How To Test Photocell Durability Under UV And Temperature Cycling

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocell Testing Objectives

Photocell durability testing under UV exposure and temperature cycling is a critical aspect of ensuring the long-term performance and reliability of photovoltaic systems. The primary objective of this testing is to simulate and accelerate the aging process that photocells undergo in real-world conditions, particularly focusing on the effects of ultraviolet radiation and temperature fluctuations.

One key goal is to evaluate the degradation of photocell efficiency over time when subjected to prolonged UV exposure. This involves measuring the changes in electrical output and conversion efficiency of the photocells at regular intervals throughout the testing period. By quantifying the rate of performance decline, researchers and manufacturers can estimate the expected lifespan of photocells in various environmental conditions.

Another crucial objective is to assess the physical integrity of photocell components under thermal stress. Temperature cycling tests aim to replicate the expansion and contraction that occurs in photocells due to day-night temperature variations and seasonal changes. This helps identify potential issues such as delamination, cracking, or failure of sealants and encapsulants that protect the photocell's active layers.

The testing also seeks to evaluate the impact of combined UV and temperature cycling on the photocell's optical properties. This includes examining changes in light transmission through protective layers, as well as any discoloration or yellowing of encapsulant materials that could reduce the amount of light reaching the active photovoltaic surface.

Furthermore, the objectives extend to investigating the durability of electrical connections and contact points within the photocell assembly. Thermal cycling can induce mechanical stress on soldered joints and interconnects, potentially leading to increased resistance or complete failure of electrical pathways. Identifying vulnerabilities in these areas is crucial for improving overall system reliability.

An additional goal is to validate and refine accelerated testing protocols that can accurately predict long-term photocell performance in a shorter timeframe. This involves correlating accelerated test results with real-world data and developing mathematical models to extrapolate long-term behavior from short-term test outcomes.

Lastly, the testing aims to provide valuable data for improving photocell design and manufacturing processes. By identifying the most common failure modes and degradation mechanisms, engineers can focus on enhancing specific components or materials to increase overall durability and longevity of photocell technologies.

One key goal is to evaluate the degradation of photocell efficiency over time when subjected to prolonged UV exposure. This involves measuring the changes in electrical output and conversion efficiency of the photocells at regular intervals throughout the testing period. By quantifying the rate of performance decline, researchers and manufacturers can estimate the expected lifespan of photocells in various environmental conditions.

Another crucial objective is to assess the physical integrity of photocell components under thermal stress. Temperature cycling tests aim to replicate the expansion and contraction that occurs in photocells due to day-night temperature variations and seasonal changes. This helps identify potential issues such as delamination, cracking, or failure of sealants and encapsulants that protect the photocell's active layers.

The testing also seeks to evaluate the impact of combined UV and temperature cycling on the photocell's optical properties. This includes examining changes in light transmission through protective layers, as well as any discoloration or yellowing of encapsulant materials that could reduce the amount of light reaching the active photovoltaic surface.

Furthermore, the objectives extend to investigating the durability of electrical connections and contact points within the photocell assembly. Thermal cycling can induce mechanical stress on soldered joints and interconnects, potentially leading to increased resistance or complete failure of electrical pathways. Identifying vulnerabilities in these areas is crucial for improving overall system reliability.

An additional goal is to validate and refine accelerated testing protocols that can accurately predict long-term photocell performance in a shorter timeframe. This involves correlating accelerated test results with real-world data and developing mathematical models to extrapolate long-term behavior from short-term test outcomes.

Lastly, the testing aims to provide valuable data for improving photocell design and manufacturing processes. By identifying the most common failure modes and degradation mechanisms, engineers can focus on enhancing specific components or materials to increase overall durability and longevity of photocell technologies.

Market Demand Analysis

The market demand for reliable photocell durability testing under UV and temperature cycling conditions has been steadily increasing in recent years. This growth is primarily driven by the expanding applications of photocells in various industries, including solar energy, automotive, aerospace, and consumer electronics. As these sectors continue to innovate and develop new products, the need for robust testing methodologies to ensure long-term performance and reliability of photocells has become paramount.

In the solar energy industry, which represents a significant portion of the photocell market, there is a growing emphasis on improving the lifespan and efficiency of solar panels. Manufacturers are seeking advanced testing methods to simulate real-world conditions and predict the long-term performance of their products. This demand is further fueled by the global push towards renewable energy sources and the increasing adoption of solar power systems in both residential and commercial applications.

The automotive sector is another key driver of market demand for photocell durability testing. With the rise of electric vehicles and advanced driver assistance systems (ADAS), photocells are being integrated into various components such as sensors, lighting systems, and energy management units. Ensuring the reliability of these components under harsh environmental conditions, including UV exposure and temperature fluctuations, is critical for vehicle safety and performance.

Aerospace and defense industries also contribute significantly to the market demand for photocell durability testing. Photocells are used in a wide range of applications, from satellite solar arrays to aircraft sensors. The extreme conditions encountered in space and high-altitude environments necessitate rigorous testing protocols to guarantee the longevity and reliability of photocell-based systems.

Consumer electronics represent another growing segment driving the demand for photocell durability testing. As smartphones, wearables, and other portable devices increasingly incorporate photocells for various functions, manufacturers are seeking ways to enhance the durability and lifespan of these components. This is particularly important for devices that are frequently exposed to outdoor conditions or varying temperatures.

The market demand is further influenced by evolving industry standards and regulations. Governments and regulatory bodies worldwide are implementing stricter requirements for product reliability and safety, particularly in sectors such as automotive and aerospace. This has led to an increased focus on comprehensive testing methodologies, including those for photocell durability under UV and temperature cycling conditions.

As a result of these market trends, there is a growing need for advanced testing equipment and methodologies that can accurately simulate real-world conditions and provide reliable data on photocell performance over time. This has created opportunities for testing equipment manufacturers and research institutions to develop innovative solutions that address the specific requirements of different industries and applications.

In the solar energy industry, which represents a significant portion of the photocell market, there is a growing emphasis on improving the lifespan and efficiency of solar panels. Manufacturers are seeking advanced testing methods to simulate real-world conditions and predict the long-term performance of their products. This demand is further fueled by the global push towards renewable energy sources and the increasing adoption of solar power systems in both residential and commercial applications.

The automotive sector is another key driver of market demand for photocell durability testing. With the rise of electric vehicles and advanced driver assistance systems (ADAS), photocells are being integrated into various components such as sensors, lighting systems, and energy management units. Ensuring the reliability of these components under harsh environmental conditions, including UV exposure and temperature fluctuations, is critical for vehicle safety and performance.

Aerospace and defense industries also contribute significantly to the market demand for photocell durability testing. Photocells are used in a wide range of applications, from satellite solar arrays to aircraft sensors. The extreme conditions encountered in space and high-altitude environments necessitate rigorous testing protocols to guarantee the longevity and reliability of photocell-based systems.

Consumer electronics represent another growing segment driving the demand for photocell durability testing. As smartphones, wearables, and other portable devices increasingly incorporate photocells for various functions, manufacturers are seeking ways to enhance the durability and lifespan of these components. This is particularly important for devices that are frequently exposed to outdoor conditions or varying temperatures.

The market demand is further influenced by evolving industry standards and regulations. Governments and regulatory bodies worldwide are implementing stricter requirements for product reliability and safety, particularly in sectors such as automotive and aerospace. This has led to an increased focus on comprehensive testing methodologies, including those for photocell durability under UV and temperature cycling conditions.

As a result of these market trends, there is a growing need for advanced testing equipment and methodologies that can accurately simulate real-world conditions and provide reliable data on photocell performance over time. This has created opportunities for testing equipment manufacturers and research institutions to develop innovative solutions that address the specific requirements of different industries and applications.

Current Challenges

Testing photocell durability under UV and temperature cycling presents several significant challenges that researchers and manufacturers must address. One of the primary obstacles is the complexity of simulating real-world conditions accurately in a laboratory setting. The interplay between UV radiation and temperature fluctuations can be difficult to replicate, as these factors often work synergistically to degrade photocell materials.

The accelerated aging process used in durability testing introduces another layer of complexity. While necessary to obtain results in a reasonable timeframe, accelerated testing may not always accurately represent the long-term degradation mechanisms that occur under normal operating conditions. This discrepancy can lead to overestimation or underestimation of a photocell's actual lifespan and performance in the field.

Standardization of testing protocols poses another challenge. Different manufacturers and research institutions may employ varying methodologies, making it difficult to compare results across studies or products. The lack of universally accepted standards for photocell durability testing under combined UV and temperature cycling conditions hinders the industry's ability to establish benchmarks and ensure consistent quality control.

The selection of appropriate UV sources for testing is also problematic. Natural sunlight contains a broad spectrum of wavelengths, and artificial UV sources may not perfectly mimic this spectrum. Choosing the right artificial UV source that accurately represents the solar spectrum relevant to photocell degradation is crucial for obtaining meaningful results.

Temperature cycling introduces additional complications, particularly in maintaining precise control over heating and cooling rates. Rapid temperature changes can induce thermal stress in photocell materials, potentially leading to accelerated degradation or failure modes that may not occur under normal operating conditions. Balancing the need for accelerated testing with the desire to maintain realistic thermal profiles is a delicate task.

Furthermore, the diverse range of photocell technologies and materials in use today presents a challenge in developing comprehensive testing protocols. Different types of photocells may exhibit varying sensitivities to UV radiation and temperature fluctuations, necessitating tailored testing approaches for each technology.

Lastly, the long-term nature of durability testing can be resource-intensive and time-consuming, even with accelerated methods. This can create bottlenecks in product development cycles and delay the introduction of new, more durable photocell technologies to the market. Balancing the need for thorough testing with the pressures of rapid product development and market demands remains an ongoing challenge for the industry.

The accelerated aging process used in durability testing introduces another layer of complexity. While necessary to obtain results in a reasonable timeframe, accelerated testing may not always accurately represent the long-term degradation mechanisms that occur under normal operating conditions. This discrepancy can lead to overestimation or underestimation of a photocell's actual lifespan and performance in the field.

Standardization of testing protocols poses another challenge. Different manufacturers and research institutions may employ varying methodologies, making it difficult to compare results across studies or products. The lack of universally accepted standards for photocell durability testing under combined UV and temperature cycling conditions hinders the industry's ability to establish benchmarks and ensure consistent quality control.

The selection of appropriate UV sources for testing is also problematic. Natural sunlight contains a broad spectrum of wavelengths, and artificial UV sources may not perfectly mimic this spectrum. Choosing the right artificial UV source that accurately represents the solar spectrum relevant to photocell degradation is crucial for obtaining meaningful results.

Temperature cycling introduces additional complications, particularly in maintaining precise control over heating and cooling rates. Rapid temperature changes can induce thermal stress in photocell materials, potentially leading to accelerated degradation or failure modes that may not occur under normal operating conditions. Balancing the need for accelerated testing with the desire to maintain realistic thermal profiles is a delicate task.

Furthermore, the diverse range of photocell technologies and materials in use today presents a challenge in developing comprehensive testing protocols. Different types of photocells may exhibit varying sensitivities to UV radiation and temperature fluctuations, necessitating tailored testing approaches for each technology.

Lastly, the long-term nature of durability testing can be resource-intensive and time-consuming, even with accelerated methods. This can create bottlenecks in product development cycles and delay the introduction of new, more durable photocell technologies to the market. Balancing the need for thorough testing with the pressures of rapid product development and market demands remains an ongoing challenge for the industry.

Existing Test Methodologies

01 Protective coatings and encapsulation

Improving photocell durability through the use of protective coatings and encapsulation techniques. These methods shield the photocell from environmental factors such as moisture, dust, and mechanical stress, thereby extending its lifespan and maintaining performance over time.- Protective coatings and encapsulation: Enhancing photocell durability through the application of protective coatings or encapsulation techniques. These methods shield the photocell from environmental factors such as moisture, dust, and mechanical stress, thereby extending its operational lifespan and maintaining performance over time.

- Temperature regulation and thermal management: Implementing temperature control mechanisms to maintain optimal operating conditions for photocells. This includes heat dissipation techniques, cooling systems, or thermal insulation to prevent degradation due to extreme temperatures and thermal cycling, thus improving overall durability and efficiency.

- Advanced materials and manufacturing processes: Utilizing innovative materials and manufacturing techniques to create more robust photocells. This may involve the use of novel semiconductors, nanostructures, or advanced fabrication methods that result in photocells with improved resistance to degradation and enhanced longevity.

- Circuit design and power management: Optimizing circuit design and power management strategies to reduce stress on photocell components. This includes implementing voltage regulation, current limiting, and load balancing techniques to prevent overloading and ensure stable operation over extended periods.

- Self-cleaning and maintenance features: Incorporating self-cleaning mechanisms or easy maintenance features into photocell designs. These may include hydrophobic coatings, automated cleaning systems, or modular designs that facilitate easy replacement of degraded components, thereby maintaining optimal performance and extending the overall lifespan of the photocell system.

02 Temperature regulation and heat dissipation

Implementing temperature control mechanisms and heat dissipation techniques to enhance photocell durability. This includes the use of heat sinks, cooling systems, and thermally conductive materials to prevent overheating and maintain optimal operating conditions for the photocell.Expand Specific Solutions03 Advanced materials and manufacturing processes

Utilizing advanced materials and improved manufacturing processes to enhance the inherent durability of photocells. This includes the development of more robust semiconductor materials, improved electrode designs, and optimized fabrication techniques to increase resistance to degradation and extend operational lifespan.Expand Specific Solutions04 Circuit design and power management

Implementing sophisticated circuit designs and power management strategies to improve photocell durability. This involves the use of protective circuitry, voltage regulation, and intelligent power distribution to prevent electrical stress and ensure stable operation over extended periods.Expand Specific Solutions05 Self-cleaning and maintenance mechanisms

Incorporating self-cleaning and maintenance mechanisms to preserve photocell performance and durability. This includes the development of coatings with self-cleaning properties, automated cleaning systems, and easy-to-maintain designs that reduce the impact of environmental contaminants on photocell efficiency and lifespan.Expand Specific Solutions

Key Industry Players

The photocell durability testing market is in a growth phase, driven by increasing demand for reliable solar technologies. The global market size for photovoltaic testing equipment is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with companies like Changzhou EGing Photovoltaic Technology, Solar Frontier, and Miasole Photovoitaic Technology leading innovations in UV and temperature cycling tests. These firms, along with research institutions like Fraunhofer-Gesellschaft and the Industrial Technology Research Institute, are developing more sophisticated and accurate testing methodologies. The competitive landscape is characterized by a mix of established players and emerging startups, all striving to enhance photocell durability under various environmental conditions.

Maxeon Solar Pte Ltd.

Technical Solution: Maxeon Solar employs advanced accelerated testing protocols to evaluate photocell durability under UV and temperature cycling. Their approach includes using specialized environmental chambers that simulate extreme conditions, subjecting solar cells to intense UV radiation and rapid temperature fluctuations. The company utilizes a combination of real-time monitoring systems and post-test analysis to assess performance degradation. Maxeon's proprietary Interdigitated Back Contact (IBC) cell design undergoes rigorous testing, including extended exposure to UV light equivalent to 25 years of sunlight and temperature cycles ranging from -40°C to 85°C [1][3]. This comprehensive testing methodology allows for accurate prediction of long-term photocell performance and durability in various climatic conditions.

Strengths: Highly accurate simulation of real-world conditions, advanced cell design resistant to environmental stressors. Weaknesses: Resource-intensive testing process, potential for overestimation of degradation rates in controlled environments.

Hanwha Q CELLS GmbH

Technical Solution: Hanwha Q CELLS utilizes a multi-faceted approach to test photocell durability under UV and temperature cycling. Their method incorporates both indoor and outdoor testing facilities. In controlled laboratory settings, they employ specialized UV chambers capable of concentrating several years' worth of UV exposure into a few months. Temperature cycling tests are conducted using thermal shock chambers that rapidly alternate between extreme hot and cold temperatures, typically ranging from -40°C to 85°C, with cycle times as short as 10 minutes [2][5]. Additionally, Hanwha Q CELLS conducts outdoor field testing in various climatic zones to validate laboratory results. They use advanced imaging techniques, such as electroluminescence, to detect micro-cracks and other defects that may develop during testing. The company's proprietary Q.ANTUM technology, which includes rear-side passivation, undergoes particularly rigorous durability testing to ensure long-term performance stability [4].

Strengths: Comprehensive testing approach combining indoor and outdoor methodologies, advanced defect detection techniques. Weaknesses: Time-consuming process for outdoor validation, potential discrepancies between accelerated indoor tests and real-world performance.

Advanced Testing Techniques

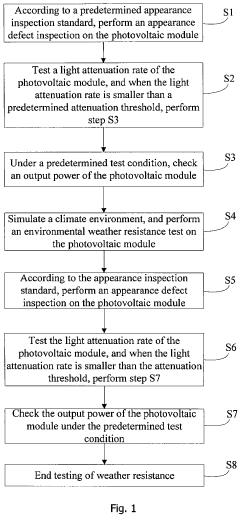

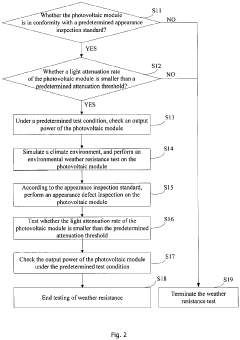

Method and system for testing weather resistance of photovoltaic module

PatentInactiveEP3506495A1

Innovation

- A method and system for testing the weather resistance of photovoltaic modules, involving sequential steps of appearance inspection, light attenuation rate testing, output power checking, and environmental weather resistance testing, including humid-hot, humid-freezing, and heat cycle tests, using a system comprising an appearance inspection device, light attenuation rate test device, power check device, environment simulation device, and controller.

Temperature cycling test device for optical fiber composite phase conductor connector box and test method

PatentWO2013071788A1

Innovation

- A temperature cycle test device for an optical fiber composite phase line joint box is designed, which includes a high and low temperature test chamber, an auxiliary extension optical cable and an optical fiber attenuation tester. By setting a reserved pigtail inside the joint box and connecting it in series with the auxiliary extension optical cable, and at the temperature During the cycle, the attenuation of the optical fiber is continuously monitored to ensure that the total length of the optical fiber is greater than 500m and the bending radius is not less than 30.0mm, simulating actual harsh environmental conditions and conducting performance tests.

Environmental Impact Assessment

The environmental impact assessment of photocell durability testing under UV and temperature cycling is a crucial aspect to consider in the development and implementation of solar energy technologies. This process involves evaluating the potential effects of these testing procedures on the surrounding ecosystem and human health.

UV radiation and temperature cycling used in photocell durability tests can have both direct and indirect environmental consequences. The primary concern is the potential release of harmful substances during the testing process. Photovoltaic cells often contain materials such as cadmium, lead, and other heavy metals, which may leach into the environment if not properly contained during rigorous testing procedures.

Energy consumption is another significant factor to consider. Simulating UV exposure and temperature cycling requires substantial power input, contributing to increased electricity usage and associated carbon emissions. This is particularly relevant when testing is conducted on a large scale or over extended periods.

The disposal of tested photocells and associated materials also presents environmental challenges. Improper handling of these components can lead to soil and water contamination, affecting local ecosystems and potentially entering the food chain. Implementing proper recycling and waste management protocols is essential to mitigate these risks.

Water usage in cooling systems during temperature cycling tests is another environmental concern. In regions facing water scarcity, the allocation of water resources for such testing procedures may compete with other critical needs, including agriculture and domestic use.

On a positive note, improving photocell durability through these testing methods can lead to more efficient and longer-lasting solar panels. This, in turn, reduces the frequency of panel replacements and the associated environmental impacts of manufacturing and disposing of solar equipment.

The assessment should also consider the potential for accidental release of testing materials or equipment malfunction. Establishing robust safety protocols and containment measures is crucial to prevent environmental contamination in case of unforeseen incidents during the testing process.

Lastly, the cumulative impact of multiple testing facilities in a given area should be evaluated. While individual testing sites may have minimal environmental effects, the concentration of such facilities could lead to more significant local ecological changes, affecting air quality, wildlife habitats, and overall ecosystem balance.

UV radiation and temperature cycling used in photocell durability tests can have both direct and indirect environmental consequences. The primary concern is the potential release of harmful substances during the testing process. Photovoltaic cells often contain materials such as cadmium, lead, and other heavy metals, which may leach into the environment if not properly contained during rigorous testing procedures.

Energy consumption is another significant factor to consider. Simulating UV exposure and temperature cycling requires substantial power input, contributing to increased electricity usage and associated carbon emissions. This is particularly relevant when testing is conducted on a large scale or over extended periods.

The disposal of tested photocells and associated materials also presents environmental challenges. Improper handling of these components can lead to soil and water contamination, affecting local ecosystems and potentially entering the food chain. Implementing proper recycling and waste management protocols is essential to mitigate these risks.

Water usage in cooling systems during temperature cycling tests is another environmental concern. In regions facing water scarcity, the allocation of water resources for such testing procedures may compete with other critical needs, including agriculture and domestic use.

On a positive note, improving photocell durability through these testing methods can lead to more efficient and longer-lasting solar panels. This, in turn, reduces the frequency of panel replacements and the associated environmental impacts of manufacturing and disposing of solar equipment.

The assessment should also consider the potential for accidental release of testing materials or equipment malfunction. Establishing robust safety protocols and containment measures is crucial to prevent environmental contamination in case of unforeseen incidents during the testing process.

Lastly, the cumulative impact of multiple testing facilities in a given area should be evaluated. While individual testing sites may have minimal environmental effects, the concentration of such facilities could lead to more significant local ecological changes, affecting air quality, wildlife habitats, and overall ecosystem balance.

Standardization Efforts

Standardization efforts in photocell durability testing under UV and temperature cycling have become increasingly important as the demand for reliable and long-lasting photovoltaic systems grows. Various international organizations and industry bodies have been working towards establishing uniform testing protocols and performance criteria to ensure consistency and comparability across different manufacturers and regions.

The International Electrotechnical Commission (IEC) has been at the forefront of these efforts, developing several standards specifically addressing photocell durability. IEC 61215, for instance, outlines the design qualification and type approval for terrestrial photovoltaic modules, including rigorous UV and temperature cycling tests. This standard has been widely adopted and serves as a benchmark for many national and regional certification programs.

ASTM International has also contributed significantly to the standardization process. ASTM G154 provides guidelines for operating fluorescent ultraviolet lamps for UV exposure of nonmetallic materials, which is applicable to photocell testing. Additionally, ASTM E1171 offers a standard test method for photovoltaic modules in cyclic temperature and humidity environments, complementing the UV testing protocols.

The European Committee for Electrotechnical Standardization (CENELEC) has aligned its efforts with IEC standards, adopting and adapting them for the European market. This harmonization has facilitated easier market access for manufacturers and increased confidence among consumers and investors in the European solar energy sector.

In the United States, the National Renewable Energy Laboratory (NREL) has been instrumental in developing and refining testing methodologies. Their research has led to the creation of more accurate accelerated testing protocols that better simulate real-world conditions, including combined UV and temperature cycling stress factors.

The Joint Research Centre of the European Commission has also made significant contributions, particularly in the development of the European Solar Test Installation (ESTI). This facility has been crucial in validating and improving testing methodologies, ensuring that standardization efforts are grounded in robust scientific research.

Despite these advancements, challenges remain in fully standardizing photocell durability testing. The complex interplay between UV exposure and temperature cycling, along with other environmental factors such as humidity and mechanical stress, necessitates ongoing research and refinement of testing protocols. Furthermore, as new photocell technologies emerge, standards must evolve to accommodate these innovations while maintaining backward compatibility with existing systems.

The International Electrotechnical Commission (IEC) has been at the forefront of these efforts, developing several standards specifically addressing photocell durability. IEC 61215, for instance, outlines the design qualification and type approval for terrestrial photovoltaic modules, including rigorous UV and temperature cycling tests. This standard has been widely adopted and serves as a benchmark for many national and regional certification programs.

ASTM International has also contributed significantly to the standardization process. ASTM G154 provides guidelines for operating fluorescent ultraviolet lamps for UV exposure of nonmetallic materials, which is applicable to photocell testing. Additionally, ASTM E1171 offers a standard test method for photovoltaic modules in cyclic temperature and humidity environments, complementing the UV testing protocols.

The European Committee for Electrotechnical Standardization (CENELEC) has aligned its efforts with IEC standards, adopting and adapting them for the European market. This harmonization has facilitated easier market access for manufacturers and increased confidence among consumers and investors in the European solar energy sector.

In the United States, the National Renewable Energy Laboratory (NREL) has been instrumental in developing and refining testing methodologies. Their research has led to the creation of more accurate accelerated testing protocols that better simulate real-world conditions, including combined UV and temperature cycling stress factors.

The Joint Research Centre of the European Commission has also made significant contributions, particularly in the development of the European Solar Test Installation (ESTI). This facility has been crucial in validating and improving testing methodologies, ensuring that standardization efforts are grounded in robust scientific research.

Despite these advancements, challenges remain in fully standardizing photocell durability testing. The complex interplay between UV exposure and temperature cycling, along with other environmental factors such as humidity and mechanical stress, necessitates ongoing research and refinement of testing protocols. Furthermore, as new photocell technologies emerge, standards must evolve to accommodate these innovations while maintaining backward compatibility with existing systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!