How to Enhance K24 Engine Aesthetics with Custom Covers?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Cover Evolution

The K24 engine cover has undergone significant evolution since its introduction, reflecting both functional improvements and aesthetic considerations. Initially designed primarily for protection and heat management, early K24 engine covers were largely utilitarian in nature, focusing on durability and efficiency rather than visual appeal.

As automotive design trends shifted towards more visually striking engine bays, manufacturers began to recognize the potential of engine covers as a canvas for brand expression and aesthetic enhancement. This led to a gradual transformation in the design philosophy of K24 engine covers, with an increasing emphasis on form alongside function.

The evolution of materials played a crucial role in this transformation. Early covers were predominantly made of stamped steel or basic plastics, chosen for their cost-effectiveness and heat resistance. However, advancements in polymer technology and manufacturing processes allowed for the introduction of more sophisticated materials, such as high-grade thermoplastics and composite materials. These new materials offered improved heat management properties while also providing greater design flexibility.

Color became an important aspect of K24 engine cover evolution. While early covers were often left in basic black or unpainted metal finishes, later iterations saw the introduction of color-matched covers that complemented the vehicle's exterior paint. This trend extended to the use of contrasting colors and even metallic finishes to create visual interest within the engine bay.

Texture and surface treatment also evolved significantly. Smooth, featureless covers gave way to more intricate designs featuring embossed patterns, raised logos, and varying surface finishes. These elements not only enhanced the visual appeal but also served to reinforce brand identity and model differentiation.

The integration of functional elements into the aesthetic design marked another milestone in K24 engine cover evolution. Manufacturers began incorporating air intake vents, oil fill caps, and other necessary components into the cover design in more visually pleasing ways. This integration of form and function represented a more holistic approach to engine bay aesthetics.

Recent trends in K24 engine cover design have seen a move towards minimalism and clean lines, influenced by broader automotive design trends. Some manufacturers have experimented with transparent or partially transparent covers, allowing glimpses of the engine beneath while maintaining protection and heat management properties.

The aftermarket industry has also played a significant role in the evolution of K24 engine covers, offering custom solutions that range from subtle enhancements to radical redesigns. These aftermarket options have pushed the boundaries of what's possible in engine cover aesthetics, often incorporating advanced materials, unique finishes, and innovative lighting solutions.

As automotive design trends shifted towards more visually striking engine bays, manufacturers began to recognize the potential of engine covers as a canvas for brand expression and aesthetic enhancement. This led to a gradual transformation in the design philosophy of K24 engine covers, with an increasing emphasis on form alongside function.

The evolution of materials played a crucial role in this transformation. Early covers were predominantly made of stamped steel or basic plastics, chosen for their cost-effectiveness and heat resistance. However, advancements in polymer technology and manufacturing processes allowed for the introduction of more sophisticated materials, such as high-grade thermoplastics and composite materials. These new materials offered improved heat management properties while also providing greater design flexibility.

Color became an important aspect of K24 engine cover evolution. While early covers were often left in basic black or unpainted metal finishes, later iterations saw the introduction of color-matched covers that complemented the vehicle's exterior paint. This trend extended to the use of contrasting colors and even metallic finishes to create visual interest within the engine bay.

Texture and surface treatment also evolved significantly. Smooth, featureless covers gave way to more intricate designs featuring embossed patterns, raised logos, and varying surface finishes. These elements not only enhanced the visual appeal but also served to reinforce brand identity and model differentiation.

The integration of functional elements into the aesthetic design marked another milestone in K24 engine cover evolution. Manufacturers began incorporating air intake vents, oil fill caps, and other necessary components into the cover design in more visually pleasing ways. This integration of form and function represented a more holistic approach to engine bay aesthetics.

Recent trends in K24 engine cover design have seen a move towards minimalism and clean lines, influenced by broader automotive design trends. Some manufacturers have experimented with transparent or partially transparent covers, allowing glimpses of the engine beneath while maintaining protection and heat management properties.

The aftermarket industry has also played a significant role in the evolution of K24 engine covers, offering custom solutions that range from subtle enhancements to radical redesigns. These aftermarket options have pushed the boundaries of what's possible in engine cover aesthetics, often incorporating advanced materials, unique finishes, and innovative lighting solutions.

Market Demand Analysis

The market demand for custom K24 engine covers has been steadily growing, driven by the increasing popularity of automotive customization and the desire for unique, personalized vehicle aesthetics. This trend is particularly prominent among Honda enthusiasts and performance car owners who seek to enhance the visual appeal of their engines.

The K24 engine, known for its reliability and performance, is widely used in various Honda and Acura models. As these vehicles age, owners are looking for ways to refresh their appearance and stand out from stock models. Custom engine covers provide an effective solution, allowing for personalization without compromising engine functionality.

Market research indicates that the global automotive aftermarket industry, which includes custom engine components, is expected to grow significantly in the coming years. This growth is fueled by rising disposable incomes, a growing car culture, and the increasing average age of vehicles on the road. The custom engine cover segment, while niche, is benefiting from this overall market expansion.

Consumer surveys reveal that aesthetics and uniqueness are primary drivers for purchasing custom engine covers. Buyers are willing to invest in high-quality, visually appealing covers that complement their vehicle's overall design. There is a particular demand for covers that showcase the engine's performance potential or reflect the owner's personal style.

The market for K24 engine covers is not limited to individual consumers. Automotive shops, custom car builders, and even some dealerships are recognizing the value of offering aesthetic engine upgrades. This B2B segment represents a growing market opportunity, as these businesses seek to differentiate their services and cater to discerning customers.

Environmental considerations are also influencing market demand. As sustainability becomes a more significant concern, there is an increasing interest in engine covers made from eco-friendly materials or those that offer improved heat management, potentially contributing to better engine efficiency.

The digital marketplace has significantly impacted the custom engine cover market. Online platforms and social media have made it easier for consumers to discover and purchase unique designs, while also providing a showcase for custom builds. This digital presence has expanded the market reach beyond traditional automotive enthusiast circles.

In conclusion, the market demand for custom K24 engine covers is robust and diverse, driven by aesthetic preferences, personalization trends, and the broader growth of the automotive aftermarket industry. As technology advances and consumer preferences evolve, this market segment is likely to continue expanding, offering opportunities for innovation in design, materials, and manufacturing processes.

The K24 engine, known for its reliability and performance, is widely used in various Honda and Acura models. As these vehicles age, owners are looking for ways to refresh their appearance and stand out from stock models. Custom engine covers provide an effective solution, allowing for personalization without compromising engine functionality.

Market research indicates that the global automotive aftermarket industry, which includes custom engine components, is expected to grow significantly in the coming years. This growth is fueled by rising disposable incomes, a growing car culture, and the increasing average age of vehicles on the road. The custom engine cover segment, while niche, is benefiting from this overall market expansion.

Consumer surveys reveal that aesthetics and uniqueness are primary drivers for purchasing custom engine covers. Buyers are willing to invest in high-quality, visually appealing covers that complement their vehicle's overall design. There is a particular demand for covers that showcase the engine's performance potential or reflect the owner's personal style.

The market for K24 engine covers is not limited to individual consumers. Automotive shops, custom car builders, and even some dealerships are recognizing the value of offering aesthetic engine upgrades. This B2B segment represents a growing market opportunity, as these businesses seek to differentiate their services and cater to discerning customers.

Environmental considerations are also influencing market demand. As sustainability becomes a more significant concern, there is an increasing interest in engine covers made from eco-friendly materials or those that offer improved heat management, potentially contributing to better engine efficiency.

The digital marketplace has significantly impacted the custom engine cover market. Online platforms and social media have made it easier for consumers to discover and purchase unique designs, while also providing a showcase for custom builds. This digital presence has expanded the market reach beyond traditional automotive enthusiast circles.

In conclusion, the market demand for custom K24 engine covers is robust and diverse, driven by aesthetic preferences, personalization trends, and the broader growth of the automotive aftermarket industry. As technology advances and consumer preferences evolve, this market segment is likely to continue expanding, offering opportunities for innovation in design, materials, and manufacturing processes.

Current Challenges

The enhancement of K24 engine aesthetics with custom covers faces several significant challenges in the current automotive landscape. One of the primary obstacles is the limited space within the engine bay, which restricts the design possibilities for custom covers. Modern vehicles are increasingly compact, with engine compartments tightly packed to optimize performance and efficiency. This spatial constraint makes it difficult to incorporate elaborate or expansive cover designs without interfering with essential components or compromising functionality.

Another challenge lies in the material selection for custom covers. The engine environment is characterized by high temperatures, vibrations, and exposure to various fluids. Consequently, materials used for aesthetic covers must withstand these harsh conditions while maintaining their visual appeal over time. Balancing durability with aesthetic quality presents a significant engineering challenge, as materials that excel in one aspect may fall short in another.

Heat management is a critical concern when designing custom engine covers. The K24 engine, like most internal combustion engines, generates substantial heat during operation. Custom covers must not impede the engine's cooling system or trap excessive heat, which could lead to performance issues or accelerated wear of engine components. Designers must carefully consider ventilation and thermal properties when developing aesthetic solutions.

Regulatory compliance poses another hurdle in the customization process. Engine covers must adhere to safety standards and emissions regulations, which can limit design freedom. For instance, covers must not interfere with emissions control systems or obstruct access to critical maintenance points. Navigating these regulatory requirements while achieving desired aesthetic enhancements requires a delicate balance.

Cost-effectiveness is a significant challenge in the custom cover market. While enthusiasts may be willing to invest in unique aesthetic enhancements, the production of custom covers often involves specialized manufacturing processes and materials. Achieving a balance between affordability and quality, especially for low-volume production runs, remains a persistent challenge for aftermarket manufacturers.

Lastly, the integration of modern technology into engine aesthetics presents both opportunities and challenges. As vehicles become more technologically advanced, there is growing interest in incorporating smart features or displays into engine covers. However, implementing such features while maintaining the cover's primary protective and aesthetic functions adds layers of complexity to the design and manufacturing process.

Another challenge lies in the material selection for custom covers. The engine environment is characterized by high temperatures, vibrations, and exposure to various fluids. Consequently, materials used for aesthetic covers must withstand these harsh conditions while maintaining their visual appeal over time. Balancing durability with aesthetic quality presents a significant engineering challenge, as materials that excel in one aspect may fall short in another.

Heat management is a critical concern when designing custom engine covers. The K24 engine, like most internal combustion engines, generates substantial heat during operation. Custom covers must not impede the engine's cooling system or trap excessive heat, which could lead to performance issues or accelerated wear of engine components. Designers must carefully consider ventilation and thermal properties when developing aesthetic solutions.

Regulatory compliance poses another hurdle in the customization process. Engine covers must adhere to safety standards and emissions regulations, which can limit design freedom. For instance, covers must not interfere with emissions control systems or obstruct access to critical maintenance points. Navigating these regulatory requirements while achieving desired aesthetic enhancements requires a delicate balance.

Cost-effectiveness is a significant challenge in the custom cover market. While enthusiasts may be willing to invest in unique aesthetic enhancements, the production of custom covers often involves specialized manufacturing processes and materials. Achieving a balance between affordability and quality, especially for low-volume production runs, remains a persistent challenge for aftermarket manufacturers.

Lastly, the integration of modern technology into engine aesthetics presents both opportunities and challenges. As vehicles become more technologically advanced, there is growing interest in incorporating smart features or displays into engine covers. However, implementing such features while maintaining the cover's primary protective and aesthetic functions adds layers of complexity to the design and manufacturing process.

Existing Cover Solutions

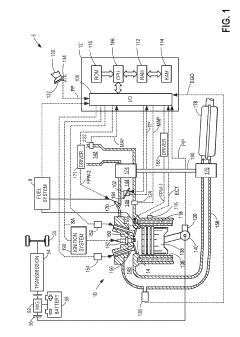

01 Engine cover design for aesthetic appeal

Designing aesthetically pleasing engine covers for the K24 engine to enhance its visual appeal. This may include incorporating sleek lines, textures, or branded elements to create a more attractive appearance while maintaining functionality.- Engine cover design for aesthetic appeal: Designing aesthetically pleasing engine covers for the K24 engine to enhance its visual appeal. This may include incorporating sleek lines, textures, and materials that complement the engine's performance while providing an attractive appearance under the hood.

- Color schemes and finishes for engine components: Applying various color schemes and finishes to K24 engine components to improve their visual appeal. This can include anodized or powder-coated parts, custom paint jobs, or the use of contrasting colors to highlight specific engine features.

- Integration of lighting elements: Incorporating lighting elements into the K24 engine bay to enhance its aesthetic appeal. This may involve LED lighting systems, illuminated logos, or strategically placed lights to showcase the engine's design features, especially during nighttime displays or in dimly lit environments.

- Custom fabrication of engine accessories: Creating custom-fabricated accessories for the K24 engine to improve its overall aesthetics. This can include bespoke intake manifolds, valve covers, oil caps, and other visible components that contribute to a unique and visually appealing engine bay.

- Digital visualization and customization tools: Developing digital tools and software for visualizing and customizing K24 engine aesthetics. These may include 3D modeling applications, augmented reality interfaces, or online configurators that allow users to experiment with different aesthetic modifications before implementing them on the actual engine.

02 Color and finish optimization

Applying specialized coatings, paints, or finishes to the K24 engine components to improve their visual appearance. This can include using high-gloss, matte, or metallic finishes to enhance the engine's aesthetics and protect against corrosion.Expand Specific Solutions03 Integration of lighting elements

Incorporating LED or other lighting elements into the K24 engine design to create visual interest and highlight key components. This can include accent lighting, illuminated logos, or functional lighting for improved visibility during maintenance.Expand Specific Solutions04 3D modeling and visualization techniques

Utilizing advanced 3D modeling and visualization software to design and showcase aesthetic improvements for the K24 engine. This allows for rapid prototyping and evaluation of different design options before physical implementation.Expand Specific Solutions05 Custom component design

Creating custom-designed components for the K24 engine, such as intake manifolds, valve covers, or pulleys, that combine improved performance with enhanced visual appeal. These components can be manufactured using materials and processes that result in a more attractive appearance.Expand Specific Solutions

Key Aftermarket Players

The K24 engine aesthetics enhancement market is in a growth phase, driven by increasing consumer demand for personalized vehicle aesthetics. The market size is expanding, with a growing aftermarket segment for custom engine covers. Technologically, the field is evolving, with companies like Honda Motor Co., Ltd. and Toyota Motor Corp. leading in innovative designs. Ford Global Technologies LLC and Mazda Motor Corp. are also making strides in this area, focusing on lightweight materials and aerodynamic designs. The competition is intensifying as both established automakers and specialized aftermarket manufacturers vie for market share in this niche but growing segment.

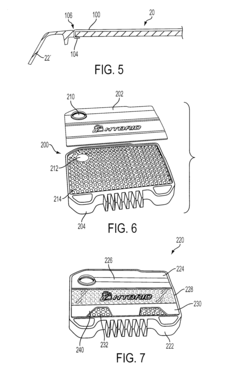

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a range of custom engine covers for their K24 engine, focusing on both aesthetics and functionality. Their approach includes the use of lightweight, high-strength materials such as carbon fiber and aluminum composites. Honda's design incorporates advanced thermal management features, with strategically placed vents and heat-resistant coatings to optimize engine performance while maintaining an attractive appearance. The company has also introduced customizable color options and modular designs, allowing for easy personalization[1]. Honda's K24 engine covers feature integrated LED lighting systems, enhancing the visual appeal, especially for showcase vehicles or night-time displays[2].

Strengths: Brand reputation, extensive R&D capabilities, and integration with existing Honda systems. Weaknesses: Potentially higher cost compared to aftermarket options, limited to Honda-specific engines.

Toyota Motor Corp.

Technical Solution: Toyota's approach to enhancing K24 engine aesthetics focuses on a blend of traditional Japanese craftsmanship and modern technology. They have developed a series of engine covers using a technique called "Takumi craftsmanship," which involves hand-finished details combined with precision manufacturing. Toyota's covers feature intricate patterns inspired by nature, such as sakura blossoms or bamboo textures, etched onto high-grade aluminum surfaces[3]. The company has also incorporated smart materials that change color or transparency based on engine temperature, providing both aesthetic appeal and functional information to the user[4]. Additionally, Toyota has implemented a modular design system that allows for easy customization and replacement of individual cover components.

Strengths: Unique cultural design elements, innovative use of smart materials, and modular customization options. Weaknesses: Potentially high production costs, may not appeal to all market segments.

Innovative Materials

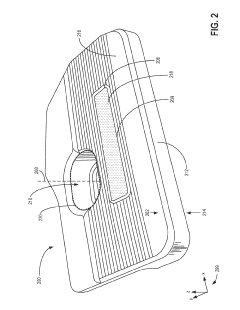

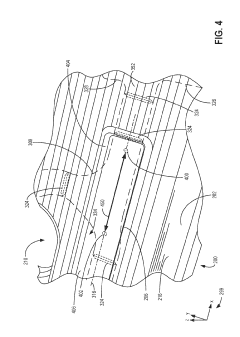

Modular engine cover

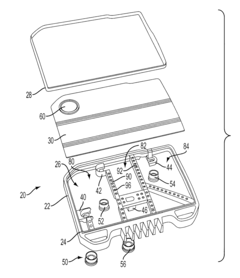

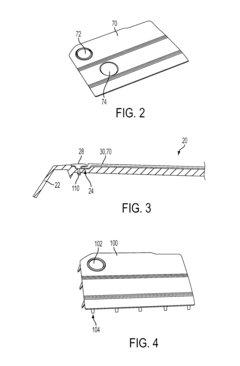

PatentInactiveUS7389760B2

Innovation

- A modular engine cover design featuring a molded plastic frame with a stamped metal skin, allowing for interchangeable skins and isolators to reduce weight and tooling costs, while providing structural integrity and noise reduction.

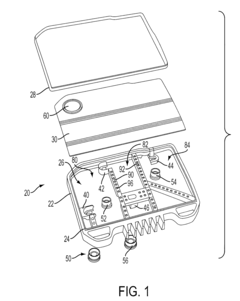

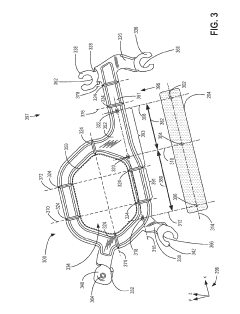

Reinforced vehicle component cover

PatentActiveUS20190106065A1

Innovation

- A vehicle component cover design featuring a solid encasement with embedded support structures containing lock orifices that allow emblems to be securely locked in place without additional fasteners, utilizing sliding extensions that engage with the lock orifices to maintain position and reduce assembly complexity.

Manufacturing Processes

The manufacturing processes for custom K24 engine covers play a crucial role in enhancing the aesthetics of the engine while maintaining functionality. These processes typically involve a combination of traditional and advanced manufacturing techniques to create visually appealing and durable covers.

One of the primary manufacturing methods for custom engine covers is CNC machining. This process allows for precise cutting and shaping of materials such as aluminum or stainless steel. CNC machines can create intricate designs, logos, and textures on the cover surface, giving it a unique and premium appearance. The ability to program complex patterns and shapes enables manufacturers to produce covers with high levels of detail and consistency.

Another popular manufacturing technique is casting, particularly for more complex shapes or larger production runs. Investment casting, also known as lost-wax casting, is often used for creating engine covers with intricate designs. This process involves creating a wax pattern of the cover, which is then coated with ceramic material to form a mold. Once the wax is melted out, molten metal is poured into the mold to create the final product. Casting allows for the production of covers with smooth surfaces and complex geometries that might be challenging to achieve through machining alone.

For engine covers requiring a combination of strength and lightweight properties, composite materials are increasingly being used. Manufacturing processes for composite covers often involve layup techniques, where carbon fiber or fiberglass sheets are impregnated with resin and molded into the desired shape. Vacuum bagging and autoclave curing are commonly employed to ensure proper consolidation and curing of the composite materials, resulting in a high-strength, lightweight cover with a distinctive appearance.

Surface finishing processes play a crucial role in enhancing the final aesthetics of custom K24 engine covers. These may include polishing, brushing, or anodizing for metal covers to achieve different textures and colors. For composite covers, gel coating or painting processes are often used to provide a smooth, glossy finish and protect the underlying material.

Additive manufacturing, or 3D printing, is emerging as an innovative method for producing custom engine covers. This technology allows for the creation of complex geometries and internal structures that would be difficult or impossible to achieve with traditional manufacturing methods. Materials such as high-performance polymers or metal powders can be used to create lightweight yet durable covers with unique designs.

The choice of manufacturing process depends on factors such as material selection, design complexity, production volume, and cost considerations. Often, a combination of these processes is used to achieve the desired aesthetic and functional properties of custom K24 engine covers.

One of the primary manufacturing methods for custom engine covers is CNC machining. This process allows for precise cutting and shaping of materials such as aluminum or stainless steel. CNC machines can create intricate designs, logos, and textures on the cover surface, giving it a unique and premium appearance. The ability to program complex patterns and shapes enables manufacturers to produce covers with high levels of detail and consistency.

Another popular manufacturing technique is casting, particularly for more complex shapes or larger production runs. Investment casting, also known as lost-wax casting, is often used for creating engine covers with intricate designs. This process involves creating a wax pattern of the cover, which is then coated with ceramic material to form a mold. Once the wax is melted out, molten metal is poured into the mold to create the final product. Casting allows for the production of covers with smooth surfaces and complex geometries that might be challenging to achieve through machining alone.

For engine covers requiring a combination of strength and lightweight properties, composite materials are increasingly being used. Manufacturing processes for composite covers often involve layup techniques, where carbon fiber or fiberglass sheets are impregnated with resin and molded into the desired shape. Vacuum bagging and autoclave curing are commonly employed to ensure proper consolidation and curing of the composite materials, resulting in a high-strength, lightweight cover with a distinctive appearance.

Surface finishing processes play a crucial role in enhancing the final aesthetics of custom K24 engine covers. These may include polishing, brushing, or anodizing for metal covers to achieve different textures and colors. For composite covers, gel coating or painting processes are often used to provide a smooth, glossy finish and protect the underlying material.

Additive manufacturing, or 3D printing, is emerging as an innovative method for producing custom engine covers. This technology allows for the creation of complex geometries and internal structures that would be difficult or impossible to achieve with traditional manufacturing methods. Materials such as high-performance polymers or metal powders can be used to create lightweight yet durable covers with unique designs.

The choice of manufacturing process depends on factors such as material selection, design complexity, production volume, and cost considerations. Often, a combination of these processes is used to achieve the desired aesthetic and functional properties of custom K24 engine covers.

Performance Impact

When considering the enhancement of K24 engine aesthetics with custom covers, it is crucial to evaluate the potential performance impact of such modifications. Custom engine covers, while primarily designed for visual appeal, can have both positive and negative effects on engine performance.

One of the primary concerns when adding custom covers is the potential for increased heat retention. Engine covers can act as insulators, trapping heat within the engine bay. This increased thermal load may lead to higher operating temperatures, which can negatively impact engine efficiency and longevity. However, some custom covers are designed with heat-dissipating materials or ventilation features that can mitigate this issue.

Weight is another factor to consider. Depending on the materials used, custom covers may add extra weight to the vehicle. While the additional weight of engine covers is typically minimal, it can still contribute to a slight decrease in overall performance, particularly in high-performance applications where every gram counts.

On the positive side, well-designed custom covers can potentially improve aerodynamics within the engine bay. By smoothing out the surface area and reducing turbulence, these covers may contribute to better airflow management. This can lead to improved cooling efficiency and, in some cases, a marginal increase in engine performance.

Custom covers can also provide an additional layer of protection for engine components. By shielding sensitive parts from debris, dust, and moisture, they may help maintain optimal performance over time. This protective function can be particularly beneficial in harsh driving conditions or off-road environments.

It's worth noting that some custom covers are designed with performance in mind. These may incorporate features such as cold air intake systems or ram air ducts, which can potentially boost engine performance by increasing the volume of cool, dense air entering the engine.

When installing custom covers, it's essential to ensure proper fitment and clearance. Ill-fitting covers can interfere with moving parts or restrict access to critical components, potentially leading to performance issues or maintenance difficulties.

In conclusion, while the primary goal of custom engine covers is aesthetic enhancement, their impact on performance should not be overlooked. Careful consideration of materials, design, and installation is necessary to minimize potential negative effects and maximize any performance benefits. Ultimately, the performance impact of custom covers on a K24 engine will depend on the specific design, materials, and quality of the chosen covers.

One of the primary concerns when adding custom covers is the potential for increased heat retention. Engine covers can act as insulators, trapping heat within the engine bay. This increased thermal load may lead to higher operating temperatures, which can negatively impact engine efficiency and longevity. However, some custom covers are designed with heat-dissipating materials or ventilation features that can mitigate this issue.

Weight is another factor to consider. Depending on the materials used, custom covers may add extra weight to the vehicle. While the additional weight of engine covers is typically minimal, it can still contribute to a slight decrease in overall performance, particularly in high-performance applications where every gram counts.

On the positive side, well-designed custom covers can potentially improve aerodynamics within the engine bay. By smoothing out the surface area and reducing turbulence, these covers may contribute to better airflow management. This can lead to improved cooling efficiency and, in some cases, a marginal increase in engine performance.

Custom covers can also provide an additional layer of protection for engine components. By shielding sensitive parts from debris, dust, and moisture, they may help maintain optimal performance over time. This protective function can be particularly beneficial in harsh driving conditions or off-road environments.

It's worth noting that some custom covers are designed with performance in mind. These may incorporate features such as cold air intake systems or ram air ducts, which can potentially boost engine performance by increasing the volume of cool, dense air entering the engine.

When installing custom covers, it's essential to ensure proper fitment and clearance. Ill-fitting covers can interfere with moving parts or restrict access to critical components, potentially leading to performance issues or maintenance difficulties.

In conclusion, while the primary goal of custom engine covers is aesthetic enhancement, their impact on performance should not be overlooked. Careful consideration of materials, design, and installation is necessary to minimize potential negative effects and maximize any performance benefits. Ultimately, the performance impact of custom covers on a K24 engine will depend on the specific design, materials, and quality of the chosen covers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!