Photocell Calibration Protocol For Industrial Light Measurement

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocell Calibration Background and Objectives

Photocell calibration has been a critical aspect of industrial light measurement since the early 20th century. The development of this technology has been driven by the increasing demand for precise light measurement in various industries, including manufacturing, agriculture, and environmental monitoring. As light-sensitive devices, photocells have evolved from simple selenium-based components to sophisticated silicon photodiodes, offering improved accuracy and reliability.

The primary objective of photocell calibration is to ensure the accuracy and consistency of light measurements across different devices and environments. This process involves establishing a standardized protocol that can be replicated across various industrial settings, allowing for reliable comparisons and data analysis. The calibration protocol aims to address several key challenges, including variations in photocell sensitivity, spectral response, and environmental factors that can affect measurement accuracy.

Over the years, the field of photocell calibration has seen significant advancements in both methodology and technology. Early calibration techniques relied on simple comparison methods using standard light sources. However, as the demand for higher precision grew, more sophisticated approaches were developed, incorporating spectroradiometers and integrating spheres to achieve greater accuracy and repeatability.

The evolution of calibration protocols has been closely tied to the development of international standards and traceability to national metrology institutes. Organizations such as the National Institute of Standards and Technology (NIST) in the United States and the International Commission on Illumination (CIE) have played crucial roles in establishing guidelines and reference standards for photocell calibration.

Current trends in photocell calibration focus on enhancing the accuracy and efficiency of the calibration process. This includes the development of automated calibration systems, the use of advanced data analysis techniques to account for environmental variables, and the integration of machine learning algorithms to improve calibration models. Additionally, there is a growing emphasis on extending the calibration range to cover a wider spectrum of light sources, including LED-based illumination systems.

The future objectives of photocell calibration protocols for industrial light measurement are centered around achieving higher levels of precision, expanding the applicability across diverse industrial environments, and streamlining the calibration process to reduce time and cost. There is also a push towards developing more robust calibration methods that can maintain accuracy over extended periods, reducing the frequency of recalibration and minimizing downtime in industrial applications.

As industries continue to rely more heavily on precise light measurements for quality control, energy efficiency, and environmental monitoring, the importance of accurate photocell calibration protocols will only increase. The ongoing research and development in this field aim to meet these growing demands while adapting to new technologies and industrial requirements.

The primary objective of photocell calibration is to ensure the accuracy and consistency of light measurements across different devices and environments. This process involves establishing a standardized protocol that can be replicated across various industrial settings, allowing for reliable comparisons and data analysis. The calibration protocol aims to address several key challenges, including variations in photocell sensitivity, spectral response, and environmental factors that can affect measurement accuracy.

Over the years, the field of photocell calibration has seen significant advancements in both methodology and technology. Early calibration techniques relied on simple comparison methods using standard light sources. However, as the demand for higher precision grew, more sophisticated approaches were developed, incorporating spectroradiometers and integrating spheres to achieve greater accuracy and repeatability.

The evolution of calibration protocols has been closely tied to the development of international standards and traceability to national metrology institutes. Organizations such as the National Institute of Standards and Technology (NIST) in the United States and the International Commission on Illumination (CIE) have played crucial roles in establishing guidelines and reference standards for photocell calibration.

Current trends in photocell calibration focus on enhancing the accuracy and efficiency of the calibration process. This includes the development of automated calibration systems, the use of advanced data analysis techniques to account for environmental variables, and the integration of machine learning algorithms to improve calibration models. Additionally, there is a growing emphasis on extending the calibration range to cover a wider spectrum of light sources, including LED-based illumination systems.

The future objectives of photocell calibration protocols for industrial light measurement are centered around achieving higher levels of precision, expanding the applicability across diverse industrial environments, and streamlining the calibration process to reduce time and cost. There is also a push towards developing more robust calibration methods that can maintain accuracy over extended periods, reducing the frequency of recalibration and minimizing downtime in industrial applications.

As industries continue to rely more heavily on precise light measurements for quality control, energy efficiency, and environmental monitoring, the importance of accurate photocell calibration protocols will only increase. The ongoing research and development in this field aim to meet these growing demands while adapting to new technologies and industrial requirements.

Industrial Light Measurement Market Analysis

The industrial light measurement market has experienced significant growth in recent years, driven by increasing demand for precision lighting control across various industries. This market encompasses a wide range of applications, including manufacturing, automotive, aerospace, and healthcare sectors, where accurate light measurement is crucial for quality control, safety, and efficiency.

The global industrial light measurement market was valued at approximately $1.2 billion in 2020 and is projected to reach $1.8 billion by 2025, growing at a CAGR of 8.5% during the forecast period. This growth is primarily attributed to the rising adoption of automation and smart manufacturing technologies, which require precise light measurement for optimal performance.

One of the key drivers of market growth is the increasing focus on energy efficiency and sustainability in industrial processes. Accurate light measurement enables organizations to optimize their lighting systems, reduce energy consumption, and minimize their carbon footprint. This trend is particularly prominent in developed economies, where stringent regulations and environmental policies are pushing industries to adopt more efficient lighting solutions.

The automotive industry represents a significant segment of the industrial light measurement market, with applications ranging from headlight testing to interior lighting quality control. The growing complexity of automotive lighting systems, including adaptive headlights and ambient interior lighting, has led to increased demand for sophisticated light measurement tools and protocols.

In the manufacturing sector, light measurement plays a crucial role in ensuring product quality and consistency. Industries such as electronics, pharmaceuticals, and food processing rely heavily on precise light measurement for visual inspection, color matching, and defect detection. The integration of machine vision systems and artificial intelligence in manufacturing processes has further amplified the importance of accurate light measurement.

The healthcare industry is another key contributor to market growth, with applications in medical imaging, surgical lighting, and phototherapy. The need for precise light control in operating rooms and diagnostic equipment has driven the development of advanced light measurement technologies and calibration protocols.

Geographically, North America and Europe currently dominate the industrial light measurement market, owing to their well-established industrial base and early adoption of advanced technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing investments in manufacturing infrastructure, and growing awareness of the importance of light measurement in quality control processes.

As the market continues to evolve, there is a growing trend towards the development of portable and wireless light measurement devices, enabling real-time monitoring and data collection across various industrial applications. This shift towards more flexible and connected solutions is expected to create new opportunities for market players and drive further innovation in the field of industrial light measurement.

The global industrial light measurement market was valued at approximately $1.2 billion in 2020 and is projected to reach $1.8 billion by 2025, growing at a CAGR of 8.5% during the forecast period. This growth is primarily attributed to the rising adoption of automation and smart manufacturing technologies, which require precise light measurement for optimal performance.

One of the key drivers of market growth is the increasing focus on energy efficiency and sustainability in industrial processes. Accurate light measurement enables organizations to optimize their lighting systems, reduce energy consumption, and minimize their carbon footprint. This trend is particularly prominent in developed economies, where stringent regulations and environmental policies are pushing industries to adopt more efficient lighting solutions.

The automotive industry represents a significant segment of the industrial light measurement market, with applications ranging from headlight testing to interior lighting quality control. The growing complexity of automotive lighting systems, including adaptive headlights and ambient interior lighting, has led to increased demand for sophisticated light measurement tools and protocols.

In the manufacturing sector, light measurement plays a crucial role in ensuring product quality and consistency. Industries such as electronics, pharmaceuticals, and food processing rely heavily on precise light measurement for visual inspection, color matching, and defect detection. The integration of machine vision systems and artificial intelligence in manufacturing processes has further amplified the importance of accurate light measurement.

The healthcare industry is another key contributor to market growth, with applications in medical imaging, surgical lighting, and phototherapy. The need for precise light control in operating rooms and diagnostic equipment has driven the development of advanced light measurement technologies and calibration protocols.

Geographically, North America and Europe currently dominate the industrial light measurement market, owing to their well-established industrial base and early adoption of advanced technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing investments in manufacturing infrastructure, and growing awareness of the importance of light measurement in quality control processes.

As the market continues to evolve, there is a growing trend towards the development of portable and wireless light measurement devices, enabling real-time monitoring and data collection across various industrial applications. This shift towards more flexible and connected solutions is expected to create new opportunities for market players and drive further innovation in the field of industrial light measurement.

Current Challenges in Photocell Calibration

Photocell calibration in industrial light measurement faces several significant challenges that hinder the accuracy and reliability of measurements. One of the primary issues is the inherent instability of photocells over time. As these devices age, their sensitivity to light can change, leading to drift in measurements and potentially inaccurate readings. This drift is often unpredictable and can vary significantly between individual photocells, making it difficult to establish a standardized calibration protocol.

Environmental factors pose another substantial challenge in photocell calibration. Temperature fluctuations, humidity, and electromagnetic interference can all affect the performance of photocells. These variables are particularly problematic in industrial settings where conditions can change rapidly and dramatically. Calibrating photocells to account for these environmental variations requires complex compensation algorithms and frequent recalibration, which can be time-consuming and resource-intensive.

The spectral response of photocells presents an additional layer of complexity. Different photocells may have varying sensitivities to different wavelengths of light. This becomes particularly challenging when measuring light sources with complex spectral distributions, such as LED lighting or natural daylight. Ensuring that calibration protocols account for these spectral variations is crucial for accurate measurements across different light sources and environments.

Traceability to national or international standards is another critical challenge in photocell calibration. Establishing and maintaining a clear chain of calibration that links industrial measurements to recognized standards can be difficult, especially given the variability in photocell performance and the range of industrial applications. This challenge is compounded by the need for regular recalibration to maintain accuracy over time.

The increasing diversity of light sources in industrial settings further complicates calibration efforts. With the widespread adoption of LED lighting and other advanced illumination technologies, photocells must be calibrated to accurately measure a wide range of spectral distributions and intensities. This requires more sophisticated calibration equipment and procedures, as well as a deeper understanding of the interaction between different light sources and photocell responses.

Lastly, the demand for higher precision in industrial light measurement is pushing the limits of current calibration techniques. As industries require more accurate and reliable measurements for quality control, energy efficiency, and regulatory compliance, the tolerances for calibration errors become increasingly tight. Meeting these stringent requirements while addressing the other challenges mentioned above requires continuous innovation in calibration protocols and technologies.

Environmental factors pose another substantial challenge in photocell calibration. Temperature fluctuations, humidity, and electromagnetic interference can all affect the performance of photocells. These variables are particularly problematic in industrial settings where conditions can change rapidly and dramatically. Calibrating photocells to account for these environmental variations requires complex compensation algorithms and frequent recalibration, which can be time-consuming and resource-intensive.

The spectral response of photocells presents an additional layer of complexity. Different photocells may have varying sensitivities to different wavelengths of light. This becomes particularly challenging when measuring light sources with complex spectral distributions, such as LED lighting or natural daylight. Ensuring that calibration protocols account for these spectral variations is crucial for accurate measurements across different light sources and environments.

Traceability to national or international standards is another critical challenge in photocell calibration. Establishing and maintaining a clear chain of calibration that links industrial measurements to recognized standards can be difficult, especially given the variability in photocell performance and the range of industrial applications. This challenge is compounded by the need for regular recalibration to maintain accuracy over time.

The increasing diversity of light sources in industrial settings further complicates calibration efforts. With the widespread adoption of LED lighting and other advanced illumination technologies, photocells must be calibrated to accurately measure a wide range of spectral distributions and intensities. This requires more sophisticated calibration equipment and procedures, as well as a deeper understanding of the interaction between different light sources and photocell responses.

Lastly, the demand for higher precision in industrial light measurement is pushing the limits of current calibration techniques. As industries require more accurate and reliable measurements for quality control, energy efficiency, and regulatory compliance, the tolerances for calibration errors become increasingly tight. Meeting these stringent requirements while addressing the other challenges mentioned above requires continuous innovation in calibration protocols and technologies.

Existing Calibration Protocols

01 Light source calibration techniques

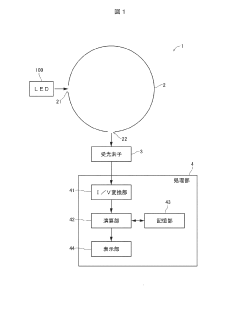

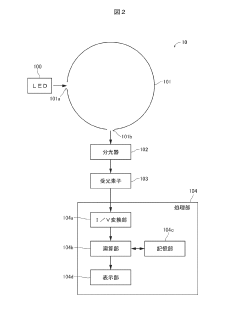

Various methods for calibrating light sources used in photocell systems. These techniques involve adjusting the intensity, wavelength, or other parameters of the light source to ensure accurate and consistent photocell measurements. Calibration may involve comparing the light source output to known standards or using specialized equipment to measure and adjust the light source characteristics.- Light source calibration techniques: Various methods for calibrating light sources used in photocell systems. These techniques involve adjusting the intensity, wavelength, or other parameters of the light source to ensure accurate photocell measurements. Calibration may include comparing the light source output to known standards or using specialized equipment to measure and adjust the light source characteristics.

- Photocell sensitivity adjustment: Methods for adjusting the sensitivity of photocells to optimize their performance in different lighting conditions. This may involve electronic circuits that automatically adjust the photocell's response based on ambient light levels, or manual calibration procedures to set the photocell's threshold for activation. Techniques may also include compensating for temperature variations or aging effects on the photocell.

- Calibration using reference standards: Procedures for calibrating photocells using known reference standards or calibrated light sources. This approach involves comparing the photocell's output to a traceable standard, allowing for precise adjustment of the photocell's response. The process may include using calibrated neutral density filters, spectral calibration sources, or certified reference materials to ensure accuracy across different light intensities and wavelengths.

- Automated calibration systems: Development of automated systems for photocell calibration, reducing the need for manual intervention. These systems may incorporate microprocessors or dedicated hardware to perform regular calibration checks and adjustments. Features can include self-diagnostic routines, error detection, and automatic recalibration based on environmental factors or usage patterns.

- Spectral response calibration: Techniques for calibrating the spectral response of photocells to ensure accurate measurements across different wavelengths of light. This may involve using monochromators or tunable light sources to characterize the photocell's response at various wavelengths. Calibration procedures can include adjusting filters or electronic compensation to achieve a desired spectral sensitivity profile.

02 Photocell sensitivity adjustment

Methods for adjusting the sensitivity of photocells to optimize their performance in different lighting conditions. This may involve electronic circuits or software algorithms that modify the photocell's response to light input. Techniques can include gain adjustment, threshold setting, or dynamic range expansion to improve accuracy and reliability of photocell measurements.Expand Specific Solutions03 Environmental compensation in photocell calibration

Approaches to compensate for environmental factors that can affect photocell performance, such as temperature, humidity, or ambient light. These methods may involve using additional sensors to measure environmental conditions and applying correction factors to the photocell output. Some techniques use adaptive algorithms to continuously adjust calibration based on changing environmental conditions.Expand Specific Solutions04 Automated calibration systems

Development of automated systems for photocell calibration that reduce human intervention and improve efficiency. These systems may use robotics, computer vision, or artificial intelligence to perform calibration tasks. Automated calibration can involve self-testing routines, error detection, and automatic adjustment of photocell parameters to maintain optimal performance over time.Expand Specific Solutions05 Multi-spectral photocell calibration

Techniques for calibrating photocells that are sensitive to multiple wavelengths of light. These methods address the challenges of ensuring accurate response across different parts of the spectrum. Calibration may involve using specialized light sources or filters to isolate specific wavelengths, and developing algorithms to process and interpret multi-spectral data accurately.Expand Specific Solutions

Key Players in Photocell Industry

The photocell calibration protocol for industrial light measurement market is in a growth phase, driven by increasing demand for precise light measurement in various industries. The global market size for light measurement devices is projected to reach several billion dollars by 2025, with a compound annual growth rate of around 6-8%. Technologically, the field is advancing rapidly, with key players like Applied Materials, Mitutoyo, and Tokyo Electron leading innovation in sensor technology, calibration methods, and integration with industrial IoT systems. Companies such as Raytheon and IBM are also contributing to the development of advanced algorithms and data processing techniques, enhancing the accuracy and reliability of photocell calibration protocols.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed an advanced Photocell Calibration Protocol for industrial light measurement applications. Their system utilizes a multi-point calibration approach, incorporating a high-precision spectroradiometer as a reference standard[1]. The protocol employs machine learning algorithms to compensate for environmental factors such as temperature and humidity, ensuring consistent measurements across various industrial settings[3]. The calibration process includes automated dark current subtraction and linearity correction, enhancing the accuracy of light intensity measurements[5]. Additionally, the system features real-time drift compensation, allowing for long-term stability in continuous monitoring applications[7].

Strengths: High accuracy and precision, adaptability to various industrial environments, long-term stability. Weaknesses: Potentially higher cost due to advanced technology, may require specialized training for operators.

Mitutoyo Corp.

Technical Solution: Mitutoyo's Photocell Calibration Protocol focuses on traceability and repeatability in industrial light measurement. Their system employs a NIST-traceable light source for initial calibration, ensuring global standardization[2]. The protocol incorporates a unique step-wise calibration process, which allows for fine-tuning of photocell response across different light intensities and wavelengths[4]. Mitutoyo's approach includes a proprietary software algorithm that compensates for photocell aging, maintaining calibration accuracy over extended periods[6]. The system also features an integrated temperature control mechanism to minimize thermal drift during the calibration process[8].

Strengths: High traceability to international standards, excellent long-term stability, comprehensive wavelength coverage. Weaknesses: May be less flexible for non-standard light sources, potentially longer calibration time due to step-wise process.

Innovative Calibration Methods

Methods and apparatus providing calibration of background illumination for sample and/or sample container characterization

PatentActiveUS20240159786A1

Innovation

- A calibration method that identifies the mechanical center of each light panel, adjusts the drive current to achieve consistent background illumination across multiple spectrums and machines, ensuring precise detection of HIL and artifacts by determining the optimal optical center and region of interest for backlight calibration.

Method for calibrating light measuring device

PatentActiveJP2023132561A

Innovation

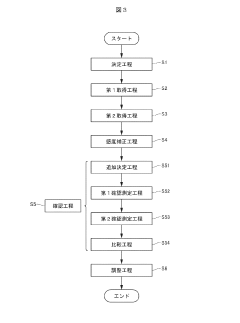

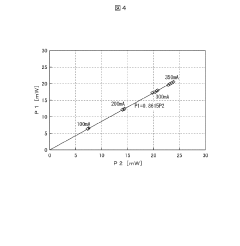

- A method involving determining equivalent light emission conditions for LEDs across various wavelengths, obtaining measurement results using a prototype and a calibrated device, and correcting the device's sensitivity based on these results to suppress wavelength dependence.

Standardization and Certification

Standardization and certification play a crucial role in ensuring the reliability and accuracy of photocell calibration protocols for industrial light measurement. The development of industry-wide standards and certification processes is essential for maintaining consistency and quality across different manufacturers and applications.

International organizations such as the International Commission on Illumination (CIE) and the International Organization for Standardization (ISO) have established guidelines and standards for light measurement and photocell calibration. These standards provide a framework for manufacturers and users to follow, ensuring that calibration procedures are consistent and traceable.

One of the key aspects of standardization is the establishment of reference light sources and measurement conditions. These reference standards allow for the comparison and validation of calibration results across different laboratories and facilities. The National Institute of Standards and Technology (NIST) in the United States and similar organizations in other countries maintain primary standards for light measurement, which serve as the basis for calibration chains.

Certification programs have been developed to verify the competence of laboratories and personnel involved in photocell calibration. These programs typically involve proficiency testing, on-site assessments, and regular audits to ensure compliance with established standards. Accreditation bodies such as the International Laboratory Accreditation Cooperation (ILAC) provide recognition for certified calibration laboratories, enhancing the credibility of their measurements.

The standardization of calibration protocols also extends to the documentation and reporting of results. Standardized formats for calibration certificates and uncertainty budgets help ensure that calibration data can be easily interpreted and compared across different organizations. This standardization facilitates the exchange of information and promotes transparency in the calibration process.

As technology advances, standards and certification processes must evolve to keep pace with new developments in light measurement and photocell technology. Regular reviews and updates of existing standards are necessary to address emerging challenges and incorporate new best practices. Collaborative efforts between industry stakeholders, research institutions, and standardization bodies are essential for driving continuous improvement in calibration protocols.

The implementation of standardized calibration protocols and certification processes brings numerous benefits to the industrial light measurement sector. It enhances the reliability of measurements, reduces measurement uncertainties, and improves the comparability of results between different laboratories and instruments. This, in turn, supports quality control processes, product development, and regulatory compliance across various industries that rely on accurate light measurements.

International organizations such as the International Commission on Illumination (CIE) and the International Organization for Standardization (ISO) have established guidelines and standards for light measurement and photocell calibration. These standards provide a framework for manufacturers and users to follow, ensuring that calibration procedures are consistent and traceable.

One of the key aspects of standardization is the establishment of reference light sources and measurement conditions. These reference standards allow for the comparison and validation of calibration results across different laboratories and facilities. The National Institute of Standards and Technology (NIST) in the United States and similar organizations in other countries maintain primary standards for light measurement, which serve as the basis for calibration chains.

Certification programs have been developed to verify the competence of laboratories and personnel involved in photocell calibration. These programs typically involve proficiency testing, on-site assessments, and regular audits to ensure compliance with established standards. Accreditation bodies such as the International Laboratory Accreditation Cooperation (ILAC) provide recognition for certified calibration laboratories, enhancing the credibility of their measurements.

The standardization of calibration protocols also extends to the documentation and reporting of results. Standardized formats for calibration certificates and uncertainty budgets help ensure that calibration data can be easily interpreted and compared across different organizations. This standardization facilitates the exchange of information and promotes transparency in the calibration process.

As technology advances, standards and certification processes must evolve to keep pace with new developments in light measurement and photocell technology. Regular reviews and updates of existing standards are necessary to address emerging challenges and incorporate new best practices. Collaborative efforts between industry stakeholders, research institutions, and standardization bodies are essential for driving continuous improvement in calibration protocols.

The implementation of standardized calibration protocols and certification processes brings numerous benefits to the industrial light measurement sector. It enhances the reliability of measurements, reduces measurement uncertainties, and improves the comparability of results between different laboratories and instruments. This, in turn, supports quality control processes, product development, and regulatory compliance across various industries that rely on accurate light measurements.

Environmental Factors in Calibration

Environmental factors play a crucial role in the accuracy and reliability of photocell calibration for industrial light measurement. Temperature fluctuations can significantly impact the performance of photocells, affecting their sensitivity and response characteristics. As ambient temperature changes, the electrical properties of semiconductor materials used in photocells may vary, leading to shifts in calibration curves and potential measurement errors.

Humidity is another critical environmental factor that must be considered during the calibration process. High humidity levels can lead to condensation on optical surfaces, altering light transmission and potentially causing long-term damage to sensitive components. Conversely, extremely low humidity environments may contribute to static electricity buildup, which can interfere with delicate electronic circuits and compromise measurement accuracy.

Atmospheric pressure variations, while often overlooked, can influence the behavior of certain types of photocells, particularly those used in specialized applications such as aerospace or high-altitude industrial settings. Changes in pressure can affect the gas composition within sealed photocell units, potentially altering their response characteristics over time.

Dust and particulate matter present in industrial environments pose significant challenges to maintaining accurate calibration. Accumulation of particles on optical surfaces can reduce light transmission, leading to gradual degradation of measurement accuracy. Regular cleaning and maintenance protocols must be established to mitigate these effects and ensure consistent performance.

Electromagnetic interference (EMI) from nearby electrical equipment or power sources can introduce noise and distortions in photocell measurements. Proper shielding and grounding techniques must be implemented to minimize EMI effects and maintain calibration integrity. Additionally, vibration and mechanical stress can impact the physical alignment of optical components, necessitating robust mounting solutions and periodic verification of optical alignment.

Light source stability is a critical factor in photocell calibration. Fluctuations in the intensity or spectral characteristics of calibration light sources can lead to inconsistent results. Careful selection of stable, well-characterized light sources and regular verification of their output is essential for maintaining calibration accuracy over time.

To address these environmental challenges, comprehensive calibration protocols must incorporate strategies for environmental control and monitoring. This may include the use of temperature-controlled calibration chambers, humidity regulation systems, and air filtration to create stable, reproducible conditions for calibration procedures. Additionally, the development of compensation algorithms that account for environmental variations can help maintain measurement accuracy across a range of operating conditions.

Humidity is another critical environmental factor that must be considered during the calibration process. High humidity levels can lead to condensation on optical surfaces, altering light transmission and potentially causing long-term damage to sensitive components. Conversely, extremely low humidity environments may contribute to static electricity buildup, which can interfere with delicate electronic circuits and compromise measurement accuracy.

Atmospheric pressure variations, while often overlooked, can influence the behavior of certain types of photocells, particularly those used in specialized applications such as aerospace or high-altitude industrial settings. Changes in pressure can affect the gas composition within sealed photocell units, potentially altering their response characteristics over time.

Dust and particulate matter present in industrial environments pose significant challenges to maintaining accurate calibration. Accumulation of particles on optical surfaces can reduce light transmission, leading to gradual degradation of measurement accuracy. Regular cleaning and maintenance protocols must be established to mitigate these effects and ensure consistent performance.

Electromagnetic interference (EMI) from nearby electrical equipment or power sources can introduce noise and distortions in photocell measurements. Proper shielding and grounding techniques must be implemented to minimize EMI effects and maintain calibration integrity. Additionally, vibration and mechanical stress can impact the physical alignment of optical components, necessitating robust mounting solutions and periodic verification of optical alignment.

Light source stability is a critical factor in photocell calibration. Fluctuations in the intensity or spectral characteristics of calibration light sources can lead to inconsistent results. Careful selection of stable, well-characterized light sources and regular verification of their output is essential for maintaining calibration accuracy over time.

To address these environmental challenges, comprehensive calibration protocols must incorporate strategies for environmental control and monitoring. This may include the use of temperature-controlled calibration chambers, humidity regulation systems, and air filtration to create stable, reproducible conditions for calibration procedures. Additionally, the development of compensation algorithms that account for environmental variations can help maintain measurement accuracy across a range of operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!