How to Enhance Silicone Rubber's Environmental Impact?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Eco-Enhancement Goals

Silicone rubber, a versatile synthetic polymer, has been widely used across various industries due to its exceptional properties. However, as environmental concerns grow, there is an increasing need to enhance its eco-friendliness. The primary goal of improving silicone rubber's environmental impact is to create a more sustainable material that maintains its beneficial characteristics while minimizing negative effects on the ecosystem.

One of the key objectives is to reduce the carbon footprint associated with silicone rubber production. This involves optimizing manufacturing processes to consume less energy and resources, as well as exploring alternative energy sources for production facilities. Additionally, there is a focus on developing bio-based silicone precursors to decrease reliance on petroleum-derived raw materials, thereby reducing the overall environmental impact of the material's life cycle.

Another crucial aim is to enhance the biodegradability of silicone rubber. While traditional silicone rubber is known for its durability and resistance to degradation, this characteristic becomes problematic at the end of the product's life. Research efforts are directed towards creating silicone rubber formulations that can break down more readily in natural environments without releasing harmful byproducts.

Improving the recyclability of silicone rubber products is also a significant goal. This involves developing efficient methods for separating and purifying used silicone rubber, as well as creating new techniques for reprocessing the material without significant loss of its original properties. The aim is to establish a circular economy model for silicone rubber, where waste is minimized, and resources are continually reused.

Reducing the leaching of potentially harmful additives from silicone rubber products is another important objective. This includes finding safer alternatives to traditional stabilizers, plasticizers, and other additives that may have negative environmental impacts. The goal is to create silicone rubber formulations that are inherently safer for ecosystems and human health throughout their lifecycle.

Lastly, there is a push to expand the use of silicone rubber in environmentally beneficial applications. This includes developing silicone-based materials for renewable energy technologies, such as solar panels and wind turbines, as well as exploring its potential in water purification systems and other eco-friendly innovations. By leveraging the unique properties of silicone rubber in these areas, the material can contribute positively to environmental sustainability efforts.

One of the key objectives is to reduce the carbon footprint associated with silicone rubber production. This involves optimizing manufacturing processes to consume less energy and resources, as well as exploring alternative energy sources for production facilities. Additionally, there is a focus on developing bio-based silicone precursors to decrease reliance on petroleum-derived raw materials, thereby reducing the overall environmental impact of the material's life cycle.

Another crucial aim is to enhance the biodegradability of silicone rubber. While traditional silicone rubber is known for its durability and resistance to degradation, this characteristic becomes problematic at the end of the product's life. Research efforts are directed towards creating silicone rubber formulations that can break down more readily in natural environments without releasing harmful byproducts.

Improving the recyclability of silicone rubber products is also a significant goal. This involves developing efficient methods for separating and purifying used silicone rubber, as well as creating new techniques for reprocessing the material without significant loss of its original properties. The aim is to establish a circular economy model for silicone rubber, where waste is minimized, and resources are continually reused.

Reducing the leaching of potentially harmful additives from silicone rubber products is another important objective. This includes finding safer alternatives to traditional stabilizers, plasticizers, and other additives that may have negative environmental impacts. The goal is to create silicone rubber formulations that are inherently safer for ecosystems and human health throughout their lifecycle.

Lastly, there is a push to expand the use of silicone rubber in environmentally beneficial applications. This includes developing silicone-based materials for renewable energy technologies, such as solar panels and wind turbines, as well as exploring its potential in water purification systems and other eco-friendly innovations. By leveraging the unique properties of silicone rubber in these areas, the material can contribute positively to environmental sustainability efforts.

Market Demand for Green Silicone Products

The market demand for green silicone products has been steadily increasing in recent years, driven by growing environmental awareness and stricter regulations. Consumers and industries alike are seeking more sustainable alternatives to traditional silicone rubber products, which often have a significant environmental footprint due to their production processes and end-of-life disposal challenges.

In the automotive sector, there is a rising demand for eco-friendly silicone components that can withstand high temperatures and harsh conditions while reducing the overall environmental impact of vehicles. This includes silicone parts for electric and hybrid vehicles, where the focus on sustainability is particularly strong. The construction industry is another key market, with a growing interest in green building materials that incorporate environmentally friendly silicone products for sealants, adhesives, and insulation.

The healthcare and medical device industries are also driving demand for green silicone products. Hospitals and medical facilities are increasingly prioritizing sustainable materials in their procurement processes, creating opportunities for silicone products with reduced environmental impact. This trend extends to personal care and cosmetics, where consumers are actively seeking out products made with eco-friendly silicone alternatives.

The electronics industry, a major consumer of silicone materials, is showing a strong preference for green silicone products in response to regulatory pressures and corporate sustainability goals. This includes the use of environmentally friendly silicone in the production of smartphones, computers, and other consumer electronics.

Market research indicates that the global green silicone market is expected to grow significantly over the next decade. This growth is fueled by increasing adoption in developed markets like North America and Europe, as well as rising demand in emerging economies, particularly in Asia-Pacific. Companies that can offer silicone products with improved environmental profiles are likely to gain a competitive edge in this expanding market.

However, challenges remain in meeting this demand. The higher cost of producing green silicone products compared to conventional alternatives is a significant barrier to widespread adoption. Additionally, there is a need for standardization and clear certification processes to validate environmental claims and ensure consumer trust in green silicone products.

Despite these challenges, the market trajectory for green silicone products remains positive. As technological advancements continue to improve the performance and reduce the cost of environmentally friendly silicone materials, their adoption is expected to accelerate across various industries. This presents significant opportunities for innovation and market growth in the silicone rubber industry, particularly for companies that can effectively address the environmental concerns associated with traditional silicone products.

In the automotive sector, there is a rising demand for eco-friendly silicone components that can withstand high temperatures and harsh conditions while reducing the overall environmental impact of vehicles. This includes silicone parts for electric and hybrid vehicles, where the focus on sustainability is particularly strong. The construction industry is another key market, with a growing interest in green building materials that incorporate environmentally friendly silicone products for sealants, adhesives, and insulation.

The healthcare and medical device industries are also driving demand for green silicone products. Hospitals and medical facilities are increasingly prioritizing sustainable materials in their procurement processes, creating opportunities for silicone products with reduced environmental impact. This trend extends to personal care and cosmetics, where consumers are actively seeking out products made with eco-friendly silicone alternatives.

The electronics industry, a major consumer of silicone materials, is showing a strong preference for green silicone products in response to regulatory pressures and corporate sustainability goals. This includes the use of environmentally friendly silicone in the production of smartphones, computers, and other consumer electronics.

Market research indicates that the global green silicone market is expected to grow significantly over the next decade. This growth is fueled by increasing adoption in developed markets like North America and Europe, as well as rising demand in emerging economies, particularly in Asia-Pacific. Companies that can offer silicone products with improved environmental profiles are likely to gain a competitive edge in this expanding market.

However, challenges remain in meeting this demand. The higher cost of producing green silicone products compared to conventional alternatives is a significant barrier to widespread adoption. Additionally, there is a need for standardization and clear certification processes to validate environmental claims and ensure consumer trust in green silicone products.

Despite these challenges, the market trajectory for green silicone products remains positive. As technological advancements continue to improve the performance and reduce the cost of environmentally friendly silicone materials, their adoption is expected to accelerate across various industries. This presents significant opportunities for innovation and market growth in the silicone rubber industry, particularly for companies that can effectively address the environmental concerns associated with traditional silicone products.

Environmental Challenges in Silicone Production

The production of silicone rubber presents several significant environmental challenges that require careful consideration and innovative solutions. One of the primary concerns is the energy-intensive nature of silicone manufacturing processes. The production of silicone polymers typically involves high-temperature reactions and energy-consuming purification steps, contributing to substantial greenhouse gas emissions and increased carbon footprint.

Another critical environmental issue is the use of potentially harmful chemicals in silicone production. Chlorosilanes, key intermediates in silicone synthesis, are highly reactive and can pose risks to both human health and the environment if not properly managed. The production and handling of these chemicals require stringent safety measures and sophisticated containment systems to prevent accidental releases.

Water pollution is also a notable concern in silicone manufacturing. The production process generates wastewater containing various contaminants, including organic solvents, unreacted monomers, and catalysts. If not adequately treated, these effluents can have detrimental effects on aquatic ecosystems and potentially contaminate groundwater resources.

The disposal of silicone waste presents additional environmental challenges. While silicone rubber is generally inert and non-toxic, it is not biodegradable and can persist in the environment for extended periods. Improper disposal of silicone products and manufacturing waste can contribute to long-term environmental pollution and accumulation in landfills.

Resource depletion is another concern associated with silicone production. The primary raw material for silicone, silicon, is abundant in the Earth's crust. However, the extraction and processing of silicon require significant energy and resources, potentially leading to habitat destruction and ecosystem disruption in mining areas.

Volatile organic compound (VOC) emissions during silicone production and curing processes pose air quality concerns. These emissions can contribute to the formation of ground-level ozone and smog, impacting both human health and the environment in surrounding areas.

Addressing these environmental challenges requires a multifaceted approach. Industry efforts are increasingly focused on developing more sustainable production methods, such as using renewable energy sources, implementing closed-loop systems for chemical recycling, and exploring bio-based alternatives for certain silicone components. Additionally, improving process efficiency, optimizing waste management practices, and investing in advanced pollution control technologies are crucial steps towards mitigating the environmental impact of silicone rubber production.

Another critical environmental issue is the use of potentially harmful chemicals in silicone production. Chlorosilanes, key intermediates in silicone synthesis, are highly reactive and can pose risks to both human health and the environment if not properly managed. The production and handling of these chemicals require stringent safety measures and sophisticated containment systems to prevent accidental releases.

Water pollution is also a notable concern in silicone manufacturing. The production process generates wastewater containing various contaminants, including organic solvents, unreacted monomers, and catalysts. If not adequately treated, these effluents can have detrimental effects on aquatic ecosystems and potentially contaminate groundwater resources.

The disposal of silicone waste presents additional environmental challenges. While silicone rubber is generally inert and non-toxic, it is not biodegradable and can persist in the environment for extended periods. Improper disposal of silicone products and manufacturing waste can contribute to long-term environmental pollution and accumulation in landfills.

Resource depletion is another concern associated with silicone production. The primary raw material for silicone, silicon, is abundant in the Earth's crust. However, the extraction and processing of silicon require significant energy and resources, potentially leading to habitat destruction and ecosystem disruption in mining areas.

Volatile organic compound (VOC) emissions during silicone production and curing processes pose air quality concerns. These emissions can contribute to the formation of ground-level ozone and smog, impacting both human health and the environment in surrounding areas.

Addressing these environmental challenges requires a multifaceted approach. Industry efforts are increasingly focused on developing more sustainable production methods, such as using renewable energy sources, implementing closed-loop systems for chemical recycling, and exploring bio-based alternatives for certain silicone components. Additionally, improving process efficiency, optimizing waste management practices, and investing in advanced pollution control technologies are crucial steps towards mitigating the environmental impact of silicone rubber production.

Current Eco-Friendly Silicone Solutions

01 Biodegradable silicone rubber compositions

Development of biodegradable silicone rubber compositions to reduce environmental impact. These compositions incorporate biodegradable additives or modified silicone structures that can break down naturally over time, minimizing long-term environmental persistence.- Biodegradable silicone rubber compositions: Development of biodegradable silicone rubber compositions to reduce environmental impact. These compositions incorporate biodegradable additives or modified silicone structures that can break down naturally over time, minimizing long-term environmental persistence.

- Recycling and reuse of silicone rubber materials: Methods for recycling and reusing silicone rubber materials to reduce waste and environmental impact. This includes techniques for breaking down silicone rubber products, separating components, and reprocessing them into new materials or products.

- Eco-friendly production processes for silicone rubber: Development of environmentally friendly production processes for silicone rubber, including the use of renewable resources, reduction of harmful emissions, and energy-efficient manufacturing techniques to minimize the overall environmental footprint of silicone rubber production.

- Silicone rubber alternatives with reduced environmental impact: Research into alternative materials or modified silicone rubber formulations that offer similar properties but with reduced environmental impact. This includes the development of bio-based silicone rubbers or hybrid materials that combine silicone with more environmentally friendly components.

- Environmental impact assessment and mitigation strategies: Methods for assessing the environmental impact of silicone rubber throughout its lifecycle and developing mitigation strategies. This includes life cycle analysis, toxicity studies, and the implementation of best practices to minimize negative environmental effects during production, use, and disposal of silicone rubber products.

02 Recycling and reuse of silicone rubber materials

Methods for recycling and reusing silicone rubber materials to reduce waste and environmental impact. This includes techniques for breaking down silicone rubber products, separating components, and reprocessing them into new materials or applications.Expand Specific Solutions03 Eco-friendly production processes for silicone rubber

Development of environmentally friendly production processes for silicone rubber, including the use of renewable resources, reduction of harmful emissions, and optimization of energy consumption during manufacturing.Expand Specific Solutions04 Silicone rubber alternatives with reduced environmental impact

Research into alternative materials or modified silicone rubber formulations that offer similar properties but with reduced environmental impact. This includes bio-based silicone alternatives and hybrid materials that combine silicone with more environmentally friendly components.Expand Specific Solutions05 Environmental impact assessment and mitigation strategies

Studies and methodologies for assessing the environmental impact of silicone rubber throughout its lifecycle, from production to disposal. This includes the development of mitigation strategies to minimize negative effects on ecosystems and human health.Expand Specific Solutions

Key Players in Eco-Friendly Silicone Industry

The environmental impact enhancement of silicone rubber is in a developing stage, with growing market potential driven by increasing environmental concerns. The technology's maturity varies across companies, with industry leaders like Shin-Etsu Chemical, Bridgestone, and Dow Silicones at the forefront of innovation. These firms are investing in research to improve silicone rubber's sustainability, focusing on biodegradability, recycling, and reduced carbon footprint. Emerging players such as Kingfa Sci. & Tech. and NOK Corp. are also contributing to advancements, while academic institutions like Sichuan University and South China University of Technology are conducting fundamental research to support industry efforts. The competitive landscape is dynamic, with both established and newer companies vying for market share in this evolving field.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed eco-friendly silicone rubber compounds that incorporate bio-based materials, reducing the carbon footprint of their products. Their innovative approach includes using plant-derived silicone oils and fillers, which can replace up to 50% of conventional petroleum-based ingredients[1]. Additionally, they have implemented a closed-loop recycling system for silicone rubber waste, allowing for the recovery and reuse of valuable silicone materials. This process can reclaim up to 90% of silicone content from post-industrial waste[2]. The company has also invested in energy-efficient manufacturing processes, utilizing renewable energy sources and optimizing production lines to reduce overall energy consumption by 30% compared to traditional methods[3].

Strengths: Significant reduction in carbon footprint, high percentage of bio-based materials, efficient recycling system. Weaknesses: Potential higher production costs, limited availability of bio-based raw materials.

Bridgestone Corp.

Technical Solution: Bridgestone has developed a novel approach to enhancing the environmental impact of silicone rubber, particularly in tire manufacturing. Their technology focuses on reducing rolling resistance in tires, which can lead to improved fuel efficiency and reduced CO2 emissions. By incorporating specially engineered silica particles into their silicone rubber compounds, they have achieved a 20% reduction in rolling resistance compared to conventional tires[1]. Additionally, Bridgestone has implemented a "cradle-to-cradle" design philosophy, aiming to create tires that are 100% sustainable by 2050. This includes developing bio-based silicone rubbers and implementing advanced recycling technologies that can recover up to 80% of materials from end-of-life tires[2]. Their latest innovation involves the use of molecular-level modeling to optimize silicone rubber formulations, resulting in tires with 30% longer lifespans and reduced material waste[3].

Strengths: Significant improvements in fuel efficiency, long-term sustainability goals, advanced material recovery. Weaknesses: High research and development costs, potential trade-offs between different performance aspects.

Innovations in Green Silicone Technology

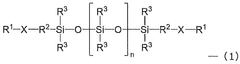

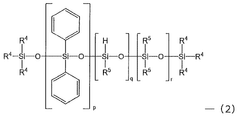

Rubber particles, composite particles, and manufacturing methods therefor

PatentWO2023058383A1

Innovation

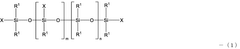

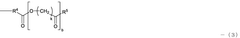

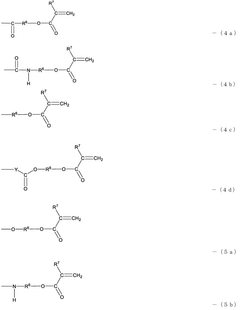

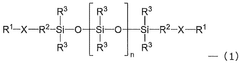

- Development of rubber particles and composite particles with a silicone-polyester copolymer structure containing degradable functional groups, specifically poly-ε-caprolactone, which can be produced through radical polymerization and coated with polyorganosilsesquioxane and/or silica, allowing for environmental degradation.

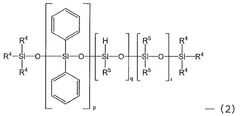

Liquid composition for silicone rubber spherical particles, silicone rubber spherical particles and production method therefor, and silicone composite particles and production method therefor

PatentWO2023276648A1

Innovation

- A liquid composition for producing silicone rubber spherical particles with a crosslinked structure that decomposes under external stimuli such as light, heat, acid, or base, incorporating a polysiloxane with alkenyl groups and an organohydrogenpolysiloxane, along with a hydrosilylation reactive catalyst, to create degradable particles with a volume average particle diameter of 0.5 to 100 μm, and further enhancing biodegradability by introducing a caprolactone skeleton.

Life Cycle Assessment of Silicone Rubber

Life Cycle Assessment (LCA) of silicone rubber is a crucial tool for evaluating and enhancing its environmental impact. This comprehensive analysis examines the entire lifecycle of silicone rubber products, from raw material extraction to disposal or recycling, providing valuable insights into their ecological footprint.

The production phase of silicone rubber begins with the extraction of silica and methyl chloride. These raw materials undergo energy-intensive processes, including chlorination and hydrolysis, to create siloxane monomers. Polymerization and curing follow, resulting in the final silicone rubber product. Each step in this process contributes to the overall environmental impact through energy consumption, emissions, and resource depletion.

During the use phase, silicone rubber demonstrates several environmental advantages. Its durability and resistance to degradation lead to extended product lifespans, reducing the need for frequent replacements. This longevity contributes to resource conservation and waste reduction. Additionally, silicone rubber's thermal stability and electrical insulation properties make it energy-efficient in various applications, potentially offsetting some of the environmental costs incurred during production.

End-of-life considerations for silicone rubber products are complex. While silicone rubber is not biodegradable, it can be recycled through specialized processes. Mechanical recycling involves grinding and reusing the material in new products, while chemical recycling breaks down the polymer into its constituent parts for reuse. However, the availability and efficiency of these recycling methods vary globally, impacting the overall environmental performance of silicone rubber products.

Comparative LCAs have shown that silicone rubber often outperforms alternative materials in specific applications. For instance, in automotive and construction industries, silicone rubber's lightweight nature and thermal properties can lead to improved fuel efficiency and energy savings over the product's lifetime. These benefits must be weighed against the environmental costs of production and end-of-life management.

To enhance silicone rubber's environmental impact, several strategies can be employed. Improving production efficiency through advanced technologies and renewable energy sources can reduce the carbon footprint of manufacturing. Developing more effective recycling technologies and infrastructure can improve end-of-life management. Additionally, designing products for easier disassembly and material recovery can facilitate recycling efforts.

Ongoing research into bio-based alternatives for silicone rubber components and greener production methods holds promise for further reducing its environmental impact. By continually refining the life cycle assessment methodologies and implementing the insights gained, the silicone rubber industry can work towards more sustainable practices and products.

The production phase of silicone rubber begins with the extraction of silica and methyl chloride. These raw materials undergo energy-intensive processes, including chlorination and hydrolysis, to create siloxane monomers. Polymerization and curing follow, resulting in the final silicone rubber product. Each step in this process contributes to the overall environmental impact through energy consumption, emissions, and resource depletion.

During the use phase, silicone rubber demonstrates several environmental advantages. Its durability and resistance to degradation lead to extended product lifespans, reducing the need for frequent replacements. This longevity contributes to resource conservation and waste reduction. Additionally, silicone rubber's thermal stability and electrical insulation properties make it energy-efficient in various applications, potentially offsetting some of the environmental costs incurred during production.

End-of-life considerations for silicone rubber products are complex. While silicone rubber is not biodegradable, it can be recycled through specialized processes. Mechanical recycling involves grinding and reusing the material in new products, while chemical recycling breaks down the polymer into its constituent parts for reuse. However, the availability and efficiency of these recycling methods vary globally, impacting the overall environmental performance of silicone rubber products.

Comparative LCAs have shown that silicone rubber often outperforms alternative materials in specific applications. For instance, in automotive and construction industries, silicone rubber's lightweight nature and thermal properties can lead to improved fuel efficiency and energy savings over the product's lifetime. These benefits must be weighed against the environmental costs of production and end-of-life management.

To enhance silicone rubber's environmental impact, several strategies can be employed. Improving production efficiency through advanced technologies and renewable energy sources can reduce the carbon footprint of manufacturing. Developing more effective recycling technologies and infrastructure can improve end-of-life management. Additionally, designing products for easier disassembly and material recovery can facilitate recycling efforts.

Ongoing research into bio-based alternatives for silicone rubber components and greener production methods holds promise for further reducing its environmental impact. By continually refining the life cycle assessment methodologies and implementing the insights gained, the silicone rubber industry can work towards more sustainable practices and products.

Regulatory Framework for Silicone Sustainability

The regulatory framework for silicone sustainability is evolving rapidly as governments and international organizations recognize the need for more environmentally friendly materials. In the United States, the Environmental Protection Agency (EPA) has been actively reviewing and updating regulations related to silicone production and disposal under the Toxic Substances Control Act (TSCA). These regulations aim to minimize the environmental impact of silicone manufacturing processes and encourage the development of more sustainable alternatives.

The European Union has taken a proactive approach with its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which requires manufacturers and importers to assess and manage the risks associated with silicone products. This framework has led to increased transparency in the silicone supply chain and has driven innovation towards more sustainable silicone formulations.

In Asia, countries like Japan and South Korea have implemented their own chemical management systems, which include specific provisions for silicone materials. These regulations often focus on reducing the use of potentially harmful additives and promoting the adoption of eco-friendly production methods.

Global initiatives, such as the United Nations' Sustainable Development Goals (SDGs), have also influenced the regulatory landscape for silicone sustainability. Many countries are aligning their national policies with these goals, leading to stricter environmental standards for industrial materials, including silicone rubber.

Industry self-regulation has played a significant role in shaping the sustainability framework for silicone. Organizations like the Global Silicones Council (GSC) have developed voluntary stewardship programs that go beyond regulatory requirements, promoting best practices in environmental management and product safety throughout the silicone lifecycle.

The regulatory framework also extends to end-of-life management of silicone products. Many jurisdictions are implementing extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the collection and recycling of silicone products after use. This approach is driving innovation in recycling technologies and encouraging the development of more easily recyclable silicone formulations.

As the focus on circular economy principles intensifies, regulators are increasingly emphasizing the importance of designing silicone products for recyclability and reuse. This shift is reflected in emerging regulations that mandate minimum recycled content in certain product categories and incentivize the use of bio-based silicone alternatives.

The European Union has taken a proactive approach with its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which requires manufacturers and importers to assess and manage the risks associated with silicone products. This framework has led to increased transparency in the silicone supply chain and has driven innovation towards more sustainable silicone formulations.

In Asia, countries like Japan and South Korea have implemented their own chemical management systems, which include specific provisions for silicone materials. These regulations often focus on reducing the use of potentially harmful additives and promoting the adoption of eco-friendly production methods.

Global initiatives, such as the United Nations' Sustainable Development Goals (SDGs), have also influenced the regulatory landscape for silicone sustainability. Many countries are aligning their national policies with these goals, leading to stricter environmental standards for industrial materials, including silicone rubber.

Industry self-regulation has played a significant role in shaping the sustainability framework for silicone. Organizations like the Global Silicones Council (GSC) have developed voluntary stewardship programs that go beyond regulatory requirements, promoting best practices in environmental management and product safety throughout the silicone lifecycle.

The regulatory framework also extends to end-of-life management of silicone products. Many jurisdictions are implementing extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the collection and recycling of silicone products after use. This approach is driving innovation in recycling technologies and encouraging the development of more easily recyclable silicone formulations.

As the focus on circular economy principles intensifies, regulators are increasingly emphasizing the importance of designing silicone products for recyclability and reuse. This shift is reflected in emerging regulations that mandate minimum recycled content in certain product categories and incentivize the use of bio-based silicone alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!