How To Validate Photocell Operation In Automotive Lighting Systems

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automotive Lighting Photocell Validation Overview

Automotive lighting systems play a crucial role in ensuring vehicle safety and visibility on the road. Photocells, also known as light sensors or photoelectric sensors, are integral components of these systems, responsible for automatically activating or deactivating lights based on ambient light conditions. Validating the operation of photocells in automotive lighting systems is essential to guarantee their reliability and effectiveness in various environmental conditions.

The validation process for photocell operation involves a comprehensive series of tests and evaluations designed to assess the sensor's performance, accuracy, and durability. These tests typically include sensitivity measurements, response time analysis, and environmental stress testing. The primary objective is to ensure that the photocell can accurately detect changes in ambient light levels and trigger the appropriate lighting response in a timely manner.

One of the key aspects of photocell validation is the assessment of its spectral response. This involves testing the sensor's ability to detect and respond to different wavelengths of light, simulating various natural and artificial lighting conditions that a vehicle may encounter. The validation process also includes evaluating the photocell's performance under extreme temperature conditions, as automotive lighting systems must function reliably in a wide range of climates.

Another critical component of the validation process is the assessment of the photocell's long-term stability and resistance to degradation. This involves subjecting the sensor to accelerated aging tests, simulating years of use in a compressed timeframe. These tests help identify potential issues related to sensor drift, material degradation, or performance deterioration over time.

Electromagnetic compatibility (EMC) testing is also a vital part of photocell validation in automotive lighting systems. This ensures that the sensor can operate correctly in the presence of electromagnetic interference from other vehicle components and external sources. EMC testing helps prevent false triggering or malfunction of the lighting system due to electromagnetic disturbances.

The validation process also includes integration testing, where the photocell is evaluated as part of the complete automotive lighting system. This involves assessing its interaction with other components, such as the lighting control module, and verifying that the entire system functions as intended under various scenarios.

Standardization and compliance with industry regulations form an essential part of the validation process. Automotive lighting systems must meet specific standards set by regulatory bodies such as the Society of Automotive Engineers (SAE) and the United Nations Economic Commission for Europe (UNECE). The validation procedures ensure that the photocell and the overall lighting system comply with these standards, meeting requirements for light sensitivity, activation thresholds, and response times.

The validation process for photocell operation involves a comprehensive series of tests and evaluations designed to assess the sensor's performance, accuracy, and durability. These tests typically include sensitivity measurements, response time analysis, and environmental stress testing. The primary objective is to ensure that the photocell can accurately detect changes in ambient light levels and trigger the appropriate lighting response in a timely manner.

One of the key aspects of photocell validation is the assessment of its spectral response. This involves testing the sensor's ability to detect and respond to different wavelengths of light, simulating various natural and artificial lighting conditions that a vehicle may encounter. The validation process also includes evaluating the photocell's performance under extreme temperature conditions, as automotive lighting systems must function reliably in a wide range of climates.

Another critical component of the validation process is the assessment of the photocell's long-term stability and resistance to degradation. This involves subjecting the sensor to accelerated aging tests, simulating years of use in a compressed timeframe. These tests help identify potential issues related to sensor drift, material degradation, or performance deterioration over time.

Electromagnetic compatibility (EMC) testing is also a vital part of photocell validation in automotive lighting systems. This ensures that the sensor can operate correctly in the presence of electromagnetic interference from other vehicle components and external sources. EMC testing helps prevent false triggering or malfunction of the lighting system due to electromagnetic disturbances.

The validation process also includes integration testing, where the photocell is evaluated as part of the complete automotive lighting system. This involves assessing its interaction with other components, such as the lighting control module, and verifying that the entire system functions as intended under various scenarios.

Standardization and compliance with industry regulations form an essential part of the validation process. Automotive lighting systems must meet specific standards set by regulatory bodies such as the Society of Automotive Engineers (SAE) and the United Nations Economic Commission for Europe (UNECE). The validation procedures ensure that the photocell and the overall lighting system comply with these standards, meeting requirements for light sensitivity, activation thresholds, and response times.

Market Demand for Reliable Automotive Lighting Systems

The automotive lighting industry has witnessed a significant surge in demand for reliable lighting systems, driven by the increasing focus on vehicle safety and the growing complexity of modern automotive designs. As vehicles become more technologically advanced, the need for sophisticated lighting systems that can adapt to various environmental conditions has become paramount. This demand is further amplified by stringent safety regulations and consumer expectations for enhanced visibility and aesthetics.

Market research indicates that the global automotive lighting market is experiencing robust growth, with a particular emphasis on advanced lighting technologies. The integration of photocells in automotive lighting systems has emerged as a critical component in meeting these market demands. Photocells enable automatic activation and adjustment of vehicle lights based on ambient light conditions, enhancing both safety and energy efficiency.

The demand for reliable photocell-based lighting systems is particularly strong in premium and luxury vehicle segments, where consumers expect cutting-edge technology and superior performance. However, this trend is gradually permeating into mid-range and entry-level vehicles as well, driven by the increasing awareness of safety benefits and the decreasing costs of advanced lighting technologies.

Automotive manufacturers are increasingly recognizing the value of reliable lighting systems in differentiating their products in a competitive market. The ability to offer advanced features such as automatic headlight control, adaptive front-lighting systems, and intelligent light distribution is becoming a key selling point for many vehicle models.

Furthermore, the rise of electric and autonomous vehicles is creating new opportunities and challenges for automotive lighting systems. These vehicles often require more sophisticated lighting solutions to compensate for the absence of traditional driver inputs and to communicate with other road users. This trend is expected to further drive the demand for reliable, sensor-based lighting systems, including those utilizing photocells.

The market demand extends beyond just the end-product manufacturers. Tier 1 and Tier 2 suppliers in the automotive industry are also experiencing increased pressure to develop and deliver more reliable and innovative lighting components. This has led to a surge in research and development activities focused on improving the performance and durability of photocells and related technologies.

In conclusion, the market demand for reliable automotive lighting systems, particularly those incorporating photocell technology, is robust and growing. This demand is driven by a combination of safety regulations, consumer expectations, technological advancements, and the evolving nature of vehicle design and functionality. As the automotive industry continues to evolve, the importance of reliable, adaptive lighting systems is expected to remain a key focus area for manufacturers and suppliers alike.

Market research indicates that the global automotive lighting market is experiencing robust growth, with a particular emphasis on advanced lighting technologies. The integration of photocells in automotive lighting systems has emerged as a critical component in meeting these market demands. Photocells enable automatic activation and adjustment of vehicle lights based on ambient light conditions, enhancing both safety and energy efficiency.

The demand for reliable photocell-based lighting systems is particularly strong in premium and luxury vehicle segments, where consumers expect cutting-edge technology and superior performance. However, this trend is gradually permeating into mid-range and entry-level vehicles as well, driven by the increasing awareness of safety benefits and the decreasing costs of advanced lighting technologies.

Automotive manufacturers are increasingly recognizing the value of reliable lighting systems in differentiating their products in a competitive market. The ability to offer advanced features such as automatic headlight control, adaptive front-lighting systems, and intelligent light distribution is becoming a key selling point for many vehicle models.

Furthermore, the rise of electric and autonomous vehicles is creating new opportunities and challenges for automotive lighting systems. These vehicles often require more sophisticated lighting solutions to compensate for the absence of traditional driver inputs and to communicate with other road users. This trend is expected to further drive the demand for reliable, sensor-based lighting systems, including those utilizing photocells.

The market demand extends beyond just the end-product manufacturers. Tier 1 and Tier 2 suppliers in the automotive industry are also experiencing increased pressure to develop and deliver more reliable and innovative lighting components. This has led to a surge in research and development activities focused on improving the performance and durability of photocells and related technologies.

In conclusion, the market demand for reliable automotive lighting systems, particularly those incorporating photocell technology, is robust and growing. This demand is driven by a combination of safety regulations, consumer expectations, technological advancements, and the evolving nature of vehicle design and functionality. As the automotive industry continues to evolve, the importance of reliable, adaptive lighting systems is expected to remain a key focus area for manufacturers and suppliers alike.

Current Challenges in Photocell Validation

The validation of photocell operation in automotive lighting systems faces several significant challenges in the current technological landscape. One of the primary issues is the complexity of modern automotive lighting systems, which often integrate multiple sensors and control units. This integration makes it difficult to isolate and test the photocell's performance independently from other components.

Environmental factors pose another substantial challenge. Photocells in automotive applications are exposed to a wide range of lighting conditions, from bright sunlight to complete darkness, as well as varying temperatures and humidity levels. Developing a comprehensive validation process that accounts for all these variables is a complex task, requiring extensive testing under diverse conditions.

The miniaturization trend in automotive design also presents difficulties for photocell validation. As lighting systems become more compact, the space available for sensors and testing equipment is reduced. This constraint can limit the types of validation methods that can be employed and may necessitate the development of new, more compact testing tools.

Reliability and longevity testing represent another significant hurdle. Automotive photocells are expected to function accurately for many years under harsh conditions. Validating their long-term performance within a reasonable testing timeframe is challenging and often requires accelerated aging techniques, which may not always accurately reflect real-world degradation patterns.

Regulatory compliance adds another layer of complexity to the validation process. Different regions have varying standards for automotive lighting systems, and photocells must meet these diverse requirements. Ensuring that validation procedures are comprehensive enough to satisfy global regulatory demands while remaining cost-effective is a delicate balance.

The rapid pace of technological advancement in automotive lighting further complicates validation efforts. As new lighting technologies emerge, such as adaptive headlights and matrix LED systems, validation methods must evolve to keep pace. This constant evolution requires ongoing investment in research and development of new validation techniques and equipment.

Lastly, the increasing integration of artificial intelligence and machine learning in automotive systems introduces new challenges in photocell validation. These advanced systems may alter the behavior of lighting systems based on complex algorithms, making it difficult to predict and validate all possible scenarios in which the photocell might operate.

Environmental factors pose another substantial challenge. Photocells in automotive applications are exposed to a wide range of lighting conditions, from bright sunlight to complete darkness, as well as varying temperatures and humidity levels. Developing a comprehensive validation process that accounts for all these variables is a complex task, requiring extensive testing under diverse conditions.

The miniaturization trend in automotive design also presents difficulties for photocell validation. As lighting systems become more compact, the space available for sensors and testing equipment is reduced. This constraint can limit the types of validation methods that can be employed and may necessitate the development of new, more compact testing tools.

Reliability and longevity testing represent another significant hurdle. Automotive photocells are expected to function accurately for many years under harsh conditions. Validating their long-term performance within a reasonable testing timeframe is challenging and often requires accelerated aging techniques, which may not always accurately reflect real-world degradation patterns.

Regulatory compliance adds another layer of complexity to the validation process. Different regions have varying standards for automotive lighting systems, and photocells must meet these diverse requirements. Ensuring that validation procedures are comprehensive enough to satisfy global regulatory demands while remaining cost-effective is a delicate balance.

The rapid pace of technological advancement in automotive lighting further complicates validation efforts. As new lighting technologies emerge, such as adaptive headlights and matrix LED systems, validation methods must evolve to keep pace. This constant evolution requires ongoing investment in research and development of new validation techniques and equipment.

Lastly, the increasing integration of artificial intelligence and machine learning in automotive systems introduces new challenges in photocell validation. These advanced systems may alter the behavior of lighting systems based on complex algorithms, making it difficult to predict and validate all possible scenarios in which the photocell might operate.

Existing Photocell Validation Methods

01 Photovoltaic cell operation

Photovoltaic cells convert light energy into electrical energy. These cells typically consist of semiconductor materials that generate an electric current when exposed to light. The efficiency of photovoltaic cells depends on factors such as material composition, cell structure, and light intensity.- Photoelectric conversion and signal processing: Photocells operate by converting light into electrical signals. This process involves the absorption of photons by semiconductor materials, generating electron-hole pairs. The resulting electrical current is then processed and amplified to produce usable output signals. Advanced signal processing techniques can enhance the sensitivity and accuracy of photocell operations.

- Light detection and measurement applications: Photocells are widely used in various light detection and measurement applications. These include ambient light sensing, optical communication systems, and scientific instruments. The ability to accurately detect and measure light intensity enables photocells to be used in diverse fields such as environmental monitoring, industrial automation, and consumer electronics.

- Power generation and solar energy harvesting: Photocells play a crucial role in solar energy harvesting and power generation. When exposed to sunlight, photovoltaic cells generate electricity through the photovoltaic effect. This principle is utilized in solar panels and other renewable energy technologies. Ongoing research focuses on improving the efficiency and cost-effectiveness of photocell-based power generation systems.

- Automatic lighting control systems: Photocells are integral components in automatic lighting control systems. They can detect ambient light levels and trigger the activation or deactivation of lighting fixtures accordingly. This application is commonly used in street lighting, security systems, and energy-efficient building management. Advanced control algorithms can optimize lighting based on time of day and occupancy patterns.

- Photocell design and manufacturing techniques: The design and manufacturing of photocells involve various techniques to enhance their performance and reliability. This includes the selection of appropriate semiconductor materials, optimization of device structure, and implementation of protective coatings. Advanced manufacturing processes, such as thin-film deposition and nanotechnology, are employed to improve the efficiency and durability of photocells.

02 Photodetector operation

Photodetectors are devices that sense light and convert it into an electrical signal. They are used in various applications, including light measurement, optical communication, and imaging systems. The operation of photodetectors involves the generation of charge carriers when photons are absorbed, which are then collected to produce an electrical output.Expand Specific Solutions03 Photocell-based control systems

Photocells are often integrated into control systems for automatic lighting or other light-sensitive applications. These systems use the photocell's response to ambient light levels to trigger actions such as turning lights on or off, adjusting brightness, or activating other devices. The operation typically involves a threshold detection mechanism and associated control circuitry.Expand Specific Solutions04 Photocell signal processing

The operation of photocells often involves processing the electrical signals they generate. This can include amplification, filtering, and conversion of analog signals to digital form. Signal processing techniques are used to improve sensitivity, reduce noise, and extract useful information from the photocell output for various applications.Expand Specific Solutions05 Photocell applications in lighting systems

Photocells play a crucial role in the operation of various lighting systems. They are used to detect ambient light levels and control the operation of lamps or LED arrays. This includes applications such as street lighting, architectural lighting, and energy-efficient building management systems. The photocell's operation in these systems often involves interfacing with dimming circuits or power controllers.Expand Specific Solutions

Key Players in Automotive Lighting Industry

The automotive lighting systems market is in a mature stage, with a global market size expected to reach $42.5 billion by 2027. The technology for validating photocell operation in these systems is well-established, with major players like Ford Global Technologies, Valeo Vision, and Continental Automotive GmbH leading innovation. Companies such as Siemens AG and Honda Motor Co. are also contributing to advancements in this field. The competitive landscape is characterized by a mix of established automotive manufacturers and specialized lighting system suppliers, with increasing focus on energy efficiency and smart lighting solutions. As the industry moves towards electric and autonomous vehicles, we can expect further technological developments in photocell validation techniques.

Valeo Vision SA

Technical Solution: Valeo Vision SA has developed an advanced photocell validation system for automotive lighting. Their approach utilizes a combination of hardware and software solutions to ensure accurate and reliable operation of photocells in various lighting conditions. The system employs a multi-sensor array that includes both ambient light sensors and dedicated photocells[1]. This array is coupled with sophisticated algorithms that can compensate for environmental factors such as temperature variations and aging effects[3]. Valeo's system also incorporates real-time monitoring capabilities, allowing for continuous validation of photocell performance during vehicle operation. The company has implemented machine learning techniques to improve the system's ability to distinguish between genuine lighting changes and false triggers, significantly reducing error rates[5].

Strengths: Comprehensive multi-sensor approach, advanced algorithms for environmental compensation, and machine learning integration for improved accuracy. Weaknesses: Potentially higher cost due to complex hardware and software requirements, may require more frequent calibration in extreme environments.

Continental Automotive GmbH

Technical Solution: Continental Automotive GmbH has developed a robust photocell validation system for automotive lighting applications. Their approach focuses on integrating photocell validation into a broader Advanced Driver Assistance Systems (ADAS) framework. The system utilizes a network of distributed sensors throughout the vehicle, including dedicated photocells and existing camera systems[2]. Continental's solution employs sensor fusion techniques to cross-validate photocell readings with other sensor data, enhancing overall reliability. The company has also implemented adaptive thresholding algorithms that dynamically adjust sensitivity based on driving conditions and vehicle speed[4]. Additionally, Continental's system includes a self-diagnostic feature that can detect photocell degradation over time, alerting users to potential issues before they impact performance[6].

Strengths: Integration with ADAS, sensor fusion for enhanced reliability, and adaptive algorithms for varying conditions. Weaknesses: Reliance on multiple vehicle systems may increase complexity and potential points of failure, could be more challenging to retrofit in older vehicles.

Innovative Approaches to Photocell Testing

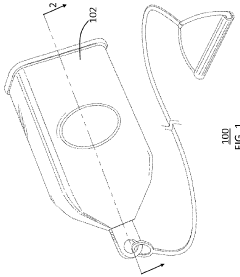

Photocell cover and method of use

PatentActiveUS20180180467A1

Innovation

- A photocell cover with an enclosed jacket and elastic band that allows for testing in any ambient light condition by blocking ambient light and providing a false-positive light activation reading, enabling testing from ground level or elevated positions without the need for dark simulation.

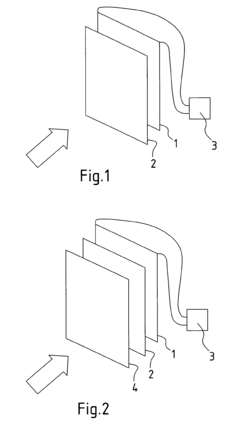

Use of a photovoltaic element as a sensor for controlling the function of infrared emitters

PatentInactiveEP1577651A1

Innovation

- A photovoltaic element is used as a sensor to check the functionality of infrared transmitters, offering a cost-effective, large-area sensing solution without the need for a power supply, utilizing silicon solar cells and evaluation electronics to generate a signal proportional to radiation power, and incorporating filters to isolate infrared radiation.

Safety Standards and Regulations

Safety standards and regulations play a crucial role in validating photocell operation in automotive lighting systems. These standards ensure that lighting systems meet the necessary safety requirements and perform reliably under various conditions. The primary regulatory bodies governing automotive lighting include the United Nations Economic Commission for Europe (UNECE), the National Highway Traffic Safety Administration (NHTSA) in the United States, and the Society of Automotive Engineers (SAE).

UNECE Regulation No. 48 specifically addresses the installation of lighting and light-signaling devices on vehicles. It outlines requirements for automatic switching of headlamps and daytime running lights, which often involve photocell operation. The regulation mandates that these systems must function reliably and consistently across different ambient light conditions.

In the United States, Federal Motor Vehicle Safety Standard (FMVSS) No. 108 governs lamps, reflective devices, and associated equipment. While it does not explicitly mention photocells, it requires automatic headlamp systems to activate under specific low-light conditions, implying the need for reliable light-sensing mechanisms.

The SAE has developed several standards relevant to automotive lighting systems, including SAE J2087, which provides guidelines for testing automatic headlamp beam switching devices. This standard outlines procedures for evaluating the performance of light sensors in various environmental conditions.

Validation of photocell operation must consider these regulatory requirements. Testing procedures typically involve simulating different light conditions and verifying that the photocell responds appropriately. This may include assessing the activation and deactivation thresholds, response times, and behavior under various environmental factors such as temperature and humidity.

Manufacturers must also ensure compliance with electromagnetic compatibility (EMC) standards, as photocells and associated circuitry can be sensitive to electromagnetic interference. Relevant standards include UNECE Regulation No. 10 and SAE J1113, which specify EMC requirements for automotive electrical components.

Additionally, durability and reliability testing is essential to meet the stringent automotive quality standards. This involves subjecting the photocell and related components to accelerated life testing, thermal cycling, and vibration tests to ensure long-term performance in harsh automotive environments.

As automotive technology advances, regulations are evolving to address new lighting technologies such as adaptive driving beams and matrix LED systems. These innovations often rely on more sophisticated light-sensing mechanisms, potentially requiring updates to existing validation procedures and standards.

UNECE Regulation No. 48 specifically addresses the installation of lighting and light-signaling devices on vehicles. It outlines requirements for automatic switching of headlamps and daytime running lights, which often involve photocell operation. The regulation mandates that these systems must function reliably and consistently across different ambient light conditions.

In the United States, Federal Motor Vehicle Safety Standard (FMVSS) No. 108 governs lamps, reflective devices, and associated equipment. While it does not explicitly mention photocells, it requires automatic headlamp systems to activate under specific low-light conditions, implying the need for reliable light-sensing mechanisms.

The SAE has developed several standards relevant to automotive lighting systems, including SAE J2087, which provides guidelines for testing automatic headlamp beam switching devices. This standard outlines procedures for evaluating the performance of light sensors in various environmental conditions.

Validation of photocell operation must consider these regulatory requirements. Testing procedures typically involve simulating different light conditions and verifying that the photocell responds appropriately. This may include assessing the activation and deactivation thresholds, response times, and behavior under various environmental factors such as temperature and humidity.

Manufacturers must also ensure compliance with electromagnetic compatibility (EMC) standards, as photocells and associated circuitry can be sensitive to electromagnetic interference. Relevant standards include UNECE Regulation No. 10 and SAE J1113, which specify EMC requirements for automotive electrical components.

Additionally, durability and reliability testing is essential to meet the stringent automotive quality standards. This involves subjecting the photocell and related components to accelerated life testing, thermal cycling, and vibration tests to ensure long-term performance in harsh automotive environments.

As automotive technology advances, regulations are evolving to address new lighting technologies such as adaptive driving beams and matrix LED systems. These innovations often rely on more sophisticated light-sensing mechanisms, potentially requiring updates to existing validation procedures and standards.

Environmental Factors Affecting Photocell Performance

Environmental factors play a crucial role in the performance and reliability of photocells used in automotive lighting systems. These factors can significantly impact the accuracy and consistency of photocell operation, necessitating a comprehensive understanding of their effects for proper validation.

Temperature variations are one of the primary environmental factors affecting photocell performance. Automotive environments can experience extreme temperature fluctuations, ranging from sub-zero temperatures in cold climates to high heat in tropical regions or engine compartments. These temperature changes can alter the photocell's sensitivity and response time, potentially leading to false triggers or delayed reactions in lighting systems.

Humidity and moisture exposure also pose significant challenges to photocell operation. High humidity levels can cause condensation on the photocell's surface, potentially interfering with light detection. In severe cases, prolonged exposure to moisture may lead to corrosion of electrical contacts or degradation of the photocell's components, compromising its long-term reliability.

Dust and particulate matter accumulation is another critical factor in automotive environments. Airborne particles can settle on the photocell's surface, reducing its sensitivity to light and potentially causing erroneous readings. This is particularly relevant in off-road or industrial settings where vehicles are exposed to higher levels of dust and debris.

Vibration and shock are inherent in automotive applications and can affect photocell performance. Constant vibrations from engine operation or road conditions may lead to mechanical stress on the photocell components, potentially causing misalignment or damage over time. Sudden shocks from impacts or rough terrain can also disrupt photocell operation or cause temporary malfunctions.

Electromagnetic interference (EMI) from various vehicle systems and external sources can impact photocell functionality. The complex electrical environment in modern vehicles, combined with potential external EMI sources, may introduce noise or false signals that interfere with accurate light detection.

Light pollution and varying ambient light conditions present challenges for photocell validation. Urban environments with artificial lighting or rapidly changing light conditions (e.g., tunnels, overpasses) can affect the photocell's ability to accurately detect natural light levels, potentially leading to inappropriate activation or deactivation of vehicle lighting systems.

Chemical exposure is another consideration, particularly in harsh environments. Automotive fluids, road salts, and atmospheric pollutants can corrode or degrade photocell components, affecting their long-term performance and reliability.

Understanding and accounting for these environmental factors is essential for developing robust validation procedures for photocell operation in automotive lighting systems. Comprehensive testing under various environmental conditions, including accelerated aging tests and simulated extreme scenarios, is crucial to ensure reliable photocell performance across the diverse range of operating environments encountered by vehicles.

Temperature variations are one of the primary environmental factors affecting photocell performance. Automotive environments can experience extreme temperature fluctuations, ranging from sub-zero temperatures in cold climates to high heat in tropical regions or engine compartments. These temperature changes can alter the photocell's sensitivity and response time, potentially leading to false triggers or delayed reactions in lighting systems.

Humidity and moisture exposure also pose significant challenges to photocell operation. High humidity levels can cause condensation on the photocell's surface, potentially interfering with light detection. In severe cases, prolonged exposure to moisture may lead to corrosion of electrical contacts or degradation of the photocell's components, compromising its long-term reliability.

Dust and particulate matter accumulation is another critical factor in automotive environments. Airborne particles can settle on the photocell's surface, reducing its sensitivity to light and potentially causing erroneous readings. This is particularly relevant in off-road or industrial settings where vehicles are exposed to higher levels of dust and debris.

Vibration and shock are inherent in automotive applications and can affect photocell performance. Constant vibrations from engine operation or road conditions may lead to mechanical stress on the photocell components, potentially causing misalignment or damage over time. Sudden shocks from impacts or rough terrain can also disrupt photocell operation or cause temporary malfunctions.

Electromagnetic interference (EMI) from various vehicle systems and external sources can impact photocell functionality. The complex electrical environment in modern vehicles, combined with potential external EMI sources, may introduce noise or false signals that interfere with accurate light detection.

Light pollution and varying ambient light conditions present challenges for photocell validation. Urban environments with artificial lighting or rapidly changing light conditions (e.g., tunnels, overpasses) can affect the photocell's ability to accurately detect natural light levels, potentially leading to inappropriate activation or deactivation of vehicle lighting systems.

Chemical exposure is another consideration, particularly in harsh environments. Automotive fluids, road salts, and atmospheric pollutants can corrode or degrade photocell components, affecting their long-term performance and reliability.

Understanding and accounting for these environmental factors is essential for developing robust validation procedures for photocell operation in automotive lighting systems. Comprehensive testing under various environmental conditions, including accelerated aging tests and simulated extreme scenarios, is crucial to ensure reliable photocell performance across the diverse range of operating environments encountered by vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!