How To Calibrate Photocells For Accurate Lux And Response Time

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocell Calibration Background and Objectives

Photocell calibration has been a critical aspect of light measurement technology since the early 20th century. The development of accurate and reliable photocells has revolutionized various industries, from photography to environmental monitoring. As technology advances, the demand for precise light measurement continues to grow, driving the need for more sophisticated calibration techniques.

The evolution of photocell technology has seen significant milestones, including the introduction of selenium cells in the 1930s, silicon-based photocells in the 1950s, and more recently, the development of high-performance photodiodes. Each advancement has brought new challenges and opportunities in calibration methodologies, pushing the boundaries of accuracy and response time.

In recent years, the proliferation of smart lighting systems, autonomous vehicles, and advanced imaging technologies has further emphasized the importance of accurate photocell calibration. These applications require not only precise lux measurements but also rapid response times to dynamic lighting conditions, presenting a dual challenge for calibration techniques.

The primary objective of photocell calibration is to ensure that the device accurately measures light intensity across a wide range of conditions. This involves establishing a reliable relationship between the photocell's electrical output and the actual light levels in lux. Additionally, calibration aims to optimize the response time of the photocell, enabling it to react swiftly to changes in illumination.

Achieving these objectives requires addressing several technical challenges. One key issue is the spectral sensitivity of photocells, which can vary depending on the type of semiconductor material used. Calibration techniques must account for these variations to provide accurate measurements across different light spectra. Another challenge lies in maintaining calibration accuracy over time, as photocells can degrade or drift due to environmental factors and aging.

The goal of this technical research is to explore innovative approaches to photocell calibration that can simultaneously improve both lux accuracy and response time. This involves investigating advanced calibration algorithms, novel hardware designs, and potential integration with machine learning techniques to enhance overall performance.

By advancing photocell calibration methods, we aim to support the development of more precise and responsive light measurement systems. These improvements have far-reaching implications, from enhancing energy efficiency in smart buildings to improving safety in automotive and industrial applications. As we delve into the current state of photocell calibration technology, we will examine the latest research, identify key challenges, and explore promising avenues for future innovation in this critical field.

The evolution of photocell technology has seen significant milestones, including the introduction of selenium cells in the 1930s, silicon-based photocells in the 1950s, and more recently, the development of high-performance photodiodes. Each advancement has brought new challenges and opportunities in calibration methodologies, pushing the boundaries of accuracy and response time.

In recent years, the proliferation of smart lighting systems, autonomous vehicles, and advanced imaging technologies has further emphasized the importance of accurate photocell calibration. These applications require not only precise lux measurements but also rapid response times to dynamic lighting conditions, presenting a dual challenge for calibration techniques.

The primary objective of photocell calibration is to ensure that the device accurately measures light intensity across a wide range of conditions. This involves establishing a reliable relationship between the photocell's electrical output and the actual light levels in lux. Additionally, calibration aims to optimize the response time of the photocell, enabling it to react swiftly to changes in illumination.

Achieving these objectives requires addressing several technical challenges. One key issue is the spectral sensitivity of photocells, which can vary depending on the type of semiconductor material used. Calibration techniques must account for these variations to provide accurate measurements across different light spectra. Another challenge lies in maintaining calibration accuracy over time, as photocells can degrade or drift due to environmental factors and aging.

The goal of this technical research is to explore innovative approaches to photocell calibration that can simultaneously improve both lux accuracy and response time. This involves investigating advanced calibration algorithms, novel hardware designs, and potential integration with machine learning techniques to enhance overall performance.

By advancing photocell calibration methods, we aim to support the development of more precise and responsive light measurement systems. These improvements have far-reaching implications, from enhancing energy efficiency in smart buildings to improving safety in automotive and industrial applications. As we delve into the current state of photocell calibration technology, we will examine the latest research, identify key challenges, and explore promising avenues for future innovation in this critical field.

Market Demand for Precise Light Measurement

The market demand for precise light measurement has been steadily increasing across various industries, driven by the growing need for accurate and reliable photometric data. This demand is particularly evident in sectors such as agriculture, smart lighting systems, automotive, and consumer electronics, where precise light control and measurement are crucial for optimal performance and energy efficiency.

In the agricultural sector, the adoption of controlled environment agriculture (CEA) and vertical farming has created a significant market for accurate light measurement devices. These systems rely on precise control of light intensity and spectrum to optimize plant growth and yield. The global CEA market is expected to grow substantially in the coming years, further fueling the demand for high-precision photocells and light sensors.

Smart lighting systems represent another major driver for precise light measurement technologies. As cities and businesses increasingly implement intelligent lighting solutions to reduce energy consumption and enhance user comfort, the need for accurate light sensors has grown exponentially. These sensors enable dynamic adjustment of lighting levels based on ambient conditions, time of day, and occupancy, leading to significant energy savings and improved user experience.

The automotive industry has also emerged as a key market for precise light measurement technologies. Advanced driver assistance systems (ADAS) and autonomous vehicles rely heavily on accurate light sensing for functions such as automatic headlight control, adaptive lighting systems, and environmental perception. As the automotive industry continues its shift towards electrification and autonomy, the demand for high-performance photocells is expected to surge.

Consumer electronics, particularly smartphones and wearable devices, have incorporated increasingly sophisticated light sensing capabilities. These devices use ambient light sensors to adjust screen brightness, improve camera performance in various lighting conditions, and enable features such as heart rate monitoring. The continuous evolution of consumer electronics and the integration of more advanced sensing technologies drive the demand for precise and fast-responding photocells.

In the industrial and manufacturing sectors, precise light measurement is essential for quality control, process monitoring, and safety applications. Industries such as semiconductor manufacturing, pharmaceutical production, and food processing rely on accurate light measurement for critical processes and product verification.

The healthcare and medical device industry also contributes to the growing demand for precise light measurement. Applications range from phototherapy devices and diagnostic equipment to surgical lighting systems, all of which require accurate light intensity control and measurement to ensure patient safety and treatment efficacy.

As environmental concerns and energy efficiency regulations become more stringent, the demand for precise light measurement in building management systems and energy auditing has increased. Accurate light sensors play a crucial role in optimizing lighting control strategies and verifying compliance with energy efficiency standards.

In the agricultural sector, the adoption of controlled environment agriculture (CEA) and vertical farming has created a significant market for accurate light measurement devices. These systems rely on precise control of light intensity and spectrum to optimize plant growth and yield. The global CEA market is expected to grow substantially in the coming years, further fueling the demand for high-precision photocells and light sensors.

Smart lighting systems represent another major driver for precise light measurement technologies. As cities and businesses increasingly implement intelligent lighting solutions to reduce energy consumption and enhance user comfort, the need for accurate light sensors has grown exponentially. These sensors enable dynamic adjustment of lighting levels based on ambient conditions, time of day, and occupancy, leading to significant energy savings and improved user experience.

The automotive industry has also emerged as a key market for precise light measurement technologies. Advanced driver assistance systems (ADAS) and autonomous vehicles rely heavily on accurate light sensing for functions such as automatic headlight control, adaptive lighting systems, and environmental perception. As the automotive industry continues its shift towards electrification and autonomy, the demand for high-performance photocells is expected to surge.

Consumer electronics, particularly smartphones and wearable devices, have incorporated increasingly sophisticated light sensing capabilities. These devices use ambient light sensors to adjust screen brightness, improve camera performance in various lighting conditions, and enable features such as heart rate monitoring. The continuous evolution of consumer electronics and the integration of more advanced sensing technologies drive the demand for precise and fast-responding photocells.

In the industrial and manufacturing sectors, precise light measurement is essential for quality control, process monitoring, and safety applications. Industries such as semiconductor manufacturing, pharmaceutical production, and food processing rely on accurate light measurement for critical processes and product verification.

The healthcare and medical device industry also contributes to the growing demand for precise light measurement. Applications range from phototherapy devices and diagnostic equipment to surgical lighting systems, all of which require accurate light intensity control and measurement to ensure patient safety and treatment efficacy.

As environmental concerns and energy efficiency regulations become more stringent, the demand for precise light measurement in building management systems and energy auditing has increased. Accurate light sensors play a crucial role in optimizing lighting control strategies and verifying compliance with energy efficiency standards.

Current Challenges in Photocell Calibration

Photocell calibration for accurate lux measurement and response time faces several significant challenges in today's technological landscape. One of the primary issues is the inherent variability in photocell sensitivity across different devices, even within the same manufacturing batch. This inconsistency necessitates individual calibration for each photocell, which can be time-consuming and resource-intensive in large-scale production environments.

Another challenge lies in the non-linear response of photocells to varying light intensities. While photocells generally exhibit a linear response within a specific range, they often deviate from linearity at very low or very high light levels. This non-linearity complicates the calibration process, requiring sophisticated algorithms and calibration curves to achieve accurate measurements across the entire operational range.

Temperature dependency presents a further obstacle in photocell calibration. The sensitivity and response characteristics of photocells can change significantly with temperature fluctuations, affecting both lux measurements and response times. Compensating for these temperature-induced variations requires additional sensors and complex compensation algorithms, adding to the overall complexity of the calibration process.

The spectral sensitivity of photocells also poses a challenge, particularly when calibrating for accurate lux measurements. Human perception of light (photopic response) differs from the spectral response of most photocells. Achieving a close match to the human eye's sensitivity curve often requires the use of optical filters or multiple sensors with different spectral responses, further complicating the calibration procedure.

Calibrating for accurate response time introduces its own set of challenges. The response time of a photocell can vary depending on the light intensity, previous exposure, and even the direction of change (increasing or decreasing light). Developing a calibration method that accounts for these factors while maintaining accuracy across different scenarios is a complex task.

Long-term stability and drift compensation represent ongoing challenges in photocell calibration. Over time, photocells may experience sensitivity drift due to aging, environmental factors, or prolonged exposure to light. Implementing effective strategies to detect and compensate for this drift, while maintaining calibration accuracy, remains a significant hurdle in the field.

Lastly, the increasing demand for miniaturization and integration of photocells into compact devices presents challenges in terms of maintaining calibration accuracy while working with smaller sensor sizes and potentially compromised optical characteristics. Balancing these conflicting requirements without sacrificing performance adds another layer of complexity to the calibration process.

Another challenge lies in the non-linear response of photocells to varying light intensities. While photocells generally exhibit a linear response within a specific range, they often deviate from linearity at very low or very high light levels. This non-linearity complicates the calibration process, requiring sophisticated algorithms and calibration curves to achieve accurate measurements across the entire operational range.

Temperature dependency presents a further obstacle in photocell calibration. The sensitivity and response characteristics of photocells can change significantly with temperature fluctuations, affecting both lux measurements and response times. Compensating for these temperature-induced variations requires additional sensors and complex compensation algorithms, adding to the overall complexity of the calibration process.

The spectral sensitivity of photocells also poses a challenge, particularly when calibrating for accurate lux measurements. Human perception of light (photopic response) differs from the spectral response of most photocells. Achieving a close match to the human eye's sensitivity curve often requires the use of optical filters or multiple sensors with different spectral responses, further complicating the calibration procedure.

Calibrating for accurate response time introduces its own set of challenges. The response time of a photocell can vary depending on the light intensity, previous exposure, and even the direction of change (increasing or decreasing light). Developing a calibration method that accounts for these factors while maintaining accuracy across different scenarios is a complex task.

Long-term stability and drift compensation represent ongoing challenges in photocell calibration. Over time, photocells may experience sensitivity drift due to aging, environmental factors, or prolonged exposure to light. Implementing effective strategies to detect and compensate for this drift, while maintaining calibration accuracy, remains a significant hurdle in the field.

Lastly, the increasing demand for miniaturization and integration of photocells into compact devices presents challenges in terms of maintaining calibration accuracy while working with smaller sensor sizes and potentially compromised optical characteristics. Balancing these conflicting requirements without sacrificing performance adds another layer of complexity to the calibration process.

Existing Photocell Calibration Methods

01 Photocell sensitivity and response time optimization

Techniques for improving photocell sensitivity and response time, including the use of advanced materials and circuit designs. These methods aim to enhance the photocell's ability to detect light changes quickly and accurately, which is crucial for applications requiring precise light measurement and control.- Photocell sensitivity and response time optimization: Techniques for improving photocell sensitivity and response time, including the use of advanced materials and circuit designs. These improvements allow for faster and more accurate light detection, which is crucial in various applications such as automatic lighting systems and camera exposure control.

- Lux measurement and calibration in photocells: Methods for accurate lux measurement and calibration of photocells, ensuring precise light intensity detection. This involves the development of calibration techniques, reference standards, and compensation algorithms to account for various environmental factors and spectral sensitivities.

- Integration of photocells in smart lighting systems: Incorporation of photocells into smart lighting systems for energy-efficient and adaptive illumination. These systems use photocell data to adjust lighting levels based on ambient light conditions, time of day, and occupancy, resulting in improved energy savings and user comfort.

- Photocell applications in imaging and display technologies: Utilization of photocells in imaging and display technologies, including cameras, screens, and image sensors. These applications focus on enhancing image quality, adjusting display brightness, and improving overall visual performance based on ambient light conditions.

- Advanced photocell designs for specific environments: Development of specialized photocell designs tailored for specific environmental conditions or applications. These include photocells optimized for low-light conditions, high-temperature environments, or rapid light fluctuations, ensuring reliable performance across various scenarios.

02 Lux measurement and calibration in photocell systems

Methods for accurate lux measurement and calibration in photocell-based systems. This involves the development of algorithms and hardware configurations to ensure precise light intensity measurements across various environmental conditions, enhancing the reliability of light-sensitive applications.Expand Specific Solutions03 Integration of photocells in imaging and display technologies

Incorporation of photocells into imaging and display systems to improve performance and functionality. This includes the use of photocells for automatic brightness adjustment, ambient light sensing, and image quality enhancement in cameras, displays, and other visual technologies.Expand Specific Solutions04 Photocell applications in energy-efficient lighting systems

Implementation of photocells in smart lighting systems for energy conservation and improved user experience. These applications involve using photocells to detect ambient light levels and automatically adjust artificial lighting, optimizing energy usage while maintaining appropriate illumination.Expand Specific Solutions05 Advanced signal processing for photocell-based systems

Development of sophisticated signal processing techniques to enhance the performance of photocell-based systems. This includes noise reduction algorithms, data filtering methods, and adaptive processing approaches to improve the accuracy and reliability of light detection and measurement in various applications.Expand Specific Solutions

Key Players in Photocell and Light Sensor Industry

The calibration of photocells for accurate lux and response time is a critical technology in the optoelectronics industry, currently in a mature development stage. The market for this technology is substantial, driven by applications in lighting control, display technologies, and industrial automation. Companies like Applied Materials, Olympus, and Konica Minolta are leading players, leveraging their expertise in precision optics and sensor technologies. The competitive landscape is characterized by a mix of established electronics giants and specialized optoelectronics firms, with ongoing innovation focused on improving accuracy, speed, and integration capabilities of photocell calibration systems.

Olympus Corp.

Technical Solution: Olympus has developed an advanced photocell calibration system for their optical instruments, focusing on both accuracy and rapid response time. Their approach utilizes a dual-beam reference method, where one beam is used for continuous calibration while the other measures the sample[1]. This real-time calibration compensates for drift and environmental changes. For lux accuracy, Olympus employs a multi-point calibration curve using NIST-traceable standards[2]. To optimize response time, they've implemented a predictive algorithm that anticipates light level changes based on recent measurements, allowing for faster adjustments[3]. Additionally, Olympus uses high-speed, low-noise amplifiers and analog-to-digital converters to minimize signal processing delays[4].

Strengths: Real-time calibration and predictive algorithms for fast response. Weaknesses: May be more complex and expensive to implement in simpler applications.

Hangzhou Everfine Photo-e-info Co., Ltd.

Technical Solution: Hangzhou Everfine has developed a comprehensive approach to photocell calibration for accurate lux and response time measurements. Their method involves a multi-step process: 1) Dark current compensation to eliminate background noise[1]. 2) Spectral response calibration using a monochromator to match the photocell's response to the human eye sensitivity curve[2]. 3) Linearity correction across a wide range of light intensities using a precision light source[3]. 4) Temperature compensation to account for thermal effects on sensitivity[4]. 5) Response time optimization through advanced signal processing algorithms and high-speed data acquisition systems[5]. This integrated approach ensures high accuracy and repeatability in photometric measurements.

Strengths: Comprehensive calibration process addressing multiple factors affecting accuracy. Weaknesses: May require specialized equipment and expertise, potentially increasing cost and complexity for end-users.

Innovations in Lux and Response Time Calibration

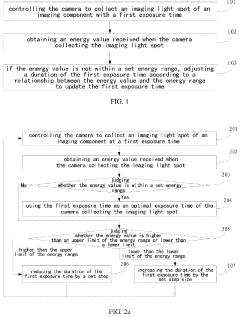

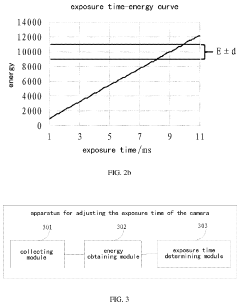

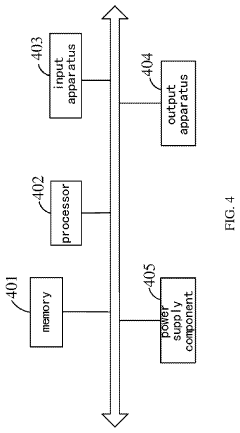

Method and apparatus for adjusting exposure time of camera and device

PatentActiveUS20210075949A1

Innovation

- A method and apparatus that adjust the exposure time of a camera by monitoring the energy value received during imaging light spot collection, adjusting the duration of exposure based on a set energy range to maintain optimal imaging quality, with the energy range being 10000±500 for a 14-bit color depth camera, ensuring consistent imaging brightness.

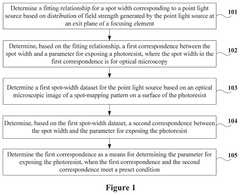

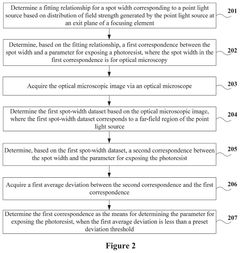

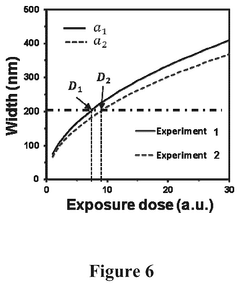

Optical method and apparatus for quickly realizing precise calibration of lithography system

PatentPendingUS20240345488A1

Innovation

- A method and apparatus for fast precise optical calibration that determines a fitting relationship for spot widths based on field strength distribution at the exit plane of a focusing element, using optical microscopy to establish correspondences between spot widths and exposure parameters, allowing for rapid determination of exposure parameters within approximately 2 minutes, compared to at least 4 hours with atomic force microscopy.

Standards and Regulations for Light Measurement

Light measurement standards and regulations play a crucial role in ensuring accurate and consistent photocell calibration for lux and response time measurements. These guidelines are established by various international and national organizations to maintain uniformity and reliability in light measurement practices across industries.

The International Commission on Illumination (CIE) is the primary authority for developing and maintaining global standards for light measurement. Their publications, such as CIE S 023/E:2013 "Characterization of the Performance of Illuminance Meters and Luminance Meters," provide comprehensive guidelines for calibrating and evaluating photocells and light meters.

In the United States, the National Institute of Standards and Technology (NIST) offers traceability for light measurement calibrations. NIST maintains primary standards for luminous intensity and spectral irradiance, which serve as references for calibrating secondary standards and working instruments.

The International Organization for Standardization (ISO) has also developed relevant standards, including ISO/CIE 19476:2014 "Characterization of the performance of illuminance meters and luminance meters." This standard outlines methods for determining the performance characteristics of instruments used for measuring illuminance and luminance.

European standards, such as EN 13032 "Light and lighting - Measurement and presentation of photometric data of lamps and luminaires," provide specific guidelines for measuring and reporting photometric data. These standards ensure consistency in light measurement practices across the European Union.

For response time measurements, standards like IEC 61000-4-29 "Electromagnetic compatibility (EMC) - Testing and measurement techniques - Voltage dips, short interruptions and voltage variations on d.c. input power port immunity tests" offer guidance on evaluating the performance of electrical and electronic equipment under various power supply conditions.

Compliance with these standards and regulations is essential for manufacturers, testing laboratories, and end-users of photocells and light measurement equipment. They ensure that calibration procedures are consistent, reproducible, and traceable to recognized national and international standards.

When calibrating photocells for accurate lux and response time measurements, it is crucial to adhere to the relevant standards and follow the prescribed methodologies. This includes using certified reference light sources, maintaining controlled environmental conditions, and employing appropriate measurement techniques as outlined in the standards.

Regular calibration and verification of photocells against these standards help maintain measurement accuracy and reliability over time. This is particularly important in applications where precise light measurements are critical, such as in scientific research, industrial quality control, and lighting design.

The International Commission on Illumination (CIE) is the primary authority for developing and maintaining global standards for light measurement. Their publications, such as CIE S 023/E:2013 "Characterization of the Performance of Illuminance Meters and Luminance Meters," provide comprehensive guidelines for calibrating and evaluating photocells and light meters.

In the United States, the National Institute of Standards and Technology (NIST) offers traceability for light measurement calibrations. NIST maintains primary standards for luminous intensity and spectral irradiance, which serve as references for calibrating secondary standards and working instruments.

The International Organization for Standardization (ISO) has also developed relevant standards, including ISO/CIE 19476:2014 "Characterization of the performance of illuminance meters and luminance meters." This standard outlines methods for determining the performance characteristics of instruments used for measuring illuminance and luminance.

European standards, such as EN 13032 "Light and lighting - Measurement and presentation of photometric data of lamps and luminaires," provide specific guidelines for measuring and reporting photometric data. These standards ensure consistency in light measurement practices across the European Union.

For response time measurements, standards like IEC 61000-4-29 "Electromagnetic compatibility (EMC) - Testing and measurement techniques - Voltage dips, short interruptions and voltage variations on d.c. input power port immunity tests" offer guidance on evaluating the performance of electrical and electronic equipment under various power supply conditions.

Compliance with these standards and regulations is essential for manufacturers, testing laboratories, and end-users of photocells and light measurement equipment. They ensure that calibration procedures are consistent, reproducible, and traceable to recognized national and international standards.

When calibrating photocells for accurate lux and response time measurements, it is crucial to adhere to the relevant standards and follow the prescribed methodologies. This includes using certified reference light sources, maintaining controlled environmental conditions, and employing appropriate measurement techniques as outlined in the standards.

Regular calibration and verification of photocells against these standards help maintain measurement accuracy and reliability over time. This is particularly important in applications where precise light measurements are critical, such as in scientific research, industrial quality control, and lighting design.

Environmental Factors Affecting Calibration Accuracy

Environmental factors play a crucial role in the calibration accuracy of photocells for measuring lux and response time. Temperature variations can significantly impact the performance of photocells, as their sensitivity and response characteristics may change with temperature fluctuations. Higher temperatures can lead to increased dark current and noise, potentially affecting the accuracy of low-light measurements. Conversely, extremely low temperatures may cause a decrease in sensitivity and slower response times.

Humidity is another critical factor that can influence calibration accuracy. Excessive moisture in the environment can lead to condensation on the photocell's surface, altering its optical properties and potentially causing measurement errors. In high-humidity conditions, the photocell's response may become less stable, affecting both lux readings and response time measurements.

Ambient light conditions during calibration are of paramount importance. Stray light from external sources can interfere with the calibration process, leading to inaccurate baseline measurements. It is essential to conduct calibrations in a controlled environment with minimal ambient light or use appropriate light-blocking enclosures to ensure precise measurements.

Dust and particulate matter in the air can accumulate on the photocell's surface over time, reducing its sensitivity and altering its spectral response. Regular cleaning and maintenance of the photocell are necessary to maintain calibration accuracy. Additionally, atmospheric pressure changes, particularly in outdoor applications, can affect the photocell's performance, albeit to a lesser extent than temperature and humidity.

Electromagnetic interference (EMI) from nearby electronic devices or power sources can introduce noise into the photocell's measurements, impacting both lux readings and response time calculations. Proper shielding and grounding techniques should be employed to minimize EMI effects during calibration.

The spectral composition of the light source used for calibration is another critical factor. Different light sources (e.g., incandescent, fluorescent, LED) have varying spectral distributions, which can affect the photocell's response. It is essential to use a calibration light source that closely matches the spectral characteristics of the intended application or employ appropriate correction factors.

Lastly, the physical orientation and positioning of the photocell during calibration can influence its accuracy. Variations in the angle of incidence of light on the photocell's surface can lead to measurement discrepancies. Ensuring consistent and precise positioning of the photocell relative to the calibration light source is crucial for obtaining reliable and repeatable results.

Humidity is another critical factor that can influence calibration accuracy. Excessive moisture in the environment can lead to condensation on the photocell's surface, altering its optical properties and potentially causing measurement errors. In high-humidity conditions, the photocell's response may become less stable, affecting both lux readings and response time measurements.

Ambient light conditions during calibration are of paramount importance. Stray light from external sources can interfere with the calibration process, leading to inaccurate baseline measurements. It is essential to conduct calibrations in a controlled environment with minimal ambient light or use appropriate light-blocking enclosures to ensure precise measurements.

Dust and particulate matter in the air can accumulate on the photocell's surface over time, reducing its sensitivity and altering its spectral response. Regular cleaning and maintenance of the photocell are necessary to maintain calibration accuracy. Additionally, atmospheric pressure changes, particularly in outdoor applications, can affect the photocell's performance, albeit to a lesser extent than temperature and humidity.

Electromagnetic interference (EMI) from nearby electronic devices or power sources can introduce noise into the photocell's measurements, impacting both lux readings and response time calculations. Proper shielding and grounding techniques should be employed to minimize EMI effects during calibration.

The spectral composition of the light source used for calibration is another critical factor. Different light sources (e.g., incandescent, fluorescent, LED) have varying spectral distributions, which can affect the photocell's response. It is essential to use a calibration light source that closely matches the spectral characteristics of the intended application or employ appropriate correction factors.

Lastly, the physical orientation and positioning of the photocell during calibration can influence its accuracy. Variations in the angle of incidence of light on the photocell's surface can lead to measurement discrepancies. Ensuring consistent and precise positioning of the photocell relative to the calibration light source is crucial for obtaining reliable and repeatable results.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!