impact the transmission of light to the photocell surface. In environments with high levels of dust or aerosols, the incident light intensity may be attenuated, potentially affecting the photocell's response characteristics and leading to inconsistent test results.

To ensure reliable and reproducible photocell response time testing, it is essential to carefully control and monitor these environmental factors. Standardized testing procedures should include specifications for acceptable ranges of temperature, humidity, and other relevant environmental parameters. Additionally, the use of environmental chambers or controlled testing facilities may be necessary to maintain consistent conditions across multiple test runs and between different testing locations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!