How to Fine-Tune K24 Engine for Circuit Racing Success?

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Racing Evolution

The K24 engine, originally designed for Honda's passenger vehicles, has undergone a remarkable evolution in the world of circuit racing. This transformation began in the early 2000s when enthusiasts and racing teams recognized the potential of this robust 2.4-liter inline-four engine for competitive motorsports.

Initially, the K24's journey into racing was marked by minor modifications, such as aftermarket air intakes and exhaust systems, to enhance its performance on the track. As racers pushed the boundaries, more substantial upgrades emerged, including high-performance camshafts, forged pistons, and strengthened connecting rods, allowing the engine to withstand higher RPMs and increased power output.

The mid-2000s saw a significant leap in K24 racing development with the introduction of forced induction. Turbocharging and supercharging kits specifically designed for the K24 became available, dramatically increasing horsepower and torque figures. This era also witnessed the refinement of engine management systems, enabling precise control over fuel injection and ignition timing, crucial for optimizing performance on various racing circuits.

By the late 2000s and early 2010s, the K24 had become a staple in grassroots racing series and time attack events. Engine builders began experimenting with hybrid setups, combining K24 blocks with cylinder heads from other Honda engines, most notably the K20, to create high-revving, powerful combinations. This period also saw advancements in thermal management, with the development of improved cooling systems to maintain engine reliability under extreme racing conditions.

The 2010s brought about a focus on weight reduction and efficiency. Lightweight components, such as titanium valves and carbon fiber intake manifolds, became more prevalent in K24 race builds. Additionally, the integration of advanced data logging and telemetry systems allowed teams to fine-tune engine parameters with unprecedented precision, optimizing performance for specific track conditions and racing formats.

Recent years have seen the K24 engine adapted for use in hybrid racing applications, combining internal combustion power with electric motors. This cutting-edge approach has opened new avenues for performance enhancement while addressing growing concerns about environmental sustainability in motorsports.

Throughout its racing evolution, the K24 engine has demonstrated remarkable versatility and potential for modification. From its humble beginnings as a reliable commuter car powerplant to its current status as a formidable racing engine, the K24 continues to be a popular choice for circuit racers seeking a balance of power, reliability, and tunability.

Initially, the K24's journey into racing was marked by minor modifications, such as aftermarket air intakes and exhaust systems, to enhance its performance on the track. As racers pushed the boundaries, more substantial upgrades emerged, including high-performance camshafts, forged pistons, and strengthened connecting rods, allowing the engine to withstand higher RPMs and increased power output.

The mid-2000s saw a significant leap in K24 racing development with the introduction of forced induction. Turbocharging and supercharging kits specifically designed for the K24 became available, dramatically increasing horsepower and torque figures. This era also witnessed the refinement of engine management systems, enabling precise control over fuel injection and ignition timing, crucial for optimizing performance on various racing circuits.

By the late 2000s and early 2010s, the K24 had become a staple in grassroots racing series and time attack events. Engine builders began experimenting with hybrid setups, combining K24 blocks with cylinder heads from other Honda engines, most notably the K20, to create high-revving, powerful combinations. This period also saw advancements in thermal management, with the development of improved cooling systems to maintain engine reliability under extreme racing conditions.

The 2010s brought about a focus on weight reduction and efficiency. Lightweight components, such as titanium valves and carbon fiber intake manifolds, became more prevalent in K24 race builds. Additionally, the integration of advanced data logging and telemetry systems allowed teams to fine-tune engine parameters with unprecedented precision, optimizing performance for specific track conditions and racing formats.

Recent years have seen the K24 engine adapted for use in hybrid racing applications, combining internal combustion power with electric motors. This cutting-edge approach has opened new avenues for performance enhancement while addressing growing concerns about environmental sustainability in motorsports.

Throughout its racing evolution, the K24 engine has demonstrated remarkable versatility and potential for modification. From its humble beginnings as a reliable commuter car powerplant to its current status as a formidable racing engine, the K24 continues to be a popular choice for circuit racers seeking a balance of power, reliability, and tunability.

Circuit Racing Market Analysis

The circuit racing market has experienced significant growth in recent years, driven by increasing interest in motorsports and the rising popularity of track day events. This market segment encompasses various forms of racing, including Formula 1, NASCAR, endurance racing, and grassroots-level competitions. The global motorsport market size was valued at approximately $4.5 billion in 2020 and is projected to reach $7.8 billion by 2026, with a compound annual growth rate (CAGR) of 9.2% during the forecast period.

Circuit racing attracts a diverse audience, ranging from casual spectators to dedicated enthusiasts and professional teams. The market is characterized by high levels of technological innovation, with continuous advancements in vehicle performance, safety features, and data analytics. This creates opportunities for engine manufacturers and tuning specialists to develop and market high-performance solutions tailored for circuit racing applications.

The K24 engine, originally designed by Honda for road-going vehicles, has gained popularity in the racing community due to its robust design and tuning potential. As more racers and teams seek to optimize this engine for circuit racing, there is a growing demand for specialized tuning services and aftermarket parts. This trend is particularly evident in grassroots and semi-professional racing categories, where cost-effective yet high-performance solutions are highly valued.

Market research indicates that the aftermarket parts industry for circuit racing is experiencing steady growth, with a particular focus on engine components, suspension systems, and aerodynamic enhancements. The global automotive aftermarket size was valued at $390.1 billion in 2020 and is expected to reach $513.1 billion by 2027, with a CAGR of 3.8%. A significant portion of this growth is attributed to the performance and racing segments.

The demand for fine-tuned K24 engines in circuit racing is driven by several factors. First, the engine's reliability and potential for high power output make it an attractive option for teams operating on limited budgets. Second, the availability of aftermarket parts and tuning expertise allows for customization to meet specific racing requirements. Lastly, the engine's compatibility with various vehicle platforms provides flexibility for racers across different categories.

Competition in the circuit racing market is intense, with numerous engine builders, tuning shops, and parts manufacturers vying for market share. This competitive landscape has led to rapid innovation and improvements in engine performance, benefiting racers and teams across all levels of competition. As a result, the market for fine-tuned K24 engines and related services is expected to continue expanding, offering significant opportunities for businesses specializing in high-performance engine development and tuning.

Circuit racing attracts a diverse audience, ranging from casual spectators to dedicated enthusiasts and professional teams. The market is characterized by high levels of technological innovation, with continuous advancements in vehicle performance, safety features, and data analytics. This creates opportunities for engine manufacturers and tuning specialists to develop and market high-performance solutions tailored for circuit racing applications.

The K24 engine, originally designed by Honda for road-going vehicles, has gained popularity in the racing community due to its robust design and tuning potential. As more racers and teams seek to optimize this engine for circuit racing, there is a growing demand for specialized tuning services and aftermarket parts. This trend is particularly evident in grassroots and semi-professional racing categories, where cost-effective yet high-performance solutions are highly valued.

Market research indicates that the aftermarket parts industry for circuit racing is experiencing steady growth, with a particular focus on engine components, suspension systems, and aerodynamic enhancements. The global automotive aftermarket size was valued at $390.1 billion in 2020 and is expected to reach $513.1 billion by 2027, with a CAGR of 3.8%. A significant portion of this growth is attributed to the performance and racing segments.

The demand for fine-tuned K24 engines in circuit racing is driven by several factors. First, the engine's reliability and potential for high power output make it an attractive option for teams operating on limited budgets. Second, the availability of aftermarket parts and tuning expertise allows for customization to meet specific racing requirements. Lastly, the engine's compatibility with various vehicle platforms provides flexibility for racers across different categories.

Competition in the circuit racing market is intense, with numerous engine builders, tuning shops, and parts manufacturers vying for market share. This competitive landscape has led to rapid innovation and improvements in engine performance, benefiting racers and teams across all levels of competition. As a result, the market for fine-tuned K24 engines and related services is expected to continue expanding, offering significant opportunities for businesses specializing in high-performance engine development and tuning.

K24 Engine Tuning Challenges

The K24 engine, renowned for its reliability and potential, presents several challenges when fine-tuning for circuit racing success. One of the primary obstacles is optimizing the engine's power output while maintaining its durability. The stock K24 engine, designed for everyday driving, requires significant modifications to withstand the rigors of high-performance racing environments.

Thermal management emerges as a critical challenge in K24 engine tuning. The increased power output generates excess heat, which can lead to reduced performance and potential engine damage. Developing effective cooling solutions, such as upgraded radiators, oil coolers, and improved airflow management, becomes essential to maintain optimal operating temperatures under extreme racing conditions.

Another significant hurdle is balancing the engine's power curve for circuit racing. The K24's stock configuration favors low-end torque, which is ideal for street driving but less suitable for high-speed circuit racing. Tuners must recalibrate the engine's power delivery to provide a broader powerband and more top-end performance without sacrificing drivability or reliability.

Fuel management presents an additional challenge in K24 engine tuning. As power output increases, so does the engine's fuel requirements. Upgrading the fuel system, including injectors, fuel pumps, and fuel pressure regulators, is necessary to ensure adequate fuel delivery under high-load conditions. Moreover, precise fuel mapping is crucial to optimize performance and prevent engine damage due to lean conditions.

The K24's valve train system also poses challenges when pushing the engine to its limits. Stock valve springs and retainers may not be sufficient to handle increased RPMs and aggressive cam profiles. Upgrading these components becomes necessary to prevent valve float and ensure proper valve control at high engine speeds.

Addressing internal engine stress is another critical aspect of K24 tuning. As power output increases, so does the stress on internal components such as pistons, connecting rods, and crankshafts. Strengthening these components or replacing them with aftermarket alternatives capable of withstanding higher loads becomes essential for building a reliable high-performance engine.

Lastly, tuning the engine management system presents a significant challenge. Optimizing ignition timing, air-fuel ratios, and VTEC engagement points requires extensive dyno testing and fine-tuning. Developing a robust engine map that balances performance, reliability, and drivability across various racing conditions demands considerable expertise and time investment.

Thermal management emerges as a critical challenge in K24 engine tuning. The increased power output generates excess heat, which can lead to reduced performance and potential engine damage. Developing effective cooling solutions, such as upgraded radiators, oil coolers, and improved airflow management, becomes essential to maintain optimal operating temperatures under extreme racing conditions.

Another significant hurdle is balancing the engine's power curve for circuit racing. The K24's stock configuration favors low-end torque, which is ideal for street driving but less suitable for high-speed circuit racing. Tuners must recalibrate the engine's power delivery to provide a broader powerband and more top-end performance without sacrificing drivability or reliability.

Fuel management presents an additional challenge in K24 engine tuning. As power output increases, so does the engine's fuel requirements. Upgrading the fuel system, including injectors, fuel pumps, and fuel pressure regulators, is necessary to ensure adequate fuel delivery under high-load conditions. Moreover, precise fuel mapping is crucial to optimize performance and prevent engine damage due to lean conditions.

The K24's valve train system also poses challenges when pushing the engine to its limits. Stock valve springs and retainers may not be sufficient to handle increased RPMs and aggressive cam profiles. Upgrading these components becomes necessary to prevent valve float and ensure proper valve control at high engine speeds.

Addressing internal engine stress is another critical aspect of K24 tuning. As power output increases, so does the stress on internal components such as pistons, connecting rods, and crankshafts. Strengthening these components or replacing them with aftermarket alternatives capable of withstanding higher loads becomes essential for building a reliable high-performance engine.

Lastly, tuning the engine management system presents a significant challenge. Optimizing ignition timing, air-fuel ratios, and VTEC engagement points requires extensive dyno testing and fine-tuning. Developing a robust engine map that balances performance, reliability, and drivability across various racing conditions demands considerable expertise and time investment.

Current K24 Tuning Methods

01 Engine design and structure

The K24 engine is a 2.4-liter inline-four cylinder engine known for its compact design and efficient performance. It features a lightweight aluminum block and cylinder head, dual overhead camshafts, and i-VTEC technology for improved power and fuel efficiency. The engine's design allows for easy integration into various vehicle models and applications.- Engine design and components: The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.

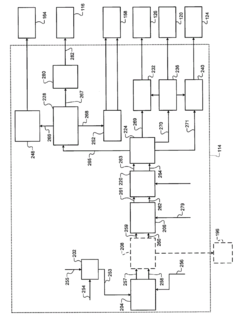

- Fuel injection and combustion system: The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features help improve fuel efficiency, power output, and emissions control.

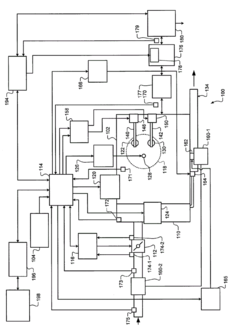

- Engine control and management: Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. These systems optimize performance, fuel economy, and emissions across different operating conditions.

- Cooling and lubrication systems: The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow, enhanced oil circulation, and temperature management. These systems help maintain optimal operating temperatures, reduce wear, and extend engine life.

- Performance enhancements and modifications: Various performance enhancements and modifications are available for the K24 engine. These may include aftermarket components, tuning options, and upgrades to improve power output, torque, and overall performance. Such modifications cater to enthusiasts seeking to maximize the engine's potential.

02 Fuel injection and combustion system

The K24 engine utilizes advanced fuel injection and combustion systems to optimize performance and reduce emissions. This includes direct fuel injection technology, variable valve timing, and precise air-fuel mixture control. The engine's combustion chamber design and piston geometry contribute to improved thermal efficiency and power output.Expand Specific Solutions03 Engine control and management

Advanced engine control systems are implemented in the K24 engine to manage various parameters such as fuel injection timing, ignition timing, and valve timing. These systems utilize sensors and electronic control units to optimize engine performance, fuel efficiency, and emissions control across different operating conditions.Expand Specific Solutions04 Engine cooling and lubrication

The K24 engine incorporates efficient cooling and lubrication systems to maintain optimal operating temperatures and reduce friction. This includes advanced coolant circulation designs, oil cooling systems, and precision-engineered components to enhance durability and longevity of the engine.Expand Specific Solutions05 Engine accessories and integration

Various accessories and components are designed to integrate seamlessly with the K24 engine, including alternators, power steering pumps, and air conditioning compressors. The engine's compact design allows for flexible mounting options and easy integration into different vehicle platforms, enhancing its versatility across multiple applications.Expand Specific Solutions

Key Players in K24 Racing

The competition landscape for fine-tuning K24 engines for circuit racing success is in a mature stage, with established players and a well-developed market. The global racing engine market size is estimated to be in the billions, driven by motorsport popularity and technological advancements. Key players like Honda Motor Co., Ltd., Toyota Motor Corp., and Mazda Motor Corp. have significant expertise in high-performance engine development. These companies, along with specialized racing engine manufacturers, are continuously innovating to improve power output, fuel efficiency, and reliability. The technology is highly mature, with ongoing refinements focusing on materials, combustion efficiency, and electronic control systems to extract maximum performance within racing regulations.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to fine-tuning the K24 engine for circuit racing success involves several key strategies. They focus on optimizing the engine's power output and reliability through advanced engineering techniques. This includes implementing a high-flow intake system with larger throttle bodies and redesigned intake manifolds to increase airflow[1]. Honda also employs precision balancing of rotating assemblies and lightweight, high-strength components to reduce internal friction and improve engine response[2]. Additionally, they utilize advanced engine management systems with custom ECU mapping to optimize fuel delivery and ignition timing for race conditions[3]. Honda's engineers have also developed specialized camshaft profiles and valve timing strategies to enhance high-RPM performance without sacrificing low-end torque[4]. To improve thermal management, they implement advanced cooling systems with larger radiators and oil coolers[5].

Strengths: Extensive racing heritage, proven reliability in high-stress environments, and a strong aftermarket support network. Weaknesses: Potential for higher costs due to specialized components and the need for expert tuning to extract maximum performance.

Toyota Motor Corp.

Technical Solution: Toyota's approach to fine-tuning the K24 engine for circuit racing success builds on their extensive motorsport experience and advanced engineering capabilities. They focus on optimizing the engine's efficiency and reliability through innovative technologies. Toyota implements their D-4S direct and port injection system to improve fuel atomization and combustion efficiency across all RPM ranges[1]. They also utilize advanced materials such as silicon-reinforced pistons and high-strength alloys for connecting rods to enhance durability[2]. Toyota's racing division develops specialized valve train components, including titanium valves and high-performance valve springs, to support higher RPM limits[3]. They employ sophisticated engine management systems with adaptive learning algorithms to optimize performance in real-time during race conditions[4]. Additionally, Toyota implements advanced cooling strategies, including precision-controlled electric water pumps and oil coolers, to maintain optimal operating temperatures under extreme conditions[5].

Strengths: Vast resources for research and development, proven track record in various motorsport disciplines, and expertise in reliability engineering. Weaknesses: Potential for a more conservative approach compared to specialized racing engine builders, which may limit ultimate performance gains.

Innovative K24 Mods Analysis

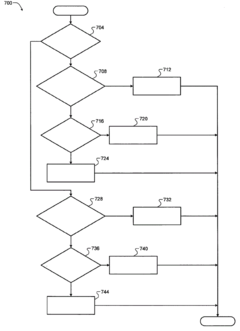

Engine control systems and methods

PatentActiveCN102748147A

Innovation

- A system is designed that includes a power request module, a first desired engine speed (DRPM) determination module, a driver torque request module, and an actuation module to determine a target DRPM based on accelerator pedal position, vehicle speed, turbine speed, and k-factor, and torque control via engine actuators.

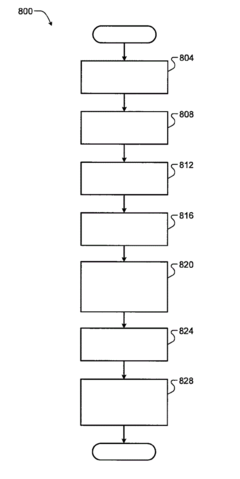

A method to improve efficiency of an engine in a vehicle

PatentInactiveIN201841024311A

Innovation

- An electronic control unit in vehicles communicates with a fuel station's IoT server to receive knock adaptation values based on detected fuel parameters, adjusting ignition timing accordingly to optimize engine efficiency.

Aerodynamic Considerations

Aerodynamic considerations play a crucial role in fine-tuning the K24 engine for circuit racing success. The interaction between the vehicle's body and the surrounding air significantly impacts performance, particularly at high speeds encountered on racing circuits. Optimizing aerodynamics can lead to improved downforce, reduced drag, and enhanced overall vehicle stability.

One of the primary focuses in aerodynamic tuning is the generation of downforce. This vertical force pushes the car towards the track, increasing tire grip and allowing for higher cornering speeds. For the K24 engine-equipped vehicle, strategically placed wings, splitters, and diffusers can be employed to manipulate airflow and create areas of low pressure beneath the car. The front splitter, in particular, can be designed to direct air around and under the vehicle, reducing lift and improving front-end stability.

The rear wing is another critical component in aerodynamic optimization. Its angle of attack can be adjusted to balance downforce with drag, depending on the specific circuit characteristics. A steeper angle generates more downforce but also increases drag, which may be beneficial on tracks with numerous tight corners. Conversely, a shallower angle reduces drag for better straight-line speed on circuits with long straights.

Side skirts and underbody panels also contribute to aerodynamic efficiency by managing airflow underneath the vehicle. These components help create a venturi effect, accelerating air beneath the car and further enhancing downforce. Additionally, they can be designed to direct air towards the rear diffuser, which plays a vital role in reducing drag and creating a low-pressure area behind the vehicle.

The integration of vortex generators on various body surfaces can help control airflow separation, reducing turbulence and drag. These small fins or ridges are particularly effective on the roof and sides of the vehicle, helping to keep airflow attached to the body for longer distances.

Cooling considerations must also be addressed in the aerodynamic package. Efficient air intake and exhaust systems are essential for maintaining optimal engine temperature while minimizing drag. Carefully designed brake ducts can provide necessary cooling to the braking system without significantly compromising overall aerodynamics.

Wind tunnel testing and computational fluid dynamics (CFD) simulations are invaluable tools in refining the aerodynamic package for a K24-powered race car. These methods allow engineers to visualize airflow patterns and quantify the effects of various aerodynamic modifications, enabling data-driven decisions in the fine-tuning process.

One of the primary focuses in aerodynamic tuning is the generation of downforce. This vertical force pushes the car towards the track, increasing tire grip and allowing for higher cornering speeds. For the K24 engine-equipped vehicle, strategically placed wings, splitters, and diffusers can be employed to manipulate airflow and create areas of low pressure beneath the car. The front splitter, in particular, can be designed to direct air around and under the vehicle, reducing lift and improving front-end stability.

The rear wing is another critical component in aerodynamic optimization. Its angle of attack can be adjusted to balance downforce with drag, depending on the specific circuit characteristics. A steeper angle generates more downforce but also increases drag, which may be beneficial on tracks with numerous tight corners. Conversely, a shallower angle reduces drag for better straight-line speed on circuits with long straights.

Side skirts and underbody panels also contribute to aerodynamic efficiency by managing airflow underneath the vehicle. These components help create a venturi effect, accelerating air beneath the car and further enhancing downforce. Additionally, they can be designed to direct air towards the rear diffuser, which plays a vital role in reducing drag and creating a low-pressure area behind the vehicle.

The integration of vortex generators on various body surfaces can help control airflow separation, reducing turbulence and drag. These small fins or ridges are particularly effective on the roof and sides of the vehicle, helping to keep airflow attached to the body for longer distances.

Cooling considerations must also be addressed in the aerodynamic package. Efficient air intake and exhaust systems are essential for maintaining optimal engine temperature while minimizing drag. Carefully designed brake ducts can provide necessary cooling to the braking system without significantly compromising overall aerodynamics.

Wind tunnel testing and computational fluid dynamics (CFD) simulations are invaluable tools in refining the aerodynamic package for a K24-powered race car. These methods allow engineers to visualize airflow patterns and quantify the effects of various aerodynamic modifications, enabling data-driven decisions in the fine-tuning process.

Racing Regulations Impact

Racing regulations play a crucial role in shaping the development and fine-tuning of engines for circuit racing, including the K24 engine. These regulations are designed to ensure fair competition, maintain safety standards, and promote technological innovation within specific boundaries.

In the context of circuit racing, governing bodies such as the FIA (Fédération Internationale de l'Automobile) or national motorsport authorities establish and enforce regulations that directly impact engine performance and modifications. These rules often specify limitations on engine displacement, power output, fuel consumption, and emissions.

For the K24 engine, understanding and adhering to these regulations is paramount when fine-tuning for racing success. Regulations may dictate maximum engine capacity, compression ratios, or restrict the use of certain materials or technologies. This necessitates a careful balance between maximizing performance and staying within the legal framework.

One significant aspect of racing regulations is the concept of homologation, which requires manufacturers to produce a certain number of road-legal vehicles with the same specifications as their racing counterparts. This rule ensures that racing technology has some relevance to production vehicles and prevents the development of purely specialized racing engines.

Fuel regulations also play a critical role in engine tuning. Many racing series mandate the use of specific fuel types or blends, which directly affects engine performance and tuning strategies. Engineers must optimize the K24 engine to extract maximum power and efficiency from the permitted fuel while ensuring reliability over race distances.

Weight regulations indirectly influence engine tuning by necessitating a balance between power output and overall vehicle weight. This may lead to compromises in engine design or the use of lightweight materials to offset the weight of performance-enhancing modifications.

Noise regulations are another factor to consider when fine-tuning the K24 engine. Many circuits have strict noise limits, requiring engineers to develop exhaust systems that balance performance with acceptable sound levels. This can impact engine breathing and overall power output.

Lastly, regulations often evolve to address emerging technologies or to level the playing field. For instance, restrictions on electronic aids or turbocharging may be introduced or modified, forcing teams to adapt their engine tuning strategies accordingly. Staying abreast of these changes and anticipating future regulatory trends is crucial for long-term success in circuit racing with the K24 engine.

In the context of circuit racing, governing bodies such as the FIA (Fédération Internationale de l'Automobile) or national motorsport authorities establish and enforce regulations that directly impact engine performance and modifications. These rules often specify limitations on engine displacement, power output, fuel consumption, and emissions.

For the K24 engine, understanding and adhering to these regulations is paramount when fine-tuning for racing success. Regulations may dictate maximum engine capacity, compression ratios, or restrict the use of certain materials or technologies. This necessitates a careful balance between maximizing performance and staying within the legal framework.

One significant aspect of racing regulations is the concept of homologation, which requires manufacturers to produce a certain number of road-legal vehicles with the same specifications as their racing counterparts. This rule ensures that racing technology has some relevance to production vehicles and prevents the development of purely specialized racing engines.

Fuel regulations also play a critical role in engine tuning. Many racing series mandate the use of specific fuel types or blends, which directly affects engine performance and tuning strategies. Engineers must optimize the K24 engine to extract maximum power and efficiency from the permitted fuel while ensuring reliability over race distances.

Weight regulations indirectly influence engine tuning by necessitating a balance between power output and overall vehicle weight. This may lead to compromises in engine design or the use of lightweight materials to offset the weight of performance-enhancing modifications.

Noise regulations are another factor to consider when fine-tuning the K24 engine. Many circuits have strict noise limits, requiring engineers to develop exhaust systems that balance performance with acceptable sound levels. This can impact engine breathing and overall power output.

Lastly, regulations often evolve to address emerging technologies or to level the playing field. For instance, restrictions on electronic aids or turbocharging may be introduced or modified, forcing teams to adapt their engine tuning strategies accordingly. Staying abreast of these changes and anticipating future regulatory trends is crucial for long-term success in circuit racing with the K24 engine.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!