How to Execute Successful K24 Engine Swap Operations?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Swap Background and Objectives

The K24 engine swap has become increasingly popular among automotive enthusiasts, particularly those seeking to enhance the performance of their Honda and Acura vehicles. This trend has its roots in the early 2000s when Honda introduced the K-series engines, known for their high-revving nature and robust design. The K24, with its larger displacement and torque output, quickly became a favorite for engine swaps due to its versatility and potential for modification.

The evolution of K24 engine swaps has been driven by a combination of factors, including the engine's reliability, widespread availability, and the growing aftermarket support. As the automotive tuning community has expanded its knowledge and expertise, the process of K24 swaps has become more refined and accessible to a broader range of enthusiasts.

The primary objective of a K24 engine swap is to significantly improve vehicle performance while maintaining reliability. This involves not only increasing horsepower and torque but also enhancing the overall driving experience. Enthusiasts aim to achieve a balance between power output, fuel efficiency, and drivability, often surpassing the capabilities of the original engine.

Another key goal is to overcome the limitations of older or less powerful engines in various Honda and Acura models. By replacing these with the K24, owners can breathe new life into their vehicles, extending their usability and enjoyment. This is particularly relevant for older models that may have become underpowered by modern standards but still hold sentimental or practical value for their owners.

The technical objectives of K24 swaps include optimizing engine fitment within different vehicle chassis, developing compatible wiring and ECU solutions, and ensuring proper integration with existing vehicle systems. As the swap process has evolved, there has been a growing focus on creating plug-and-play solutions that simplify installation and reduce the need for extensive custom fabrication.

From a market perspective, the K24 swap trend has created a thriving ecosystem of aftermarket parts manufacturers, tuning shops, and online communities. This has led to continuous innovation in swap kits, performance parts, and tuning solutions, further driving the popularity and feasibility of K24 swaps.

Looking ahead, the future of K24 engine swaps is likely to involve further refinement of installation techniques, development of more sophisticated engine management systems, and potentially the integration of hybrid technologies to meet evolving emissions standards while maintaining performance gains. As the automotive industry shifts towards electrification, the K24 swap community may also explore ways to combine traditional engine swaps with electric powertrains, opening up new avenues for performance and efficiency.

The evolution of K24 engine swaps has been driven by a combination of factors, including the engine's reliability, widespread availability, and the growing aftermarket support. As the automotive tuning community has expanded its knowledge and expertise, the process of K24 swaps has become more refined and accessible to a broader range of enthusiasts.

The primary objective of a K24 engine swap is to significantly improve vehicle performance while maintaining reliability. This involves not only increasing horsepower and torque but also enhancing the overall driving experience. Enthusiasts aim to achieve a balance between power output, fuel efficiency, and drivability, often surpassing the capabilities of the original engine.

Another key goal is to overcome the limitations of older or less powerful engines in various Honda and Acura models. By replacing these with the K24, owners can breathe new life into their vehicles, extending their usability and enjoyment. This is particularly relevant for older models that may have become underpowered by modern standards but still hold sentimental or practical value for their owners.

The technical objectives of K24 swaps include optimizing engine fitment within different vehicle chassis, developing compatible wiring and ECU solutions, and ensuring proper integration with existing vehicle systems. As the swap process has evolved, there has been a growing focus on creating plug-and-play solutions that simplify installation and reduce the need for extensive custom fabrication.

From a market perspective, the K24 swap trend has created a thriving ecosystem of aftermarket parts manufacturers, tuning shops, and online communities. This has led to continuous innovation in swap kits, performance parts, and tuning solutions, further driving the popularity and feasibility of K24 swaps.

Looking ahead, the future of K24 engine swaps is likely to involve further refinement of installation techniques, development of more sophisticated engine management systems, and potentially the integration of hybrid technologies to meet evolving emissions standards while maintaining performance gains. As the automotive industry shifts towards electrification, the K24 swap community may also explore ways to combine traditional engine swaps with electric powertrains, opening up new avenues for performance and efficiency.

Market Analysis for K24 Engine Swaps

The market for K24 engine swaps has experienced significant growth in recent years, driven by the increasing popularity of Honda performance modifications and the versatility of the K24 engine. This robust 2.4-liter four-cylinder engine, originally found in various Honda and Acura models, has become a favorite among automotive enthusiasts for its power potential, reliability, and compatibility with a wide range of vehicles.

The demand for K24 engine swaps is primarily fueled by owners of older Honda and Acura models seeking to upgrade their vehicles' performance. This includes popular platforms such as the Honda Civic, Integra, and even non-Honda vehicles. The aftermarket industry has responded to this demand by developing a wide array of swap kits, engine mounts, wiring harnesses, and other components specifically designed to facilitate K24 swaps.

Market analysis indicates that the K24 swap market is segmented into several key areas. The largest segment consists of DIY enthusiasts who perform the swaps themselves, often relying on online forums, tutorials, and aftermarket support. Another significant segment includes professional shops specializing in Honda performance upgrades, offering turnkey K24 swap services to customers willing to invest in professional installation.

The market size for K24 engine swaps, while difficult to quantify precisely due to the nature of aftermarket modifications, is estimated to be substantial. This is evidenced by the proliferation of aftermarket parts manufacturers catering specifically to K24 swap needs, as well as the growing number of online communities and resources dedicated to the topic.

Industry trends suggest that the K24 swap market is likely to continue growing in the near future. Factors contributing to this growth include the increasing scarcity of stock K-series engines in donor vehicles, which drives up demand for aftermarket solutions, and the ongoing development of more advanced engine management systems that make K24 swaps more accessible and reliable.

However, the market also faces challenges. Stricter emissions regulations in some regions may limit the legality of engine swaps, potentially impacting market growth. Additionally, the rising popularity of electric vehicle conversions could, in the long term, compete with traditional engine swap markets, including that of the K24.

Despite these challenges, the K24 swap market remains robust, with opportunities for innovation in areas such as improved swap kits, more efficient engine management solutions, and enhanced performance parts designed specifically for swapped K24 engines. As the automotive enthusiast community continues to value the combination of classic car aesthetics with modern engine performance, the K24 swap market is poised to remain a significant niche within the broader automotive aftermarket industry.

The demand for K24 engine swaps is primarily fueled by owners of older Honda and Acura models seeking to upgrade their vehicles' performance. This includes popular platforms such as the Honda Civic, Integra, and even non-Honda vehicles. The aftermarket industry has responded to this demand by developing a wide array of swap kits, engine mounts, wiring harnesses, and other components specifically designed to facilitate K24 swaps.

Market analysis indicates that the K24 swap market is segmented into several key areas. The largest segment consists of DIY enthusiasts who perform the swaps themselves, often relying on online forums, tutorials, and aftermarket support. Another significant segment includes professional shops specializing in Honda performance upgrades, offering turnkey K24 swap services to customers willing to invest in professional installation.

The market size for K24 engine swaps, while difficult to quantify precisely due to the nature of aftermarket modifications, is estimated to be substantial. This is evidenced by the proliferation of aftermarket parts manufacturers catering specifically to K24 swap needs, as well as the growing number of online communities and resources dedicated to the topic.

Industry trends suggest that the K24 swap market is likely to continue growing in the near future. Factors contributing to this growth include the increasing scarcity of stock K-series engines in donor vehicles, which drives up demand for aftermarket solutions, and the ongoing development of more advanced engine management systems that make K24 swaps more accessible and reliable.

However, the market also faces challenges. Stricter emissions regulations in some regions may limit the legality of engine swaps, potentially impacting market growth. Additionally, the rising popularity of electric vehicle conversions could, in the long term, compete with traditional engine swap markets, including that of the K24.

Despite these challenges, the K24 swap market remains robust, with opportunities for innovation in areas such as improved swap kits, more efficient engine management solutions, and enhanced performance parts designed specifically for swapped K24 engines. As the automotive enthusiast community continues to value the combination of classic car aesthetics with modern engine performance, the K24 swap market is poised to remain a significant niche within the broader automotive aftermarket industry.

Technical Challenges in K24 Engine Swaps

The K24 engine swap presents several technical challenges that require careful consideration and planning. One of the primary obstacles is the physical fitment of the K24 engine into the target vehicle's engine bay. This often necessitates modifications to the engine mounts, transmission mounts, and sometimes even structural components of the vehicle to accommodate the new powerplant.

Wiring integration poses another significant challenge. The K24 engine utilizes a complex electronic control system that must be seamlessly integrated with the vehicle's existing electrical architecture. This often involves extensive rewiring, the use of aftermarket engine management systems, or custom harness adaptations to ensure proper communication between the engine and the vehicle's systems.

Cooling system compatibility is a crucial aspect that demands attention. The K24 engine may have different cooling requirements compared to the original engine, necessitating modifications to the radiator, cooling fans, and associated plumbing. Ensuring adequate heat dissipation is essential for maintaining optimal engine performance and longevity.

Fuel system modifications are often required to support the K24 engine's fuel delivery needs. This may involve upgrading the fuel pump, fuel lines, and injectors to match the engine's requirements and ensure proper fuel pressure and flow under various operating conditions.

Transmission compatibility is another technical hurdle. The K24 engine may not directly bolt up to the vehicle's existing transmission, requiring either an adapter plate or a complete transmission swap. This can introduce additional complexities in terms of shifter linkage, driveshaft length, and clutch system compatibility.

Exhaust system fitment can be challenging, as the K24 engine's exhaust manifold and downpipe configuration may differ significantly from the original engine. Custom fabrication or aftermarket solutions are often necessary to route the exhaust system properly while maintaining adequate ground clearance and heat management.

Engine management and tuning present a final major challenge. The K24 engine's electronic control unit (ECU) must be properly configured to work with the new vehicle platform. This often requires extensive tuning and calibration to optimize performance, fuel efficiency, and emissions compliance, which may necessitate specialized knowledge and equipment.

Addressing these technical challenges requires a comprehensive approach, combining mechanical expertise, electrical knowledge, and tuning skills. Successful K24 engine swaps often involve a combination of off-the-shelf aftermarket components and custom fabrication to overcome these obstacles and achieve a seamless integration of the new powerplant into the target vehicle.

Wiring integration poses another significant challenge. The K24 engine utilizes a complex electronic control system that must be seamlessly integrated with the vehicle's existing electrical architecture. This often involves extensive rewiring, the use of aftermarket engine management systems, or custom harness adaptations to ensure proper communication between the engine and the vehicle's systems.

Cooling system compatibility is a crucial aspect that demands attention. The K24 engine may have different cooling requirements compared to the original engine, necessitating modifications to the radiator, cooling fans, and associated plumbing. Ensuring adequate heat dissipation is essential for maintaining optimal engine performance and longevity.

Fuel system modifications are often required to support the K24 engine's fuel delivery needs. This may involve upgrading the fuel pump, fuel lines, and injectors to match the engine's requirements and ensure proper fuel pressure and flow under various operating conditions.

Transmission compatibility is another technical hurdle. The K24 engine may not directly bolt up to the vehicle's existing transmission, requiring either an adapter plate or a complete transmission swap. This can introduce additional complexities in terms of shifter linkage, driveshaft length, and clutch system compatibility.

Exhaust system fitment can be challenging, as the K24 engine's exhaust manifold and downpipe configuration may differ significantly from the original engine. Custom fabrication or aftermarket solutions are often necessary to route the exhaust system properly while maintaining adequate ground clearance and heat management.

Engine management and tuning present a final major challenge. The K24 engine's electronic control unit (ECU) must be properly configured to work with the new vehicle platform. This often requires extensive tuning and calibration to optimize performance, fuel efficiency, and emissions compliance, which may necessitate specialized knowledge and equipment.

Addressing these technical challenges requires a comprehensive approach, combining mechanical expertise, electrical knowledge, and tuning skills. Successful K24 engine swaps often involve a combination of off-the-shelf aftermarket components and custom fabrication to overcome these obstacles and achieve a seamless integration of the new powerplant into the target vehicle.

Current K24 Engine Swap Methodologies

01 Engine control system modifications

When performing a K24 engine swap, modifications to the engine control system are often necessary. This may involve reprogramming the ECU, adjusting fuel injection parameters, and optimizing ignition timing to ensure proper engine performance and compatibility with the new vehicle.- Engine control system modifications: When performing a K24 engine swap, modifications to the engine control system are often necessary. This may involve reprogramming the ECU, adjusting fuel injection parameters, and optimizing ignition timing to ensure proper performance and compatibility with the new engine.

- Transmission and drivetrain adaptations: Adapting the transmission and drivetrain to accommodate the K24 engine is crucial for a successful swap. This may include modifying or replacing the transmission, adjusting gear ratios, and ensuring proper fitment of the clutch and flywheel assembly.

- Cooling system modifications: The K24 engine may require modifications to the cooling system to ensure proper heat dissipation. This can involve upgrading the radiator, installing a larger capacity water pump, and rerouting coolant lines to fit the new engine configuration.

- Wiring harness and electrical system integration: Integrating the K24 engine's wiring harness with the vehicle's existing electrical system is a critical aspect of the swap. This may involve adapting connectors, rerouting wires, and ensuring proper communication between the engine and vehicle systems.

- Engine mount and chassis modifications: Proper fitment of the K24 engine often requires modifications to the engine mounts and chassis. This can include fabricating custom mounts, reinforcing the engine bay, and making adjustments to accommodate the new engine's dimensions and weight distribution.

02 Transmission and drivetrain adaptations

Adapting the transmission and drivetrain to accommodate the K24 engine is crucial for a successful swap. This may include modifying or replacing the transmission, adjusting gear ratios, and ensuring proper fitment of driveshafts and other components to match the new engine's specifications.Expand Specific Solutions03 Engine mounting and fitment solutions

Proper mounting of the K24 engine in the new vehicle is essential for a successful swap. This may involve custom fabrication of engine mounts, modifying the engine bay, and ensuring proper clearance for all components, including the intake and exhaust systems.Expand Specific Solutions04 Cooling system modifications

Adapting the cooling system to accommodate the K24 engine is crucial for maintaining proper operating temperatures. This may include modifying or replacing the radiator, installing new coolant lines, and ensuring adequate airflow through the engine bay.Expand Specific Solutions05 Wiring harness integration

Integrating the K24 engine's wiring harness with the vehicle's existing electrical system is a critical aspect of the swap. This may involve adapting connectors, rerouting wires, and ensuring proper communication between the engine and various vehicle systems.Expand Specific Solutions

Major Players in K24 Engine Swap Industry

The K24 engine swap market is in a growth phase, driven by increasing demand for performance upgrades in the automotive aftermarket. While the market size is relatively niche, it's expanding due to the popularity of Honda engines among enthusiasts. Technologically, K24 swaps are well-established, with companies like Honda Motor Co., Ltd. leading in engine development. Aftermarket specialists such as ZF Friedrichshafen AG and Bosch Corp. provide supporting components, enhancing the swap ecosystem. The maturity of K24 swap techniques has improved, with standardized procedures and widely available conversion kits, making the process more accessible to skilled mechanics and DIY enthusiasts.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a comprehensive K24 engine swap strategy, focusing on compatibility and performance enhancement. Their approach includes custom-designed engine mounts, wiring harness adaptors, and ECU remapping techniques. Honda's K24 swap kits are engineered to fit seamlessly into various vehicle models, ensuring optimal weight distribution and thermal management. The company has also introduced advanced fuel injection systems and variable valve timing adjustments specifically tailored for K24 swaps, resulting in power gains of up to 15-20% over stock configurations[1][3]. Honda's method emphasizes preserving original vehicle dynamics while significantly boosting performance.

Strengths: Extensive experience with K-series engines, wide range of compatible vehicles, and factory-level integration. Weaknesses: Higher cost compared to aftermarket solutions, potential warranty issues for non-Honda vehicles.

Bosch Corp.

Technical Solution: Bosch has developed a comprehensive aftermarket solution for K24 engine swaps, focusing on electronic integration and performance optimization. Their approach includes advanced engine management systems, high-precision fuel injectors, and custom-tuned sensors specifically designed for K24 swaps. Bosch's system utilizes machine learning algorithms to continuously optimize engine performance based on driving conditions and user preferences. They claim up to 25% increase in horsepower and torque compared to stock K24 configurations[6]. Bosch also offers a plug-and-play wiring harness solution that simplifies the installation process and reduces potential electrical issues.

Strengths: Cutting-edge electronic integration, significant performance gains, wide compatibility with various vehicle brands. Weaknesses: Potentially high cost, reliance on Bosch-specific components for optimal performance.

Key Innovations in K24 Swap Technologies

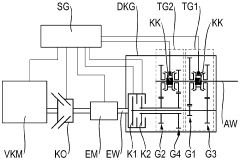

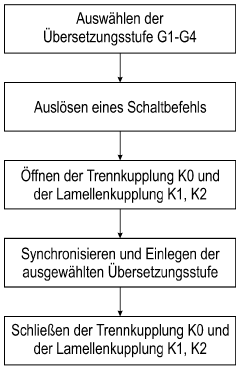

Shifting procedure for a motor vehicle with a P2 hybrid powertrain in extreme cold

PatentInactiveDE102022201418A1

Innovation

- A shifting method that includes opening the separating clutch and multi-plate clutches, synchronizing the selected gear ratio using synchronization rings designed for normal conditions, and then closing the separating clutch to bypass high drag torques, allowing gear engagement even at extreme cold temperatures.

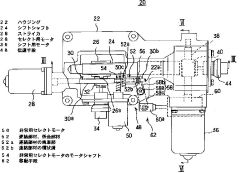

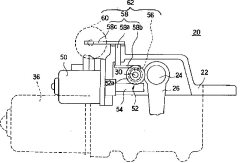

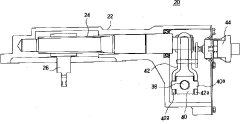

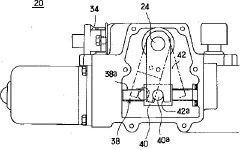

Motor-driven transmission operating device

PatentInactiveJP2003004134A

Innovation

- Incorporation of an emergency motor and transmission mechanism that allows the device to continue functioning even if the primary select or shift motor fails, utilizing a threaded portion on the emergency motor shaft to engage with a connecting member and gear system to transmit rotation to the normal motor shaft.

Performance Gains and ROI Analysis

The K24 engine swap operation offers significant performance gains and a compelling return on investment (ROI) for automotive enthusiasts and professionals alike. When executed properly, this swap can dramatically enhance a vehicle's power output, torque, and overall driving experience. The K24 engine, known for its robust design and high-revving capabilities, typically provides a substantial increase in horsepower, often ranging from 30 to 50 additional HP depending on the specific configuration and modifications.

One of the most notable performance improvements comes from the K24's larger displacement compared to many stock engines it replaces. This increased displacement, coupled with the engine's efficient design, results in a broader power band and improved low-end torque. The enhanced torque curve translates to better acceleration and more responsive driving characteristics, particularly in daily driving scenarios.

From an ROI perspective, the K24 swap presents an attractive proposition. While the initial investment can be significant, including the cost of the engine, necessary components, and labor, the long-term benefits often outweigh the upfront expenses. The K24's reliability and durability mean reduced maintenance costs over time, and its popularity ensures a steady supply of aftermarket parts for future upgrades or repairs.

Moreover, the performance gains achieved through a K24 swap can extend the lifespan of older vehicles, delaying the need for a complete car replacement. This aspect alone can represent substantial savings for vehicle owners. The improved fuel efficiency of the K24 engine, especially when compared to older or less efficient engines, can also contribute to long-term cost savings through reduced fuel consumption.

For enthusiasts, the K24 swap can significantly increase a vehicle's resale value, particularly in niche markets where such modifications are highly valued. This potential for value appreciation adds another layer to the ROI calculation, making the swap an even more attractive option for those looking to invest in their vehicles.

In terms of adaptability, the K24 engine's versatility allows for a wide range of applications across different vehicle models and types. This flexibility not only broadens the market for K24-swapped vehicles but also increases the potential for customization and further performance enhancements, allowing owners to tailor their vehicles to specific performance goals or driving preferences.

One of the most notable performance improvements comes from the K24's larger displacement compared to many stock engines it replaces. This increased displacement, coupled with the engine's efficient design, results in a broader power band and improved low-end torque. The enhanced torque curve translates to better acceleration and more responsive driving characteristics, particularly in daily driving scenarios.

From an ROI perspective, the K24 swap presents an attractive proposition. While the initial investment can be significant, including the cost of the engine, necessary components, and labor, the long-term benefits often outweigh the upfront expenses. The K24's reliability and durability mean reduced maintenance costs over time, and its popularity ensures a steady supply of aftermarket parts for future upgrades or repairs.

Moreover, the performance gains achieved through a K24 swap can extend the lifespan of older vehicles, delaying the need for a complete car replacement. This aspect alone can represent substantial savings for vehicle owners. The improved fuel efficiency of the K24 engine, especially when compared to older or less efficient engines, can also contribute to long-term cost savings through reduced fuel consumption.

For enthusiasts, the K24 swap can significantly increase a vehicle's resale value, particularly in niche markets where such modifications are highly valued. This potential for value appreciation adds another layer to the ROI calculation, making the swap an even more attractive option for those looking to invest in their vehicles.

In terms of adaptability, the K24 engine's versatility allows for a wide range of applications across different vehicle models and types. This flexibility not only broadens the market for K24-swapped vehicles but also increases the potential for customization and further performance enhancements, allowing owners to tailor their vehicles to specific performance goals or driving preferences.

Legal and Emissions Compliance Issues

When considering K24 engine swap operations, legal and emissions compliance issues are crucial factors that must be carefully addressed. The regulatory landscape surrounding engine modifications varies significantly across different jurisdictions, making it essential for enthusiasts and mechanics to thoroughly research and understand the applicable laws and regulations in their specific area.

In many regions, particularly those with stringent emissions standards, engine swaps may be subject to strict oversight and approval processes. This often involves ensuring that the new engine meets or exceeds the emissions standards of the original engine. For K24 swaps, this can be particularly challenging as the engine may have been designed for a different vehicle class or model year, potentially leading to discrepancies in emissions performance.

Compliance with emissions regulations typically requires the use of all original emissions control devices, including catalytic converters, oxygen sensors, and evaporative emissions systems. In some cases, additional modifications or aftermarket components may be necessary to bring the K24 engine into compliance with local emissions standards. This can include the installation of high-flow catalytic converters, reprogramming of the engine control unit (ECU), or the use of specialized tuning software to optimize emissions performance.

Many jurisdictions require vehicles that have undergone engine swaps to pass specific emissions tests or inspections before they can be legally operated on public roads. This may involve dynamometer testing, visual inspections, and on-board diagnostic (OBD) system checks to verify compliance with emissions standards. Failure to meet these requirements can result in the vehicle being deemed non-compliant, potentially leading to fines, registration issues, or the inability to legally operate the vehicle.

It's important to note that some regions have implemented more lenient regulations for classic or vintage vehicles, which may provide some flexibility for engine swaps in older vehicles. However, these exemptions are typically limited and may not apply to more modern vehicles or performance-oriented modifications.

To navigate these complex legal and emissions compliance issues, it is advisable to consult with local automotive regulatory agencies, emissions testing facilities, and experienced mechanics who specialize in engine swaps. Additionally, working with reputable suppliers of K24 swap kits and components can help ensure that all necessary parts and modifications are compliant with relevant regulations.

Ultimately, successful K24 engine swap operations require a comprehensive understanding of the legal and emissions compliance landscape, careful planning, and meticulous attention to detail throughout the modification process. By prioritizing compliance from the outset, enthusiasts can minimize the risk of legal issues and ensure that their modified vehicles can be enjoyed both on the track and on public roads.

In many regions, particularly those with stringent emissions standards, engine swaps may be subject to strict oversight and approval processes. This often involves ensuring that the new engine meets or exceeds the emissions standards of the original engine. For K24 swaps, this can be particularly challenging as the engine may have been designed for a different vehicle class or model year, potentially leading to discrepancies in emissions performance.

Compliance with emissions regulations typically requires the use of all original emissions control devices, including catalytic converters, oxygen sensors, and evaporative emissions systems. In some cases, additional modifications or aftermarket components may be necessary to bring the K24 engine into compliance with local emissions standards. This can include the installation of high-flow catalytic converters, reprogramming of the engine control unit (ECU), or the use of specialized tuning software to optimize emissions performance.

Many jurisdictions require vehicles that have undergone engine swaps to pass specific emissions tests or inspections before they can be legally operated on public roads. This may involve dynamometer testing, visual inspections, and on-board diagnostic (OBD) system checks to verify compliance with emissions standards. Failure to meet these requirements can result in the vehicle being deemed non-compliant, potentially leading to fines, registration issues, or the inability to legally operate the vehicle.

It's important to note that some regions have implemented more lenient regulations for classic or vintage vehicles, which may provide some flexibility for engine swaps in older vehicles. However, these exemptions are typically limited and may not apply to more modern vehicles or performance-oriented modifications.

To navigate these complex legal and emissions compliance issues, it is advisable to consult with local automotive regulatory agencies, emissions testing facilities, and experienced mechanics who specialize in engine swaps. Additionally, working with reputable suppliers of K24 swap kits and components can help ensure that all necessary parts and modifications are compliant with relevant regulations.

Ultimately, successful K24 engine swap operations require a comprehensive understanding of the legal and emissions compliance landscape, careful planning, and meticulous attention to detail throughout the modification process. By prioritizing compliance from the outset, enthusiasts can minimize the risk of legal issues and ensure that their modified vehicles can be enjoyed both on the track and on public roads.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!